I think what has happened to collectable automobiles may be happening to collectable firearms. There was as time when very limited production, high performance muscle cars could fetch hundreds of thousands of dollars. Then people figured out that they could pull a 6 cylinder beater out of a salvage yard, buy a powerful crate engine and get to the same place for $20, 000 – $30,000. Additionally, they end up with a car they can actually drive all of the time.

There are many military firearms that were once dirt cheap and readily available. As time went by and inventories were depleted prices on many soared. When there were no numbers matching, quality firearm available for a reasonable price, people began to assemble them from barrels of mismatched or reproduction parts and they were more over priced than the originals. That is where we are with the WWII era 30 caliber M1 Carbines.

I am not a collector, so spending hours tracing prime and subcontractors that had been involved in the production of a single specimen only represents tedium for me. Nostalgia takes me to this type of rifle, but not a single rifle as it would not have been my rifle. So any vintage M1 Carbine only represents someone else’s history. Still, I respect the history of these firearms and what they mean to someone else, so I would never modify a vintage carbine. Nor would I shoot it extensively, carry it in the woods or use it to develop handloads. Instead, if possible. I would buy a modern .30 Caliber M1 Carbine and do with it whatever I felt like doing, without seeking external concurrence.

It’s like the Beatles said, “Let it be… Let it be”

I made but two changes to the Auto-Ordnance 30 Caliber M1 Carbine; I installed a sling to make it easier to carry the carbine, arm loads of ammunition and equipment from the shop to the shooting range and I installed a scope to give the little rifle the best possible chance to demonstrate its accuracy.

Funny, but there are some folks who get into a tizzy over mounting a scope on a carbine as they feel it is not necessary to be accurate out to 300 yards. I tend to ignore them and side with folks who actually own firearms and place the importance of hitting a target over feeding their giant BS ego. The carbine with its flip sight and no elevation and windage adjustment is about like shooting a GI 45 Auto pistol 300 yards.

There are two basic mount types that don’t require permanent modification of the firearm, scout mounts that affix in the area of the handguard and traditional placement mounts that attach at the rear sight dovetail. Both are typically Weaver or Picatinny type rails that offer the most flexible positioning of an electronic or optical sighting device and work with any rings made to that standard.

Remember when they just sold books?

I picked up a UTG Deluxe M1 Carbine Mount Complete With 1 -Inch Rings from Amazon; $18 and free shipping which was almost the right set up, but took a little work to get to the configuration pictured above. The rings supplied with the mount are see through, one of the many products that cater to the folks who can’t commit to a type of sight… so they install many… at the same time.

In any event, once installed, the scope would too high and even a maxed out scope elevation adjustment put point of impact 6″ below point of aim. Installing a set of medium height Burris Signature Zee Rings with Posi-Align Offset Inserts provided a sound solution.

If you’re not familiar with this type of ring, it is a gimbal design which allows the inserts to rotate within the rings. The alignment of the scope to the rifle can be altered without external shims or flexing the scope’s tube. Each half circle insert has a thickness value from 0.00″ for no offset to 0.020″ maximum offset. They can be used in any increment combination to move the scope’s longitudinal axis relative to the bore centerline in any direction. I use them on personal rifles to sight in the rifle with scope set to mid range adjustment.

Installation of the mounts systems is easy. The original sight is tapped out left to right to avoid damaging the dovetail. A piece of Nylon 6/6 bar stock takes the place of a punch to protect the surface of the sight. The supplied dovetail insert is installed, the rail is dropped over the top and secured.

During a good deal of shooting, the rail never interfered with ejection or the motion of the slide. The rail did shoot loose the first time around, however, the problem was resolved by putting a dab of Loctite Blue on the fastener threads.

Magazines? Oh my, oh my…

The Auto-Ordnance carbine never failed to extract or eject once a round was chambered. However, its feed/magazine problems were notable. It is incredibly frustrating to fire two shots of a three shot, then stop to clear a jam or to hear the sound of a firing pin falling on an empty chamber.

One beat up magazine (#2) was received with the new Auto-Ordinance carbine. It was a 10 round version that was scratched, battered and obviously use worn. It correctly fed the carbine approximately most of the time. A new 10 shot magazine (3) from Auto-Ordnance failed 2 to 3 times out of 6, usually the result of round being released early and wedging between the magazine and the top of the carbine’s chamber wall.

A new 15 round Pro Mag M1 replacement magazine (#1) failed most of the time with the bolt sliding over the magazine without stripping a round from the magazine, unless the magazine was either held up or grasped at the bottom and pushed to one side. The Kahr manual indicates standard magazines must be used, although it does not reference which standard. This is supposed to be a Saginaw clone so expecting it to work with a GI spec magazine wouldn’t be much of a stretch. Still, I will take the blame on this last one as it was not an Auto-Ordnance magazine.

The performance personality of each magazine was essentially the same, whether factory ammunition or high performance handloads. Usually, feed problems of this type are the result of shallow insertion or malformed feed lips so I took few measurements to see if there was anything obvious.

| Magazine | A | B | C | D | E | F | G | H |

| #1 15 Round ProMag | 0.464 | 0.473 | 0.781 | 0.541 | 0.542 | 1.496 | 1.498 | 0.763 |

| #2 10 Round Original | 0.460 | 0.456 | 0.841 | 0.532 | 0.545 | 1.514 | 1.522 | 0.750 |

| #3 10 Round AO Replacement | 0.473 | 0.453 | 0.838 | 0.527 | 0.560 | 1.525 | 1.521 | 0.742 |

There are some dimensions that might partially explain some of the problems. The 15 round ProMag is short from the retention tabs to the top of the rear feed lips, which would contribute to rounds not being picked up by the closing bolt. The replacement magazine might be releasing rounds too early and causing jams. When I have some spare time I will go back and work on the magazines and the magazine catch and see if I can make the carbine feed reliably. I can’t say if this carbine is representative, or this may be a unique situation.

Accuracy and related…

Accuracy and related…

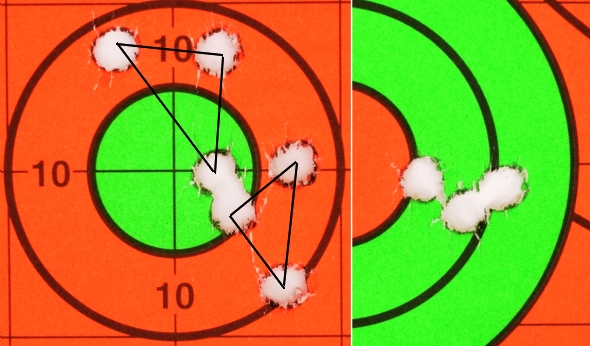

The two 50 yard groups below… left target, were shot with factory ammo; top, Aguila 110 Grain FMJ 1″ and, bottom, Remington UMC 110 grain FMJ 3/4″. The 50 Yard group, right target, came from handloads with Lil’ Gun powder and Prvi 110 grain soft point round nose bullets and CCI Bench Rest primers, 1/2″. The worst handload group shot, regardless powder type, was 7/8″.

Generally speaking, I thought the factory ammo performance was exceptional for this type of firearm. Anything under 2″ at 50 yards for this type of firearm would be fine with me, although I might work to improve that performance. Accuracy was consistent within an ammo type. There were no signs of stringing, or groups opening up as heat built up.

Factory ammo recorded muzzle velocity was 1987 fps for the Aguila ammo and 2006 fps for the Remington ammo. The handload average with soft points was 2071 fps.

Warning: Bullet selections are specific, and loads are not valid with substitutions of different bullets of the same weight. Variations in bullet length will alter net case capacity, pressure and velocity. Primer selection is specific and primer types are not interchangeable. These are maximum loads in my firearms and may easily be excessive in others. All loads should be reduced by 5%, and developed following safe handloading practices as represented in established reloading manuals produced by component manufacturers. Presentation of these loads does not constitute a solicitation for their use, nor a recommendation.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I did not shoot 100 yard groups so I do not know if extrapolating 50 yard groups into 100 yard groups is accurate or not. Sometimes accuracy falls off with distance and sometimes it actually improves. The problem is that these light 0.308″ bullets have the ballistic coefficient of a cardboard box and fall away quickly with distance. The best performer, from the Real Guns Ballistic Calculator –

| 30 Caliber Carbine 110 Grain Handload | |||||||

| Yards | 0 | 50 | 100 | 150 | 200 | 250 | 300 |

| Velocity – fps | 2071 | 1814 | 1579 | 1375 | 1209 | 1087 | 1002 |

| Energy – ft.-lbs. | 1047 | 803 | 609 | 462 | 357 | 288 | 245 |

| Momentum – lbs-sec | 1.01 | 0.88 | 0.77 | 0.67 | 0.59 | 0.53 | 0.49 |

| Path – in. | -1.5 | 2.0 | 2.9 | 0.2 | -7.0 | -20.2 | -40.8 |

| Best Zero Results | |||

| Near-Zero – yds. | 17 | Midrange – yds. | 89 |

| Far-Zero – yds. | 152 | Max Ordinate – in. | +3.0 |

| Point-Blank – yds. | 177 |

– |

– |

For a cartridge that draws a lot of “not enough power” parroting, it can stay with a 44 Mag handgun power, and a 357 Mag fired from a rifle length barrel firearm. Would I take it deer hunting? No, but it would make for a good close in varmint rifle and a heck of a plinker.

Kahr Auto-Ordnance 30 Caliber Carbine shooting impressions?

I think a word that comes to mind is “rough”. It certainly isn’t my M1 Carbine of old. Those firearms were decently finished, made of better materials and they were reliable. The Auto-Ordnance parts are crude by comparison in fit and finish, including the feed ramp which is tattooed with tool marks. Feed is not reliable, at least with the new carbine and magazines used for this project, although it does cycle, extract and eject when it has chambered a round.

The factory rear sight is less than exciting. The whole notion of non-windage adjustable sights and no fine incremental adjustment of elevation on a rifle, to me, is odd and makes me wonder what applications they had in mind when they configured this model. The trigger has a good deal of take up and creep, which only compounds the issue of inadequate sights. Mount a scope, even if temporarily, shoot from a rest and concentrate through the trigger pull and the carbine delivers good accuracy.

I guess all of this means that I selected the carbine motivated by a sense of nostalgia. What I seem to have is a relatively pricey, $846, project rifle that I will fix and finish until it looks and shoots to my liking… because I want a good shooting M1 Carbine… motivated by nostalgia. I have no particular application for it, not hunting or defense or even plinking. I just want to be able to pull the trigger and be reminded of when weighted less and had a lot more hair… without feeling I’m wearing out or abusing a national treasure. When I get dug out a little bit from other projects, there will be a part 3.

Email Notification