I like the little Ruger American Rifle Ranch, standard size or compact, and I was pretty excited about the potential of the Winchester 350 Legend cartridge. At the time of this writing, ammunition is making its way into retail channels and should be widely available well before traditional deer hunting seasons. Winchester’s line up includes Winchester USA 145 grain TC FMJ Target, Winchester Deer Season Extreme Point 150 grain, Winchester Power Max Bonded 160 Grain, Winchester Super X Soft Point 180 Grain, and Winchester Super Suppressed 265 grain. Others like Hornady and Federal have their products in the works.

Initial measured performance with Winchester USA 145 grain truncated cone ammunition, intended for recreational target shooting and competitive shooting events, played out as 2293 fps muzzle velocity and 100 yard three shot groups measured 1 1/8″. By no means subpar performance, however, experience with Ruger American Rifle Ranch suggested there was more left in the rifle – cartridge combination. Subsequently, handloading, at least in the short term, seemed the way to go. This may take a while, so pack a lunch.

So why are we gathered here, Joe?

Handloading a new cartridge is like playing the old text-based computer game Colossal Cave Adventure. There are no instructions, no pictures or illustrations to lead the way, the solution to each challenge encountered is unknown, progress come only with patience and caution, and mistakes in direction or approach can lead to less than desirable results.

Handloading a new cartridge is like playing the old text-based computer game Colossal Cave Adventure. There are no instructions, no pictures or illustrations to lead the way, the solution to each challenge encountered is unknown, progress come only with patience and caution, and mistakes in direction or approach can lead to less than desirable results.

Like Adventure’s derivative Zork, there is always a handloading Grue hiding ahead, and saying “Xyzzy” repeatedly and frustratingly mostly has dubious effect. No, I don’t still own a DEC PDP 11. No I don’t still run Free BSD Unix. No, I have not upgraded to Windows 10. Yes, I do still have Zork I, II and III running on DOS when I am supposed to be working. Move along. Move along. Ignore the old guy behind the keyboard.

What follows is what for me is a preliminary examination of the 350 Legend cartridge. The round is not as yet prominent enough on the priority list to invest in test barrel and conformal transducer for the universal receiver to pressure check handloads and I did not want to deface a rifle to wire it for strain measurement. Therefore, handloads were developed the old fashioned way, by examining existing cartridges with lots of published data that approximate the 350 Legend’s capacity, sorting through bullets that may and may not work and then assembling and testing the output until safe and accurate results are found.

Every handload fired was subjected to an autopsy for material changes in brass, firearm function and any classic signs of excessive pressure; flattened primers, case fractured, bolt face stamping, sticking extraction, excess velocity, excessive expansion at the extractor groove, odd report, singed eyebrows. Even then, this information is being provided for the sake of sharing information and not as industry vetted handload data.

If there was a problematic incident that arose during the process, it is noted. In other words, it is intended for use by folks who have been handloading long enough to have impaired hearing, but are cautious enough in examining data on the Internet to still have all of their digits.

All the work that was done here was based on the Ruger American Rifle Ranch Compact with 16.38″ barrel. The SAAMI test barrel standard is 16″, even though Winchester bases their ammunition ratings on a 20″ barrel rifle. Beyond barrel length differences, none of this work included the AR platform. The project was enjoyable and rewarding and I hope the results will be beneficial to others.

When is a 350, really a .357, but really a .355?

Pulling the bullet on a Winchester 145 grain 350 Legend cartridge will yield the above. A straight wall brass casing, a 145 grain lead core, FMJ truncated cone bullet and 21.0 grains of ball powder.

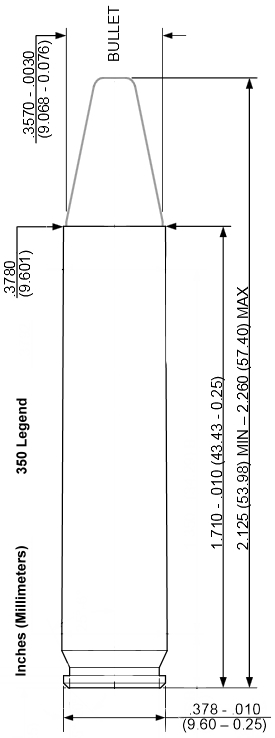

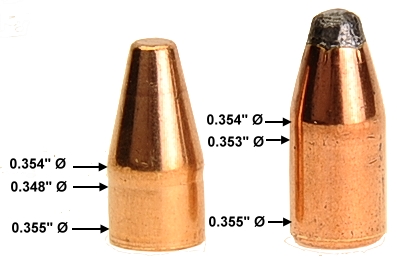

.The 350 Legend factory 145 grain bullet is of the full metal jacket, open base, truncated cone variety. While the SAAMI 350 Legend bullet specification at its largest diameter measures 0.357″ +0.000″/-0.003″, the 145 grain factory bullet measures 0.355″, as does the Winchester 180 grain soft point.

The shank of the Winchester 145 grain bullet remains parallel for only 0.180″ before tapering into a cannelure just aft of the onset of the bullet’s ogive. The Winchester 180 grain shank remains parallel for 0.360″. Bullet dimensions are uniform within a respective population. With a SAAMI 350 Legend bore/groove diameter of respectively 0.346″/0.355″, the bullet is sized appropriately. Winchester literature indicates a 0.357″ bullet across all 350 Legend ammunition product lines, but in actuality, bullet diameter is 0.355″. Which leads to the interesting bullet selection quandary.

For the sake of illustration, above L-R: 0.355″ 145 grain 350 Legend bullet, 0.355″ 180 grain 350 Legend bullet, 0.357″ 158 grain 357 Mag bullet, 0.357 200 grain rifle bullet.

Historically, a 0.355″ diameter bullet has been for handgun applications, mostly autoloader, and 0.357″ bullets was typically assigned to revolver cartridges and 0.358″ bullets were primarily for rifle applications. In handgun hunting and silhouette competition, single shot, long barrel handguns often used specialty cartridges like the 357 Maximum or 357 Herrett. The latter often used 0.357″ bullets up to 158 grains, handgun cartridge bullets, and then 0.358″ for heavier weights, rifle bullets, but barrels and chambers were spec’d to accommodate the dimensional differences.

When investigation for suitable component bullets for reloading the 350 Legend, I found that pistol and revolver bullets that might meet the diameter criteria, 0.355″ to 0.357″, in addition to having a very low ballistic coefficient, had too long of a shank and too short of an ogive. Unfortunately, this placed most below the 350 Legend minimum cartridge overall length specification of 2.125″. Additionally, 0.357″ bullets typically measured 0.3575″. When combined with 0.012″ case wall thickness, they assembled to a 0.3815″ diameter, compared to a SAAMI spec of 0.3780″ +0.000″/-0.008″. The result was a bolt that would not travel full forward and close on a chambered cartridge.

A 0.358″ rifle bullet’s spec is usually 0.359″ +0.000″/-0.003″ with bore/groove diameters of 0.349″/0.357″. Rifle bullets examined, 0.3575″ and 0.3580″, tended to have a shorter than handgun bullet shank length, a longer ogive for a better ballistic coefficient and they could be seated to the bullet’s cannelure where present and clear the Ruger’s rifling. However, again brass wall thickness of 0.012″ resulted in a 0.382″ case mouth when assembled. The inability to drive the bolt home worsened with a 0.358″ rifle bullet. The Dychem coated round below shows points of contact with the round only partially chambered.

Where a round would chamber with the bolt closed, the chamber walls drove the brass case against a bullets shank so tightly, it spiked pressure so high that even a modest charge would blow primers out and there were few choices for handloading.

Solution are not always elaborate or expensive…

Sizer dies are used in the shop, but primarily in concert with a Lube-A-Matic press. Case bullets are sized with minimal dimension changes and bullet lube is pressed into grease grooves. With minor amounts of material displaced, it tends to migrate from the driving bands into the grease grooves, so little mechanical effort is required. Jacketed bullets, however, have a relatively hard jacket devoid of grease grooves and, typically, a hardened lead core.

Sizer dies are used in the shop, but primarily in concert with a Lube-A-Matic press. Case bullets are sized with minimal dimension changes and bullet lube is pressed into grease grooves. With minor amounts of material displaced, it tends to migrate from the driving bands into the grease grooves, so little mechanical effort is required. Jacketed bullets, however, have a relatively hard jacket devoid of grease grooves and, typically, a hardened lead core.

The Lee Precision Bullet Sizing Kit 0.356″ SKU 90046 has an MSRP of $25.98, but a typical price of $17.00 from online discount suppliers. Used primarily for sizing and lubing cast bullets, the bottom punch is inserted into any sturdy reloading press, the ram is raise and the die is screwed in until it bottoms on the punch. The ram is lowered, a lubricated bullet is placed atop the punch, then the ram is raised to force the bullet through the die.

Press effort required to draw selected cast and jacketed bullets through the sizer was minimal. There was no bullet surface galling and all came out the end of the die a uniform and concentric 0.356″. Assembled in trial and, later, loaded cartridges, none had a problem feeding, chambering, extracting, or ejecting.

Left to right: Hornady FTX 140 grains 0.357″, Winchester TC 145 grain 0.355″ Cast Performance (pre-lube) 180 grain 0.357″, Speer Hot-Cor 180 grain 0.358″, Winchester 180 grain SP 0.355″, Hunters Supply 190 grain 0.357″, Hornady SP 200 grain 0.358″, Speer Hot-Core 220 grain 0.358″. All cleared the Lee die with modest effort, no hammering or jumping up and down on the press handle, and the finished bullets all measured a very uniform 0.356″.

Lee Precision 350 Legend 3 die set…

I was planning on making a set of dies on the lathe from 7/8″-14 threaded rod, an approach that allowed us to design a number of wildcats and avoid the cost of custom dies and four to six month lead time. These don’t last forever, but it is a good way to get an ideal fit and to modify as needed. The set below was cut for a 7mm-30RG, a 7mm version of the 30 Remington AR.

Lee Precision started shipping 350 Legend dies. I looked at the backlog of project work in the shop, looked at the $19.98 price for the die set and bought a set. Lee Precision makes some very useful products, for the most part they are a value and, sometimes, they are innovative. The Lee Precision 350 Legend set was not a terrific execution.

A Lee Precision 3 die 350 Legend set was used for assembly; full length sizer, expander and bullet seating/crimp die. The expander could not be setup to the instructions without crushing the case and badly belling the case mouth. The seater did not have enough range of adjustment to assemble a minimum COL cartridge without forcing a crimp, a situation that came to light when loading the Winchester 180 grain soft point bullet used in factory ammo. There was so much slop in the shell holder, it would not hold an in spec case rim perpendicular enough to raise the ram without manually guiding the case into the die. Without guiding the case, the die would smack into the case mouth and cause irreparable case damage. Perhaps Lee Precision was in a rush to get 350 Legend dies into production?

350 Legend case dimensions and capacities

Case capacity is moderate, which limits powder choices to types normally used for larger magnum handgun cartridges. Still, even with a bullet deep seated and taking 10 – 12 grains of powder capacity, compressed loads are not necessary. I did try some of the newer powders that are a good fit for the 300 Blackout and 7.62×39 Russian, but the charge sizes could not be accommodated.

Case capacity is moderate, which limits powder choices to types normally used for larger magnum handgun cartridges. Still, even with a bullet deep seated and taking 10 – 12 grains of powder capacity, compressed loads are not necessary. I did try some of the newer powders that are a good fit for the 300 Blackout and 7.62×39 Russian, but the charge sizes could not be accommodated.

| Case Condition | Case head Ø” |

Case Mouth Ø” |

Case Length “ |

Capacity Grains H2O |

| New Brass | 0.385 | 0.376 | 1.705 | 35.7 |

| Once Fired | 0.389 | 0.379 | 1.700 | 36.7 |

| FL Sized | 0.389 | 0.372 | 1.714 | 35.7 |

Three cases above; new brass, once fired, once fired resized. In each case, case tenth represents the maximum reading taken. Case mouths were not uniformly perpendicular; 1.698 – 1.709 on same case as an example. The lots I was working with needed to be trimmed to 1.695″ to a squared surface, which is 0.005″ under minimum specification

Putting it all together…

Every bullet used in the data below were sized to 0.356″, with the exception of Winchester factory bullets that already measured 0.355″. Bullets 0.3575″ and 0.3580″ either prevented the Ruger’s bolt from closing… smart bolt, or they generated enough pressure to blow out primers. None of the bullets sized to 0.356″ showed excessive pressure signs. At some point in time, component manufacturers will offer appropriate bullets for handloaders and this sizing step will not be necessary.

Warning: Bullet selections are specific, and loads are not valid with substitutions of different bullets of the same weight. Variations in bullet length will alter net case capacity, pressure and velocity. Primer selection is specific and primer types are not interchangeable. These are maximum loads in my firearms and may be excessive in others. All loads should be reduced by 5% as a starting point for development where cartridges have greater than 40 grains in capacity and 10% for cartridges with less than 40 grain capacity following safe handloading practices as represented in established mainstream reloading manuals. Presentation of these loads does not constitute a solicitation for their use, nor a recommendation.

| Cartridge – 350 Legend – All Bullets Sized to 0.356″ |

|

| Firearm | Ruger American |

| Barrel Length | 16.38″ |

| Min – Max Case Length | 1.710″ +0.0″/-0.010″ |

| Min – Max Cartridge Overall Length | 2.125″ to 2.260″ |

| Primer | CCI BR4 |

| Bullet Diameter As Loaded |

0.355″ to 0.356″ |

| Reloading Dies | Lee Precision |

| Bullet Type |

Bullet Weight Grains |

Bullet Ø “ |

Net H2O Grains Capacity |

COL” | Powder Type | Powder Charge Grains |

Muzzle Velocity fps |

Muzzle Energy ft/lbs |

3 shot 100 YD group |

| Hornady FTX |

140 |

0.356 |

26.9 |

2.165 |

Alliant 2400 |

21.5 |

2225 | 1539 | 0.6 |

| Hornady FTX | 140 |

0.356 | 26.9 |

2.165 |

L’il Gun |

25.0 |

2331 | 1690 | 0.4 |

| Hornady FTX | 140 |

0.356 | 26.9 |

2.165 |

H110 |

25.5 |

2343 | 1707 | 0.5 |

| Hornady FTX | 140 |

0.356 | 26.9 |

2.165 |

Win 296 |

25.5 |

2288 | 1628 | 0.7 |

| Winchester TC FMJ |

145 |

0.355 |

28.7 |

2.170 |

Alliant 2400 |

22.0 |

2215 |

1580 | 0.8 |

| Winchester TC FMJ | 145 |

0.355 | 28.7 | 2.170 |

L’il Gun |

26.0 |

2560 |

2111 | 0.6 |

| Winchester TC FMJ | 145 |

0.355 | 28.7 | 2.170 |

H110 |

26.5 |

2349 |

1777 | 0.9 |

| Winchester TC FMJ | 145 |

0.355 | 28.7 | 2.170 |

Win 296 |

26.0 |

2131 |

1462 | 0.8 |

| Cast Performance (Cast) |

180 |

0.356 | 24.8 |

2.005 |

Alliant 2400 |

12.0 |

1351 | 730 | 1.1 |

| Speer Hot-Cor | 180 | 0.356 | 27.6 | 2.255 | Alliant 2400 | 20.0 | 1935 | 1497 | 0.8 |

| Speer Hot-Cor | 180 | 0.356 | 27.6 | 2.255 | L’il Gun | 21.5 | 2075 | 1721 | 0.8 |

| Speer Hot-Cor | 180 | 0.356 | 27.6 | 2.255 | H110 | 22.5 | 2023 | 1636 | 0.6 |

| Speer Hot-Cor | 180 | 0.356 | 27.6 | 2.255 | Win 296 | 23.0 | 2048 | 1677 | 0.7 |

| Speer Hot-Cor | 180 | 0.356 | 27.6 | 2.255 | Trail Boss | 8.0 | 1022 | 418 | 1.2 |

| Winchester PP |

180 |

0.355 | 24.5 |

2.100 |

Alliant 2400 |

19.0 |

1951 |

1533 | 0.9 |

| Winchester PP | 180 |

0.355 | 24.5 |

2.100 |

L’il Gun |

22.0 |

2225 |

1979 | 0.7 |

| Winchester PP | 180 |

0.355 | 24.5 |

2.100 |

H110 |

23.0 |

2275 |

2069 | 0.7 |

| Winchester PP | 180 |

0.355 | 24.5 |

2.100 |

Win 296 |

23.0 |

2090 |

1746 | 0.8 |

| Hunters Supply (cast) |

190 |

0.356 | 24.7 |

2.025 |

Alliant 2400 |

12.0 |

1325 | 741 | 1.2 |

| Hornady SP | 200 | 0.356 | 23.9 | 2.295 | Alliant 2400 | 17.0 | 1790 | 1423 | 0.6 |

| Hornady SP | 200 | 0.356 | 23.9 | 2.295 | L’il Gun | 19.5 | 1932 | 1658 | 0.5 |

| Hornady SP | 200 | 0.356 | 23.9 | 2.295 | H110 | 20.5 | 1904 | 1610 | 0.5 |

| Hornady SP | 200 | 0.356 | 23.9 | 2.295 | Win 296 | 20.5 | 1919 | 1636 | 0.8 |

| Speer Hot-Core | 220 | 0.356 | 21.8 | 2.255 | Alliant 2400 | 16.5 | 1696 | 1405 | 0.9 |

| Speer Hot-Core | 220 | 0.356 | 21.8 | 2.255 | L’il Gun | 18.0 | 1769 | 1529 | 0.8 |

| Speer Hot-Core | 220 | 0.356 | 21.8 | 2.255 | H110 | 20.0 | 1755 | 1505 | 1.0 |

| Speer Hot-Core | 220 | 0.356 | 21.8 | 2.255 | Win 296 | 20.0 | 1758 | 1527 | 0.8 |

L’il Gun was easy to work with to get results in accuracy and velocity, but also the most sensitive to charge changes. I’ve used Alliant 2400 in everything from magnum handgun cartridges to plinking loads for the 500 Jeffery. However, the 350 Legend charges got to a point where velocity gains were modest in comparison to charge increases and peak was not exciting. I am reasonably sure that there was more velocity to be had from 296 loads, but accuracy and reasonable velocity were the objectives.

I added a couple of cast bullet loads because they are an inexpensive way to shoot in volume and their accuracy was good enough for recreational target practice. The Hunters Supply bullet was prelubed, Lyman’s Range Magic was used for the Cast Performance bullet. One Speer 180 grain Hot-Cor was intentionally subsonic loaded with IMR Trail Boss and was quite consistent in performance.

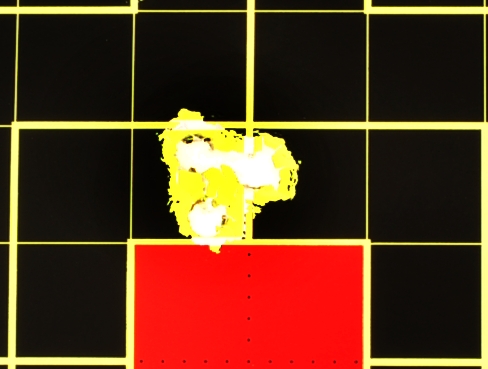

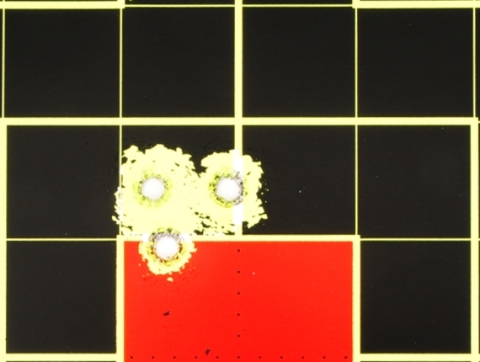

This was the best 100 yard, 3 shot group from Winchester USA 145 grain factory ammo. It measures 1.1″ center to center farthest holes.

Same bullet as above, Winchester 145 grain incorporated into a L’il Gun handload, a little under 0.6″ farthest holes center to center at 100 yards.

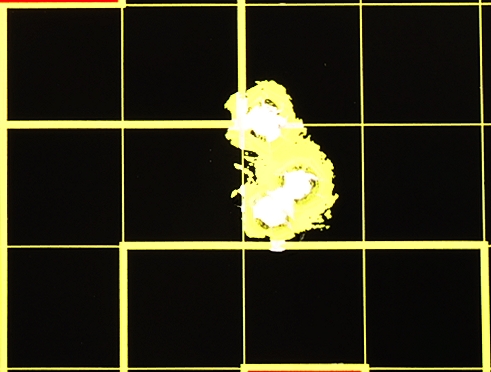

This group was shot with the Winchester 180 grain soft point incorporated into a L’il Gun handload. The 3 shot, 100 yard group measured a bit over 0.7″, center to center, farthest holes.

Best Speer Hot-Cor 180 grain 3 shot, 100 yard group, a nudge over 0.6″ center to center. Powder was H110.

This sub 0.4″ 3 shot, 100 yard group with 140 grain FTX handgun bullet was shot almost immediately after theorizing that a long shank, short ogive handgun bullet could not possibly stabilize in the Ruger. The combination of Ruger American Rifle Ranch and 350 Legend is clearly beyond my horizons.

Please stop! Sure… didn’t mean to go on.

Talk about familiarity breeds contempt. I know the Ruger American Rifle Ranch is good hardware, value priced, high end performance, but I could not see the 350 Legend doing much beyond adding another straight wall cartridge to states with such restrictions on hunting cartridges. Fortunately, it turned out to be an easy to shoot and accurate 250 yard rifle. Recoil is minor, short barrel report is not exceptional and ammo and reloading costs are modest. The Ruger American Ranch Compact version is particularly a useful tool for younger shooters or anyone else who could take advantage of short length of pull and light weight… like me.

We’ll take another look at the combination when I have a variety of ammo on hand and component bullets are available that don’t require resizing.

Email Notification