Some time ago, I’m not sure exactly when, I would hide my use of RCBS equipment from other handloaders. Whenever I’d mention green equipment in a Usenet newsgroup, or BBS, the other guys would make fun of me. The worst of the bunch were those Dillon guys; ranting about 1,000 round per hour output and auto case feeders. I was never able to shout over the noise to explain I hardly ever loaded 1,000 rounds of .416 Weatherby during a single session, and I really didn’t mind lifting my hand to place a case in a shell holder. For me, RCBS has always had the best total system for handloaders like myself, and each piece of equipment seems to integrate well with a companion piece. APS is one of those well integrated system pieces.

Some time ago, I’m not sure exactly when, I would hide my use of RCBS equipment from other handloaders. Whenever I’d mention green equipment in a Usenet newsgroup, or BBS, the other guys would make fun of me. The worst of the bunch were those Dillon guys; ranting about 1,000 round per hour output and auto case feeders. I was never able to shout over the noise to explain I hardly ever loaded 1,000 rounds of .416 Weatherby during a single session, and I really didn’t mind lifting my hand to place a case in a shell holder. For me, RCBS has always had the best total system for handloaders like myself, and each piece of equipment seems to integrate well with a companion piece. APS is one of those well integrated system pieces.

APS has become such a part of my handloading routine, it’s difficult to remember a time when I used anything else. The APS, or Automatic Priming System, is fast, clean and safe. The related tools take little bench space and there are a number of configurations to suit various applications. The system is comprised of two major components: 1) The plastic APS Primer Strip, or carrier for primers, which is designed to automate primer feed and reduce contact with primer compound during the priming process. 2) APS priming tools that are designed to utilize these strips and provide uniform primer seating.

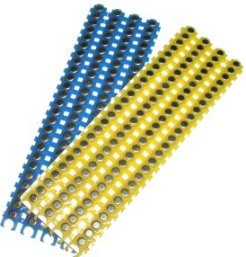

Primer Strips

![]()

In principle, mounting primers into ASP strips is not unlike loading rounds into the belt feeding system of a machine gun; the rounds feed a lot faster and more reliably than if someone were attempting to feed the gun one round at a time. In fact, consistent with the machine gun analogy, APS strips can be linked together for continual feed beyond the individual strips 25 primer capacity. Strips are produced in six colors, each color coded to match a primer type. The physical size difference between large and small primers permits use of a common color, while primer compound types are separated by the code.

| Color Code | CCI# |

Primer Type Description |

|

| White | 300/500 | large and small pistol standard | |

| Red | 350/550 | large and small pistol magnum | |

| Yellow | 200/400 | large and small rifle standard | |

| Blue | 250/450 | large and small rifle magnum | |

| Black | BR2/BR4 | large and small rifle benchrest | |

| Orange | 34/41 | large and small rifle military | |

Preloaded CCI strips are packed 1,000 to a carton, each carton contains 10 adhesive backed cards, each card holds 4 APS strips mounted compound side down for protection from contamination. The adhesive back cards are oddly similar to Avery white removable labels, allowing partially used strips to be returned their cards for storage. Empty strips are refilled and strips may be purchased without primers, 8 strips to the pack with the same 25 primer per strip capacity and in the same color codes. Prefilled APS strips run about the same as conventionally packaged primers; $17~$19 per 1000. Less exciting – empty APS strips are a little pricey at $3 for 8 strips, or almost the same as those containing primers. I guess RCBS primarily wants us to use CCI primers. If you sense a referral company relationship developing, it is probably because ATK, Alliant Powders parent company, owns Federal Premium, Speer Bullets,CCI Ammunition, RCBS, and others. Considering the ATK structure, this is a good thing.

Preloaded CCI strips are packed 1,000 to a carton, each carton contains 10 adhesive backed cards, each card holds 4 APS strips mounted compound side down for protection from contamination. The adhesive back cards are oddly similar to Avery white removable labels, allowing partially used strips to be returned their cards for storage. Empty strips are refilled and strips may be purchased without primers, 8 strips to the pack with the same 25 primer per strip capacity and in the same color codes. Prefilled APS strips run about the same as conventionally packaged primers; $17~$19 per 1000. Less exciting – empty APS strips are a little pricey at $3 for 8 strips, or almost the same as those containing primers. I guess RCBS primarily wants us to use CCI primers. If you sense a referral company relationship developing, it is probably because ATK, Alliant Powders parent company, owns Federal Premium, Speer Bullets,CCI Ammunition, RCBS, and others. Considering the ATK structure, this is a good thing.

APS Primer Strip Loader

Most of us use a variety of primer brands; an accommodation to a critical load recipe, close adherence to published handload data or as a function of price and availability opportunities. RCBS, in their wisdom for removing roadblocks to the sale of APS related products, offers a APS Primer Strip Loader. Smart move and an honest move. RCBS customers could switch to this system of increased priming speed and contamination reduction, applying it to any brand of primer the customer might have in their handloading component inventory. The customer could use newly purchased empty APS strips, or refill previously emptied APS strips with any brand of primer of the correct type.

Most of us use a variety of primer brands; an accommodation to a critical load recipe, close adherence to published handload data or as a function of price and availability opportunities. RCBS, in their wisdom for removing roadblocks to the sale of APS related products, offers a APS Primer Strip Loader. Smart move and an honest move. RCBS customers could switch to this system of increased priming speed and contamination reduction, applying it to any brand of primer the customer might have in their handloading component inventory. The customer could use newly purchased empty APS strips, or refill previously emptied APS strips with any brand of primer of the correct type.

The loader is very easy to use. An appropriately colored empty APS strip is inserted into the slide at the rear of the press, in this instance “Large Pistol – Standard” as denoted by the white strip (arrow). The clear plastic lid is removed, loose primers are dropped in, then the loader is gently shifted side to side so the ribbed primer flipper surface can correctly orient the primers compound side up. The clear plastic cover is put in place to prevent the primers from flipping over or out of the loader, the APS Strip side of the loader is tipped down, and the loader is rocked side to side until a primer drops into each opening on the APS Strip. Then the loader is tipped back to move excess primers away from the strip, the loader is placed on a work surface, and the black frame is pressed downward to seat the primers in the strip. Slight pressure is maintained on the frame while the finished strip is pulled from the press. Actual use is a snap. It took a couple of minutes to load 4 strips with the contents of a box of 100 Federal brand primers. When finished, the strips were placed on the adhesive backed labels to shield the primer compound from incidental contact. Each pack of new APS strips comes with sets of these reusable labels.

APS Priming Tools

RCBS Priming Tools come in three versions: bench mount, press mount and hand held. While they all accomplish pretty much the same thing, each goes about it a little bit differently. Since I’m a handloading relic, I tend to prime cases off my loading press and as a discrete operation. My feeling is that the toggled mechanical advantage of the loading press takes away the feel of seating primers, and there are too many particles of contamination clinging loosely to the loading press and dies.

RCBS Priming Tools come in three versions: bench mount, press mount and hand held. While they all accomplish pretty much the same thing, each goes about it a little bit differently. Since I’m a handloading relic, I tend to prime cases off my loading press and as a discrete operation. My feeling is that the toggled mechanical advantage of the loading press takes away the feel of seating primers, and there are too many particles of contamination clinging loosely to the loading press and dies.

The APS bench mounted press has a small foot print. I anchor mine with screws and wing nuts so it is easily removed from the bench. The press has an adjustable handle position for comfort of use, and an adjustable travel limit stop to assure proper primer seating depth. The bench tool utilizes standard shell holders, so the operator would equipped to prime any case they were equipped to load. One of these days, I will make a useful work surface that mounts flush just below the shell holder so everything will be in easy reach; case loading blocks within a couple of inches of the shell holder.

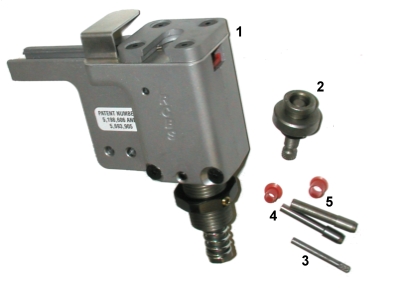

The press is supplied with 1) a cam lock pin to prevent primers from being fed while adjusting the press. 2) a small primer plug that is used to seat small primers. 3) a large primer plug for large primers. 4) a large bushing that fits beneath the shell holder and guides the primer up from below on press stroke. 5) a small bushing in position in the center of a shell holder. primer plugs are installed with the handle down, or the plug will drop down inside, allowing for exploration of the inner workings of the press. It takes seconds to change plugs, shell holders and bushings or loaded strips.

The press is supplied with 1) a cam lock pin to prevent primers from being fed while adjusting the press. 2) a small primer plug that is used to seat small primers. 3) a large primer plug for large primers. 4) a large bushing that fits beneath the shell holder and guides the primer up from below on press stroke. 5) a small bushing in position in the center of a shell holder. primer plugs are installed with the handle down, or the plug will drop down inside, allowing for exploration of the inner workings of the press. It takes seconds to change plugs, shell holders and bushings or loaded strips.

The Press mounted APS priming tool is very similar to the bench mounted tool in appearance and function. It is supplied with: 1) tool body 2) adjustment rod assembly 3) cam lock pin 4) small primer plug and bushing 5) large primer plug and bushing.

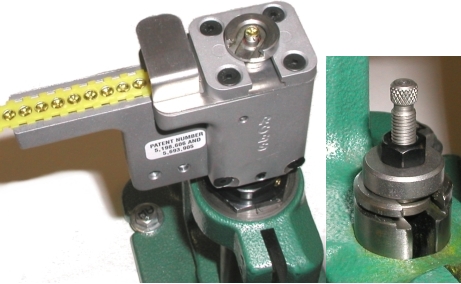

I installed the press mount APS system in both a Rock Chucker and Turret press, then began writing a less than positive perspective on its use. I decided to spend a little more time with the unit and used it to prime a few hundred cases before making further comment. In practice, the press mounted APS priming tool works just like the bench mounted unit, with the exception primer seating depth is controlled by a adjustment rod assembly that mounts in the reloading press ram. This was a little awkward to set up, and the press could not be used for any other purpose until the adjusting rod was removed. I felt the reloading press’ mechanical advantage made me rely too heavily on the mechanical stop setting to achieve proper primer seating depth, and the width of the tool and need for APS feed and eject clearance pretty much eliminated installing other dies in the turret head for use in combination with almost any other operation. In all fairness, RCBS did not suggest mounting the tool for use in concert with any other operation. The press mount tool runs about $20 less than the $70 or so price of the bench mounted unit. I think the convenience of the bench unit justifies its extra $20 cost.

The installed press mounted tool is solid in the Rock Chucker. The primer feeds through the shell holder (left), and the adjustment rod is inserted in the press ram. I’m not sure if it’s the ratio of the press arm or length of stroke, but it seems to take a lot of motion to seat a primer and it is hard to feel seating pressure. I’m not sure, it could just be my perception. In any event, from a practical standpoint, the press mounted set up performed well and there were no rejects in crushed primers or not fully seated primers. Maybe I’ll set one up with a Hornady Lock-N-Load bushing and make it a quick change set up. I tried it on a turret head that contained utility tools; universal decapper and collect bullet puller. It worked like a champ but, because it obstructed several other die locations on the head, it just didn’t make much sense for routine usage.

The installed press mounted tool is solid in the Rock Chucker. The primer feeds through the shell holder (left), and the adjustment rod is inserted in the press ram. I’m not sure if it’s the ratio of the press arm or length of stroke, but it seems to take a lot of motion to seat a primer and it is hard to feel seating pressure. I’m not sure, it could just be my perception. In any event, from a practical standpoint, the press mounted set up performed well and there were no rejects in crushed primers or not fully seated primers. Maybe I’ll set one up with a Hornady Lock-N-Load bushing and make it a quick change set up. I tried it on a turret head that contained utility tools; universal decapper and collect bullet puller. It worked like a champ but, because it obstructed several other die locations on the head, it just didn’t make much sense for routine usage.

The handheld APS tool is very neat. I had a loose primer version I rarely used, but the combination of APS strips and universal shell holder makes this a really useful tool. Lots of times I find myself working up handloads where the great majority call for standard primers, but a few require magnum types. With the handheld, I can pop in these magnum primers easily without pulling the standard APS strip already loaded in the bench press. I don’t believe the handheld would be my first choice for a primary priming tool, but clearly as a useful secondary or short run tool. At a little over $30, it is a value.

The handheld APS tool is very neat. I had a loose primer version I rarely used, but the combination of APS strips and universal shell holder makes this a really useful tool. Lots of times I find myself working up handloads where the great majority call for standard primers, but a few require magnum types. With the handheld, I can pop in these magnum primers easily without pulling the standard APS strip already loaded in the bench press. I don’t believe the handheld would be my first choice for a primary priming tool, but clearly as a useful secondary or short run tool. At a little over $30, it is a value.

The handheld has low mechanical advantage, so the seating feel is sensitive, making it almost impossible to improperly seat primers. The universal shell holder built into this APS tool is truly universal. That is a .416 Weatherby case in the holder pictured right, and the .45-70 and .25-05 next to the tool were held just as securely. I brochure indicates the holder will work with all cartridges from 32 ACP to the pictured large cases. Loading and unloading of the holder requires only slight pressure in and out. Both small and large primer plugs are provided, changed with a small supplied hex tool complete with spots for plug storage, a set screw holds the grip closed to facilitate changing plugs. I primed 40 or 50 cases with the handheld without any difficulties.

Summary

I spent quite a bit of handloading time with single station, progressive, auto progressive and turret presses, using various schemes for priming cartridges. Most are relatively reliable and virtually all seat properly with experience in use. Unfortunately, priming isn’t something most handloaders look at as being done almost always right. I would get really annoyed when a shuttle feed on an auto progressive press skipped a beat and a case went almost to the next step without a primer. I disliked double feeds and scrubbing t he insides of primer tubes almost as much as flipping primers and pecking at them to fill primer tubes, and I refuse to leave primers in tubes as a form of storage. There are lots of tools out there that have limited practical application, those that collect dust, waiting for that very special circumstance that never seems to develop. APS is not one of those systems, it is a very practical and inexpensive way to improve the quality and performance of the handloading operation, not some times, but every time.

Thanks

Joe

Email Notification