01/19/2020 – Today was a planned range day; some final data collecting and testing 7mm Remington Magnum handloads for a Browning X-Bolt rifle. Unfortunately, there is about 8″ of Maine sunshine on the ground and another eight hours of snowfall in the forecast. My next work project will be tractor snow removal duty. Until then, I am confined to quiet reflection, or at least as quiet as possible while cracking walnuts.

Walnuts are a very healthy food for many reasons and cracking whole walnuts, rather than grabbing a handful out of a bag, slows consumption and gives the brain a chance to keep pace with the gut. Yes, the sound of cracking walnuts does have its down side as my wife could testify. Trapped in the house during a snow storm, Kindle open to her favorite author, with her husband sitting not two feet away on the sofa, spacing and cracking walnuts. A great opening for a murder mystery.

Background

The Hornady Lock-N-Load® Power Case Prep Center is a mature product that was introduced to the world mid 2011, but somehow did not make it to my reloading bench until very recently. “But Joe, shouldn’t you have been aware of this nine years ago? Perhaps if you didn’t spend so much time cracking walnuts and irritating your wife?”. Actually, I was well aware of the Power Case Prep Center, but there is a big difference between what is new and what finds its way onto my bench and into my handloading process.

While I handload a good deal of ammunition, most is not production; defining production as routinely assembling more than 100 plus rounds of the same cartridge and component pieces. At the risk of drawing the ire of statisticians, even when developing handloads and qualifying results, there isn’t much insight to be gained from firing more than 20 rounds within an anomaly free population than firing 100 rounds of the same.

Subsequently, case trimming, for the most part, has been accomplished on one of three manual trimmers; one that lends itself to very small caliber cartridges, one for common length cartridges and one that is suited for use on giant size British/German cartridges with bullets the size of door knobs. Each trimmer is accompanied with proprietary cutters, holders and pilots and method of anchoring to a bench.

When trim jobs rose above 100 pieces, a relic RCBS Trim Pro™ Power Case Trimmer was cranked up. Not the “2” version, this one dated back to the prior millennium, and was purchased when my wife pointed out that years of manual trimming caused me to become physically asymmetrical. My right arm, the one with the handle cranking hand, had grown Popeye like. My left arm, with the spectating hand, had dwindled to nearly infant size.

When trim jobs rose above 100 pieces, a relic RCBS Trim Pro™ Power Case Trimmer was cranked up. Not the “2” version, this one dated back to the prior millennium, and was purchased when my wife pointed out that years of manual trimming caused me to become physically asymmetrical. My right arm, the one with the handle cranking hand, had grown Popeye like. My left arm, with the spectating hand, had dwindled to nearly infant size.

The RCBS had a great deal of personality and with personality comes little quirks. The Trim Pro required a second set of shell holders. The trim length adjustment collar was held in place with a small set screw pressed against the trimmer’s round shaft and was prone to slipping. Cutter pressure was applied by a spring that carries the tension of a front coil spring from a 1976 Oldsmobile station wagon. It was not uncommon for a 7mm Remington Magnum case to be trimmed to 7×57 Mauser case length, beginning at spec and meandering down to the shorter length over a span of 100 pieces. Yes, I am exaggerating, but not by a lot, and I am trying to make a point.

This is an excerpt from a twenty year old article, a review of the Trim Pro, “I’d like to see a more modern approach to the packaging, and maybe a shot at designing the tool for vertical actuation like a drill press, which would give a more natural feel to the operation for those of us who are not lathe operators, and a vertical approach would take up much less bench real estate. Maybe this type of layout could serve as an all in one power unit for a series of easy to set up powered reloading tools”.

No, I am not even remotely suggesting that Hornady followed my suggestions. However, I am saying that good equipment design conforms to intuitive use and serves multiple purposes, which certainly applies to the Hornady Lock-N-Load® Power Case Prep Center. More people are comfortable with operating a drill press than operating a lathe.

Finding production work within short run batch processing

Where my old RCBS power trimmer was limited in use to infrequent occurrences of trimming larger quantities of the same case type, the Hornady Lock-N-Load® Power Case Prep Center offered greater potential. A preliminary run of twenty count of ten different types of cartridges still represented two-hundred cases that universally needed to be inside/outside case mouth reamed, primer pockets cleaned and inside necks brushed. Additionally, simplified trimmer set up made the Power Case Prep Center useful for even short runs.

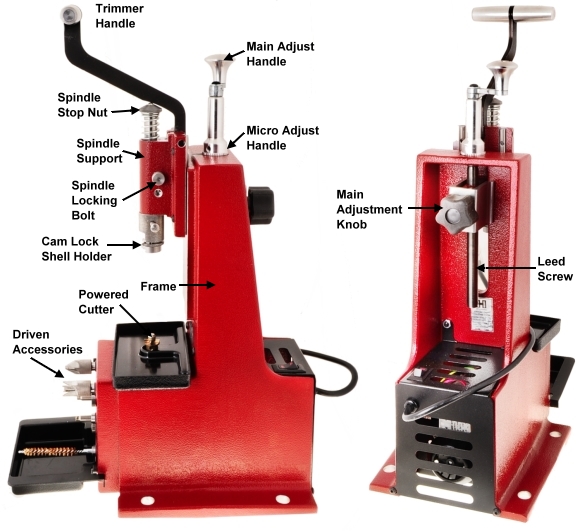

The Hornady Lock-N-Load® Power Case Prep Center is a vertical case trimmer, with gear driven piloted cutter and six forward facing accessory tool attachment points. Power is provided by a fused, 115v 1.3 amp AC motor producing 90 RPM spindle speed. The fuse is listed as a 1 1/4 amp 1/4″x1 1/4″ fast acting glass fuse, which is commonly referred to as a 1.25A 3AG Fast Blow Fuse which is very common.

The Prep Center’s frame and spindle support are 0.435″ thick aluminum castings. The spindle support position on the frame is determined by a leed screw that passes through the support. The position of the spindle support determines depth of cut and, subsequently, case overall length. Adjustment is coarse at the main adjust handle and fine at the leed screw micro adjust handle. Movement is indexed in 0.001″ increments.

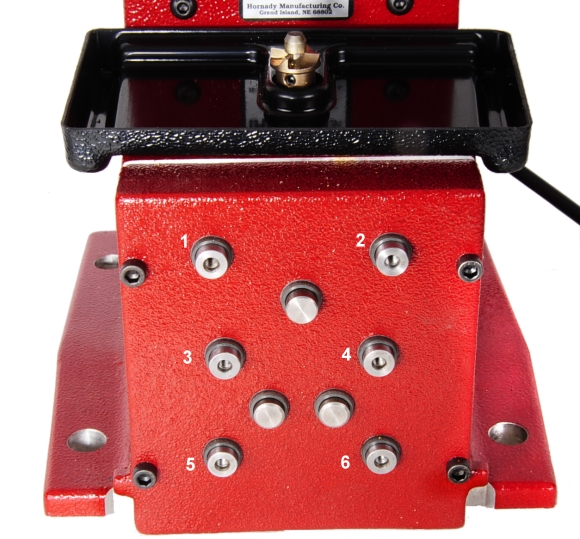

The front accessory holders, 1-6, have 8-32 female threads and rotate counterclockwise to prevent the tools from backing out in use. The three central shafts are comprised of one driven shaft and two idlers. Above the accessory drive is the replaceable powered cutter and pilot. Pilots, cutters and shell holders are common to other Hornady equipment.

Tools mounted in front are powered by a single driven shaft and one driving gear that turns all of the tools concurrently through beefy nylon gears. There is one power switch that is mounted on the power supply enclosure at the rear of the trimmer.

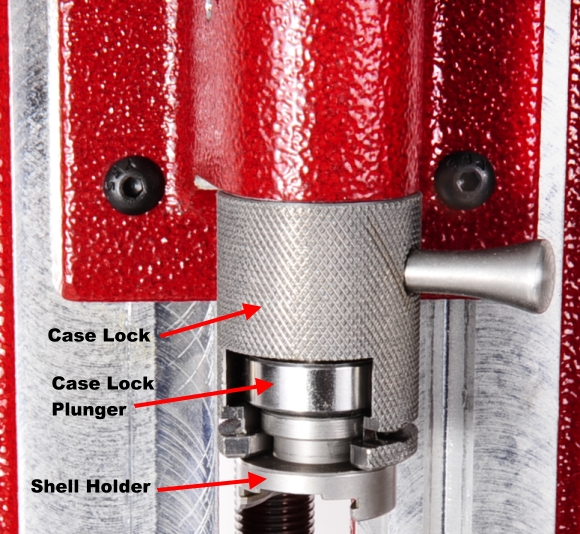

Cases are held in standard Hornady shell holders, anchored by a case lock plunger that passes through the shell holder and cams against the case.

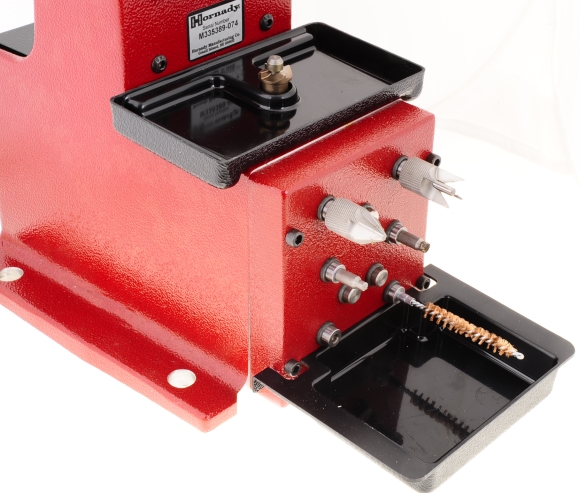

The Hornady trimmer comes with enough accessory pieces to handle most cartridges including: inside/outside chamfer/deburr tools, large and small primer pocket cleaners, six neck brush sizes (22 cal, 25 cal/6mm, 270 cal/6.5mm/7mm, 30 cal, 35 cal and 45 cal), the same sizes in cutter pilots, and Hornady shell holders #s 1, 2, 5, 16, 35.

Below – bottom row: cam lock plunger center, Hornady shell holder left, RCBS shell holder right. Hornady cutter pilot top left, RCBS cutter pilot right. Probably because most brand shell holders will fit most other brand presses, I took a look to see if there was cross compatibility with these pieces, even though there was no suggestion that there would be, and I had no such expectations.

The Hornady cutter pilots measured 0.186″ in diameter to the RCBS too small 0.152″ stems. The plunger stem diameter measured 0.284″, the center holes in Hornady, Lee and RCBS measured respectively 0.295″, 0.252″ and 0.265″ with only the Hornady part functional in the trimmer. Yes, that was a relaxing walk to nowhere, just to satisfy my curiosity.

How did it work?

The Hornady Lock-N-Load® Power Case Prep Center manual begins with instructions to anchor the press to your bench with 1/2″ bolts, nuts and appropriate combination of lock and flat washers. My bench is laid out in free form fashion and to my liking. Components are also very mobile and constantly reorganized to suit my purpose, so the trimmer was anchored to my bench with C clamps. I do not recommend my shoddy approach to others.

My first use of the Hornady Lock-N-Load® Power Case Prep Center was for a 7mm Remington Magnum Project. The SAAMI min-max case length spec for the 7mm Rem Mag is 2.480″ to 2.500″. Hornady’s reloading manual suggesting a trim to length of 2.490″. Measurement of ten samples from the brass lot assigned ran from 2.489″ to 2.493″ after full length sizing, so trim length was set at to 2.485″ to make sure cases were uniform in length and mouths were cut parallel to bore and cleanly finished.

The first ten pieces processed through the trimmer did not hold the initial case length setting, varying as much as 0.007″. After a little head scratching, I realized it was operator error. Because I rarely crimp cartridges of this type, I make under size expander balls which leave an opening larger than using no expander at all, but still smaller than 0.280″ to increase neck tension.

Using 7mm cutter pilot, which measured 0.280″, a good deal of effort was required on the handle for the case mouth to pass over the pilot on the trimmer’s down stroke, which heavily loaded the spindle and the spindle support. The fit was so tight that the handle would not return under trimmer return spring pressure and needed to be tapped with a poly head mallet.

A 270 Winchester pilot was substituted, which measured 0.275″, and 100 pieces were run that measured between 2.485″ and 2.486″. For the sake of comparison, I ran fifty pieces of 7x57mm Mauser with standard expander ball and the 7mm Hornady cutter pilot and the trimmer provided very uniform results without any issues surfacing. Yes, the 270″ cutter worked without a problem trimming 270 Winchester cases.

The 7mm Remington Magnum trimming issue was not a problem with the Hornady Lock-N-Load® Power Case Prep Center, but rather something brought on by Joe making little non-standard tool to suit his specific preferences and personal dies sets.

The prep tools location up front are used even if length trimming wasn’t on the agenda. The speed is right for the purpose and it is easy to move brass from one tool to the next following a standard sequence. Trays included with the trimmer caught the brass particles. It is actually a very clean operating machine.

The Prep Center is a good solution for me, replacing my old power trimmer and a bunch of separate hand and small power tools, and it handles cases lengths from 0.750″ to 3.25″, 9mm Luger to 577 Nitro Express. Discount retail prices I’ve seen run from $480 to $520. Not a minor investment in equipment, but for the frequent handloader it will deliver quality product and last a very long time.

Email Notification