I like writing about higher than SAAMI pressure cartridge loads. The response always begins with knee jerk reactions, then immediately deteriorates into an emotional issue, rife with illogical arguments and lots of insults cast from afar. I don’t know why. It’s sort of like when people are ordinarily great drivers, then one drop of rain hits the pavement and they forget how to brake and steer. I’m going to do this in three parts. Part I is dedicated to a little background and gun preparation. Part II will address component and handload combinations. Part III will be range results and a recap.

In the Beginning

Increasing powder charges to improve external and/or terminal ballistic performance is not a new concept. Captain Walker and Samuel Colt took this route in 1847 when they produced the Walker Colt. In 1855, the U.S. arsenal at Harper’s Ferry did the same when they introduced the Model 1855 Horse Pistol. Both guns, and many similar, produced exceptional performance primarily by increasing powder charges, sometimes a 2x – 3x increase over charges appropriate for standard firearms. In more modern times, ammunition manufacturers have taken advantage of the potential offered by exceptionally strong firearms to handle higher than SAAMI standard spec pressure, by releasing +P and other heavy load versions of everything from the 257 Roberts +P and 45-70, to the 38 Special and .45 Long Colt.

Increasing powder charges to improve external and/or terminal ballistic performance is not a new concept. Captain Walker and Samuel Colt took this route in 1847 when they produced the Walker Colt. In 1855, the U.S. arsenal at Harper’s Ferry did the same when they introduced the Model 1855 Horse Pistol. Both guns, and many similar, produced exceptional performance primarily by increasing powder charges, sometimes a 2x – 3x increase over charges appropriate for standard firearms. In more modern times, ammunition manufacturers have taken advantage of the potential offered by exceptionally strong firearms to handle higher than SAAMI standard spec pressure, by releasing +P and other heavy load versions of everything from the 257 Roberts +P and 45-70, to the 38 Special and .45 Long Colt.

The legitimate controversy surrounding the use of greater than standard charges to improve performance naturally, and reasonably, centers around the issue of firearm strength and safety. Steel 5″ barrel 1911 type pistols have been chambered by factories for a number of cartridges that generate considerably higher maximum pressure than the .45 ACP cartridge. Examples ? The .38 Super +P produces 36,500 PSI of pressure, the 40 S&W is a 35,000 PSI cartridge, the 10mm auto generates 37,500 PSI. Each cartridge generates different breech face thrust based upon the maximum pressure and interior case head surface area. Breech thrust for the cartridges indicated are : 45 ACP = 2,639 PSI, 38 Super +P = 3,009 PSI, 40 S&W = 3066 PSI, and 10mm Auto = 3,286 PSI. From a pressure standpoint, as well as breech face thrust, the standard .45 ACP is the least stressful cartridge of the bunch for a firearm of this type to ingest.

A while ago, I developed an interest in .45 ACP type cartridges that operate above SAAMI .45 ACP and .45 ACP+ MAP levels; 21,000 PSI and 23,000 PSI respectively. There are two specific pressure increments above the 45 ACP +P that offer significantly enhanced performance. The 45 Super® cartridge is reputed to operate in the 28,000 PSI range. The 460 Rowland, a step above the .45 Super® in performance, operates in the 38,000~40,000 CUP range. Where only minor changes are required to a full size steel .45 Model 1911 type to accommodate a 28,000 PSI level cartridge, the Rowland’s 40,000 CUP and 1/6″ longer case length require a compensated barrel with a 460 Rowland chamber. The 45 Super®, or 28,000 PSI loads, when fired from a full size steel 1911 type pistol, requires an increase in slide resistance and the use of brass with a reinforced web. For further background and basis for these opinions please see the related articles in the Real Guns’ archive section.

A while ago, I developed an interest in .45 ACP type cartridges that operate above SAAMI .45 ACP and .45 ACP+ MAP levels; 21,000 PSI and 23,000 PSI respectively. There are two specific pressure increments above the 45 ACP +P that offer significantly enhanced performance. The 45 Super® cartridge is reputed to operate in the 28,000 PSI range. The 460 Rowland, a step above the .45 Super® in performance, operates in the 38,000~40,000 CUP range. Where only minor changes are required to a full size steel .45 Model 1911 type to accommodate a 28,000 PSI level cartridge, the Rowland’s 40,000 CUP and 1/6″ longer case length require a compensated barrel with a 460 Rowland chamber. The 45 Super®, or 28,000 PSI loads, when fired from a full size steel 1911 type pistol, requires an increase in slide resistance and the use of brass with a reinforced web. For further background and basis for these opinions please see the related articles in the Real Guns’ archive section.

The gun I used for the original hyper 45 ACP project was a Kimber Gold Match fitted with a 28 lb. Wolff recoil spring, and all handloads utilized Starline brass headstamped 45 Super. The gun worked without a hitch and generally cycled properly even with lower pressure +P and high velocity standard .45 ACP ammo. Breech face thrust at the 28,000 lbf level increase to 3,518 lbf, a 33% increase over the 2,639 lbf for the standard 45 ACP, and an increase of 7% over the 10mm Auto. I concluded the project series with the thoughts that at some future date I would try some other cartridge component combinations, and I would find a better way to increase slide resistance to reduce long term wear and tear on the pistol. Then I proceeded to get sidetracked in other areas and my work on the Kimber was limited to fancy grips and steel mainspring housing.

The gun I used for the original hyper 45 ACP project was a Kimber Gold Match fitted with a 28 lb. Wolff recoil spring, and all handloads utilized Starline brass headstamped 45 Super. The gun worked without a hitch and generally cycled properly even with lower pressure +P and high velocity standard .45 ACP ammo. Breech face thrust at the 28,000 lbf level increase to 3,518 lbf, a 33% increase over the 2,639 lbf for the standard 45 ACP, and an increase of 7% over the 10mm Auto. I concluded the project series with the thoughts that at some future date I would try some other cartridge component combinations, and I would find a better way to increase slide resistance to reduce long term wear and tear on the pistol. Then I proceeded to get sidetracked in other areas and my work on the Kimber was limited to fancy grips and steel mainspring housing.

A couple of weeks ago, I received a new product mailer from Brownells. One of the items listed was a Sprinco Semi-Auto Guide Rod System. One configuration listed was for the 1911 5″ for use with +P+ .40 and- .45 Super® loads, so I figured this would be a good item to check out and resume work on the high pressure .45 ACP project. This Sprinco model carried an MSRP of approximately $74, however, there are other models for a variety of applications.

A little background – Sprinco U.S. is located in Austin, Texas. Its parent company, Sprinco. Spring Manufacturing CO. LTD. is based in Israel, and was formed in 1935. Sprinco U.S. markets: recoil springs, recoil reducers, Plate + lubricant, AK and SKS recoil buffers, stainless guide rods, and P-T Night Sights. Products can be purchased directly from the Sprinco site at full MSRP, or at discounted prices through the usual distributors.

Kimber vs. Sprinco

The stock Kimber set up is pretty straight forward; a one piece guide rod, single recoil spring and though-hole spring plug. Under recoil, the slide moves toward the rear, and the plug compresses the spring around the guide rod. Generally, the standard recoil spring is rated at 16 lbs. Springs can be substituted in the range of 7 lbs to 28 lbs for the purpose of tuning for specific loads and cartridges.

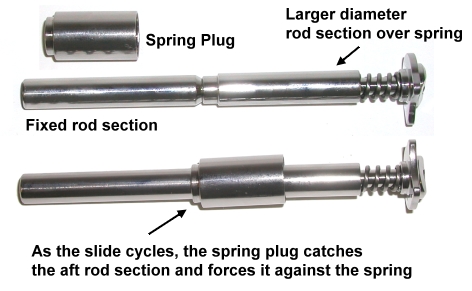

The Sprinco guide rod is made in two pieces; the forward portion if fixed, the rear portion is located over a spring. In recoil, the slide carries the spring plug rearward until the plug contacts the second, larger diameter portion of the spring guide. For the slide to move farther, it must then overcome the resistance of the guide rod spring.

The Sprinco guide rod is made in two pieces; the forward portion if fixed, the rear portion is located over a spring. In recoil, the slide carries the spring plug rearward until the plug contacts the second, larger diameter portion of the spring guide. For the slide to move farther, it must then overcome the resistance of the guide rod spring.

The guide rod spring, alone, does not offer sufficient resistance. It is used in combination with the pistol’s standard spring as pictured on the left. Unlike factory dual counter wound spring set ups, these two springs wont bind.

The guide rod spring, alone, does not offer sufficient resistance. It is used in combination with the pistol’s standard spring as pictured on the left. Unlike factory dual counter wound spring set ups, these two springs wont bind.

Springs do not always perform as labeled and springs fatigue over time. I don’t think it takes a multi thousand dollar spring tester to do basic checking, and this set up appears to work just fine. If you have an interest in building one like this check out “Building a recoil spring tester”. A digital scale that resolves to 1/2 lb replaced the mechanical scale.

Recoil springs are qualified in several ways. A standard Colt Government type spring has an average weight of 16 lbs, a reference that appears in the Kuhnhausen .45 Colt Automatic shop manuals. The actual specification is: 32 coils, free length 6.55″, solid or fully compressed length 1.375″ maximum, load at 73% of compression (1.81″) 13.55 lbs, fully compressed 17.36 lbs, average rate of compression 2.65 lbs/inch. Some of this can be calculated. As an example, if the wire stock for the spring is .0445″ is diameter, 30 coils will pretty much result in a 1.365″ compressed length, or .010″ under maximum. At 73% compression the original Kimber spring offered approximately 13.5 lbs of resistance, and a little over 16 lbs at full compression just prior to coil bind. Not too bad considering the number of rounds that have passed through the Kimber over an extended period of time and after handling lots of ammo.

The Sprinco guide rod spring checked out at 12.5 lbs at full compression. Instructions suggested utilizing the standard 16 lb recoil spring, or possibly reducing the spring weight. I decided to install a 22 lbs spring which I felt would maximize protection from the heavy loads, with the idea I could reduce the rate as needed while range testing until the gun functioned properly and empty case ejection was to a reasonable distance, 6 to 9 feet.

The only problem I encountered during installation was the length of the Sprinco rod, a possibility that was noted in the assembly instructions. The Sprinco was 4.050″ compared to 4.000″ for the Kimber. Not a huge difference, but enough to stop the barrel bushing from rotating into position when assembling the gun. A quick hit on the belt sander and a clean up with a stone put everything in the right place.

The finished product looked stock and all of the parts fit neatly together. Since no permanent modifications were required, I can always return the gun back to the original configuration when completed. Even though the Sprinco internal spring does not come into play until halfway through the slide cycle, there was no abrupt change in force required to open the slide manually and the parts functioned smoothly together.

I have a different combination of bullets on the way, a new selection of powder, so I will be spending some time in defining and assembling a batch of handloads. None of the loads will be suitable for use in a standard .45, and any of the changes I am making pertain only to this model Kimber. I frequently get email requesting insight into other 1911 type pistols that might be converted or some models of revolvers. The answer is, I don’t know if they are candidates or not. A lot of the spring selections are dependent on specific handloads and weight and friction of the gun’s slide. Unfortunately, even just the difference in carbon steel versus stainless steel in a gun’s construction make a big difference in spring selection. What I am getting at is that I am experimenting, not creating a list of .45 ACP handloads for general application.

More “Hyper .45 ACP Loads and the .45 Thuper Revisited”:

Hyper .45 ACP Loads and the .45 Thuper Revisited Part I

Hyper .45 ACP Loads and the .45 Thuper Revisited Part II

Handload Data 45 ACP

Handload Data 45 Super level loads

Thanks,

Joe

Email Notification