10/08/2013 – There are many techniques for detecting excessive pressure within a population of handloads. Some are ineffective, none are singularly adequate, all require a good deal of subjective interpretation. Still, everyday, handloaders find safe passage, as evidenced by the number of us that still have a full compliment of original digits and eyebrows.

My approach to non-instrumented excessive pressure detection is a combination of: primer reading, fired case dimensional changes, interior/exterior case inspection for structural failure, excessive or diminished muzzle velocity, and fired case extraction effort, bolt face case head tattoos. As individual checks, none are adequate, but they are very effective when combined.

Case head expansion measurement

One method I have often seen promoted, and just as often mischaracterized, is case head expansion measurement.For anyone interested in this process, I would suggest the Lyman Reloading Handbook, or the Speer Reloading Manual prior to the 14th Edition where the topic was dropped. Lee Modern Reloading and Hornady manuals mention the approach in passing, but provide no detail.

Like every pressure checking method employing piezo transducer, copper crusher cylinder, or strain gauge, case expansion measurement is suggested as a way of detecting excessive pressure through inference.

In concept, the case head expansion measurement method assesses the change in case head diameter caused by pressure induced bolt thrust… the longitudinal force acting on the breech face of a discharging firearm.

A handload is assembled using between once and three times fired brass. The case’s diameter is then measured above the extractor groove for rimless or belted cartridge, or just above the rim for rimmed cartridges. The cartridge is fired, the same point of diameter on the case is measured, and the difference between the first reading and the second are noted.

According to Speer’s reloading manual, within a population of fired brass, diameter increased between 0.0003″ and 0.0005″ are deemed acceptable, with expansion inferring 50,000 CUP (Copper Units of Pressure). Coincidentally, 50,000 CUP is the SAAMI MAP (maximum average pressure) for the 30-06 Springfield and just under all 30-06 Springfield derivative cartridges, including the 308 Winchester. 50,000 CUP is also within 4,000 CUP of most 30-06 length belted magnum cartridges.

The Lyman manual restates what appears in the Speer manual, gives the method a stronger endorsement and indicated that 0.0005″ is a 60,000 PSI equivalent. They go on to suggest only once fired brass be used, as brass fired two and three times is too work hardened to provide consistent readings.

Sounds exciting, and a perfect tool… Sure. Why not?

The method may work well for many cartridges, but it is also not useful for many. Contradicting yourself, Joe? They say the memory is the first to go? I call BS. The hair is the first to go and losing memory of some details of a long life may even be therapeutic. Anyway…

Cartridges traditionally slated for lever action rifles, and most older any kind of rifles, often operate well below 50,000 CUP: 30-30 WCF 38,000 CUP, 35 Remington 35,000 CUP, 44 Remington Magnum 40,000 CUP, and the standard pressure 45-70 Gov’t is only 28,000 CUP. So any of these cartridge would be operating well in excess of safe pressure by the time 0.0003″ to 0.0005″ expansion would occur.

Additionally, many popular cartridges came into production after SAAMI switched from copper crusher to piezo transducer method, so there is no reference copper crusher CUP standard. Please don’t email and tell me there is a guy who did the conversion. He did not.

Lyman didn’t extrapolate the 60,000 PSI level for 0.0005″ expansion from the CUP reading. They took the SAAMI 50,000 CUP 30-06 copper crusher standard, and the 60,000 PSI 30-06 transducer standard, and declared them to be the same and, therefore, the effect on headspace expansion to be the same. Is that correct? I don’t know, I wasn’t there, but it sounds logical.

So, 50,000 CUP or 60,000 PSI and 0.0005″ case head expansion are the outer limits for for the method. Nowhere is it written that 0.0006″ or 0.0007″ expansion interprets into a quantifiable, higher pressure ceiling. Unfortunately, most newer generations of cartridges not intended for an AR application, and all Weatherby cartridges since 1942, operate at 5%-6% higher pressure levels. A cartridge of this type would show 0.0005″ case head expansion, maximum, at the equivalent of a starting load, with no guidance beyond.

Critical considerations… Any excuse to play with the milling machine

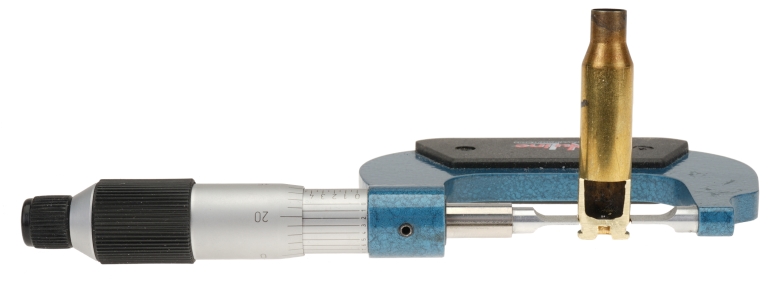

To give case head expansion measurement a fair shake, a blade micrometer with 0.0000″ accuracy is required, as the section being measured is only the solid portion of the case head, which is a relatively thin piece of brass residing horizontally between the case web and primer pocket. In the cutaway 7mm-08 Remington case pictured above, the solid surface is only 0.065″ thick.

Using a full round anvil and spindle micrometer that would cover a larger area on the case, it could pick up the thinner walls higher on the case web, which are prone to greater expansion than the solid case head area, or the rim which may be a slightly larger diameter then the case head. Either situation would yield an erroneous result.

Virgin brass varies in hardness, so using brass that has been fired one to three times will be slightly work hardened and yield the most consistent results.

Cartridge cased should be indexed to a rifle’s barrel. In this case, a test barrel, but the same applies to standard barrels. The objective is to create a reference point of measurement and to match the case to the chamber position each time it is fired.

| Brass Brand | Reading 1 | Rotated 90° | Δ |

| RP | 0.4706″ | 0.4707″ | 0.0001″ |

| RP | 0.4706″ | 0.4707″ | 0.0001″ |

| RP | 0.4707″ | 0.4707″ | 0.0000″ |

| RP | 0.4705″ | 0.4706″ | 0.0001″ |

| RP | 0.4708″ | 0.4709″ | 0.0001″ |

| RP | 0.4686″ | 0.4687″ | 0.0001″ |

| RP | 0.4698″ | 0.4712″ | 0.0012″ |

| RP | 0.4692″ | 0.4712″ | 0.0020″ |

| RP | 0.4669″ | 0.4675″ | 0.0006″ |

| RP | 0.4693″ | 0.4710″ | 0.0017″ |

Above, once fired, same lot, 7mm-08 Remington brass. The variations in dimension are not a problem, as long as the points of initial measurement are noted and the case always goes in the chamber indexed to the same position. If not indexed and a case is rotated to a different position, the variation in diameter for the last four samples would easily mask any changes resulting from pressure.

Loved the wandering narrative, Joe, but how did it work out?

Before committing to a larger sample size, I decided to track five rounds. The thinking was that if the case head expansion measurement method did not hold up, I might as well stop, save the expanded test time and change the hydraulic system filter screen on the tractor.

The load for all was a 140 grain Berger VLD Hunting bullet, 47 grains of Alliant Reloder 17, 2.800″ COL, using CCI 400 primers (LR). That charge is about 1 full grain under my maximum load. Bullets were scaled, powder charges were scaled, gross case capacity (spill over full) was uniformly 55.2 grains of distilled water.

| Brand | Case Head Diameter Before |

Case Head Diameter After |

Δ | Headspace Before |

Headspace After |

Δ | Chrono Readings FPS |

| RP | .4685″ |

0.4706″ | 0.0021″ | 1.625 |

1.622 |

-0.003 |

2793 |

| RP | .4686″ |

0.4706″ | 0.0020″ | 1.626 |

1.623 |

-0.003 |

2817 |

| RP | .4674″ |

0.4707″ | 0.0033″ | 1.626 |

1.622 |

-0.004 |

2792 |

| RP | .4698 |

0.4705″ | 0.0007″ | 1.625 |

1.622 |

-0.003 |

2775 |

| RP | .4691 |

0.4708″ | 0.0017″ | 1.627 |

1.623 |

-0.006 |

2804 |

If there is a dimensional correlation, other than the round with the least case head expansion producing the lowest velocity, it eludes me. The highest velocity did not drive the greatest case head expansion, or headspace increase.

Case head expansion was 1.5x to 6x the case head expansion measurement method holds as acceptable at 50,000 CUP and the 7mm-08 Remington is very close to that at 52,000 CUP. The load is not hot, and I have validated it for my own use using a strain gauge method. There were no signs of excessive pressure, beyond the case head expansion as noted.

Conclusion

In some ways, brass will be what it wants to be. Besides being a nifty place to stash powder and making ammunition easy to transport, it acts as a gasket and flows to some degree to seal the chamber. If all of the readings were somewhat consistent, but larger than the method specifies, I would be tempted to go on a load testing, data collecting crusade and establish my own expansion specs. However, they weren’t, so I didn’t.

Is case head measurement a way to monitor for excessive pressure in someone else’s hands? Someone younger, taller, smarter and better… ok, not better looking. I won’t go that far. Maybe someone else can make this work for them. But I noticed that the method was detailed in Speer reloading manuals, under the “Velocity, Energy & Pressure” section, through the 13th Edition, then omitted in the 14th Edition.

Email Notification