04/21/2024 – Someone, whom I greatly admired, once told me, that the cure for introversion is to think of a circumstance that would make me feel the most awkward, and jump in. So, occasionally, I do. In fact, my entire career of fifty years was predicated on a seemly endless stream of awkward human interactions. Fortunately, that was in a segment of the tech industry, so I was pretty much like everyone else.

More recently, overcoming social awkwardness put me through the process of an old man buying a motorcycle… from seemingly, children. Yesterday. it was exchanging funny faces with an extroverted toddler in an elevator. The latter, the more difficult of the two. Is writing before an audience a problem? No, I love writing, even if I suck at it. Writing, to me, is the same as Jack Benny’s relationship with the violin. I get to make all of the noise I want, and the audience gets to watch a train wreck real time.

I was born in a log cabin, which I helped my father build…

My first reloading equipment purchase was a Lyman All American Turret Press, circa 1958, with a set of .30-30 Winchester dies.

An unsupervised thirteen year old handloading, in retrospect, may not have been the best activity to engage. However, in my defense, I was in the pyrotechnic phase of childhood development, and blowing up model planes, boats and cars… and eyebrows faster than I could build/regrow them. A change was needed.

Learning how to handload was a struggle. Many false starts, wrong equipment selections, wrong component selection, nowhere to get good information, or bad information for that matter. There was no clear path toward pulling a cohesive system together. The first enduring lesson learned from that experience was don’t buy equipment ahead of knowledge.

Making $1.25/hr from my part time job, that first attempt at handloading proved a devastatingly costly lesson, which resulted in an equally dismal failure. So much of a failure, in fact, that I did not attempt handloading again for twenty years, after developing patience and an ability to read instructions. That was forty five years ago. Still with ten fingers, ten toes and both eyebrows, I feel… redeemed, and thankful for retained tactile dexterity.

Packaged systems – Cohesive solutions

Manufacturers, such as Hornady, have bundled their equipment into cohesive systems that are structured along application lines. I would not label them as “Getting started” kits, because that would suggest they are small budget driven, rudimentary tools for the inexperienced. Tools that would need to be upgraded or replaced, as experience was amassed. That is definitely not the case.

Hornady offers the pictured Lock-N-Load Classic Kit Deluxe, a single station press, for moderate and batch oriented production… like the type of reloading I do. However, Hornady also offer kits, such as the Lock-N-Load® Ammo Plant, five station progressive press, that can be expanded to include automated case and bullet feeding capability.

The entire equipment range shares the same high quality, the different kits are just structured to suit different handloading circumstances. Production wise, the Classic Deluxe tops out at approximately fifty rounds per hour, the way I work, while the Ammo Plant has the potential to produce ten times that amount.

How complete are kits? Good question, which I will attempt to answer, by applying the Lock-N-Load Classic Kit Deluxe (MSRP $682.94, less through discount retail) to an active handloading project and seeing what works, what does not work and what alternatives are available.

Handloading is a process of nuance. Subsequently, there are many ways to accomplish the same task, some better than others. It is impossible to include every possible tool and accessory in a kit. Sort of like Sandra Bullock, in the role of Angela Bennett in that old movie The Net, downloading the entire Internet to a single floppy disk.

I will try to do this in two parts. I am much too old and much too slow to do this in one shot. The first part is working through the contents, identifying each, and adding pithy and invaluable, if irrelevant, editorial comment. The second part will handloading, identifying specific process steps, using the kits and seeing what works and what needs a bit of attention.

First up, the brains of the outfit

The book of mysteries, a reloading manual. It is amazing to follow a social media exchange on handloading. People lined up on one side in need of technical information, refusing to read a reloading manual, but instead posing their questions to anonymous social media participants. The anonymous responding participants, who range from twelve year olds bored watching TV, to people with lots of actual experience, both readily answering the questions. What could go wrong?

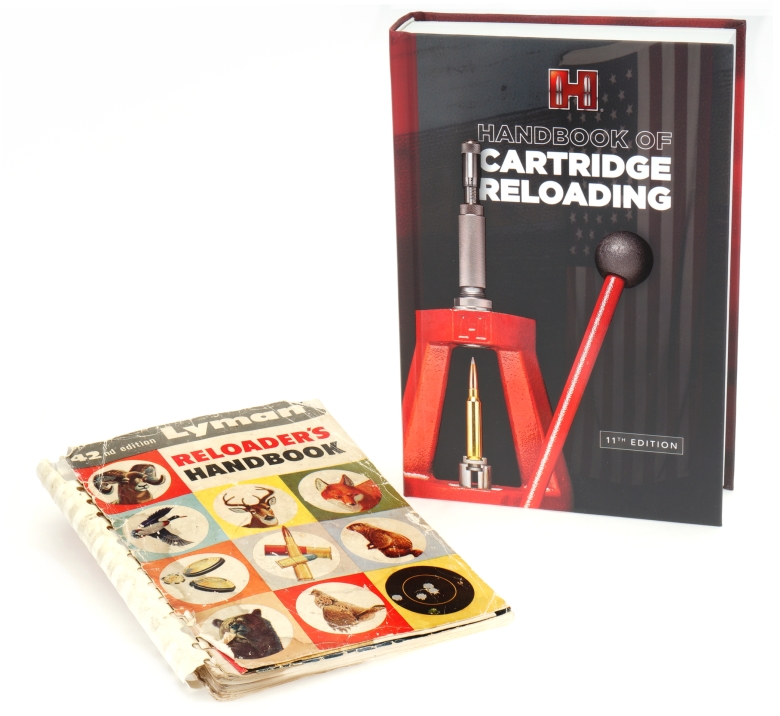

Pictured above is the Lyman reloading manual that came with my first reloading press. It is only 186 pages long and it covers handgun, rifle, shotgun, and muzzle loader load date. It is a little light on instruction, underlying theory, associated reference material, and assembled cartridge critical specs. It was written by a collection of experienced old timers, for the same demographic.

At one thousand plus well organized pages, the Hornady Handbook Of Cartridge Reloading is an education. In addition to expansive handload data, there are detailed instruction on handloading, press set up, bullet selection, case preparation and inspections, assembled cartridge inspection, and projections of handloading results. An excellent and safe informational alternative to social media interrogation. It is a reference book that provides answers to a myriad of handloading questions.

Pressing matters

The Hornady’s Lock-N-Load Classic as it comes out of the box, before attaching and or inserting any accessories or tools. With the exception of the steel handle, ram and toggle links, the press is fabricated from cast aluminum. An O frame design, the press is exceptionally strong, dimensionally stable and precise in repetitious motion.

With a 3.75″ stroke and 4″ window, the Classic has sufficient capacity to accommodate even 3.60″ full length 375 H&H derivative cartridge. The long handle provides a 6.4x mechanical advantage. Pulling downward with 20 lbs of force at the handle knob will exert 128 lbs of upward force at the ram. Much more than required for full length resizing cases.

The frame opening is angled toward the right, which provides clear line of sight to the ram and cartridge being processed. A nice touch.

Lock-N-Load Die Changes and the Positive Priming System

The die station is fitted with a Lock-N-Load bushing to facilitate preset die adjustment and quick change over. The Deluxe kits includes six Lock-N-Load die bushings, with additional available as needed.

The Classic Deluxe kit includes PPS, a Positive Priming System which allows manual on press priming. Parts are included for both large and small primers. An optional, tube fed, press mounted Automatic Primer Feed is available, and the Classic kit includes a second off press priming system.

Hornady Handheld Priming Tool

I do all of my priming off the press, using a variety of tools, based upon primer packaging type; strips or boxes. One of the tools I use is this Hornady Handheld. Easy to use, good feel for a seated primer and relatively quick. Additionally, I do not have to touch the primers.

One hundred from a box are placed in the appropriate tray, the tray is gently shaken to get the primers correct side up, and cases are primed. The one in the subject press kits come with large and small primer seater pins. It also includes a black tray for priming with Hornady shell holders, and a green tray when using RCBS shell holders. The Hornady shell holder has a larger center hole.

The Classic Deluxe kit includes five shell holders (#s 1, 2, 5, 16, 35) that work in both the press and priming tool… or with any other Hornady equipment, including powered case prep machines and manual trimmers. The shell holders included cover seventy five popular cartridges. For any not covered, Hornady shell holders retail for under $4.

Hornady Pocket Scale

Nifty little scale and powder trickler combo. Because of the nature of my handloading activities, handload development across a large number of cartridge types, my bench powered powder scale and dispenser combo does not get much of a workout. Mostly the scale is used, hand metered individual loads. This would get a lot of use.

Using load cell technology, this battery powered scale powered by 2 AAA batteries, holds 1/10th grain accuracy up to 500 grains. No cords to plug in, no charger attachments.

Throwing charges – a generous inclusion

Within the Lock-N-Load Classic Kit Deluxe Hornady, includes their very popular Lock-N-Load® Powder Measure. It has a very wide range of charges, from 0.5 grains to 265 grains of smokeless powder. Because it is Lock-N-Load bushing capable, it can be mounted to a work bench or directly to Hornady presses. A bracket is also included that permits mounting without using the Lock-N-Load system.

The measure is supplied with both large and small capacity rotors, a bench stand, a powder baffle, large and small drop tubes. The measure’s hopper tube is translucent. I inserted some black construction paper so it would contrast with the white background. Yes, I suppose I could lean to be a better photographer. Another project, another time.

Lock-N-Load & Sure-Lock® Lock Rings

The Hornady Lock-N-Load Classic Press is fitted with a Lock-N-Load female press bushing at its die station. This accommodates male Hornady Lock-N-Load bushings, pictured top, above. I expect a call from HR. Like the locking lugs on the bolt of a firearm, the six lug bushing system locks up solidly, but only require fractional rotation to engage or disengage. The O rings on the bushing provide tension to keep the bushings in place while in use.

Lock-N-Load bushings are used throughout the Hornady handloading product lines; presses, dies, accessory mounting for good reason. They are strong, and fast in use. Mounted on a die and adjusted in a press, no further adjustment is required for future use. The bushing is left on the die, the die can then be taken on and off the press, as adjustment to the press is retained.

Sure-Lock® Lock Rings, no doubt living in the shadow of the Lock-N-Load bushings, are unique in their own right. Unlike competing brands that are knurled rings, locked in place with a set screw, or hex rings held in place with an O ring, the Sure-Lock® Lock Rings forms a collar that compresses completely around a die to hold in place. Yes, they are also knurled and they have flats for wrench removal.

Measuring up

Another quality inclusion in the kit, a hardened, stainless steel dial caliper instead of one of those useless cartridge length stepped gauges. It is a good six inch caliper, accurate to 0.001″ and capable of four way measurement; inside, outside, depth and step. It was good thinking, on Hornady’s part, to include this as it is destined for heavy use.

Yes, Hornady does also make a digital version for folks who can’t read the face of an analog clock. I started out in a manufacturing environment where engineers used eye loops and carried slide rules. A digital caliper was considered an act against nature and the onset of the end of civilization as we knew it. Being broke, and saving for a set of Brown & Sharpe or Starrett calipers and micrometers, represented a right of passage.

The Hammer of Thor? OK. A little overboard, perhaps.

The L-N-L® Impact Bullet Puller, is a different kind of kinetic bullet puller. A long handle, a hand filling cushioned grip and three collet sizes included. No more tapping on the top of my barrel vise like a woodpecker, with a green or blue puller, to disassemble ammo. True, I am so near perfect at handloading that I rarely need one, but when I do… Yes, that was sarcasm.

Should not be without one…

Good move for kit inclusion. I don’t handload for any rifle cartridges, or break action/bolt action handguns, without checking for rifling clearance with each bullet type being loaded. Yes, including those combinations listed in mainstream reloading manuals.

The first reason for checking with an OAL gauge is safety. If a bullet comes to rest on a firearm’s rifling when the breech is closed, it will pressure spike on discharge. Where loads are high pressure, a pressure spike of this type could exceed the capacity of the firearm.

The second reason for checking with an OAL gauge is when extending the overall length of cartridge to gain powder capacity, or for those handloaders that feel 0.020″ bullet clearance to leade should be maximum, magazine clearance permitting. I lean on the former when trying to stretch a handload to the next step in slow burning powder or using VLD bulets.

The latter I don’t pay much attention to and freebore diameter is kept so tight these days, there is little to me gained in seating within close proximity of rifling. I am also not shooting firearms that are shot so frequently or so carelessly as to eat up chamber throats.

Hornady’s OAL gauge also comes in a curved version, to fit through the ejection port of lever action rifles. This one is not included in the kits, but not overly expensive. Something on the order of $40 from online retail.

Use of the gauge required the purchase or a Hornady Modified Case for each cartridge to be loaded. A modified case is an unfired cartridge case, drilled and tapped at the primer pocket, to mount on the gauge. The gauge pictured above is connected to a 6mm ARC modified case.

Prices vary for modified cases, but average around $10. They are available for virtually every cartridge. In the case of oddball cartridges, wildcat cartridges or on a project deadline and poor planning left me with no time to order on, I make my own. Not difficult. It just requires a drill, a bit, a tap, a small duck, a tuna sandwich, and a paperclip. The procedure is on Real Guns, easy to find with site search.

Bring on the miscellaneous…

Every every needs a funnel to avoid carpeting in smokeless powder. The trickler made a cameo appearance in the scale section but, again, a powder trickler is included and fosters accuracy in metered charges. The double sided universal loading block accommodates cartridges from .223 Rem and .308 Win, to large belted magnums.

Can’t go anywhere without case lube. so the One Shot will come in handy. As an alternative, Hornady also offers a stuck case remover tool and a stuck case removal service. Both should be supplied with a can of One Shot.

And Finally…

OK, so now you know at least as much as I do, if not more, about Hornady’s Lock-N-Load Classic Kit Deluxe. So, in Part II, we’ll put all of it through its paces in the next reloading project and see how the metaphorical chips fall.

Pretty all-inclusive kit for many reloaders, and certainly everything needed to get started learning.

I started much later (and older) than you, in 1991. Shortly after my first firearm purchase of a brand new Colt 1991A1. Started with 45ACP, added 45 Colt for #2 purchase of a 4 5/8” Blackhawk, and never looked back. Last count, I’ve loaded for 40 different chamberings without ever getting into shot shells.

I started with a Hornady reloading manual (read cover to cover before trying to load), and mostly RCBS gear including a Rockchucker press. I’ve largely migrated to include Redding as my default, RCBS my next choice for dies. The Redding single stage press was driven by the purchase of a 416 Rigby, which was just too long to reasonably load on the Rockchucker. I’ve always used hand primer tools (off press) and have gone through a few manufacturers to find the one that’s most comfortable for me.

Never tempted to go to a turret or progressive press as I just load a few boxes at a time of any given chambering so doing batch work fits my needs well. I’m an experimenter at heart, but the engineering side (my education and profession) keeps me respectful of the materials and forces involved, plus I have no need to push the envelope. Beating up a 130 year old rifle ( or a new one) just isn’t what I want to do. Getting something long obsolete making noise and punching respectable groups is my preferred goal.

Anyway, nice start to an interesting topic for your articles Joe. I personally enjoy the variety of subjects you cover and the doses of humor are the icing on the cake. Thank you!

You’re welcome Scott. I can tell your approach to reloading is not casual. Redding’s equipment is top notch and they engineer some very solid designs.