Ruger firearms are not pretentious. The typically applied adjectives: “sturdy”, “reliable”, and “adaptive” are hardly superlatives expressing aesthetic excellence, but they do describe great value. The truth of the matter is, whenever I’ve purchased a new Ruger, I’ve put it to work as though I would a new hammer or circular saw – hard use, and without particular concern. I’ve performed experimental trigger surgery on them, I’ve rebarrel/rechamber them for ridiculous size cartridges and I’ve glued strain gauges on them and used them for high pressure handload development. I’ve never felt badly about the treatment and, quite frankly, they’ve never complained. The 375 Ruger Model 77 Hawkeye African is different kind of Ruger…one with a very, very…very long name.

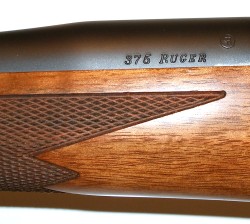

A couple of weeks ago, one of our gun shop’s suppliers, Lipsey’s, of Baton Rouge, LA received a few very early production 375 Rugers. Lipsey’s always seems to have Ruger products well before other sources, and we were more than a little happy to get our hands on this new model. The Ruger M77 Hawkeye African isn’t a typical Ruger, something I discovered the moment I opened the box. For one thing, the gun is beautiful; no qualifiers to follow. While, the pictures absolutely doesn’t do justice to the gun, they do illustrate the traditionally cut walnut stock with lots of figure and tiger tail, cleanly and sharply cut 18 LPI checkering and a perfectly uniform satin finish that compliments the matte blue and stainless metal surfaces.

A couple of weeks ago, one of our gun shop’s suppliers, Lipsey’s, of Baton Rouge, LA received a few very early production 375 Rugers. Lipsey’s always seems to have Ruger products well before other sources, and we were more than a little happy to get our hands on this new model. The Ruger M77 Hawkeye African isn’t a typical Ruger, something I discovered the moment I opened the box. For one thing, the gun is beautiful; no qualifiers to follow. While, the pictures absolutely doesn’t do justice to the gun, they do illustrate the traditionally cut walnut stock with lots of figure and tiger tail, cleanly and sharply cut 18 LPI checkering and a perfectly uniform satin finish that compliments the matte blue and stainless metal surfaces.

I love the notion of bone crunching big and dangerous game rifles; powerful and fast handling. While the M77 can certainly fit that description, it is actually compact, dwarfed by my CZ American Safari 375 H&H and Weatherby Mark V 416 Weatherby Mag. In fact, it is more similar in look and feel to a Whitworth Express rifle. At 7 ¾ lbs, it is also one of the lightest big guns in my collection. In terms of shooting stance and hold, the length of pull is similar to the others at 13 ⅝”, however, the central placement of the forearm checkering is a full 2″ forward more typical to sporters. I don’t know if this was the intention, but with the shooter’s supporting arm slightly extended, there is more leveraged resistance to recoil.

I love the notion of bone crunching big and dangerous game rifles; powerful and fast handling. While the M77 can certainly fit that description, it is actually compact, dwarfed by my CZ American Safari 375 H&H and Weatherby Mark V 416 Weatherby Mag. In fact, it is more similar in look and feel to a Whitworth Express rifle. At 7 ¾ lbs, it is also one of the lightest big guns in my collection. In terms of shooting stance and hold, the length of pull is similar to the others at 13 ⅝”, however, the central placement of the forearm checkering is a full 2″ forward more typical to sporters. I don’t know if this was the intention, but with the shooter’s supporting arm slightly extended, there is more leveraged resistance to recoil.

Along side of a Howa Short Mag with a Hogue OverMolded stock, the Ruger is only ¼” longer all the way up to the front of the action and floorplate; quite an accomplishment for a gun with 4 5/8” of bolt travel. I think this relatively short length speaks well for Ruger’s decision to offer a high performance .375 cartridge in a 30-06 Springfield length package. Other little touches, the swivels are stud mounted and there is a cross bolt, not unlike the cross bolt on the Austrian CZ Safari stock. Yes, it is a bolt and, yes, it does cross through the stock. I’m not sure how much purpose it serves.

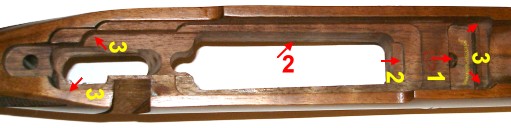

Ruger has an excellent system for handling recoil. The company’s precision casting talent shows with lots of carefully placed and constructed shoulders and radiuses on the action that fit tightly into the stock’s inletting. Recoil is spread over a large area so no single point takes a beating. Point 1 is a cutout that contains a large recoil lug that is integral to the receiver. Point 2 is for another receiver lug that angles downward to engage and locate the magazine box to the action. Points 3 hold the action by a perimeter shoulder on the bottom of the receiver. There are three fasteners that clamp the stock and action together; one through the front recoil lug, one behind the magazine well and one through the action’s tang.

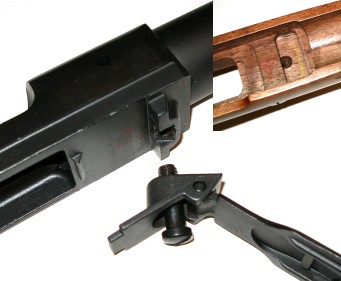

I thought this was a pretty spiffy approach to triangulation and utilizing the lower floor plate and trigger guard in the recoil absorbing scheme of things The lower fastener passes through the front of the floor plate hinge that is set into the stock on an angle. The fastener passes through the stock and into the forward recoil lug of the action. When the floor place is closed and latched against the front of the trigger guard, it effectively braces the stock against the recoil lug. Virtually every piece of wood and hardware is tied together to absorbing recoil.

I thought this was a pretty spiffy approach to triangulation and utilizing the lower floor plate and trigger guard in the recoil absorbing scheme of things The lower fastener passes through the front of the floor plate hinge that is set into the stock on an angle. The fastener passes through the stock and into the forward recoil lug of the action. When the floor place is closed and latched against the front of the trigger guard, it effectively braces the stock against the recoil lug. Virtually every piece of wood and hardware is tied together to absorbing recoil.

With all of the care taken to protect the stock from recoil, I can’t help but wonder why the Ruger didn’t do as much for the shooter. The African has a small 1/4″ thick Ruger red recoil pad stuck on a 3/16″ hard spacer. The Model 77 Hawkeye Alaskan model, with it’s synthetic Hogue OverMolded stock, has a 1″ recoil pad but, based on my experience with magnum cartridges and the Hogue stock, even that is not as recoil absorbing as a good pad like the Pachmayr Decelerator and can become downright unpleasant to shoot after a dozen rounds or so. With the Ruger’s 50+ ft/lbs of recoil, and that thin red pad on the African model many color coordinate well with the black and blue on the shooter’s shoulder.

Last couple of notes on the stock – Forward of the recoil lug the barrel floats, or at least that seems the intention. The stock is relieved along the length of the barrel channel to prevent wood to metal contact. I was able to pull a 0.004″ slip of paper from forearm tip to action without meeting resistance, which should be enough to prevent pressure points along the barrel, without having ugly 1/16″ clearance gaps along the barrel that are currently so prevalent with other brands. All of the inner wood surfaces are sealed against moisture and cleaning solvents. It is a nice stock, well thought out and complementary to the rifle. I would not extend the same assessment to the Hogue stocked Alaskan until I see one close up. On the Howa I didn’t get too distressed by the OverMolded stock’s poor fit and general flimsiness because it is basically an inexpensive rifle where cost cutting is expected. Some models of the Hogue product are better made and feature an integral aluminum frame that adds a good deal of structural integrity and improved contact with a barreled action. If Ruger us the first version on the Alaskan, I would be surprised as this is not an economy gun with its $1000 MSRP.

The sights are interesting. The front is a banded ramp with an ivory bead, same as the Ruger No. 1 or M77 Magnum rifles. The rear sight on both the African and Alaskan models has no facility for elevation adjustment, only windage, elevation is preset to approximately 50 yards. I would guess this is a concession to the appearance of an express rifle with last resort sights, blended with the reality this rifle will see duty with a scope. I am glad Ruger did not get caught by the temptation of mounting one of those useless three leaf express sights. The African includes a set of Ruger rings that mount directly and securely to the gun’s receiver.

The sights are interesting. The front is a banded ramp with an ivory bead, same as the Ruger No. 1 or M77 Magnum rifles. The rear sight on both the African and Alaskan models has no facility for elevation adjustment, only windage, elevation is preset to approximately 50 yards. I would guess this is a concession to the appearance of an express rifle with last resort sights, blended with the reality this rifle will see duty with a scope. I am glad Ruger did not get caught by the temptation of mounting one of those useless three leaf express sights. The African includes a set of Ruger rings that mount directly and securely to the gun’s receiver.

Ruger’s scope mount system, integral ring/base assemblies that lock into recesses in the receiver, is appropriate for this rifle. The rings are steel, the equivalent to a 0.580″ base height, and are included free of charge with the rifle. I was amazed, after recently shelling out a similar amount for a CZ American Safari rifle, that CZ did not include mounts, since the gun requires a CZ proprietary ring set. Making matters worse, the factory actually packs a set with every gun they ship. I guess CZ USA thought removing them from the box was a good way to make a few more dollars, selling them back to customers at $50/set as an accessory. Ruger did the right thing in making the rings part of the package and the gesture is appreciated.

The African has a 3 shot magazine capacity. The hinged floorplate is released with a button at the front of the trigger guard, right, located to prevent accidental release under less than optimal conditions, and sprung heavily for the same reason.

The M77 Hawkeye has what Ruger refers to as an improved L6 trigger assembly, but I don’t know what that means outside of it being a different mechanical assembly than the original, and without the potential for adjustment. What I did notice is that the trigger breaks really cleanly and that with a digital trigger pull gauge, the sear released without a bit of creep at exactly 5 lbs 1 ounce, five times in a row. I personally don’t like set and featherweight triggers on hunting rifle, so this is exactly what I would want in a gun like this.

The M77 Hawkeye has what Ruger refers to as an improved L6 trigger assembly, but I don’t know what that means outside of it being a different mechanical assembly than the original, and without the potential for adjustment. What I did notice is that the trigger breaks really cleanly and that with a digital trigger pull gauge, the sear released without a bit of creep at exactly 5 lbs 1 ounce, five times in a row. I personally don’t like set and featherweight triggers on hunting rifle, so this is exactly what I would want in a gun like this.

The African has a 23″ barrel to get the most out of a flat shooting 375 Ruger cartridge, compared to the Alaskan model with its 20″ barrel. The African barrel is approximately 1.158″ where it enters the receiver and 0.660″ at the muzzle. The rifling is 6 groove 1:12″ twist, the same as their Model 77 Magnum rifle with a 375 H&H chamber.

A stainless bolt and carbon steel action is an interesting combination; looks good and is probably a bit better from a maintenance standpoint. The Ruger has a three position safety; forward to fire, mid to load, unload, back to lock the bolt and prevent firing by physically blocking travel of the cocking piece and a little foot that projects from the trigger.

For all of the rifle’s compact design, the bolt travel is 4 ⅝” and the mag well is 3.520″. I always thought the real boomer would be a 30-06 length Ultra Mag type cartridge, however, this is not the case with the 375 Ruger as the chamber at the case head measures 0.536″; too small for the 0.550″ Ultra Mag and WSM type cartridges based on the 404 Jeffery. The 375 Ruger has, as Ruger indicates, a case diameter nearly the same diameter as the 375 H&H belt, only without the belt.

If case diameter is on the small side, the rim size potential is not. The picture to the left shows the non-rotating Mauser type claw extractor and bolt face holding onto an unaltered 375 Remington Ultra Mag case. I was unable to get brass or ammo for this first installment, and I have to say companies participating in the project were not particularly friendly, to the point they seemed a little silly. I called Hornady for ammo and was told no 300 grain FMJ ammo until the end of January, all others are TBA. I asked about brass, they said they had no plans to release brass or bullets. When I reminded the sales person this is a .375″ cartridge and bullets have been out there for approximately 100 years for other applications, I was told that is true, but if they were thinking about releasing bullets, they were not going to. Huh ? More than a little attitude.

I called Ruger and that was futile. First it was the customer service person who explained to me I had to find an ammo maker because, and she spoke slowly for this part, Ruger only makes firearms. I explain I was aware of this, however, the 375 Ruger is a proprietary Ruger cartridge and Ruger considered people might have an interest in locating ammo, AND didn’t they feel some responsibility to point customers in some helpful direction. She apparently did not. I called Ruger sales at their corporate office and was told the firearms would not be available until after the Shot Show in Florida. So I asked if that included the one I had in front of me on my work bench, to which she replied, “Oh, dear. Let me ask someone about ammunition”. She returned and said no brass, no ammunition, perhaps sometime in July. I also spoke to RCBS who said they never heard of the cartridge – which, unfortunately, these day I think I could believe. Ruger and Hornady were beginning to take on the appearance of a superficial celebrity who calls the paparazzi to report they are about to walk their dog then, when the photographers show up, they complain about their inability to find privacy. Growing weary, or wary, of the conversations, and accepting these people were losing their entertainment value, I called a couple of folks who would really know. Formal release of the firearms after the Shot Show, ammo starting to trickle out after mid January with 300 grain ammo first. No loading dies until July when the cartridge had received an affirmative vote to be standardized and receive a SAAMI spec and stamp of pressure approval.

About that 200 fps more…

What was beginning to bother me about the 375 Ruger was the presence of production guns, but the total absence of brass, dies and loaded ammo, and too much happy sunshine published data that didn’t add up. These days the release of a product is so controlled, writers are becoming essentially house writers who will not publish anything other than favorable information, unless the market has come to a contrary conclusion, and then a critique is written only to preserve some semblance of integrity for future product releases. When Hornday and Ruger decided to send out press releases and have writers crank out tons of favorable data, it would have been nice if at least some ammo was available when production rifles shipped, so there could be some concurrence by independent sources. I mean how ridiculous is the notion there are no published proposed cartridge specs? Is Ruger planning on changing the chamber specs on their production guns after an initial run? Are they thinking they might not ship 375 Ruger ammunition ? No, I can’t help but think there is a very good reason for a manufacturer to withhold factory ammunition AFTER a new rifle is launched. In the absence of cooperation, I did the next best thing, I made a chamber cast, modeled the cartridge and drew comparisons  to the 375 H&H and 375 Ultra Mag. I wanted to discover where some mainstream writers, shooting factory head stamped 375 Ruger ammo, were finding their reported 200 fps edge over the 375 H&H.

to the 375 H&H and 375 Ultra Mag. I wanted to discover where some mainstream writers, shooting factory head stamped 375 Ruger ammo, were finding their reported 200 fps edge over the 375 H&H.

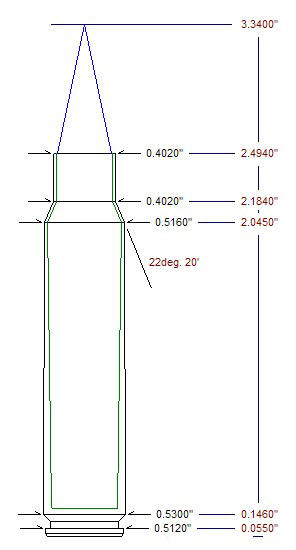

Based on a very accurate chamber cast and normal dimensional differences between production chambers and production cartridges, with the exception of the rim, the 375 Ruger should look a lot like the drawing below. The neck is relatively short, the shoulder angle more acute than the 375 H&H (bottom cartridge right), and a body below the shoulder considerably smaller in diameter than the 375 Ultra Mag (Top cartridge). The rim size is a guess as it is beyond the chamber and not detected in casting. As I noted earlier, from a bolt face standpoint is could easily be the same as an H&H or Ultra Mag footprint and have no impact on case capacity.

The thing I did not find in the Ruger’s chamber was room for a capacity of any consequence greater than the 375 H&H, but 20 grains or so less than the Remington Ultra Mag. A performance 300 grain factory load for the Ultra Mag has a muzzle velocity of 2760 fps, the same type of load for the H&H has a muzzle velocity of 2530 fps whether packaged by Remington or Winchester. Even Hornady’s Heavy Magnum 375 H&H load generates only 2705 fps. Apparently someone forgot to tell Hornady the Ruger round is suppose to be 200 fps faster than the H&H because they have the 300 grain 375 Ruger listed at 2660 fps, which seems just about right when a long bullet is put into a shorter case with the same powder capacity; shorter case, shorter neck, means more bullet intrusion into the case and less net powder capacity.

The thing I did not find in the Ruger’s chamber was room for a capacity of any consequence greater than the 375 H&H, but 20 grains or so less than the Remington Ultra Mag. A performance 300 grain factory load for the Ultra Mag has a muzzle velocity of 2760 fps, the same type of load for the H&H has a muzzle velocity of 2530 fps whether packaged by Remington or Winchester. Even Hornady’s Heavy Magnum 375 H&H load generates only 2705 fps. Apparently someone forgot to tell Hornady the Ruger round is suppose to be 200 fps faster than the H&H because they have the 300 grain 375 Ruger listed at 2660 fps, which seems just about right when a long bullet is put into a shorter case with the same powder capacity; shorter case, shorter neck, means more bullet intrusion into the case and less net powder capacity.

The H&H operates at 62,000+ PSI; considerably more than after dinner gas levels. In estimating how much more pressure would be required to yield another 200 fps, I matched the velocity of Remington factory 375 H&H loads with 75.4 grains of H414, at just about maximum pressure and got 2560 fps. Pressure required to generate an additional 200 fps surpassed the 94,000 PSI mark! I don’t care what special powder a factory has blended, the 200 fps more reported for the 375 Ruger, I believe, exists only in the minds and computers of overzealous Ruger friendly writers and Internet rumors. I would be willing to bet the 375 Ruger produces the same, or perhaps a bit less muzzle velocity than the 375 H&H – See Hornady data.

The cartridge may shine with 270 grain loads, which should keep pace with the H&H round and is consistent with Hornady’s ballistics for this lighter bullet load. Still, no 200 fps bonus. Ultimately, I will have brass and ammo and dies and I will wring the gun and cartridge out and publish my own load data. I think all of the exaggerated prerelease nonsense will have a negative impact on follow on sales when real data is published. The unfortunate part of this prerelease scenario is that the rifle may seem to pale in comparison to ballistic performance reported by sources other than the gun or ammo makers, but then, these are the people the factories solicited to write about their products. I think this gun and combination could do very well without the exaggerations.

Is the Model 77 375 Ruger a winner or loser ?

Honestly, if Ruger doesn’t get bitten by a backlash, when unchecked and overly enthusiastic initial reporting runs head on into reality, the combination should be a big hit. Let’s go back to what’s important, the application for the combination. Clearly the 375 Ruger, in African or Alaskan configurations, can instantly fill any spot currently occupied by the H&H. The preference for the Ruger rifle would generally be a lighter and more compact firearm, USA made Ruger Quality and service, ownership of a very attractive firearm. Is the 375 Ruger cartridge a necessary or a reasonable differentiation from the 375 H&H ? Probably not. The two R’s, reach and recoil are about the same, rifles are approximately the same in cost. I don’t understand the selection of the smallish diameter case. If they had based the Ruger on a 30-06 length version of 404 Jeffery case as Remington did for their Ultra Mags and Winchester did for their Short Mags, Ruger would have at least picked up 10% more powder capacity and maybe found a 100 fps improvement in velocity. Ruger would still have been able to build the gun on a standard length action and Hornady could utilize tooling intended for UM and WSM type cases. I can ‘t believe one of the top three manufacturers won’t admit Ultra is too big, WSM is too small, and a 30-06 Springfield length cartridge of this type is absolutely just right.

375 H&H Vs 375 Ruger Part I of II

375 H&H Vs 375 Ruger Part II of II

375 Ruger Handload Data

375 H&H Handload Data

Thanks,

Joe

Email Notification