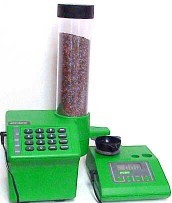

The RCBS ChargeMaster Combo is a computerized system that automates the process of dispensing smokeless powder charges by weight. The system, comprised of a linked ChargeMaster 1500 digital scale and ChargeMaster powder dispenser, has a dispensing range of 2.0 to 300 grains.

The ChargeMaster Combo MSRP is $417.95, however, it can be found from a low of $254.95 at Natchez Shooting Supply, to a high of $299.99 at Cabelas. Scale and dispenser may be purchased separately, $160 and $179 respectively, for folks who buy the scale, then want to add the dispenser at a later date. The dispenser, powered by the scale, is not intended for independent operation.

And I would want to use this gadget because…?

The energy content of smokeless powder is determined by its weight, not its volume. Consequently, powder charges metered through a conventional Culver type dispenser, or any other type of mechanical dispensers that measure by volume, can only be an approximation. In some applications, mechanical dispensers do an OK job; spherical powder and less than maximum charges. The spherical granules maintain a relatively uniform volume density, the material flow is almost fluid and there is virtually no shearing of granules when the dispenser’s metering drum is rotated from the reservoir fill to dispense position.

The energy content of smokeless powder is determined by its weight, not its volume. Consequently, powder charges metered through a conventional Culver type dispenser, or any other type of mechanical dispensers that measure by volume, can only be an approximation. In some applications, mechanical dispensers do an OK job; spherical powder and less than maximum charges. The spherical granules maintain a relatively uniform volume density, the material flow is almost fluid and there is virtually no shearing of granules when the dispenser’s metering drum is rotated from the reservoir fill to dispense position.

Lack of charge uniformity develops when extruded powder, particularly long granule extruded powder metering is attempted. Extruded powder doesn’t always fill the same space with the same density; by weight, one cavity full is rarely the exact same as the next. Granules laying at the top of the drum cavity have just as much chance of being pushed back into the reservoir as they do getting squished into the drum cavity as part of the metered charge. These problems aren’t caused by defective dispensers, but rather underscore the mechanical dispenser’s design limitations and the nature of extruded powder. Real Guns has previously covered the degree of charge consistency produced by a number of mechanical dispensers. I believe my statements regarding spherical and extruded powder metering are supported within these earlier articles. The answer to critical charge levels and large capacity case filling is typically a mechanical or digital scale. The problem with charge weighing with a mechanical or digital scale is the tedium of pan filling and powder trickling.

Enter the ChargeMaster Combo…

The ChargeMaster Combo components, scale and dispenser, are linked through a 32 pin connector that permits bidirectional communication between the two units and provides power to the dispenser. In short form – The dispenser moves some powder to the scale then pauses. The scale weighs and reports this information back to the dispenser. The dispenser, based on the feedback from the scale, moves more powder to the scale. This process continues until the charge weight in the scale’s pan is precisely what the operator requested.

Sounds like a long drawn out process, but it is not. The spec sheet indicates the average charge metering time is under 30 seconds. Measured average time, dependent on powder type, was below 23 seconds regardless the charge. My average time for manually weighing charges with a mechanical scale, regardless the amount, is near the same. However, where I’m good for about 20 cycles of scale weighing the same charge amount before I begin thinking about lunch or something shiny, the ChargeMaster has no such limitations. Where the ChargeMaster components have large concise numeric key pads and bright backlit displays for operational control, manually making small tens, single and tenth grain adjustments in proper increments is part of the routine of the mechanical scale.

The ChargeMaster can be utilized in a number of ways. The operator can enter a charge amount through the keypad, hit “DISP” (dispense), and the dispenser will fill the scale’s pan to the amount selected. If the same charge will be required a number of times, the operator can enter the amount, hit “MEM” (memory) and, from then on, they only need to select “DISP” for the same amount to be metered each time. There is small database where 30 favorite loads can be stored and selected on demand. The database stores and indicates from a selectable list: cartridge name, bullet weight, powder type, charge weight. An operator can also moderate the “trickle” key and directly meter a desired charge, although I’m not sure why anyone would want to use this approach. Finally, there is an auto dispense setting; the charge amount is set, then the unit begins to meter as soon as the scale pan is placed on scale’s platen. This last setting is actually pretty handy.

ChargeMaster versus PowderMaster

I initially thought the ChargeMaster was a modest revision, perhaps repackaging, of the old RCBSPowderMaster, a product OEM’d from PACT; it is not. The new product is from Excel Precision and manufactured in China. The company has been making precision digital scales since 1979 for many applications, which means the unit should perform well but, as recent news reports suggest, I wouldn’t suggest chewing on it.

The older PowderMaster dispenser and Powder Pro scale combination was accurate, but dog slow when metering; if not a minute, then multiple minutes per charge. In addition, the units had to calibrate to each powder charge. Sometimes this was a mater of minutes, sometimes the unit would go out to lunch after an extended period of time and the process would have to be restarted. The data link between the two units was through projected infra red beam. Since the connection wasn’t mechanical, there was nothing that put the units in proper alignment, or kept them there, so set up was trial and error and units could not me moved around on the bench without losing alignment. The older unit metered with two metering tubes, one higher speed for coarse feed, the other slower for fine feed or final trickle which made for a more complicated mechanical assembly. I used mine for a couple of days then put it in the cabinet of “Useless gadgets I have purchased”. The ChargeMaster is none of the above.

Both the old PowderMaster and new ChargeMaster use computer controlled metering tubes driven by a servo motor(s) to transport powder from the dispenser’s hopper to the scale’s pan. The tubes are cut away on the hopper side so they scoop powder as they rotate, and threaded on the inside so the rotation moves powder toward the open end of the tube and into the scale’s pan. The PowderMaster utilized a two tube set up, one high speed for coarse metering, a slower for fine or trickle metering. The ChargeMaster utilizes a single tube that is driven fast or slow as dictated by scale readings, changes in readings and intended charge weight.

The ChargeMaster has a deeper well below its metering tube that is intended to channel powder to a drain spout on the side of the unit (left, bottom photo). The drain is handy when emptying the unit, but the deeper well means more than 455 grains of spherical powder has to remain in the unit for powder to dispense. I’d rather have a shallow well and turn the unit upside down when I want it emptied. Much ado about nothing, as it actually takes less than a minute to empty the hopper and change over powder.

In terms of product packaging, enclosure and controls, the new ChargeMaster is head and shoulders above PowderMaster. The styling is more consumer and less industrial in appearance. The display is bright and backlit with much easier to read characters and the sealed control key pads are positive in use and have a more substantial in feel. There is no dispenser calibrating for different powders, the Combo does this on the fly. Calibration of the digital scale component is as it is on virtually every other digital scale; zero without the pan, run the check weights, then zero with the pan in place.

The ChargeMaster clear wind guard is a welcome addition. Scales are sensitive to drafts and out of shape handloaders huffing and puffing in their general direction. The wind guard minimizes this problem and it is ball detent retention means it can be opened from either side and easily removed. In a home environment, with normal winter heating air circulation, I found the cover reduced metering time significantly by stabilizing the scale reading, as much as 10 to 12 seconds per charge. During the first few cycles of dispensing I got aggravated because every time I closed the door a few grains of powder would dribble from the metering tube into the pan. Eventually, I head the loud “Duh” in my head and realized the scale would just count this as part of the powder charge accumulation. In fact, I am not sure how anyone could screw up using this equipment.

Small charges do not proportionally meter faster than larger charges. The far greatest portion of metering time is spent on finesse, low speed trickling the last few tenths of a grain for each charge. The coarse metering that delivers the bulk of the charge to the pan is actually very fast. Not unlike manually metering charges with a mechanical scale. 120 grains of IMR 7828 SSC may meter in 28 seconds where a 15 grain charge of Lil’ Gun takes 21 seconds. Detail to follow.

The scale display indicates and over or under condition if applicable. Within a sample of several hundred readings, there were 7% occurrences of indicated over dispensing and less than 1% of under dispensing. In all but two cases the overage was less than one tenth grain and, in those two cases, none exceeded two tenth grains. Under dispensing, none exceeded one tenth grain. In very practical terms, this level of over/under out is as good as on target. I do not believe there is another scale’s resolution, or powder burn rate consistency, that makes a tenth grain or even two tenths grains of consequence. If I were concerned with the variance, all I had to do was open the wind guard and make a correction before counting the metering complete as the scale remains active. Over/under did not follow any particular powder type, charge size, or frequency of metering although I did notice over conditions occurred when the high speed portion of the metering was extended and the low speed was brief.

Metering Performance by Powder Type

| Seconds to Process | |||||

| Powder | Type | Charge Grains | High Speed | Low Speed | Total time |

| Power Pistol | Spherical | 5 | 7 | 7 | 14 |

| 8 | 9 | 5 | 14 | ||

| 10 | 6 | 10 | 16 | ||

| AA 9 | Spherical | 10 | 8 | 4 | 12 |

| 15 | 7 | 11 | 18 | ||

| 25 | 9 | 12 | 21 | ||

| Lil’ Gun | Spherical | 15 | 3 | 16 | 19 |

| 20 | 3 | 13 | 16 | ||

| 30 | 5 | 17 | 22 | ||

| H110 | Spherical | 20 | 3 | 19 | 22 |

| 25 | 3 | 19 | 22 | ||

| 30 | 3 | 20 | 23 | ||

| H4350 | Extruded | 40 | 6 | 17 | 23 |

| 55 | 7 | 16 | 23 | ||

| 70 | 8 | 18 | 26 | ||

| IMR7828 SSC | Extruded | 55 | 6 | 18 | 24 |

| 70 | 8 | 18 | 26 | ||

| 110 | 15 | 19 | 34 | ||

| MagPro | Spherical | 60 | 9 | 14 | 23 |

| 65 | 10 | 14 | 24 | ||

| 70 | 9 | 13 | 22 | ||

| Re25 | Extruded | 50 | 9 | 19 | 21 |

| 75 | 17 | 6 | 23 | ||

| 120 | 19 | 9 | 28 | ||

I attempted to put together a reasonable cross section of powder types and typical charges for each. “High Speed” is the duration of high speed metering tube rotation, “Low Speed” is the duration of the low speed metering tube rotation, “Total Time” is as suggested – the total time to meter a charge. I posted this information to make it obvious that the Combo isn’t so much different from us when we manually scale weigh powder; we get the bulk done quickly, then spend out time finessing a grain of powder to get an exact charge. Each line represents 100 metering samples. Each change over was immediately followed by three unrecorded meters of powder intended to fill the metering tube and allow powder to settle in the hopper. The scale and dispenser were given fifteen minutes to come up to operating temperature whenever placed into operation.

Final Observations

I think much of the time taken by the unit has not much to do with circuit and processing speed as much as the laws of physics (inertia, mass) and fluid mechanics (how individual grains and clumps of grains behave as they move through and along a mechanical path) I am assuming the algorithm making feed or not feed decisions is improved on the current unit because there are fewer errors, the metering feeds are faster and the controls offer improved functionality.

My personal preferences? Glad you asked. I would like to see the hopper made from a material that is inert when in contact with smokeless power. I left a hopper filled with Power Pistol for ten hours while I was working and it left a residue on the inside of the hopper that etched the plastic. The residue washed out, the etching did not go away. I would like to see the inert material tubes sleeved with a rotating cut off valve so I can fill the tubes, label them and keep them on my bench for times I load with 5 types of powder within a short period of time.

I would like to see one side of the wind guard anchored with a removable pin so it can be switched to the side that favors the operator, but better retain the guard. The little roller detents are a nice touch, but I pulled that guard out of both spring loaded points with some frequency. And yes, this did happen somewhat less with more experience in use.

I’d like to lose the powder drain, reduce the open area under the metering tube and put an outward funnel shape cap on the hopper so the unit could be flipped for emptying and all of that dead space under the metering tube could be recovered. I am sure RCBS would tell me good designs never fight gravity.

Overall, the new ChargeMaster is a good piece of equipment that fits my type of handloading. Knocking off 100 pieces of short magnum loads or 223 Remingtonloads would be a snap and I could load near capacity without concern.

Overall, the new ChargeMaster is a good piece of equipment that fits my type of handloading. Knocking off 100 pieces of short magnum loads or 223 Remingtonloads would be a snap and I could load near capacity without concern.

For comparison, I timed myself manually metering charges with a conventional mechanical scale. On the average, cycle time was in the 21 – 23 seconds range. There is no way I would be able to maintain the speed or the accuracy over a large number of handloads, however, the ChargeMaster would.

Thanks,

Joe

Email Notification