The MEC Marksman Metallic Reloading Press is a relatively new product, introduced November 1 2016. The Marksman is single stage; a single die of the correct type must be installed in accordance with the ammunition assembly progression. Single stage presses are popular, because the are strong, compact, yield precisely assembled ammunition, and are comparatively low in cost.

Pictured above, a Lee Breech Lock Challenger and an RCBS Rock Chucker II are examples of “O” frame presses; the frame forms a closed loop above the mount. The RCBS Rock Chucker II has evolved into the “Supreme” model which extends the window to a full 4 1/4″ inches to accommodate the longest cartridges. Hornady, Lee, RCBS, and Redding also offer presses of this type.

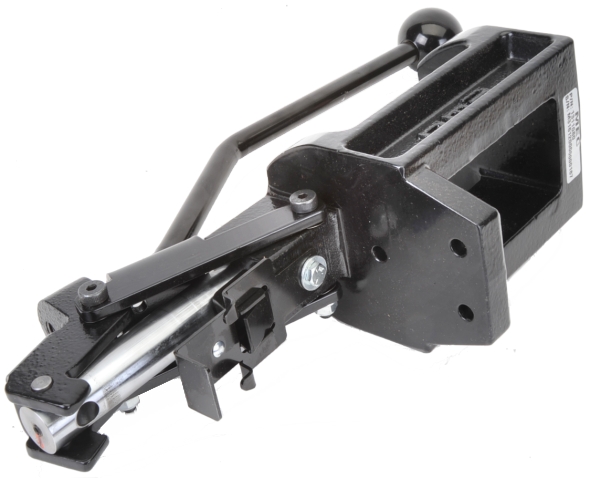

The MEC Marksman is a “C” frame press where the load bearing portions of the frame are located over the press’s mount pad and work bench, with the die station cantilevered forward over the edge of the bench. Redding’s Ultra Mag and Sinclair’s Bench Rest are other examples of “C” frame presses.

Theoretically, the closed loop “O” frame is more rigid, but both designs are much more robust than necessary for case forming and other reloading processes and the “C” type offers greater visibility and access during the reloading process. Because there is a wide variety of cartridges being loaded in the shop, the primary press is a 7 die head Redding Turret, which is also a type of “C” and the lack of front frame obstruction is greatly appreciated.

| Dimensions & Characteristics | Lee Breech Lock Challenger |

Rock Chucker* Supreme |

MEC Marksman |

| Manufacturers Suggested Retail Price | $99 | $214 | $225 |

| Typical Online Discount Retail | $69 | $185 | $179 |

| Press Type | Single Stage | Single Stage | Single Stage |

| Frame Material | Cast Aluminum | Cast iron | Cast Iron |

| Weight | 4 lbs 10 oz | 16 lbs 4 oz | 15 Lbs 14 Oz. |

| Die sizes accommodated | 7/8″x14 | 7/8″x14 and 1¼”x12 | 7/8×14 and 1 1/4″-12 |

| Mechanical advantage – Measured | 3.25:1 | 6.5:1 | 7.5:1 |

| Press Window Height | 4 1/4″ | 4 1/4″ | 4 5/8″ |

| Ram Diameter | 0.815″ | 1.000″ | 1.020″ |

| Ram Stroke | 3 1/2″ | 4″ | 4″ |

| Ram Support Bearing Surface | 5.3 sq.in. | 12.6 sq.in. | 10.85 sq. in. |

| On Press Priming | Yes | Yes | No |

| Riser Mount Available | Yes | Yes | Yes |

| Original Rock Chucker shown in pictures. Current Rock Chucker Supreme specifications are as indicated on this table. ** Bushed, but not to accommodate larger dies. |

|||

MEC Marksman press… some observations

The press is a heavy duty, but compact press. The channeled side rails on the casting and thick base make for a very rigid piece of equipment. A mount template is included with the press as is all mounting hardware. Spent primers pass through a passage in the ram and accumulate in a tray mounted under the press. The tray and tray bracket are also included with the press.

In operation, the long handle provides exceptional mechanical advantage, which makes full length resizing and bullet seating and crimping an easy task. The die bushing can be removed from the press to permit the use of larger 1 1/4″-12 dies which accommodates shotshells and most of the largest African big and dangerous game cartridges. The Marksman is a flexible tool for the handloader.

The Marksman utilizes and unique shell holder clip which is presented as self aligning. In use, the front of the spring is depressed to allow the shell holder to slip onto the ram. The spring doesn’t anchor the shell holder as much as it traps the shell holder and allows it to center to a reloading die overhead.

Die/ram alignment, malleable brass and tolerances require some movement at the shell holder. I kind of like this set up because it allows the holder to float laterally as the case centers to the die. At some point I will check the design’s influence on cartridge concentricity,

MEC offers a riser base to elevate the Marksman on the bench. At $45 MSRP, it is almost half the price of accessory products offered by third party companies like Inline Fabrication’s Ultramount. The accessory mount is a very useful accessory that makes for a more comfortable press position. MEC offers other accessories to support the press; powder measure, trickler, digital scale, vibratory cleaner, digital caliper, and numerous others. If there was one function not covered, it would be case priming. There is no provision on the press and there is no tool available from MEC separately. Personally, I never use a press mounted priming tools, so this would be of no consequence.

The company behind the limited lifetime warranty…

Prior to the new Marksman product, my exposure to MEC, Mayville Engineering Company, Inc, was limited to a MEC Steelmaster shotshell press and some related accessories. The Steelmaster was a nice piece of equipment, well made and and easy to use. I guess I should not have been surprised to learn it is the product of a large and successful American contract manufacturing company. MEC operates at fifteen facilities, spread across five different states, with a total of 2.1 million square feet of manufacturing floor space. MEC is owned by its 2,000 employees. The company’s know how and dedication to excellence shows in its products.

Email Notification