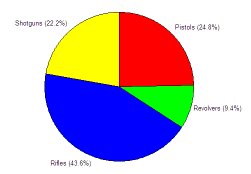

Approximately 3.3 million firearms of all types and for all purposes were produced in this country in 2003, the last year reported through the Treasury Department. This number does not include fully automatic firearms, or imported firearms. Approximately 22% of the 3.3 million were shotguns. Apparently, that 22% group didn’t sleep very much as they bagged more than half the deer harvested in the Untied States. Riflemen may find this last statistic distressing, embarrassing and encroaching, however, the problem can be solved through annexation of at least a part of the shotgun crowd. Calling some firearms shotguns is just a distortion of reality.

Approximately 3.3 million firearms of all types and for all purposes were produced in this country in 2003, the last year reported through the Treasury Department. This number does not include fully automatic firearms, or imported firearms. Approximately 22% of the 3.3 million were shotguns. Apparently, that 22% group didn’t sleep very much as they bagged more than half the deer harvested in the Untied States. Riflemen may find this last statistic distressing, embarrassing and encroaching, however, the problem can be solved through annexation of at least a part of the shotgun crowd. Calling some firearms shotguns is just a distortion of reality.

When is a shotgun not a shotgun?

Shotguns have gone through quite a metamorphosis. Years ago, good shotguns had a barrel length ramp to assist in pointing, not aiming and, even if there was no ramp, chances are there was only a single gold bead at the end of the barrel as the only point of reference for target acquisition. Today, there are guns optimized for turkey hunting; smooth bore, short barrel, full choke and rifle like sights. Typically pump or auto loaders, these are meant to be aimed and to deliver dense shot patterns within a relatively small area. Dedicated deer guns are even more specialized, predominately configured with rifled slug barrels. In truth, if a gun is held to the shoulder when fired, utilizes a long rifled barrel, is singular in projectile and charged with a self contained cartridge, it is a rifle. This will be the theme the series will follow, extracting the rifles and ammo hiding behind the shotgun misnomer, and exercising some of their potential.

Sabot…Saybow

Enunciation is much more important in the world of shotguns than in rifle or handgun communities. I suspect this is the result of French influence and the application of words not designed to be spoken with American tongues. Sabot looms large in slug load configurations, just as it does in muzzle loader and military vocabulary. In literal translation from French, “sabot” means “shoe” and, as we all know, in France “shoe” means “Cylindrical piece of resilient material enclosing an undersize projectile to seal it to a larger bore”. For years, American hunters unable to pronounce the word saybow, settled on the word sābutt” as in “Give me some of them sābutt loads”. Eventually, American manufacturers changed general descriptions to nomenclatures more consistent with the spirit of hunting: Vital Shok, KO, Copper Solid, Buck Hammer and, my favorite, Black Magic Magnum – Strangely enough, exactly all of the names I’ve never been called by Pam Andersen during a private moment.

In addition to sabot rounds, bare naked slugs are also loaded to near gauge cylinder diameter; the projectile is diameter reduced just enough to pass through a full choke smooth bore, or about a .030″-.035″ restriction in a .729″ cylinder for a 12 gauge. So both rifles and smooth bore guns fire slugs, both much more accurately then shotguns of yesterday. Full bore diameter slugs are primarily optimal for smoothbore use and have fins that appear as positive rifling that is designed to induce stabilizing spin. Sabot type slugs are generally more accurate in rifled guns as they compress when passed through the bore and spin as the result of contact with rifling, however, some slug loads cross in application over so it’s a good idea to look for manufacturers’ recommendations.

|

|

|||||

|

Ammunition |

Sabot | Slug – Grains | MV fps | ME ft.lbs |

Cost Per |

| Brenneke Black Magic Magnum | Y | 601 | 1,502 | 3,014 | $1.36 |

| Brenneke KO Sabot | Y | 437 | 1,673 | 2,686 | $1.79 |

| Federal Vital Shok – Barnes | Y | 437 | 1,525 | 2,257 | $2.40 |

| Remington Buck Hammer | Y* | 601 | 1,500 | 3,207 | $1.80 |

| Remington Copper Solid | Y | 437 | 1,550 | 2,331 | $2.30 |

|

Perspective |

|||||

| 30-06 Springfield | – | 180 | 2,750 | 3,022 | – |

| 45-70 Gov’t | – | 405 | 1,800 | 2,914 | – |

| * Sabot, but exposed tip full diameter slug | |||||

I threw a couple of old standby cartridges into the table for the sake of context. The surface area of a full bore slug is very large, approximately ..407 square inches. By comparison the .308″ slug is .074 sq.in. and the 45-70 bullet is .165 sq.in. The slug surface area is 447% and 147% larger, respectively which isn’t peanuts when it comes to punching holes in animals. Contrary to the notion such a large surface area would be stopped quickly on contact, slugs have a tendency to deeply penetrate. Olympic Arms has some interesting data on exterior wall and ballistic gelatin penetration; over 27″ for the 12 gauge soft led slug when fired at close range, compared to 5.5″ for the .223 Remington. Check out the Olympic site for more details and full context, they obviously put a lot of work into the report.

While the table shotshell examples are all described as 3″ slug loads, they actually range from 2.50″ to 2.7″ in overall length. Why the disparity? Is this a case for consumer fraud and short shot shotshells (Try saying that one fast) ? No. The 3″ designation refers to the hull length when fully extended and not crimped. Think of the stack up of various shotshell loads as similar to varying COL in metallic cartridge length when reloading. In a slug load, hull (case) base wad, powder charge, more wads, and projectile are combined to reach a length and pressure objective, so overall ammo length may vary accordingly depending on where the components reside when the shell is crimped closed. Shotshell, like a lot of cylindrical metallic cartridges, need a solid crimp to ensure enough resistance to achieve proper pressure and subsequent combustion.

Slugs and shot, similar but different…just to prove a point

Slugs are loaded in 2 ½”, 2 ¾” and 3″ lengths. I hear whispering about 3 ½” slugs, however, like the white buffalo and good grammar, I have no direct knowledge. In addition to overall shotshell length, brass base height varies. The examples above run from .630″ to .930″ and seem to not follow pressure and performance as much as the physical height of the powder charge over the base wad. So I will make a giant leap in logic here and assume the intent is to envelope the charge in brass.

Slugs are loaded in 2 ½”, 2 ¾” and 3″ lengths. I hear whispering about 3 ½” slugs, however, like the white buffalo and good grammar, I have no direct knowledge. In addition to overall shotshell length, brass base height varies. The examples above run from .630″ to .930″ and seem to not follow pressure and performance as much as the physical height of the powder charge over the base wad. So I will make a giant leap in logic here and assume the intent is to envelope the charge in brass.

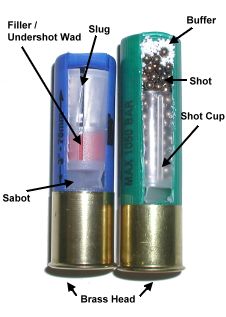

A pretty good example of what goes on inside shot shells; slug left, #6 shot right. In this example, the shot filled shell is a 12 gauge 3 ½” magnum load. In the land of shotshells, “magnum” tends to reflect the weight of the projectile(s) and not the amount of powder and when handloading shotshells the weight of all wads and projectile(s) are taken into consideration. Both of these examples have one piece wads; sabot for the slug load, shot cup for the other. There is no separate over powder wad or filler wad with the exception of the skirt attached to the slug for stability. The shot buffer is designed to fill the space between shot in magnum loads so a more even force will be exerted on the shot. This is suppose to yield a more dense and uniform pattern. The shot cup contributes to the same.

The sabot looks like a shot cup, with the notable difference the shot cup contains only about two thirds of the charge where the sabot completely encloses the slug. In some slug handloads, the slug is wrapped in thin sheet Teflon, again, to seal the projectile to the bore and reduce bore friction and lead sticking. You’ll note the slug is not a thing of grace and beauty, it looks more like a 38 special wad cutter with a row of ’59 Chevy fins. This particular slug is very similar to a full bore slug where external vanes are intended to cause rotation when the vanes contact a smooth bore. The lead portion is slightly recessed at the base. It is approximately .780″ in length, .635″ in diameter over the fins, .525″ inside the fins. Wrapped in the sabot, the overall diameter is .730″, to compress inside a rifled barrel; .720″ groove diameter, .702 bore diameter, approximately .019″ under an non-choked smooth bore.

The sabot looks like a shot cup, with the notable difference the shot cup contains only about two thirds of the charge where the sabot completely encloses the slug. In some slug handloads, the slug is wrapped in thin sheet Teflon, again, to seal the projectile to the bore and reduce bore friction and lead sticking. You’ll note the slug is not a thing of grace and beauty, it looks more like a 38 special wad cutter with a row of ’59 Chevy fins. This particular slug is very similar to a full bore slug where external vanes are intended to cause rotation when the vanes contact a smooth bore. The lead portion is slightly recessed at the base. It is approximately .780″ in length, .635″ in diameter over the fins, .525″ inside the fins. Wrapped in the sabot, the overall diameter is .730″, to compress inside a rifled barrel; .720″ groove diameter, .702 bore diameter, approximately .019″ under an non-choked smooth bore.

Mossberg rifled barrels have a 36″ twist and I am not sure why. Traditional methods of calculating twist rate based on projectile dimensions and velocity suggest a 70″ twist is more appropriate. For the sake of comparison, Hastings rifled shotgun barrels have a 34″ twist. I have to admit it doesn’t make much sense to me when muzzle loaders of same or similar caliber and velocity employ a 72″ twist. I’d like to try a replacement barrel with a slower twist. Maybe that would move 3″ groups to rifle like groups. I’d also like to see a projectile designed as it would be for a metallic cartridge rather than a black powder firearm.

Some slugs are more streamlined than other, not much more then a conventional bullet suspended in a sabot. Both the Federal Vital-Shok Barnes Expander and Remington Copper Solid fall into this category. They contain solid copper projectiles with very large recessed hollow points that are designed for rapid moderate velocity expansion. These slugs have a ballistic coefficient of .217 and the streamlining works to make the most of this combination. At 50 yards the differences are not significant between the flat nose and spire tip slugs for the one ounce loads, 437 grains, but at 100 yards spire tip are 15% – 20% better than their flat nosed counterparts.

Some slugs are more streamlined than other, not much more then a conventional bullet suspended in a sabot. Both the Federal Vital-Shok Barnes Expander and Remington Copper Solid fall into this category. They contain solid copper projectiles with very large recessed hollow points that are designed for rapid moderate velocity expansion. These slugs have a ballistic coefficient of .217 and the streamlining works to make the most of this combination. At 50 yards the differences are not significant between the flat nose and spire tip slugs for the one ounce loads, 437 grains, but at 100 yards spire tip are 15% – 20% better than their flat nosed counterparts.

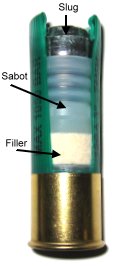

The Federal Vital Shok Banes Expander, pictured right, is pretty straight forward in construction, but different from some of the others. There is the basic hull, high base brass head, one piece split sabot and solid copper hollow point projectile, however, there is also a single over powder cushioned wad just below the sabot. The Sabot is spilt to accommodate variations in bore diameter and looks like a garden variety muzzle loader sabot round. I don’t believe the sabot should play a more significant role in load calculations than taking it’s weight into consideration. It’s length does not figure into twist rates as it parts company with the projectile shortly after leaving the gun’s barrel.

The outside diameter of the slug / sabot combination is .730″, just like the Brenneke slug load. The actual projectile is .572″ in diameter and 1.017″ in length. The nose cavity is .750″ deep and .300″ across.

The outside diameter of the slug / sabot combination is .730″, just like the Brenneke slug load. The actual projectile is .572″ in diameter and 1.017″ in length. The nose cavity is .750″ deep and .300″ across.

Federal is the only manufacturer I found posting a BC for a slug and for publishing data beyond 100 yards. The information is appreciated. With a ballistic coefficient of .217 it still doesn’t perform much better than a flat nose slug with a BC closer to .100. The low velocity of a slug tends to diminish the importance of streamlining.

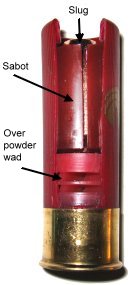

The Remington Buck Hammer 3″ data seems to be entered in error on the Remington site. The slug is ⅛ ounce heavier than their 2 ¾” version of the same product and this is reflected in a 50 fps lower muzzle velocity. The subsequent ballistics data does not track to 1,500 fps , but rather the heavier weight at 1,550 fps. In peeking inside a loaded 3″ Buck Hammer, the difference between it and the 2 ¾” is taken up by a filler wad beneath the sabot and not additional powder. In any event, the round qualifies as a boomer.

The Remington Buck Hammer 3″ data seems to be entered in error on the Remington site. The slug is ⅛ ounce heavier than their 2 ¾” version of the same product and this is reflected in a 50 fps lower muzzle velocity. The subsequent ballistics data does not track to 1,500 fps , but rather the heavier weight at 1,550 fps. In peeking inside a loaded 3″ Buck Hammer, the difference between it and the 2 ¾” is taken up by a filler wad beneath the sabot and not additional powder. In any event, the round qualifies as a boomer.

The Buck Hammer’s construction is a little different than the other slug loads. There is the over powder and filler wads to contain the charge and set the height of the stack up of components, then a less traditional sabot drives a stepped diameter slug with a large forward positioned driving band. The slug appears to be graphite or moly coated, something done to prevent soft lead from galling against the interior walls of the barrel and usually reserved for smooth bores. The Buck Hammer is represented by Remington as applicable to both smooth bore and rifled barrels.

The Buck Hammer’s construction is a little different than the other slug loads. There is the over powder and filler wads to contain the charge and set the height of the stack up of components, then a less traditional sabot drives a stepped diameter slug with a large forward positioned driving band. The slug appears to be graphite or moly coated, something done to prevent soft lead from galling against the interior walls of the barrel and usually reserved for smooth bores. The Buck Hammer is represented by Remington as applicable to both smooth bore and rifled barrels.

I think Remington did something very unique with this product in comparison to its competitors. They put up a lot of weight, but limited the seal to a .230″ wide driving band that is actually .005″ larger is diameter than the grooves of my Mossberg rifled barrel. Remington built their slug to seal like a bullet, but made the sealing surface narrow to avoid excess pressures when forced to conform with rifling. Neat. The overall length is .765″. I suspect this will prove to be one of the more accurate slugs from the sample population I put together.

I thought, if I measured enough components and combination of components I would find some common denominator that would break the case and allow me to find the relationship that would lead to safe experimental handload development, but I found none that were obvious. The predominant height of the stack of components inside the shell was 1.750″, but the Federal load was only 2.500″. Looking at a total from case head to top of highest components yielded similar mixed results.

|

Ammo |

List Weight | Slug | Slug+Wads |

| Brenneke KO | 437.0 | 432.6 | 486.4 |

| Federal Vital-Shok | 437.0 | 436.0 | 518.6 |

| Remington Buck Hammer | 601.0 | 602.2 | 680.1 |

I also weighed all of the components and arrived at the conclusion slug load weights on the box related only to the slug and was wait is substantial at 50-80 grains. I was not looking in the right place or from the correct perspective to find a uniform rule. So I shelved the thought for awhile.

Still, pretty remarkable performance

| Ammunition | Grains | MV | 50 | 100 | ME | 50 | 100 |

| Brenneke Black Magic | 601 | 1502 | 1144 | 936 | 3017 | 1749 | 1240 |

| Brenneke KO | 437 | 1673 | 1325 | 1090 | 2686 | 1685 | 1139 |

| Federal Vital-Shok* | 437 | 1525 | 1389 | 1270 | 2260 | 1876 | 1568 |

| Rem Buck Hammer | 601 | 1500 | 1234 | 1059 | 3003 | 2033 | 1497 |

| Rem Copper Solid* | 437 | 1550 | 1331 | 1161 | 2331 | 1923 | 1597 |

| *Sabot mounted traditional hollow point projectile | |||||||

If you are willing to accept a 5″ kill zone, the total span of rise and fall of the projectile’s trajectory, you would be point blank out to 150 yards with the Vital-Shok Barnes Expander. I think this is incredible performance from a firearm with such a sloppy bullet / bore fit, a low sectional density and flat nosed bullet, operating at under 11,000 psi – about the amount of pressure expended just to form a brass casing to a chamber wall. It seems the best direction to take here is optimizing bore fit, optimizing sight stability and work toward an objective of a dynamite 100 yard deer – bear gun…err…rifle.

Converting the Model 835 for Slugs

The rifled barrel I ordered from Mossberg arrived in about 4 weeks; 24″ length, ported, Parkerized finish, Fiber Optic sights which look an awful like Williams Fire Sights, only green up front and red at the rear sight. All was well except the plastic ramp insert up front arrived broken in half. A call into Mossberg service in Texas got a replacement on its way in the mail. The barrel was $154, $7 of that price was attributed to rifle sights. A barrel integral scope mount or ramp was less and they would have immediately shipped from stock, but I thought this combination was more in keeping with the project. Barrels can also be purchased from retailers like Cabelas, and Hastings makes barrels for the 835 Mossberg. All and all, I think the gun looks pretty good and feels a lot more rifle like with the shorter barrel installed.

The rifled barrel I ordered from Mossberg arrived in about 4 weeks; 24″ length, ported, Parkerized finish, Fiber Optic sights which look an awful like Williams Fire Sights, only green up front and red at the rear sight. All was well except the plastic ramp insert up front arrived broken in half. A call into Mossberg service in Texas got a replacement on its way in the mail. The barrel was $154, $7 of that price was attributed to rifle sights. A barrel integral scope mount or ramp was less and they would have immediately shipped from stock, but I thought this combination was more in keeping with the project. Barrels can also be purchased from retailers like Cabelas, and Hastings makes barrels for the 835 Mossberg. All and all, I think the gun looks pretty good and feels a lot more rifle like with the shorter barrel installed.

I have a few more accessories to add to the gun, I have a large carton of ammo sitting under the bench and I expect I will be back with the next installment when I have collected some range data. I also have a sub project of installing a Limb Saver on a Mossberg as I expect this project will kick the crap out of me.

Everything I know About Shotguns… Part 1

Everything I know About Shotguns… Part 2

Everything I know About Shotguns… Part 3

Everything I know About Shotguns… Part 4

Thanks,

Joe

Email Notification