If there was anything notable about the day, I would have to say that would be the fog. First it rolled in, closing all the shooting positions, then it rolled out, and all positions were open. Then it rolled in again during a break for target check and, while it wasn’t their intention, half the guys who wandered out there ended up at the Denny’s at the bottom of the mountain in Saratoga. For me, it was just nice to get out to the range with handloads for my favorite cartridge, the 45-70.

If there was anything notable about the day, I would have to say that would be the fog. First it rolled in, closing all the shooting positions, then it rolled out, and all positions were open. Then it rolled in again during a break for target check and, while it wasn’t their intention, half the guys who wandered out there ended up at the Denny’s at the bottom of the mountain in Saratoga. For me, it was just nice to get out to the range with handloads for my favorite cartridge, the 45-70.

The following loads were all tested in a stout Ruger No. 1, modified to check pressure in conjunction with an Oehler Model 43 Personal Ballistics Lab. Not a very exotic set up, but a very safe and useful tool for handload development.

Bullet Selection

The bullets selection for this project had to meet two criteria; hard enough alloy or gas checked to permit higher than SAAMI level velocity for any given bullet weight, of a profile and length to permit use in a Ruger No. 1 or modern Marlin Model 1895 Guide Gun. The bullets shown above meet both considerations. If you follow across the cannelure positions on each, you’ll notice there isn’t much difference in the length projecting forward of the cannelure. The extremes where the Oregon Trail Laser Cast 300 grain, far left, with a COL of 2.500″ and the Cast Performance WLN 405 grain second from right at 2.560″; a total spread of .060″. The greatest dimensional difference is below the cannelure which impacts net case capacity and powder selection. The longest bullet is 1.270″, the shortest .790″. None of the bullets incorporated into the project are very soft lead alloy. A Brinell hardness of 16 with a composition of 2% tin, 6% antimony and 92% lead or similar substitute alloy is typical. In short, they will expand modestly, they should not shatter. Oregon Trail also makes cast bullets in a gas checked version, “True Shot”. If you purchase 100 count boxes of Oregon Trail bullets that will universally be labeled “True Shot” – just keep in mind, gas checked is True Shot, not gas checked is Laser Cast.

Cast Performance bullets I used in this project checked a little large; .4605″ – .4610″. The other bullets checked ,4585″ – .4590″. Not much of a difference and functionally they worked fine, with the exception of one round that would not chamber the last 1/4″ or so of cartridge in the Ruger. The same round chambered normally in the guide gun. There were a few factors at play here. .461″ bullet, plus .023″ of combined case thickness yields a case mouth O.D. of .484″. The SAAMI drawing for the .45-70 Gov’t chamber indicates a spec of .4812″ and a cartridge mouth spec of .4800″. For the sake of comparison, a factory Remington Express round case mouth checked .478″ and I couldn’t find a factory jacketed bullet that ran over .4580″. My point is that these are all quality bullets that shot well, however, care is necessary to make sure handloads using cast bullets that run a little large will function properly in your firearm

Powder Selection

Powder was selected that would best suit bullet weight, while accommodating a substantial variation in bullet length and, therefore, net case capacity. I did experiment with some other products, however, they were discounted typically for inconsistent ignition. When looking for powder for the 45-70, the best place to begin is listings for powder intended for the small bore bottle neck cartridges. Most of the powder represented carry load data for the 22-250 Remington on their labels. The 45-70 is a wide open case without shoulders to delay the path of powder under pressure or to create a turbulence to insure more complete burn. A relatively fast burning powder and well crimped bullet are essential to consistent ignition.

Primers

![]()

CCI large rifle primers mounted in APS strips were my first selection regardless the type of powder and size of charge. I may utilize all large rifle magnum primers the next time around. I did encounter some ignition problems and odd pressure curves with less than solid crimps. In fact, for the first time I encountered a squib load that was not caused by a missing powder charge or charge contamination. This cartridge’s primer discharged without igniting the IMR 3031 powder, but generated enough pressure to drive the Remington 300 grain bullet a couple inches down the bore, rendering the gun useless until I could properly clear the bore. The primer issue will take a bit more analysis before a more permanent change in made. None of the published loads that follow posed a problem with reliability of ignition or consistency of velocity. The potentially problem loads were set a side for further study.

CCI large rifle primers mounted in APS strips were my first selection regardless the type of powder and size of charge. I may utilize all large rifle magnum primers the next time around. I did encounter some ignition problems and odd pressure curves with less than solid crimps. In fact, for the first time I encountered a squib load that was not caused by a missing powder charge or charge contamination. This cartridge’s primer discharged without igniting the IMR 3031 powder, but generated enough pressure to drive the Remington 300 grain bullet a couple inches down the bore, rendering the gun useless until I could properly clear the bore. The primer issue will take a bit more analysis before a more permanent change in made. None of the published loads that follow posed a problem with reliability of ignition or consistency of velocity. The potentially problem loads were set a side for further study.

Brass

Remington brass, new bulk, was selected for the project and utilized for all loads. I had several brands on hand, all virtually the same material thickness and capacity to the level of “it doesn’t matter”. Remington brass is very consistent and only needed a quick clean up and sizing before it was ready to go and I had the largest quantity on hand.

My experience with Remington, Winchester, and Starline brass with 45-70 handloads is that Starline if last through more cycles. It begins as a softer alloy and remains so through use. All respond well to annealing with less than 10 shots between re-tempering. Dimensionally they are for all intent and purposes the same including web thickness.

Firearm Capacities

Typically, I load to a length suitable for the Ruger No. 1 and to a pressure level within the capacity of the Marlin Guide Gun. From a pressure standpoint, I am sure the Marling can ingest 40,000 PSI all day long and not show signs of accelerated wear or excessive pressure. I am sure the Ruger can handle 50,000 PSI without a problem. I have one custom Ruger chambered for the Real Guns .358-378 RG wildcat and that one handles pressures well in excess of 50,000 lbs. routinely. Pushing the 45-70 to 40,000 will deliver astounding performance from this old cartridge and I believe that is enough. If I wanted more, it would make more sense to load the 458 Lott or similar.

The Ruger has a short throat. Even though it is straight breech loading, ironically it cannot handle a COL that works without a hitch, including ejection of a live round, from the Model 1895. By comparison, a 400 grain Speer can be loaded to a 2.560″ length in the Marlin, but only a .2500″ COL in the Ruger. Moot point in this case as the cannelure is set for a 2.500″ COL. The bullets listed on the load table all chambered without a hitch in both rifles, however, even published COL from quality manuals like Speer 13 should not be taken for granted. I know more recently, most firearms I purchase have a minimum chamber.

The Ruger has a short throat. Even though it is straight breech loading, ironically it cannot handle a COL that works without a hitch, including ejection of a live round, from the Model 1895. By comparison, a 400 grain Speer can be loaded to a 2.560″ length in the Marlin, but only a .2500″ COL in the Ruger. Moot point in this case as the cannelure is set for a 2.500″ COL. The bullets listed on the load table all chambered without a hitch in both rifles, however, even published COL from quality manuals like Speer 13 should not be taken for granted. I know more recently, most firearms I purchase have a minimum chamber.

Die Sets

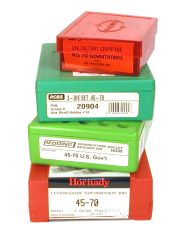

All cartridges appearing in the load data were crimped, all with a Leefactory crimp tool. This was the easiest way to get a tight crimp without ballooning the case and exacerbating the chamber minimal clearance condition. I can’t stress enough how much this tool contributed to quality handloads with the 45-70.

During the project I utilized RCBS Precision and HornadyNew Dimension dies, as well as a Redding competition grade seater die. Relevant information will be published at a later date, all of the handloads that follow were assembled using Hornady dies with RCBS shell holder. The Hornady selection was based upon their drop sleeve seater die. This is a Hornady three piece set; sizer, expander and seater die. All cases were very slightly belled to facilitate cast bullet seating. All assembled cartridges were checked with a OAL gauge, however, data appearing in following tables are COL, I thought this would be more useful.

During the project I utilized RCBS Precision and HornadyNew Dimension dies, as well as a Redding competition grade seater die. Relevant information will be published at a later date, all of the handloads that follow were assembled using Hornady dies with RCBS shell holder. The Hornady selection was based upon their drop sleeve seater die. This is a Hornady three piece set; sizer, expander and seater die. All cases were very slightly belled to facilitate cast bullet seating. All assembled cartridges were checked with a OAL gauge, however, data appearing in following tables are COL, I thought this would be more useful.

Data Collection

A Oehler 43 is very useful for safe, high performance handload development. The proof screen addition is a big plus in velocity measurement, however, the strain gauge function is the primary benefit of the system for me. I had gotten to the point where it became obvious most of us are guessing at pressure levels as there are few clues when it comes to spotting excessive pressure signs in operation of a moderate pressure firearm, or case deformity in a cartridge designed to operate under 40,000 psi.

My theory is that we all tend to BS a little about being able to “read” handloads because we usually don’t have much in the way of test equipment at our disposal. While a universal receiver, test barrels and piezo transducers may be out of economic reach, the Model 43 is a good and reasonable option. Perhaps, as a practical tool, it is more beneficial than a universal receiver because it collects data from real firearms. The first time I used this box, it was like checking distance estimating with a range finder; it’s amazing how close or distant 300 yards can be. Probably more significant than an inability to guesstimate pressures without test equipment is the lack of linear progressions in handloads when pressure is measured. All those variables we are taught to watch; COL, crimp type and pressure, case thickness, bullet construction all have a marked effect on pressure. The draw back to the M43 is that it is not a snap to set up a strain gage correctly, and it is not adaptable to all firearms and cartridges. As an example, I do all of my 45 Super load development in a Contender because of the barrel receiver configuration and ease of mounting a gage.

Handloads

|

Oregon Trail Laser Cast FP 300 Grain 2.500″ COL – CCI 200 LR Primer |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Unique |

15.0 |

LR |

1321 | 21700 | |

|

Unique |

20.0 |

LR |

1554 | 26000 | |

|

2400 |

28.0 |

LR |

1619 | 20500 | |

|

2400 |

30.0 |

LR |

1709 | 23600 | |

|

Re 7 |

50.0 |

LR |

2114 | 29400 | |

|

Re 7 |

53.5 |

LR |

2244 | 35900 | |

|

Oregon Trail Laser Cast FP 350 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

TAC |

55.0 |

LR |

1825 | 28600 | |

|

TAC |

59.0 |

LR |

1987 | 33500 | |

|

Benchmark |

50.0 |

LR |

1750 | 21600 | |

|

Benchmark |

54.5 |

LR |

1901 | 27300 | |

|

Re 7 |

42.0 |

LR |

1783 | 24700 | |

|

Re 7 |

47.0 |

LR |

1986 | 27500 | |

|

Oregon Trail Laser Cast FP 405 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Re 10 |

44.0 |

LR |

1712 | 23300 | |

|

Re 10 |

47.0 |

LR |

1836 | 30400 | |

|

Benchmark |

45.0 |

LR |

1603 | 21600 | |

|

Benchmark |

50.0 |

LR |

1810 | 33900 | |

|

Re 7 |

40.0 |

LR |

1717 | 28600 | |

|

Re 7 |

42.0 |

LR |

1733 | 30200 | |

|

Oregon Trail Laser Cast FP 500 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Re 10 |

37.0 |

LR |

1508 | 26400 | |

|

Re 10 |

39.8 |

LR |

1604 | 32600 | |

|

Benchmark |

38.0 |

LR |

1417 | 25200 | |

|

Benchmark |

41.7 |

LR |

1545 | 33500 | |

|

BL-C2 |

42.0 |

LR |

1279 | 20700 | |

|

BL-C2 |

47.0 |

LR |

1784 | 34300 | |

|

Bullet Meister Cast FP 405 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Re 10 |

45.0 |

LR |

1687 | 24200 | |

|

Re 10 |

48.0 |

LR |

1816 | 29100 | |

|

Benchmark |

47.0 |

LR |

1641 | 23800 | |

|

Benchmark |

50.5 |

LR |

1805 | 29500 | |

|

Re 7 |

40.0 |

LR |

1688 | 26400 | |

|

Re 7 |

43.0 |

LR |

1761 | 29700 | |

|

Cast Performance WLNGC Cast FP 405 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Re 10 |

45.0 |

LR |

1545 | 28600 | |

|

Re 10 |

48.5 |

LR |

1721 | 33500 | |

|

Benchmark |

47.0 |

LR |

1279 | 20700 | |

|

Benchmark |

51.5 |

LR |

1687 | 24200 | |

|

Re 7 |

40.0 |

LR |

1664 | 22500 | |

|

Re 7 |

44.0 |

LR |

1791 | 30400 | |

|

Cast Performance WLNGC Cast FP 460 Grain |

||||

|

Powder |

Charge |

Primer |

Velocity | PSI(M43) | |

|

Re 10 |

40.0 |

LR |

1539 | 23500 | |

|

Re 10 |

43.6 |

LR |

1674 | 30200 | |

|

Benchmark |

42.0 |

LR |

1611 | 23600 | |

|

Benchmark |

46.0 |

LR |

1719 | 35000 | |

|

BL-C2 |

49.0 |

LR |

1470 | 20700 | |

|

BL-C2 |

52.0 |

LR |

1606 | 28200 | |

Summary

I’d be lying if I said I didn’t enjoy this project. Good quality cast bullets are comparatively inexpensive, accurate and any number of loads on this list would be easy on the shoulder, but not on deer. A bad three shot group was 1 1/2″, a good group was 5/8″. Pressures were moderate for both the Ruger and Marlin, which is always nice.

I am saving some of my data for a second article not directly related to the 45-70, however, I would note that crimping is critical for the round, something consistent whether cast or jacketed bullet. Like most large bore cartridges where 70,000 PSI of pressure isn’t being pushed through a pin hole, faster powders work best. I believe BL-C2 and Re 10 are the outside limits of slow powder for the 4570. As I noted earlier in this piece, I will probably build controlled lots with all magnum primers. Data suggest this would result in more consistent powder burn and resulting velocity. Hope there is something here that will be useful.

Additional 45-70 handload data detail appearing on Real Guns:

Cast Bullet Loads

Jacketed Bullet Loads

T/C/ Contender Loads

Thanks,

Joe

Email Notification