With the shop in Maine, and me on the road, I found myself working with equipment that is out of the norm. It’s all good equipment, just different equipment, but for a guy who knows every tool he owns on a first name basis, adjustments were necessary. I would normally use an RCBS APS bench mounted press, or the LeeSafety Prime system, but here I used an RCBS APS hand held priming tool with integral universal shell holder. It worked like a champ even if, after a couple hundred rounds, I had forearms like Popeye and kept muttering “Uk, kuk, kuk, kuk, kuk, kuk, kuk”. In the absence of collet bullet pullers I used an RCBS Inertial Bullet Puller. Unfortunately, they don’t like short stubby WSM cartridges so the locking cap won’t fit over the WSM case, but a large elastic band retainer got me over that speed bump.

I typically weigh charges with an RCBS 1010; the thimble adjustment is quick and the short beam makes it accurate but not overly sensitive. The Hornady scale is a quality equipment, just a bit more overly sensitive when approaching a goal weight. The Hornady trickler works fine, I just don’t care for that much plastic. The Betty Crocker dispensers worked well, but the Hornady funnel needed to be shortened for the short neck and sharp shoulders of the WSM. Without a belt sander, I snipped the end off with cutting pliers and cleaned it up with one of my wife’s emery boards. I don’t think she noticed the plastic residue. The benefit of a mechanical scale is no circuit drift, no dead batteries and no odd reactions to power surges. The downside of a mechanical scale, unlike a digital scale that sticks a reading in your face, the user needs to make sure all three weights are placed correctly; tens of grains, single grains and tenths of grains. Both types are probably needed.

I use a number of trimmers, manual and powered, but I have to say I really like the Hornady unit. It is very consistent in trim lengths, fast to use and it seems to do a good job of holding cases on center. I began with new Winchester brass, ran the cases through a full length sizer to straighten the mouths, then trimmed and trued them to 2.090″. The new brass was 0.002″-0.006″ longer than minimum. Iosso case cleaner was used to flush out all of the case lube and brass particles prior to loading.

I use a lot of different brands of dies, but for the most part they are interchangeable in achieving quality production. I use full length sizers, adjusted to a headspace gauge reading from the intended gun’s chamber. In this case, with new brass, this fitting step was omitted. I do not use collet dies or neck sizers; I could never get a measurable difference in performance or brass longevity to justify the process. I selected Hornady dies this time around because I like the way the seater die guides and supports the bullet and I get good concentricity with short neck cases with this set up. I also like the spherical expander; it does not pull the case shoulder forward when exiting.

I selected a Hornady 4 hole turret for the project. I like Lee equipment. I have a Lee Classic Turret at the shop, because the more I work with them, the more I respect the quality and thinking behind the design. Everything makes good engineering sense from the mount pad pattern, to the shape of the cast parts and locking arrangement for the turret. In this case, where I am working with limited space, the press is compact, works with dies and shell holders from other manufacturers, and it consistently outputs quality handloads. The only thing different from a heavy cast iron press is the feel; a function of leverage differences and the use of light alloy in parts of the assembly. The absence of heavy casting inertia makes some operations feel more forced than typical but, after a half dozen cycles, the change is hardly noticeable. If I had my Safety Prime set up with me, this would have been the choice for priming as it is fast and reliable. I removed the indexing rod to manually control the process, but it works well with production handloading.

I selected a Hornady 4 hole turret for the project. I like Lee equipment. I have a Lee Classic Turret at the shop, because the more I work with them, the more I respect the quality and thinking behind the design. Everything makes good engineering sense from the mount pad pattern, to the shape of the cast parts and locking arrangement for the turret. In this case, where I am working with limited space, the press is compact, works with dies and shell holders from other manufacturers, and it consistently outputs quality handloads. The only thing different from a heavy cast iron press is the feel; a function of leverage differences and the use of light alloy in parts of the assembly. The absence of heavy casting inertia makes some operations feel more forced than typical but, after a half dozen cycles, the change is hardly noticeable. If I had my Safety Prime set up with me, this would have been the choice for priming as it is fast and reliable. I removed the indexing rod to manually control the process, but it works well with production handloading.

Component selection

I use QuickLOAD and some of our home brewed code to do a bit of analysis of components before loading. With this method I can determine how certain powders will generally perform with a given cartridge and spot unique characteristics. This is one of the few times where QuickLOAD was quite a bit off the mark with a bottle necked case. I would also say that the results were contrary to Hornady #7 with 139 grain bullets where, at the range, H4350 easily outperformed slower powders shown as providing higher velocity in the manual. Much of this can be chalked up to differences in hardware. Later on you’ll see a data sheet with both software predicted and recorded velocity.

Excuse the green, I didn’t want to lose the Accubond tip against the white background. In deference to the short COL limitations, I opted for the shortest bullet for each weight selected. The two concessions were the Nosler CT because I wanted to see how far I could run up the dry lubed bullet’s velocity, and the Accubond because I thought it might make for an great all around load. On paper, the 175 grainers looked surprisingly good, and this is where I felt the WSM had excellent potential.

The cast of characters, from left to right:

139 grain Hornady Interlock Soft Point

140 grain Remington Protected Soft Point

150 grain Nosler CT Ballistic Silver Tip

150 grain Winchester Power Point

154 grain Hornady Interlock Soft Point

160 grain Speer Spitzer Soft Point

160 grain Nosler Accubond

175 grain Hornady Interlock Soft Point

175 grain Remington Protected Soft Point.

| Dimension | Factory | Handload | Max Load | Drawing | ||

| Unfired – Fired | U | F | U | F | Fired | NA |

| Water Capacity Grains | 78.1 | 81.2 | 79.1 | 81.6 | 81.6 | 81.9 |

| Case Length “ | 2.100 | 2.100 | 1.094 | 1.090* | 2.093 | 2.100 |

| Shoulder Diameter “ | 0.528 | 0.541 | 0.530 | 0.540 | 0.540 | 0.538 |

| Case Head Diameter “ | 0.549 | 0.552 | 0.550 | 0.550 | 0.551 | 0.555 |

|

* Case had been trimmed to 2.090″ prior to loading. |

||||||

Nothing notable in dimensions or capacity, as received or after firing. I always full length resize so case, for the most part, will return to baseline. Case head expansion should not exceed .0004″ for seasoned cases. Anything greater is indicative of excessive pressure. For those who track this type of information, case weights in grain as ordered above: 237.9, 240.3, 237.2, 236.7, 235.8. For the life of me I could never figure out how people sort cases by weight and, if they do, how they handle them differently and to what range of grouping. Weights within lots and sources, like opinions may vary.

Production….

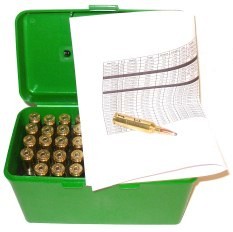

Eventually I had a pile of 50 round boxes with a variety of handloads that looked pretty good. The new Winchester brass formed well, although it was a little rough as received. I don’t know if this is a Winchester issue or a handling issue in the distribution chain. I logged all of the case dimensions prior to sizing and after, and pulled a statistically representative sample to measure capacity prior to firing. Not fun, but necessary at this stage. My objective was to best my 7mm Remington Magnum loads without signs of excessive pressure and to come away with a 139 grain – 154 grain deer load and a 160 – 175 grain heavy load. A 7mm bullet can produce substantial power; 175 grains pushing 3000 fps with a .470 BC is point blank to 300 yards on a 6″ target, and is traveling 2200 fps with a ton of energy out at 400 yards.

At the range…

Range day; 65°F or so, no crosswind, sunny and dry. Yes, I do realize I had enough sandbags on the bench to stave of a flood, but they sure help when there is lots of ammo to shoot; after 100 rounds or so I usually chew on one to stifle the screams. I brought velocity checking loads, accuracy loads and some factory stuff for the sake of comparison. I also brought a piece of soft rubber bench mat to cover the cement bench so I would leave the rifle’s finish were it belongs, on the rifle; $10 at Lowes for a 2 1/2’x10′ roll. The Hogue OverMolded stock is comfortable, a very natural feel, which made for a consistent and positive grip. That wide forearm was very steadying, and the palm swell pistol grip was perfect. Not beautiful, but not at all ugly; jut great utility.

The 270 WSM, at least when fired from a Winchester Super Shadow, is very mild in recoil. I found this not to be the case with the 7mm WSM and the Howa where recoil was similar to the 7mm Remington Magnum with similar loads. Not much of a thumper but, even with an excellent recoil pad, it was hard not to notice it against my shoulder. This 7mm WSM did distinguish itself as a gun with a substantial amount of muzzle blast, at least with pumped up handloads, and that is coming from a guy who routinely shoots big Weatherby cartridges with their signature deafening muzzle brake. In fact, at about 10′ from the muzzle, the Howa kept blowing the rods and filters off the Chrony. This is a cartridge, I believe, that could make good use of another inch or two of barrel.

The Howa is push feel, so the shooter needs to pay attention when jacking a round into the chamber, as gravity plays a substantial role in making sure the cartridge is where it needs to be after it clears the magazine. The magazine holds three rounds, a fourth can be chambered by holding down the magazine loaded ammo while the bolt is closed on the fourth. The bolt fit is tight, motion is smooth and feeding ammo in large quantities was uneventful. The three position safety is positive, as is the bolt release, and there was no binding after repeated use and at elevated temperatures.

A note on the Burris Fullfield II, it is a terrific scope. I really like the Ballistic Plex reticle and I don’t think I have worked with a scope, regardless the price, that tracked adjustments so predictably. The scope and Warne mounts held up to many, many rounds of magnum ammo and neither faltered in use. I expect there will be more of each on my personal firearms. The combination improved my shooting.

The Howa is a real shooter…

Nosler C T 150 grain bullets shot better than 3/4″ with almost any charge, as did Speer 160 grain. The groups pictured right are both 3/8″. I was able to shoot several 1/2″ groups with Nosler Accubond and the same with 175 grain Hornady and Remington. I don’t know if this is the 7mm WSM or the Howa doing a good job, but this is probably the most accurate out of the box rifle I have shot in some time. The only thing that would not group acceptably was Winchester factory 150 grain Power Point ammo and these rounds were also all over the place with velocity. The best three shot groups was 1 3/4″ and recorded velocity ran from a low of 3083fps to a high of 3307 fps. Winchester lists the ammo at 3200 fps. I of course used my special barrel break in procedure; I shot some ammo, drank some coffee, shot some more ammo, drank some more coffee, then shot some more. Finally, I put the gun in its case and brought it home, wiped it down and put it away. I intend to clean it some day soon, however, the bore did not show signs of excessive copper.

Nosler C T 150 grain bullets shot better than 3/4″ with almost any charge, as did Speer 160 grain. The groups pictured right are both 3/8″. I was able to shoot several 1/2″ groups with Nosler Accubond and the same with 175 grain Hornady and Remington. I don’t know if this is the 7mm WSM or the Howa doing a good job, but this is probably the most accurate out of the box rifle I have shot in some time. The only thing that would not group acceptably was Winchester factory 150 grain Power Point ammo and these rounds were also all over the place with velocity. The best three shot groups was 1 3/4″ and recorded velocity ran from a low of 3083fps to a high of 3307 fps. Winchester lists the ammo at 3200 fps. I of course used my special barrel break in procedure; I shot some ammo, drank some coffee, shot some more ammo, drank some more coffee, then shot some more. Finally, I put the gun in its case and brought it home, wiped it down and put it away. I intend to clean it some day soon, however, the bore did not show signs of excessive copper.

The chronograph target ended as a 2 1/2″ cluster; 50 different handloads, 9 types and weights of bullets from 139 to 175 grains and 5 different types of powder. In addition, the shots were taken over a period of time, the rifle was put down while the barrel cooled from too hot to touch to just hot. Pretty incredible for a sporter to shoot this close on point of impact with such a wide range of cartridges and velocity variations. The barrel heated quickly with 4 or 5 shots, about half way up and forward to the muzzle. The action and chamber area of the barrel remained quite cool, a symptom of lots of powder burning as well as relatively high pressure and velocity. None of this seemed to effect performance. The trigger pull was moderate, but it broke like glass, so it was easy to squeeze off controlled shots.

The 7mm WSM…

The following was extracted from my load sheets. In general, IMR 7828 probably came the closest to living up to expectations and delivering decent performance. H4350 in two case did an amazing job with less than case full loads, but this did not carry over to other loads tried with different bullets or bullet weights. I was pretty surprised as the decent performance of some of the relatively slow powder, kike Re22 and 140 grain loads. The very last load I believe is a very accurate, non-max deer loads that is inexpensive to put together. I believe 2900 fps is easily attainable with 175 grain loads and 3000 fps is a good number for 160 grain. Essentially, what we have here is performance equal to a 7mm Remington magnum and something that is probably an excellent North America big game cartridge and rifle.

Howa Hogue and 7mm WSM in summary…

If I were looking for a basic reliable rifle firearm that could handle game up to and including elk, the Howa would be a consideration right along side of the Weatherby Vanguard, Remington’s Mauser and CZ’s American products. What it has going for it is a moderate price, good quality and excellent accuracy. The gun has a very good adjustable trigger and it appears to be durable and able to take a beating. The down side is that the stock that is very good for a moderately priced firearm is less than exciting when compared to stocks found on a premium rifle. The rifle is a bit heavy, but perhaps this contributed to accuracy and comfort when shooting.

The 7mm WSM is a powerful cartridge, obviously capable of good accuracy and it can keep pace with the 7mm Remington Magnum. It is easy and relatively inexpensive to handload and the results are rewarding. There are lots of bullets from lots of sources for practically every application. Recoil is manageable; 7mm Remington Magnum like The down side is this relatively new cartridge barely matches the performance of a highly successful cartridge that has been around since 1962, the 7mm Remington Magnum. Where the 270 WSM offers some significant gains over the 270 Winchester, the 7mm WSM has predecessors that upstage it’s performance by a measurable degree; 7mm Weatherby, 7mm STW, 7mm Ultra Mag.

For someone who is looking for this type of package, I think it is a very good gun and its performance won’t be disappointing. I think it is a step up from the 280 Remington with ballistics superior to the 7mm SAUM…if that Remington cartridge is still being made. On the other hand, if it was the Howa hardware and price I found appealing, I might be tempted to go with either a 7mm Remington Magnum with lots of factor loads or the lighter recoiling 270 WSM which I think is still capable of convincingly dropping elk.

Thanks

Joe

Howa ’bout a 7mm WSM? Part I

Howa ’bout a 7mm WSM? Part II

7mm WSM Handload Data

Email Notification