I while back, I wrote an article comparing RCBS Uniflow and Hornady Lock n’ Load powder measures. Included was some analysis of the charge throwing consistency, or lack of consistency, demonstrated by each. Almost immediately, I received an e-mail, advising me to buy a Harrellmeasure, indicating the product is dead on repeatable, and different as a Culver type design. 1) My reasons for not following this advice 1) RCBS and Hornady products use the same methods to meter as the Harrell unit 2) a Harrell powder measure, of capacity similar to the RCBS and Hornady products, sells at over 4 times the price; $229 compared to $55.

I while back, I wrote an article comparing RCBS Uniflow and Hornady Lock n’ Load powder measures. Included was some analysis of the charge throwing consistency, or lack of consistency, demonstrated by each. Almost immediately, I received an e-mail, advising me to buy a Harrellmeasure, indicating the product is dead on repeatable, and different as a Culver type design. 1) My reasons for not following this advice 1) RCBS and Hornady products use the same methods to meter as the Harrell unit 2) a Harrell powder measure, of capacity similar to the RCBS and Hornady products, sells at over 4 times the price; $229 compared to $55.I don’t have much of an application for a powder measure. I load principally short runs, more reflective of experimentation and varied components than large quantities of uniform production. I’m pretty happy with beam or electronic scale measurement, especially when the use of a properly calibrated scale allows me to put together a bunch of maximum loads, and still keep my eyes open and my fingers out of my ears during range testing. However, when my very thoughtful wife recently gave me a Harrell’s powder measure as a present, what could I do but say “thank you”, and put the measure to good use.

As supplied by Sinclair International, the Harrell Premium model comes with a 6~120 grain range measure, two drop tubes and a 16 oz powder bottle (not shown). Unless it is desirable to mount the measure directly to a bench, which probably would require sitting on the floor to meter out charges, a clamp type stand is a good investment. Sinclair’s portable stand is adjustable for height, bench thickness and lateral rotation of the measure – these sell for $38.50.

The measure is threaded to directly accommodate large mouth powder bottles, as supplied by Hodgdon and Accurate. Accessory bottles are also available; round or square, 8 or 16 oz, bottom plugged or sealed. These are priced at about $7 each. A Harrell Premium set up that will handle a wide array of cartridges, handgun through Weatherby, will run about $268 inclusive of measure, bottle, drop tubes and stand.

All measures are not created equal

There are many firearm related accessories that are priced on name alone, offering comparable goods and quality, with a great disparity in price. The Harrell powder measure does not fall into this category. A Harrell measure is a little like a Jessie James custom Harley, in that both are fully functional, but they are also examples of mechanical art.

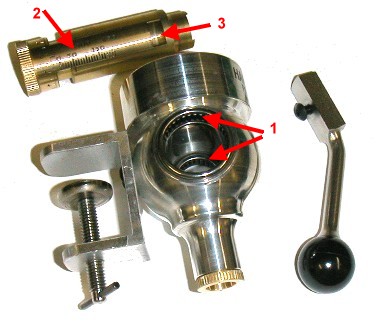

The body of the Harrell Premium measure is a precision cast aluminum piece, polished, with a lot of clean machine work for precise assembly fit. The brass metering device rotates within two roller bearings (1). The metering body is fully indexed (2) and the size of the powder metering cavity (3) is described, by the manufacturer, as adjustable in tenth or one and one half tenth grain increments. As a result of a tight mechanical fit, bearings and quality of material and assembly, the operation of the measure is very smooth. I believe this feel is quite an accomplishment, in light of the absence of mass and inertia of a heavier cast iron assembly.

To better illustrate how the measure works, I removed the baffle (3) that resides between the powder reservoir and the metering device. Essentially, the adjustment thimble (1) moves the solid center of the metering device in or out of a slotted brass sleeve. This adjustment controls the volume of the cavity (2) that is exposed to the powder reservoir when the measure’s handle is rotated to the up position. In this position, gravity moves the powder from the reservoir to fill the cavity. The measure’s handle is then rotated downward, which inverts the cavity, effectively closing the cavity to the powder reservoir, and allowing gravity to empty its contents through the bottom of the measure, and on out through the drop tube. Raising the measure’s handle begins the cycle again. I just described what represents about half a second in real-time operation. A $60 powder measure functions approximately the same way; the body of a powder measure has two ports, one on top to bring in powder, and one below to discharge powder. A drum with a variable metering cavity resides and rotates between these two ports, alternately filling from the powder reservoir above, then emptying into a cartridge case or other form of vessel below.

A nice touch – at the end of the adjustment thimble of the metering device are four set screws (A-D). By moving the retaining set screw, and contained spring and detent ball from position D to position “A”, there will be 4 clicks rather than 6 between increments. This changes the adjustment resolution from .1 grain per click to .15 grains per click. Powder measures are generally much more coarse in adjustment. The Harrell product’s brass parts are nicely finished and the index marking are very clean and easy to read, however, setting by click feel requires no visual cues; much like making click adjustments on a scope without looking at the markings.

The RCBS measure on the right is pretty typical of the construction used in lower cost powder measures. The adjusting screw (1) has a carriage bolt like head that fills the diameter of the drum’s cavity (2) and is adjusted in or out to vary the cavity’s volume. Rotated upward, the cavity aligns with the measure’s body port (3) that connects to the measure’s powder reservoir. When the drum is rotated downward, the cavity aligns with the discharge port at the bottom (4) and throws a single charge. The measure’s body is cast iron, the powder reservoir is staked in place and must be filled from a powder storage canister, there are no bearings or bushings and the drum rides directly on the machined cast walls of the body (5).

There are upgrades for low cost powder measures. Sinclair International offers kits to covert these measure for use with screw in powder containers. This change improves material handling convenience, and cuts down on handling of powder. A bottle adapter runs about $18 for an RCBS unit.

If you own an RCBS Uniflow powder measure, you can replace its course adjusting screw, with a fine thread indexed micrometer adjustment screw. The cost is about $34 from online discount retailers, and it is easy to install. The micrometer adjustment screw for my RCBS measure has been installed only twice, as it seems to offer little control or convenience over the standard adjuster.

Is the Harrell measure functionally superior?

In the final analysis, I believe a powder measure should be judged on its ability to measure powder (duh), so I set both the Harrell Premium measure, and the RCBS Uniflow not so premium measure, up on the bench and ran some sample charges. In all cases, the powder reservoirs were full. 10 throws were made before weights were recorded, and each charge was measured on an RCBS Pro Powder scale that was calibrated, and verified with a beam scale, after each table was completed. Ambient temperature varied between 68º~71º, humidity remained a constant 58%.

| Moderate Charges – Spherical Powder | ||||||

| Harrell Premium Powder Measure | RCBS Uniflow | |||||

| Throw | Grains of Win 748 |

Change from min grains |

Change from min % |

Grains of Win 748 |

Change from min Grains |

Change from min % |

| 1 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 2 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 3 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 4 | 29.8 | – | – | 38.7 | .2 | .5 |

| 5 | 29.9 | .1 | .3 | 38.5 | – | – |

| 6 | 29.8 | – | – | 38.5 | – | – |

| 7 | 29.8 | – | – | 38.5 | – | – |

| 8 | 29.8 | – | – | 38.5 | – | – |

| 9 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 10 | 29.8 | – | 38.5 | – | – | |

| 11 | 29.8 | – | 38.6 | .1 | .2 | |

| 12 | 29.8 | – | 38.6 | .1 | .2 | |

| 13 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 14 | 30.0 | .2 | .7 | 38.5 | – | – |

| 15 | 29.8 | – | – | 38.5 | – | – |

| 16 | 29.9 | .1 | .3 | 38.7 | .2 | .5 |

| 17 | 29.9 | .1 | .3 | 38.7 | .2 | .5 |

| 18 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 19 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| 20 | 29.9 | .1 | .3 | 38.6 | .1 | .2 |

| Max Variation | .2 | .7 | .2 | .5 | ||

| Temp variance 68º~71º Humidity 58% | ||||||

| Heavy Charges – Spherical Powder | ||||||

| Harrell Premium Powder Measure | RCBS Uniflow | |||||

| Throw | Grains of Win 748 |

Change from min grains |

Change from min % |

Grains of Win 748 |

Change from min Grains |

Change from min % |

| 1 | 91.2 | .1 | .1 | 92.4 | – | – |

| 2 | 91.2 | .1 | .1 | 92.5 | .1 | .1 |

| 3 | 91.2 | .1 | .1 | 92.5 | .1 | .1 |

| 4 | 91.3 | .2 | .2 | 92.6 | .2 | .2 |

| 5 | 91.1 | – | – | 92.7 | .3 | .3 |

| 6 | 91.3 | .2 | .2 | 92.4 | – | – |

| 7 | 91.2 | .1 | .1 | 92.6 | .2 | .2 |

| 8 | 91.2 | .1 | .1 | 92.6 | .2 | .2 |

| 9 | 91.2 | .1 | .1 | 92.6 | .2 | .2 |

| 10 | 91.3 | .2 | .2 | 92.4 | – | – |

| 11 | 91.3 | .2 | .2 | 92.4 | – | – |

| 12 | 91.2 | .1 | .1 | 92.7 | .3 | .3 |

| 13 | 91.3 | .2 | .2 | 92.6 | .2 | .2 |

| 14 | 91.3 | .2 | .2 | 92.7 | .3 | .3 |

| 15 | 91.3 | .2 | .2 | 92.7 | .3 | .3 |

| 16 | 91.2 | .1 | .1 | 92.5 | .1 | .1 |

| 17 | 91.3 | .2 | .2 | 92.6 | .2 | .2 |

| 18 | 91.1 | – | – | 92.7 | .3 | .3 |

| 19 | 91.1 | – | – | 92.7 | .3 | .3 |

| 20 | 91.1 | – | – | 92.7 | .3 | .3 |

| Max Variation | .2 | .2 | .3 | .3 | ||

| Temp variance 68º~71º Humidity 58% | ||||||

| Moderate Charges – Extruded Powder | ||||||

| Harrell Premium Powder Measure | RCBS Uniflow | |||||

| Throw | Grains of Re 22 |

Change from min grains |

Change from min % |

Grains of Re 22 |

Change from min Grains |

Change from min % |

| 1 | 28.9 | .5 | 2 | 32.5 | .1 | .3 |

| 2 | 28.8 | .4 | 1 | 32.9 | .5 | 2 |

| 3 | 28.9 | .5 | 2 | 32.6 | .2 | .6 |

| 4 | 28.8 | .4 | 1 | 32.4 | – | – |

| 5 | 28.8 | .4 | 1 | 33.7 | 1.3 | 4 |

| 6 | 28.7 | .3 | 1 | 33.2 | .8 | 2 |

| 7 | 28.8 | .4 | 1 | 33.3 | .9 | 3 |

| 8 | 28.4 | – | – | 32.7 | .3 | 1 |

| 9 | 28.5 | .1 | .3 | 32.8 | .4 | 1 |

| 10 | 28.8 | .4 | 1 | 33.1 | .7 | 2 |

| 11 | 28.8 | .4 | 1 | 32.5 | .1 | .3 |

| 12 | 28.8 | .4 | 1 | 32.7 | .3 | 1 |

| 13 | 28.6 | .2 | .6 | 33.0 | .6 | 2 |

| 14 | 28.8 | .4 | 1 | 32.4 | – | – |

| 15 | 28.7 | .3 | 1 | 32.5 | .1 | .3 |

| 16 | 28.7 | .3 | 1 | 33.2 | .8 | 2 |

| 17 | 28.5 | .1 | .3 | 33.6 | 1.2 | 4 |

| 18 | 28.7 | .3 | 1 | 33.1 | .7 | 2 |

| 19 | 28.7 | .3 | 1 | 32.7 | .3 | 1 |

| 20 | 28.8 | .4 | 1 | 32.4 | – | – |

| Max Variation | .4 | 2 | 1.3 | 4 | ||

| Temp variance 68º~71º Humidity 58% | ||||||

| Heavy Charges – Extruded Powder | ||||||

| Harrell Premium Powder Measure | RCBS Uniflow | |||||

| Throw | Grains of Re 22 |

Change from min grains |

Change from min % |

Grains of Re 22 |

Change from min Grains |

Change from min % |

| 1 | 85.9 | 0.5 | .5 | 84.1 | .3 | .4 |

| 2 | 87.0 | 1.6 | 2 | 83.8 | – | – |

| 3 | 85.4 | – | – | 83.8 | – | – |

| 4 | 86.5 | 1.1 | 1 | 83.8 | – | – |

| 5 | 86.4 | 1.0 | 1 | 83.8 | – | – |

| 6 | 86.1 | 0.7 | .8 | 84.4 | .6 | .7 |

| 7 | 86.2 | 0.8 | .9 | 83.9 | .1 | .1 |

| 8 | 85.8 | 0.4 | .5 | 83.8 | – | – |

| 9 | 85.7 | 0.3 | .4 | 83.8 | – | – |

| 10 | 86.8 | 1.4 | 2 | 83.9 | .1 | .1 |

| 11 | 86.1 | 0.5 | .6 | 83.8 | – | – |

| 12 | 86.5 | 1.1 | 1 | 84.1 | .3 | .4 |

| 13 | 86.5 | 1.1 | 1 | 83.8 | – | – |

| 14 | 86.8 | 1.4 | 2 | 83.9 | .1 | .1 |

| 15 | 85.6 | 0.2 | .2 | 83.8 | – | – |

| 16 | 87.4 | 2.0 | 2 | 83.8 | – | – |

| 17 | 87.2 | 1.8 | 2 | 83.8 | – | – |

| 18 | 87.5 | 2.1 | 2 | 83.9 | .1 | .1 |

| 19 | 87.3 | 1.9 | 2 | 84.2 | .4 | .5 |

| 20 | 86.9 | 1.5 | 2 | 83.9 | .1 | .1 |

| Max Variation | 2.1 | 2 | .6 | .7 | ||

| Temp variance 68º~71º Humidity 58% | ||||||

| Very Heavy Charges – Extruded Powder | ||||||

| Harrell Premium Powder Measure | RCBS Uniflow | |||||

| Throw | Grains of Re 22 |

Change from min grains |

Change from min % |

Grains of Re 22 |

Change from min Grains |

Change from min % |

| 1 | 116.4 | 1.1 | 1 | 110.4 | – | – |

| 2 | 115.7 | 0.4 | .3 | 112.8 | 2.4 | 2 |

| 3 | 116.1 | 0.8 | .7 | 113.2 | 1.8 | 2 |

| 4 | 116.0 | 0.7 | .6 | 110.4 | – | – |

| 5 | 115.3 | – | – | 112.0 | 1.6 | 1 |

| 6 | 116.5 | 1.2 | 1 | 112.3 | 1.9 | 2 |

| 7 | 115.3 | – | – | 112.0 | 1.6 | 1 |

| 8 | 115.6 | 0.3 | .3 | 112.0 | 1.6 | 1 |

| 9 | 115.9 | 0.6 | .5 | 113.1 | 1.7 | 1 |

| 10 | 115.9 | 0.6 | .5 | 111.6 | 1.2 | 1 |

| 11 | 116.3 | 1.0 | .9 | 112.8 | 2.4 | 2 |

| 12 | 115.8 | 0.5 | .4 | 112.1 | 1.7 | 1 |

| 13 | 116.2 | 0.9 | .3 | 111.9 | 1.5 | 1 |

| 14 | 116.3 | 1.0 | .9 | 111.1 | .7 | .6 |

| 15 | 116.0 | 0.7 | .6 | 112.3 | 1.9 | 2 |

| 16 | 115.8 | 0.5 | .4 | 112.2 | 1.8 | 2 |

| 17 | 116.3 | 1.0 | .9 | 113.0 | 1.6 | 1 |

| 18 | 116.5 | 1.2 | 1 | 111.8 | 1.4 | 1 |

| 19 | 115.7 | 0.4 | .3 | 112.6 | 2.2 | 2 |

| 20 | 115.9 | 0.6 | .5 | 112.7 | 2.3 | 2 |

| Max Variation | 1.2 | 1 | 2.4 | 2 | ||

| Temp variance 68º~71º Humidity 58% | ||||||

Conclusion

No form of volume based measurement will be dead on accurate. Smokeless powder is measured by weight, not volume, and any irregularity in metered charge density will cause inconsistencies in weight, regardless the use of: roller bearings, tight tolerance parts, fine resolution of adjustment, or shiny surfaces suitable for use as a shaving mirror. Spherical powder meters more uniformly because its small diameter, flat form, settles more uniformly in containers and does not typically shear when caught between the knife edges of the metering body and containing measure walls. Extruded powder, because of it’s long tubular form, is frequently sheared during metering, which jolts the measure, disturbs the powder in the reservoir above, and causes it to settle to a higher density. This change in density is the basis for charge to charge variations. Double bumping at the top and/or bottom of stoke has essentially the same effect. I could add a grain or two to charges just by bumping the handle at either end of the stroke. Neither product threw charges that would be considered unsafe, however, neither would warrant operating at the ragged edge of maximum loads.

Within the useful application of a mechanical powder measure, there is virtually no difference between a $60 powder measure and one priced at $268. Both products will measure powder to the same relative level of accuracy and consistency, both will meter spherical powder more uniformly than extruded powder. I am not suggesting there is no value in more expensive equipment, just as I would not say there isn’t a reason to purchase a Craftsman life time warranty ratchet over a store brand throw away product. The more expensive product, finished to better quality, containing roller bearings, and using better material will last longer and maintain it’s level of consistency in metering charges. It’s up to the buyer to decide if this is enough reason to part with the extra money. I honestly have never worn out an inexpensive powder measure, but then I’m not a heavy user of the equipment.

Thanks

Joe

Email Notification