I’d like to say resumption of this project was triggered by a carefully crafted strategic plan that serves as the foundation for the Real Guns editorial calendar… but I cannot. Truth be told, I was standing on a ladder, reaching for some 45-90 WCF brass and dies, when a hefty mechanical assembly, a Remington 70 action, slid off the third tier of cardboard boxes, on the top shelf and wonked me on the forehead. The combination of the head thump and the vaguely familiar parts on the floor served as a reminder that there was a project that needed to be finished. Just another episode of “Workshop Anthropology”.

Rounding up all of the associated parts and tools took a while; under benches, in cabinets, in desk drawers, and in a multitude of unmarked boxes. In fact, I had to go back and read the prior authored articles to determine where the project paused, how it got there and what was needed to move forward. When the cobwebs cleared, figuratively and literally, there was a long, magnum bolt faced, Remington Model 700 stainless steel action, trued and squared and waiting for a barrel. The following links represent previous work completed –

Either a 338 Ultra Mag… or a Nifty Paperweight Part 1

Either a 338 Ultra Mag… or a Nifty Paperweight Part 2

Either a 338 Ultra Mag… or a Nifty Paperweight Part 3

Either a 338 Ultra Mag… or a Nifty Paperweight Part 4

There is a house. One enters it blind and comes out seeing. What is it?

This action will get two barrels, but only one will be in place at any given time. The first is chambered for the 338 Remington Ultra Mag, the second is chambered for the 270 Weatherby. The 338 RUM was threaded to the shoulder, the Weatherby was not, both were short chambered. I got to thinking that the 270 Weatherby barrel was cut for a thicker recoil lug, but that wasn’t indicated on the barrel’s documentation. Hmm… (Dramatic pause suggesting thought).

One of the recoil lugs found in a project box was an oversized lug that measured 0.230″ thick. The other recoil lug was a Remington piece that measured 0.193″, or approximately standard. The solution was to trial assemble the barrel to the action with each recoil lug in turn, in place, and attempt to close the bolt on a go gauge (remember, short chamber). The bolt closed over both go and no go gauges with the oversized recoil lug assembly, it did not with the 0.193″ recoil lug. Mystery solved, the barrel was cut for the standard Remington recoil lug.

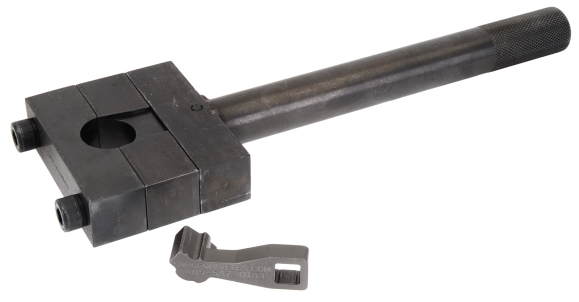

Action wrenches , big and small. Top, a Brownells action wrench with Remington head, below, a Surgeon Rifle wrench. The former clamps around the Remington action and retains proper recoil lug position, the latter slips into the bolt lug ways and applies force to the action’s most robust point. I tend to use the Brownell wrench for removing actions from mature firearms and the Surgeon tool for all others. The Model 700 action wrench kit, Brownells PN:80-800-700WB sells for $159 at Brownells.Com. The Surgeon wrench sells for $128 on Brownells, but only $65 direct from its manufacturer, Surgeon Rifles.

The recoil lug must be indexed so that it points down and fits into the recess into the stock. The tool used here is a Kleinendorst Remington recoil lug alignment tool. Brownells PN:488-004-700WB, price approximately $55, $26 from Pacific Tool & Gauge if you don’t mind waiting awhile for delivery.

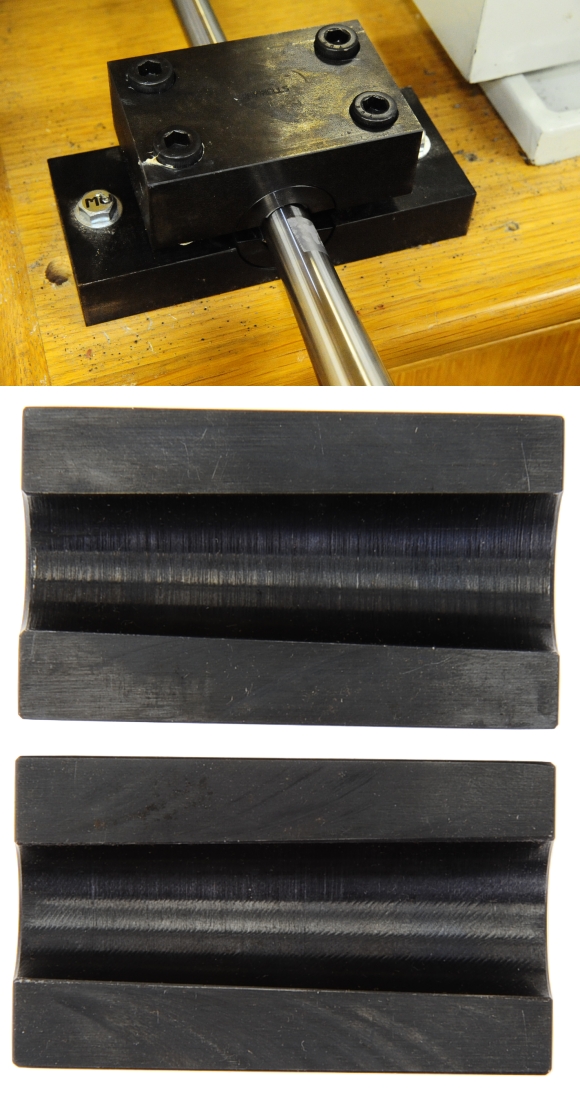

A Brownells barrel vise, bolted down to a hefty lathe bench, had the honors of holding the barrel still while I cranked away on the action. Brownells PN:080-860-006WB $155 for vise and #6 steel bushing. The bushing matches a Remington 30-06 barrel taper and, lined with lead shim stock, leaves no marks on even a polished stainless barrel.

The barrel was torqued to 75 ft-lbs. Why? I found that barrels screwed into Remington actions with dry threads stayed put and delivered good accuracy when torqued to 100 ft-lbs. When barrel swapping became common place in the shop, I began using anti seize compound on bolt action rifle threads, first Loctite Nickel on stainless assemblies, then copper based Loctite C5-A general purpose anti seize for all, and reduced torque by 25% due to the lubricity of the compound. Again, barrels stay on, accuracy of the finished firearm is good and the barrels come off as needed.

Because the Surgeon action wrench extends the 16″ torque wrench by 2.2″ and increases mechanical advantage, the wrench was set to 66 ft-lbs which resulted in the action being torqued to 75 ft-lbs.

- M1 = M2 x L1 / L2

- M1=Torque setting on wrench

- M2=Actual torque applied

- L1=Length of wrench center of grip to center of socket

- L2=Length of wrench with extension center of grip to center of socket

OK, the barrel is installed. Next up is final chambering, bolt assembly and check out.

Email Notification