I’m not sure what demographic firearm and firearm accessory companies consider when they want to name products. My all time favorite is the Burris “Mr. T” product line that was introduced 5 years after the real Mr. T had been reduced to guest oddball appearances on Howard Stern. The product line was later renamed Mr. T Black Diamond Titanium Scopes. Yeah, like that fixed the problem. I don’t know what makes a barrel fall into the dragon classification, much less a fire dragon classification, but I know I was impressed enough by the name to buy one and try it out.

The Wandering Path

I always buy both 40 S&W and 357 SIG barrels whenever I buy a SIG of this type, mostly because I am a spineless simp and can’t make a simple public commitment to shooting the best round for these guns, the 357 SIG. I need to be able to say, “Of course, I normally have the serious gunfighter 40 S&W barrel installed, I only play with that 357 SIG for personal entertainment. I did have a 357 SIG barrel for my P229, unfortunately, I treated it to inserts and other tong and hammer rework until it became the launching pad for the 17-357 RG….which in retrospect should have called something like the Valkyrie Avenger, a name that would have commanded more respect from friends and associates. In any event, I was in the market for a new barrel chambered for the 357 SIG cartridge.

A new SIG barrel carries an MSRP of $226, a semi drop in Bar-Sto Barrel carries a $200 price tag, EFK Fire Dragon offers two barrels; ported $179 and standard (unported) $149. Since EFK describes their product as “The Finest Pistol Barrels Made in the World” and, possibly, because they were the lowest in price, I decided to take them at their word and give them a try. I opted for the ported barrel because I felt, if the barrel did not live up to my expectations, I would enjoy cutting the end of the barrel and taking it down to standard unported size.

They are almost identical….well, not really

These are the SIG and Fire Dragon, lower, side by side. There are a few differences, other than length and ports.

The SIG has unfinished machined surfaces on the rear face of the lower barrel lug and back side of the feed ramp, the Fire Dragon has bead blast finish in these area. The SIG has a machined but micro tool marked feed ramp, the Fire Dragon has a highly polished feed ramp. The SIG has a simple cartridge designation stamp that is visible from the gun’s ejection port, the Fire Dragon indicates P229 NM (National Match) 357 CONV., which means conversion and omits the word “SIG” from the cartridge designation. What does this all mean? Probably nothing. The precisely machined surfaces of the SIG could have indicated a barrel finished to a closer tolerance than it’s bead blasted cousin, or it could have been a cost avoidance for final finishing. I felt the EFK feed ramp could be an improvement, although functionally none was probably needed over the SIG unit. If seemed if there were a significant difference, it would have to show up in live fire testing.

| Physical Comparisons | SIG | Fire Dragon |

| Barrel length – muzzle to breech | 3.840″ | 4.565″ |

| Active barrel length | 2.990″ | 3.140″ |

| Barrel outside diameter | 0.550″ | 0.548″ |

| Width at flats | 0.657″ | 0.649″ |

| Height at flats | 0.697″ | 0.684″ |

| Chamber diameter at case head | 0.426″ | 0.425″ |

| Case fully supported | Yes | Yes |

| Grooves | 6 | 6 |

| Twist | 1:16″ | 1:16 |

| Material | Carbon Steel | 416 Stainless |

| Weight | 2.8 oz | 3.6 oz |

Wow, what a snooze. Actually, there are two items that prevented me from falling asleep while collecting this information. The Fire Dragon barrel is stainless, the SIG is blued carbon steel. If you’re a stainless steel fan, this could be important. If you like your gun parts to match your gun, this could be of consequence, as the ported version of the Fire Dragon protrudes as bare metal approximately 3/4″ beyond the face of the black slide . The Fire Dragon ported barrel is effectively longer by about 0.150″, by “effectively ” I mean the rifled portion of the barrel forward of the chamber and prior to a compensator. Once the bullet base hits an open port, pressure drops dramatically and the additional barrel length does not significantly contribute to further bullet acceleration even though there is continuation of rifling through this area. How much is that extra Fire Dragon effective length worth? If not attributed to material selection or other interior barrel dimensions, about 31 fps with a full load of Alliant Power Pistol, or about a 2% improvement over the standard SIG barrel.

Installation and Fit

Anyone who has swapped SIG barrels knows this is a one minute proposition. You remove the magazine, lock the slide back, rotate the take down lever to vertical, then release the slide, guiding it forward and off the frame. The recoil spring and guide rod, as well as the barrel, then lift out of the slide. The Fire Dragon packaging and product listings indicate the barrel may require minor fitting. In terms of installation while retaining the ability to manually cycle the gun, the new barrel plopped into place and the recoil spring and guide rod and slide assembly all installed normally. Easy deal, but not test fired, but then most of us don’t plan on manually cycling an auto pistol in routine use.

The finished product looks ok, however, I am old and therefore believe the only thing that looks right coming out of the front of a gun is a bullet. Still, this is a good compensator solution as other means of porting requires drilling or electronically etching holes in the top of a standard length barrel and opening up a vent area on the top of the slide. This latter approach detunes cartridge performance and makes for some interesting special effects when shooting in low light conditions. Why bother with any compensator? Well, the 357 SIG is a gun rotating cartridge, so the use of any compensator isn’t a superfluous accessory. Anything that would help keep the gun on target for a second shot, or reduce the time getting back on target for a second shot, would be good. No, I didn’t say it’s a cannon, so please don’t write to tell me about your 44 Magnum you’ve named Fred, but the P229 chambered for the 357 SIG does climb a little and, because these guns are typically not for target shooting, their purpose is critical enough to warrant follow up shot consideration.

Live fire problems surface and are corrected

The first thing that became obvious was that the drop in barrel was not a drop in for live fire; the gun stove piped or the slide did not return full forward and lock up when feeding a fresh cartridge. For awhile I thought it was 1970 and I was shooting a factory 1911 Colt. There were no instructions or trouble shooting guide packaged with the barrel, however, their site and package literature said….

“And don’t forget the service. We deal with our customers on a personal level to ensure their complete satisfaction with every product we sell. Ported barrels will reduce recoil that you feel by up to 40%. All barrels can shoot lead and jacket bullets. Lead bullets are required by many gun ranges and are less expensive to shoot. Our barrels drop in, but due to the very high tolerances held by our machining standards, some fitting may be required on a small percentage of them.”

I did send an email, I did contact SIG, I did begin to analyze and research new cars. I received a helpful and thorough response from SIG, I did purchase and take delivery of a new car – still haven’t heard from EFK. I won’t “forget the service”. So I resorted to the basics; I disassembled the P229 and looked for odd contact or rub marks and made some comparative measurements between the SIG and EFK barrels. I’m trying something new, at least for me. The thumbnails below can be clicked to display a full size image. I thought this would be a good way to show detail without having giant pictures jumping out at you all of the time.

The height and width dimensions were pretty much the same between the SIG and the EFK barrels, perhaps a few thousandths in overall height or width differences, but forced contact or rub marks were found on the EFK barrel is several places. The leading edge of the barrels chamber area made contact with the slide only when the gun was live fired and not when manually cycled. The contact caused this barrel edge, from one side to another, to develop a large burr. Displaced metal, other than on the shank of a bullet, is rarely good news.

The height and width dimensions were pretty much the same between the SIG and the EFK barrels, perhaps a few thousandths in overall height or width differences, but forced contact or rub marks were found on the EFK barrel is several places. The leading edge of the barrels chamber area made contact with the slide only when the gun was live fired and not when manually cycled. The contact caused this barrel edge, from one side to another, to develop a large burr. Displaced metal, other than on the shank of a bullet, is rarely good news.

The EFK barrel’s frame contact point at the underside of the feed ramp had a high spot and a narrow concentrated rub spot. Most of the bead blasted surfaces were now contact polished where barrel metal met frame metal, but nothing excessive. I was concerned this high spot contact torqued the barrel to the left when the gun was fired, and added a good deal of drag to the slide. The SIG barrel is keyed to the slide so where ever the barrel goes, the slide goes also.

The EFK barrel’s frame contact point at the underside of the feed ramp had a high spot and a narrow concentrated rub spot. Most of the bead blasted surfaces were now contact polished where barrel metal met frame metal, but nothing excessive. I was concerned this high spot contact torqued the barrel to the left when the gun was fired, and added a good deal of drag to the slide. The SIG barrel is keyed to the slide so where ever the barrel goes, the slide goes also.

I was pretty sure barrel hood contact was the primary culprit. The barrel hood on the SIG has a small bevel on either side that lead it into the slide cutout when the gun goes to battery, the EFK barrel did not. I believe the slide moving to battery and catching on the barrel hood corner was driving the barrel into the front side of the slides ejection port, raising the burr at the leading edge of the chamber area and preventing normal lock up.

I checked the EFK barrel in a vise and beveled the sides of the barrel hood to match the SIG barrel examples I had on hand. Then I used a white Arkansas wet stone and cleaned up the surface under the feed ramp. 600 grit wet or dry paper laying on a surface plate was used to clean up the top flat of the barrel over the chamber area, mostly just getting rid of the raised burr described earlier. The barrel finished up nicely and matched the SIG exposed barrel finish. It locked up properly, the gun cycled smoothly and no more stove pipes or failure to lock up during live fire. One last note, I had been shooting hot loads out of the gun with a 19lb recoil spring. Before installing the new barrel I switched back to the factory 16 lb 40 S&W spring that came with the gun originally, and this is the spring that was in place throughout the activity outlines in this article.

I checked the EFK barrel in a vise and beveled the sides of the barrel hood to match the SIG barrel examples I had on hand. Then I used a white Arkansas wet stone and cleaned up the surface under the feed ramp. 600 grit wet or dry paper laying on a surface plate was used to clean up the top flat of the barrel over the chamber area, mostly just getting rid of the raised burr described earlier. The barrel finished up nicely and matched the SIG exposed barrel finish. It locked up properly, the gun cycled smoothly and no more stove pipes or failure to lock up during live fire. One last note, I had been shooting hot loads out of the gun with a 19lb recoil spring. Before installing the new barrel I switched back to the factory 16 lb 40 S&W spring that came with the gun originally, and this is the spring that was in place throughout the activity outlines in this article.

Did the Fire Dragon barrel make a difference?

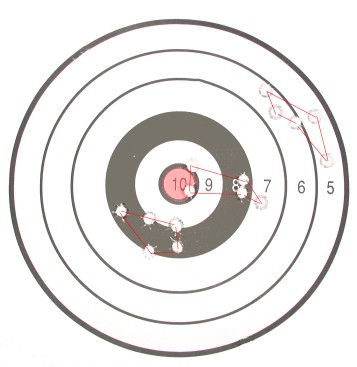

The compensator barrel made a notable difference, particularly shooting off hand. This is a cleaned up target, a few shots I made while tinkering with the hardware were taken out as not relevant. These 5 shot groups are 2″ or better at 50′, which is exceptional for a far sighted and wavering handgun shooter like myself. These were also fired relatively quickly. Typically, the SIG climbs when I shoot, particularly near the end of a long shooting day, so targets typically show vertical stringing. This didn’t happen with the EFK barrel, the gun stayed mostly level and was easy to recover after a shot.

There could have been some extra muzzle flash in front of the site, but I really didn’t notice even in a relatively dark indoor range. The flash obviously came after the shot, so if it was there, it never got in the way of the site picture.

Summary

The EFK Fire Dragon seems to be a good product. I was not put off by the clean up work, it is common in third part barrel installation in almost all pistols of this type…except for Glock, because they are buckets of bolts and plus/minus half an inch is pretty much OK. I wasn’t even put off much by the lack of EFK email response; most manufacturers, and suppliers, ignore email and, no, I don’t know why that is as it makes for an efficient support system.

The EFK Fire Dragon seems to be a good product. I was not put off by the clean up work, it is common in third part barrel installation in almost all pistols of this type…except for Glock, because they are buckets of bolts and plus/minus half an inch is pretty much OK. I wasn’t even put off much by the lack of EFK email response; most manufacturers, and suppliers, ignore email and, no, I don’t know why that is as it makes for an efficient support system.

I would buy another EFK compensator barrel, because it is the most cost effective way to get a compensator barrel and it has the potential to work well and contribute to improved accuracy. In this case, the EFK barrel will be left in place and used as the barrel of choice for the gun. If I didn’t think I could take care of the clean up fitting, I’d still probably buy the barrel, because of it’s unique design, and have a gunsmith do the initial installation. If I didn’t care about the compensator, I’d probably stick with a SIG original equipment carbon steel barrel. They are accurate and I have not encountered one that had to be touched to work properly, and this convenience is worth a few more dollars.

I think I am going to spend a little time and build a good brass catcher. I am so tired of crawling around on range floors recovering brass, or trying to use one of those fishing nets the range calls a brass catcher.

Thanks,

Joe

Email Notification