If you told me that the 444 Marlin is the best cartridge for medium to large game, 50 to 1500 lbs, I would probably say, “Uh-huh“. If you told me the 444 Marlin serves no distinct purpose, I would probably do the same. In a world of cartridges and rifles with so much application overlap, I would say the 444 Marlin warrants neither conclusion. The 444 Marlin is no more, and no less, than another good choice for a medium through big game hunting cartridge and another power cartridge option for the lever action rifle.

The 444 Marlin is a bit like growing up in the 1960s and racing Fords; you could do it and you could win decisively… you just had fewer off the shelf solutions, associated costs were higher and you had to put a lot of yourself into the effort. However, that is only my personal perspective as the 444 Marlin has a large number of very dedicated fans. It is because of that dedication I decided to run this project, probably more for my benefit than for the folks who already know the combination well.

The 444 Marlin is a bit like growing up in the 1960s and racing Fords; you could do it and you could win decisively… you just had fewer off the shelf solutions, associated costs were higher and you had to put a lot of yourself into the effort. However, that is only my personal perspective as the 444 Marlin has a large number of very dedicated fans. It is because of that dedication I decided to run this project, probably more for my benefit than for the folks who already know the combination well.

| Marlin’s 444 Marlin | |

| Origin | Ilion, NY |

| Manufacturer | Remington |

| Order# | 70540 |

| Type | Lever Action |

| Caliber | 444 Marlin |

| Capacity | 4+1 |

| Barrel Length | 22.00″ |

| Micro-Groove Rifling | 1:20″ Ballard Rifling |

| Nominal Weight | 7.0 lbs |

| Overall Length | 40.5″ |

| Stock | American Black Walnut |

| Hardware | Blued Steel |

| Length of Pull | 13 3/8″ |

| Drop at comb | 1.25″ |

| Drop at heel | 2.00″ |

| Sights Rear / Front |

Semi Buckhorn / Hooded Ramped |

| Scope | Receiver Drilled and Tapped |

| Trigger Pull | 5 lbs. 4 oz. |

| Safety | Hammer Block Safety |

| MSRP |

$815.14 |

The original Marlin Model 1895 45-70 was a square bolt Hepburn design produced, or at least shipped from Marlin, from 1895 through 1917. Before the Model 1895 was reintroduced in 1972 as a Model 336 derivative, Marlin offered big bore lever gun enthusiasts the 444 Marlin in 1964. When the Model 1895 was reintroduced with it 45-70 Gov’t chamber, 444 Marlin sales waned and then ended circa 2007 when Remington acquired Marlin and took on the huge task of transitioning manufacturing and retooling all of the Marlin lever action rifles. In 2019, production of the 444 Marlin was resumed to a waiting fan club.

Cartridge Background

Not an upstart, the 444 Marlin is nearly sixty years old. Thomas Robinson, Marlin’s then director of Research and Development and Marlin metallurgist Arthur Burns created the 444 Marlin. It was fashioned from an unfinished 30-06 Springfield case, drawn straight, with its rim turned to a semi-rimmed form. The 444 Marlin case is 0.470″ in diameter above the rim, like the 30-06 Springfield, not 0.457″ like the 44 Remington Magnum. The only thing the 444 Marlin and 44 Magnum have in common is a nominal 0.429″ bullet diameter… sort of like the 30-06 Springfield and 30-30 WCF both having 0.308″ diameter bullets.

Not an upstart, the 444 Marlin is nearly sixty years old. Thomas Robinson, Marlin’s then director of Research and Development and Marlin metallurgist Arthur Burns created the 444 Marlin. It was fashioned from an unfinished 30-06 Springfield case, drawn straight, with its rim turned to a semi-rimmed form. The 444 Marlin case is 0.470″ in diameter above the rim, like the 30-06 Springfield, not 0.457″ like the 44 Remington Magnum. The only thing the 444 Marlin and 44 Magnum have in common is a nominal 0.429″ bullet diameter… sort of like the 30-06 Springfield and 30-30 WCF both having 0.308″ diameter bullets.

Burns presented the cartridge to Remington and Remington’s Earl Larson carried the project through to completion. When? I don’t know for certain, however, I do know that Hornady had a 265 grain bullet available for the 444 Marlin in 1961. The Marlin rifle chambered for the cartridge went into production in 1965.

The cartridge’s appeal might have been dampened by the use of a light 240 grain bullet. A tough 265 grain bullet was not offered by Remington load until 1980 and when it was, it was again with the shepherding of Earl Larson 1).

The 444 Marlin cartridge is often compared to the 45-70 Government. Industry assigned ballistic values: velocity, kinetic energy and trajectory show the 42,000 PSI 444 Marlin to be superior to the standard pressure 28,000 PSI 45-70 Gov’t. Comparing the 444 Marlin to modern high pressure 45-70 Gov’t loads, is a different story where each shows its strength within the bullet weights typically assigned to each cartridge.

The 444 Marlin cartridge is often compared to the 45-70 Government. Industry assigned ballistic values: velocity, kinetic energy and trajectory show the 42,000 PSI 444 Marlin to be superior to the standard pressure 28,000 PSI 45-70 Gov’t. Comparing the 444 Marlin to modern high pressure 45-70 Gov’t loads, is a different story where each shows its strength within the bullet weights typically assigned to each cartridge.

In factory ammunition form, the 444 Marlin holds the up to 265 grain bullet weight range, with the 45-70 Gov’t in +P versions taking 300 grain to 500 grain range. Yes, there is overlap. As an example, the 444 Marlin 265 grain Hornady Superformance and the standard pressure 45-70 Gov’t Hornady 250 grain LeverEvolution occupy the same territory, however, respective velocities are 2400 fps and 2025 fps, with the 444 Marlin coming out on top.

Yes, there are non-SAAMI compliant, high pressure versions of the 300 grain 45-70 Gov’t that nearly match the 444 Marlin’s 444 Marlin’s 265 grain velocity and generate substantially greater kinetic energy. However, the performance comes with a price. An example would be Buffalo Bore 45-70 Magnum for lever guns; 300 grain bullet @ 2,350 fps with 3,678 ft-lbs of kinetic energy at $71.24/box of 20 and recoil and muzzle blast to match end of barrel performance.

The 444 conundrum… and my early Ford race car analogy

There are approximately four factory loads in general distribution for the 444 Marlin; Hornady with two 265 grain loads, Remington with one 240 grain load and Underwood with one 220 grain load. Buffalo Bore offers three; 270 grain, 300 grain and 335 grain. Hornady and Starline produce brass for handloaders. Despite the myriad of 0.429″ – 0.430″ bullets, few have the correct cannelure placement to meet the Marlin rifle’s recommended maximum overall cartridge length of 2.550″. Additionally, most o.429″ bullets are intended for use with the 44 Remington Magnum and are not designed to work properly with at the velocity levels attained by the 444 Marlin.

There are approximately forty-one factory loads for the 45-70 Gov’t, a composite of twelve brands, and the same suppliers of brass. Three are approximately one hundred eighty-eight 0.458″ bullets with approximately thirty-five with proper cannelure placement, flat nose and proper construction for 45-70 Gov’t high performance loads in concert with lever action rifles. Where the 444 Marlin was a new exploration requiring new bullets, new brass, new rifles, and education of a market place, the 45-70 was reintroduced at Marlin, it arrived to a waiting existing base of long term users, ammunition and components. The 45-70 Gov’t lever action arrived with market inertia and kept building from there.

General construction of the Marlin lever action

Photos taken from an earlier Marlin Model 336 35 Remington project. All of the part and system arrangements depicted are the same as the 444 Marlin and all Model 336 derivative products.

In terms of safety mechanisms and subsystems, in 1984, the use of the half cock position as the rifle’s only manual safety was discontinued when a hammer block safety was added. In addition to manual safeties, passive safeties remain. The trigger disconnector prevents the trigger from being pulled until the lever is completely closed and compressing the disconnector.

The Marlin 336 design utilizes a two piece firing pin, cleverly identified as rear firing pin and front firing pin. With the lever down, the rear firing pin is spring loaded down at an angle to prevent it from passing through the center of the bolt and driving the front firing pin into the primer of a chambered round. With the lever closed and the bolt pulled into battery, the locking block raises the rear firing pin into alignment with the front firing pin. In that alignment, when the hammer falls, the rear firing pin is driven into the front firing pin and into the primer of a chambered round.

Within the scheme of things, the brunt of the bolt thrust is taken by the Marlin’s locking block as set into the bolt body and receiver. The lever, lever cam and lever pivot hold the locking bolt in engagement and unlock and unlock and cycle the action. While the action is strong, I self limit handloads to pressures to the 40,000 PSI range.

The Marlin lever action is relatively easy to take down and to finesse. The adjusting plate can be easily reformed to increase or decrease tension and Wolff Springs offers a selection of reduced and extra power hammer springs that influence trigger pull. With fixtures, stones and a little patience, the factory trigger can be refined to product a clean, sub 4 lb trigger pull.

The Marlin factory sights are ramped, hooded front with brass bead and folding semi buckhorn rear. I’ve been shooting through Marlin factory sights for 100 +/- yard deer hunting for 60 + years… gees I’m old, and I have never needed more. That does not mean I do not mean I don’t use enhanced sighting systems to make life easier and kills more certain. Sometimes the change is as easy as putting a window in the top of the hood to bring light to the bead or pinning the hood to stay put under heavy recoil or passes through brush. Sometimes it is the installation of fiber optic sights. None of the changes are necessary, but they are convenient.

For the sake of fair mechanical accuracy assessment, a scope was mounted. In this case, Warne bases were used.

Warne low rings, with the Marlin’s rear sight folded down, leave a sliver a daylight between the scope’s objective bell and the rear sight leaf. The set up is low enough to keep the shooter’s head down and not bobblehead height above the stock’s comb, and set the scope back far enough for comfortable rested bench work.

Potential

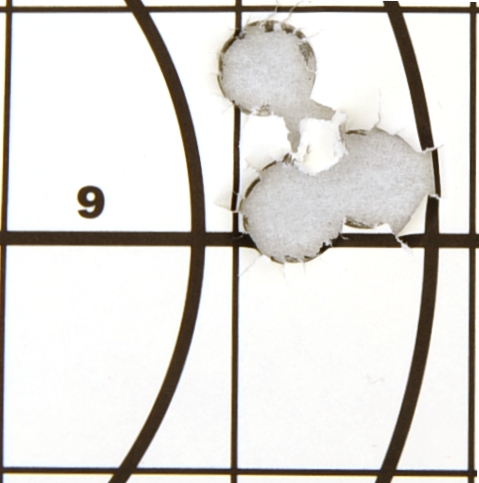

Within the scope of this project, there was much interest in factory ammunition. Not because it isn’t good, but because the interest favored heavier bullet weights and the processes necessary to accommodate them. However, four of one type of factory rounds were fired; one over the chronograph and three at a target, the first ammunition through the Ballard rifled barrel and from a cold barrel.

The ammo was Buffalo Bore 270 grain jacketed flat nose rated at 2,250 fps. The ammo clocked 2,314 fps from the Marlin’s 22″ barrel and the center to center farthest holes in the 100 yard group measured 0.66″.

Email Notification