In the old days, if you wanted to know the hardness of lead, or the legitimacy of gold currency, you bit the object. Then you’d take stock of how much your jaw hurt, the depth of your teeth marks in the object, and arrived at a conclusion – probably that we were in need of a good dentist. When you purchased ready made bullets or ammunition from Wild Earl’s Flying Lead Emporium you assumed Earl, or one of his minions, conducted at least the same comprehensive testing. Eventually, the reliability of some tests and the legitimacy of others were called into question when cast bullets occasionally melted in boxes on warm days or penetrated tank armor. An inability to test lead hardness when casting bullets from alloy of an unknown source is a handicap, not unlike the blind spot that exists when handloading ammo without the ability to measure pressure – it can be done, but most people are kidding themselves when they believe they can estimate either of these factors without proper tools to periodically substantiate the results. Cast bullet hardness effects handload pressures, barrel leading and terminal ballistics in terms of penetration, retained weight and wound channel.

In the old days, if you wanted to know the hardness of lead, or the legitimacy of gold currency, you bit the object. Then you’d take stock of how much your jaw hurt, the depth of your teeth marks in the object, and arrived at a conclusion – probably that we were in need of a good dentist. When you purchased ready made bullets or ammunition from Wild Earl’s Flying Lead Emporium you assumed Earl, or one of his minions, conducted at least the same comprehensive testing. Eventually, the reliability of some tests and the legitimacy of others were called into question when cast bullets occasionally melted in boxes on warm days or penetrated tank armor. An inability to test lead hardness when casting bullets from alloy of an unknown source is a handicap, not unlike the blind spot that exists when handloading ammo without the ability to measure pressure – it can be done, but most people are kidding themselves when they believe they can estimate either of these factors without proper tools to periodically substantiate the results. Cast bullet hardness effects handload pressures, barrel leading and terminal ballistics in terms of penetration, retained weight and wound channel.

Oh, those wacky Swedes

Somewhere between 1882 and the Paris Expo of 1900, Johan August Brinell, an employee of Sweden’s Fagersta Ironworks, devised a metal hardness test which he thoughtfully named after himself. Alright Johan! In concept, material hardness is its quantified resistance to plastic deformation. Brinell Hardness is determined by forcing a hardened steel or carbide ball of known diameter under a known load into a material’s surface and measuring the diameter of the indentation with a microscope. A Brinell Hardness Number is obtained by dividing the load, in kilograms, by the spherical area of the indentation in square millimeters. Alternatively, for $70, the process can be made a whole lot simpler with a Lee Hardness Tester. The Lee tester is comprised of (Above L-R) a calibrated hardened steel ball indenter, a V Block Cradle and a 20x optical microscope.

But when I shake it, I hear stuff moving around inside…

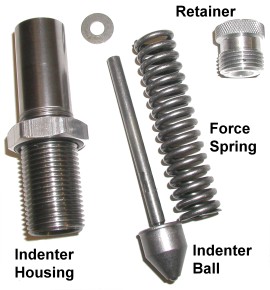

Looks can be deceiving. What looks like a die with a fixed ball point tip, is actually a an indenter ball that is preloaded with a spring within the indenter housing. When inserted in a reloading press, and placed under controlled load against lead alloy being tested, 60 lbs of force are exerted.

Looks can be deceiving. What looks like a die with a fixed ball point tip, is actually a an indenter ball that is preloaded with a spring within the indenter housing. When inserted in a reloading press, and placed under controlled load against lead alloy being tested, 60 lbs of force are exerted.

Commercial Brinell test equipment would commonly utilize a 10mm indenter ball and the load force would be 500 Kilograms. Unfortunately, 10mm is as large as, or larger than, most lead bullets and it would be necessary to keep a gorilla in a cage to apply the force; and arrangement that might not be practical in a home shop. By proportionally scaling down the ball and the force, Lee Precision was able to package a perfectly accurate and practical tester in a small package. I measured the steel ball to be approximately .156″ in diameter, a sized reduced from typical which allows a corresponding reduction in force to 60 lbs, a combination easy to handle in a reloading press.

“But it must be complicated to use!”. Glad you asked, stranger…

It takes only a few minutes to set up the tester. The Indenter is screwed into the die holder, the installed height is not critical as long as the indenter ball can reach the test bullet. The V Block slips into position like a shell holder, although I found I had to remove the retaining spring clip from the ram. This last step was not required with my turret press.

Instructions for the tester indicate a flat is to be filed on the side of the test bullet for a contact surface. The initial bullet I tested was a Cast Performance item advertised as heat treated to a BHN 16~21. I wasn’t sure how deep the heat treating went, and I didn’t want to remove too much material and get an erroneous reading. For reference, wheel weight alloy has a BHN of 9, linotype has a hardness of BHN 22, pure lead is BHN 5.

Heat treating is an easy way to get to a surface hard cast from a softer alloy recipe. The radius of the .458″ bullet is large so there is plenty of surface for the indenter ball to make contact, however, I did take two measurements; one without the flat and one with, so I could compare the two and see if filing away the surface made for a different BHN result. The flat cut was approximately .008″ deep and the readings were the same. Lee cautions to never check hardness at the base of a bullet as this surface is frequently significantly softer than the sides or nose. The base is typically used to the support the bullet in process, such as hardening, and may not be subjected to the same temperatures and treatment.

Controlling applied force…

The indenter housing has a through hole in the retaining cap. As pressure is exerted on the indenter ball, it compresses against the internal spring, pushing the indenter ball shaft up through the hole in the retaining cap. When the end of the indenter ball shaft is flush with the cap, it is held in place 30 seconds. The approximately 60 lbs of spring pressure is pretty easy to overcome with the mechanical advantage of the reloading press, care must be taken not to apply too much pressure. Generally, more than 1/64″ shaft protrusion through the retaining cap means the indenter ball was too heavily loaded and the test in invalid. I checked perhaps 20 – 30 bullets and did not encounter this problem.

The indenter housing has a through hole in the retaining cap. As pressure is exerted on the indenter ball, it compresses against the internal spring, pushing the indenter ball shaft up through the hole in the retaining cap. When the end of the indenter ball shaft is flush with the cap, it is held in place 30 seconds. The approximately 60 lbs of spring pressure is pretty easy to overcome with the mechanical advantage of the reloading press, care must be taken not to apply too much pressure. Generally, more than 1/64″ shaft protrusion through the retaining cap means the indenter ball was too heavily loaded and the test in invalid. I checked perhaps 20 – 30 bullets and did not encounter this problem.

Like reading isn’t hard enough…

The indent left by the process in the test bullet is small enough to require a magnifying optical comparator to measure its size. The included 20x microscope contains a scale reticle, not unlike the one that appears in a range finding rifle scope, that is used to acquire this measurement. The scale is .100″ long and is divided into .002″ increments.

The operator puts the nose of the microscope against the bullet, over the indentation, with the open side of the tip facing up to gather light. The reticle scale is then placed to overlay the indent, like a miniature ruler, and a measurement is taken. The measurement is than compared to the enclosed conversion chart and the corresponding BHN.

The “Brinell Hardness and Maximum Pressure Chart”, checked by calculation, provides very accurate conversion information from indent measurement to BHN and, with access to a certified digital scale that will cover the 60 lb applied force range, it is pretty easy to check tester calibration. The only piece of information in the chart I might question is the “Max PSI” column. I am not sure if the reference is an issue of gas cutting, or bore leading. According to the chart, a very popular #2 alloy carries a 16 BHN, has a strength indictor of 22,703 PSI and should be limited to 20,000 PSI as maximum pressure. Wheel weight alloy with a BHN of 9 carries a strength of 12,748 PSI and a MAX pressure rating of 11,473 PSI. The terminology is a little vague. Is this peak, max average, sustained for some period of time? I assume, because there is no reference to terminal velocity, this is a material yield strength and based on calculation; single digit odd numbers at the end of a number expressed in multiple tens of thousands. I believe this portion of the information isn’t particularly authoritative in determining limitations*.

The “Brinell Hardness and Maximum Pressure Chart”, checked by calculation, provides very accurate conversion information from indent measurement to BHN and, with access to a certified digital scale that will cover the 60 lb applied force range, it is pretty easy to check tester calibration. The only piece of information in the chart I might question is the “Max PSI” column. I am not sure if the reference is an issue of gas cutting, or bore leading. According to the chart, a very popular #2 alloy carries a 16 BHN, has a strength indictor of 22,703 PSI and should be limited to 20,000 PSI as maximum pressure. Wheel weight alloy with a BHN of 9 carries a strength of 12,748 PSI and a MAX pressure rating of 11,473 PSI. The terminology is a little vague. Is this peak, max average, sustained for some period of time? I assume, because there is no reference to terminal velocity, this is a material yield strength and based on calculation; single digit odd numbers at the end of a number expressed in multiple tens of thousands. I believe this portion of the information isn’t particularly authoritative in determining limitations*.

(* While the slip sheet does not present the detail behind the “Max PSI” entries, the basis is well defined in detail in “Modern Reloading” 2nd edition Chapter 10, page 129. Many thanks to RPJ for bringing this to my attention. Comment Added 10-13-05)

What are typical hardness levels?

On the left are examples, L-R of Oregon Trail Bullet Company’s Lasercast, Cast Performance and Meister bullets. They are good quality product that I probably push a little more than intended and have not had bullet failures or excessive leading. The BHN value is:

Oregon Trail Lasercast BHN 16.6

Cast Performance BHN 20.9

Meister BHN 16.6

I checked some of my own recycled wheel weight bullets with some added alloy for hardness and they came in at 14.4. My oven heat treated hard cast bullets were in the 27-28 range depending on lot tested. I use the latter in full tilt 45-70 loads and knock around 358-378 RG loads.

I’m not really making a pitch for certain hardness levels, I think that selection should be dictated by a shooter’s experience and the specific application. The point is, the Lee Hardness Tester puts more control in an individual’s hands; better control of bullet casting projects, verification of purchased cast bullets and better assessment of what works, or not, when hunting or target shooting. An excellent product and a typical Lee value.

Some related information on Real Guns:

Casting bullets and selecting fire extinguishers Part I

Casting bullets and selecting fire extinguishers Part II

Casting bullets and selecting fire extinguishers Part III

Casting bullets and selecting fire extinguishers – Conclusion

45-70 Cast Bullet Handloads

45-70 Cast Bullet Handload Data

Email Notification