Experienced handloaders recommend Lee products to novice handloaders all of the time. The price is always right, the equipment is innovative in design and frequently Lee is sold in all-in-one kits that make it easy to get started. $69 will get you a complete single stage reloading kit; add dies, cartridge components and you’re ready to roll. For another $20 you can get the same all inclusive kit, only built around an auto indexing turret press. Lee Precision also offers enhanced and automated products for production and commercial handloaders, each supported with a long list of standard and specialized dies and accessories. While more expensive than entry level products, they are still an excellent value.

I have a retired RCBS Ammo Master Progressive that had been in heavy use for a number of years. It was expensive to change over to accommodate different cartridges and the combination of heavy rotating mass of the steel shell holders, and in-progress ammo, would frequently cause it to overshoot indexed positions. I’d have to clear the jams and check for double or missing powder charges, then work backward in the cartridge sequence until everything was in sync again, then finish by cleaning up the spilled contents. These problems, and an inability to easily work outside of the press’ progressive sequence, caused me to finally pack it in and move to a manual RCBS Turret press, or Rock Chucker single stage press. These work find when I am assembling a box or two of ammo, or doing load development with lots of short runs, but both are too slow for production. In review, the Lee Classic Turret Press seemed to combine the best of both worlds, auto indexing progressive operation and turret design in a very compact and sturdy package, so I bought one.

The Classic, like a standard Lee turret press, but on steroids

If you are familiar with the standard 4 Hole Lee Turret Press, there are some significant differences. Most of them are obvious; the Classic model ram is 1.125″ outside diameter, where the standard model ram is roughly .825″. The bearing surface within the Classic base casting is 3/8″ longer for greater support. The base of the standard is a light die cast alloy, the Classic base is heavy cast iron. The Standard press linkage is a steel stamping, by comparison the steel linkage is stout; .170″ and .400″ respectively. The posts that support the die head on the Classic are .630″ in diameter and .560″ on the standard. The Classic has 4.5″ of cartridge clearance, the standard has 3.5″

Does this mean the standard four holt turret is a substandard product? Certainly not, it is a good production press and certainly capable of holding up under hard use. It only means that if you are evaluating brands of turret presses that are more substantial than the standard Lee Precision model, or if you need longer cartridge capacity or something you can lean on a little heavier for case sizing or forming, the Classic is a solution within the Lee Precision product line.

If you like the way machinery is put together, Lee Equipment is worth looking at more closely. There are interesting design and manufacturing approaches that are quite different from other brands. Sometimes it’s fun to try to guess the underlying logic. While the RCBS base is larger in area, the arrow shaped base of the Lee unit with its perimeter rib makes for a strong level but compliant surface. In addition, the far aft bolt anchors directly against the primary force applied to the press.

If you like the way machinery is put together, Lee Equipment is worth looking at more closely. There are interesting design and manufacturing approaches that are quite different from other brands. Sometimes it’s fun to try to guess the underlying logic. While the RCBS base is larger in area, the arrow shaped base of the Lee unit with its perimeter rib makes for a strong level but compliant surface. In addition, the far aft bolt anchors directly against the primary force applied to the press.

Turret Construction and Mounting

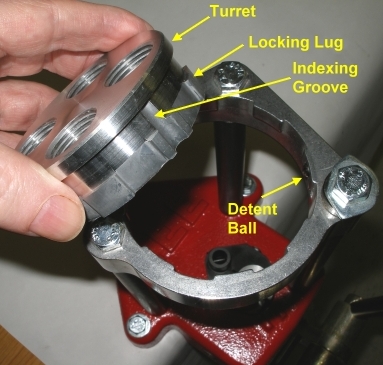

This is just good engineering. The turret, or die head, drops into the turret ring and is locked in by the locking lugs on the turret and turret ring. The turret ring retains the turret all the way around for full support against the vertical and upward force of sizing cases, seating bullets, etc. A shaft driven by the moving ram rotates the turret and dies in one station increments with each actuation. Optionally, the shaft, or “square index rod” can be popped out, a three second exercise, allowing the press to be indexed manually.

The turret is a substantial piece of machined aluminum that is heavy enough to withstand any pressure that might be applied, but light enough to not overrun the detents and cause misalignment between dies and cartridge.

Most turret presses mount the turret or die head like an umbrella as illustrated by the RCBS turret press on the right. In this design the turret head needs to be of a larger diameter to allow for the center mount bolt and the six die positions located around the outside. IN operation the distance from center will multiply the ram force exerted on the turret center bolt, and on the spring loaded ball that keeps the turret in horizontal alignment.

The Lee Turret is supported all around the outside by the turret ring, the dies are located directly over the ram and close to the retaining turret ring. With no center mounting bolt, the dies can be located closer together which contributes to the overall compact design.

The RCBS press is beefy and will no doubt hold down more paper than the Lee unit, but little of that weight goes to strength, it mostly goes to making up for a less optimal design. The shipping weight for the RCBS is 20 lbs, the Lee Turret 13.4.

The Lee Turret has lots of capacity. That is a 358-378RG wildcat in the shell holder, a slightly necked down full length 378 Weatherby Magnum case. Due to its 3.75″ length, I had to remove the index rod that drives auto indexing and index the turret manually. This is an exceptional length for a cartridge. By comparison, cartridges like a 3.300″ 7 mm Remington Magnum and shorter WSM series can be processed in auto index mode. Lee makes the comment on their web site that the press, by removing the indexing rod, can handle cases as long as the .50 BMG round. The comment has led many people to believe the press has a conversion kit available for the 50 BMG, however, it does not as the turret head is limited to 7/8″ thread capacity and not the 1¼” required for 50 BMG. Perhaps Lee might consider removing the “50 BMG” reference to avoid confusion as it has no relevance to the use of the press.

Straight wall cases require an expander step to open the mouth to the correct size, so most sets are three dies. Add a factory crimp die as would be common practice and you’re out of turret stations with no room for a powder measure. Three dies sets from Lee incorporate a “powder through” expander die that allows powder to enter the case through the top of the die. When used with a press mounted Auto-Disk Powder measure, the upstroke of the case into the expander die actuates the powder measure. Lee also produces an adapter to install in the press to trigger powder dispensing when 2 die rifle sets are installed, however, I am assuming this feature is limited to small capacity rifle cases.

Primers and Drivers

The index clamp is fixed to the ram. The index rod runs through the clamp and it is keyed into the turret at the top. When the ram is raised, the clamp is forced up the twisted portion of the index rod, forcing the rod to rotate and index the turret to the next position. Neato. For manual operation of the turret the index rod is removed.

This is what the LPS Primer Arm looks like out of the press. A large and small primer version are included and just drop into place before the shell holder is installed. It is a very simple and reliable system of priming on the press that will be covered in the operational check out part of this short series, hopefully, along with a more automated Lee Safety Prime System optional accessory for this press. I don’t care for handling individual primers, it is too easy to contaminate the material.

Die Sets

I decided I would check out the operation of the press and quality of output with several dies sets; 17-357RG which has numerous case forming steps, the 358-378RG with heavy charges and heavy bullets and the 45 Colt.

The first two are custom die sets from CH4D, the third is a Deluxe pistol die set made by Lee. The 45 Colt die set is comprised of a sizer/decapper, an expander, a bullet seater, a factory crimp die, a shell holder and a small powder measure. I am eager to see how this set sizes 45 Colt brass as most other brands size well under and excessively work the brass I wanted a couple of dimensional extremes and one typical case to test the press and accessory limits.

Conclusions So Far

So far I am pretty impressed with the Lee Classic Turret Press. It is a solid and well thought out piece of equipment that seems to have integrated well into my mixed equipment shop. It has a small footprint, handles long brass and works with any of the die sets I have in house. I did run a couple of rounds through it just to verify how things worked and, so far, no disappointments. In fact, I am looking forward to cranking out some production right along side of the RCBS Turret press to see how the output compares. I will hold off any further comment until I have a sufficient amount of operating experience.

The Lee Classic Turret Press sells for $79 at major online retailers. The Colt Deluxe Pistol Die Set that includes a factory crimp doe runs about $28. By comparison, the RCBS press is $167 similarly equipped from the same sources.

For more related information:

Lee Classic Turret Press Part I – Lee Equipment – It’s not just for Kids

Lee Classic Turret Press Part II – Form Follows Function – A closer Look

Lee Classic Turret Press Part III – It’s Pretty, But Does it Make Good Ammo?

Thanks,

Joe

Email Notification