Establishing a baseline…

Before embarking on a handload development project with an unfamiliar firearm and cartridge combination, I record the gun’s performance with factory ammunition. The gathered data aids in setting reasonable expectations for handload velocity and the range time gives me a sense of the combination’s accuracy, muzzle blast levels, felt recoil, etc. Factory published external velocity is a also a useful gauge, however, the firearm or universal receiver and test barrel employed while obtaining this data may be quite different from the object of a handloading effort. Within the ammo selection for this project, Hornady referenced a 7″ barrel, Speer a 6 1/2″ and Federal a 4″ vented barrel. The reason for utilizing barrels of varying length is not to be deceptive, but rather each manufacturer’s attempt to use a test setup that approximates the probable use of their product. Long barrels are typically employed for testing hunting loads and the short barrels are consistent with law enforcement duty revolvers. Of course the 1550 fps velocity achieved from a 7″ barrel for a specific cartridge isn’t going to materialize when fired from a 2 1/2″ snub nose.

Factory ammo and chronograph results…

I may be living in 2007, however, my sense for prices is firmly planted in 1987. Consequently, price sticker shock is my constant companion. In cases where factory ammo prices have remained relatively constant over the years, box content has shrunken from 50 to 20 cartridges. The selection below was arbitrary, however, hopefully not capricious as I did try for a cross section of ammo types; Federal was selected specifically because of the “Short barrel” designation reflecting a 4″ barrel, Hornady and Speer for bullet type and weight and Precision Cartridge specifically for the light frangible bullet.

Precision Cartridge quickly proved to be less than exciting. When received, I noted the box was marked remanufactured (reloaded) ammo, a fact that was not noted on the Graf & Son site where it was purchased, but verified as box marked with a phone call to the manufacturing company. Considering this is reloaded brass, and the manufacturer does not pay an 11% excise tax on production, Precision Cartridge ammo isn’t much of a bargain. Compared to its $25 per box of 50 price, newly manufactured Fiocchi 200 grain JHP is $23/50, American Triton 240 grain JHP is only $20/50. I had written to Graf and suggested they note Precision Cartridge is remanufactured ammo on their web site. There was a brief, friendly, but evasive exchange that left Graf with the simple question to answer, “Is this or is this not new ammunition ?”. If they respond, I’ll post an update.

|

Factory Ammunition Performance |

||||||||

|

|

||||||||

| Manufacturer | Product | Bullet Type | Weight Grains |

Ref BBL Length |

Mfg MV* |

4″ BBL MV* |

Δ | Retail Cost |

| Hornady | Custom | JHP/XTP | 180 | 7 | 1550 | 1524 | -26 | $16/20 |

| Federal | Classic | Hi-Shok JHP | 180 | 4-V | 1490 | 1447 | -43 | $17/20 |

| Precision Cartridge | Frangible | Flat Point | 185 | – | – | 1301 | – | $25/50 |

| Federal | Fusion | JHP | 240 | 4-V | 1290 | 1246 | -44 | $17/20 |

| Speer | GoldDot | GDSP | 270 | 6.5 | 1250 | 1097 | -153 | $21/20 |

|

*Note – Actual Taurus chronograph results. |

||||||||

The comparison to factory published velocity data was interesting. The greatest barrel length differential, test barrel compared to Taurus, reflected the least difference in velocity. Common barrel length, test and Taurus, was within 3% or so of one another. Speer GoldDot wasn’t exciting by comparison, but I think this difference is closer to expectation for 2 ½” barrel difference in a revolver. Generally, the Hornady performance gave cause to be optimistic about handload potential in the short barrel, the heavy GoldDot gave cause to concern. I started poking around in my 460 Rowland and heavy 45 Colt load data and realized the 4″ barrel Taurus would only trump those cartridges if I could safely edge up on 1100 fps with 300 grain loads. I am not as comfortable straying from handload data with a revolver as I might be with other firearms, however, the Taurus Model 44 with 0.090″ thick cylinder walls at the thinnest point is pretty beefy. By comparison, the medium frame S&W 7 shot 357 Magnum model 619 and 620 cylinders are only 0.055″ thick with equal sacrifice to cylinder stop notches.

Shooting impressions…

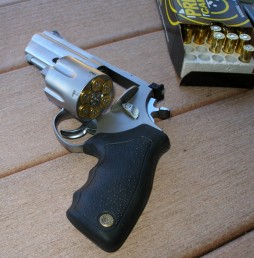

The first shot with 185 grain Precision Cartridge frangible loads left me thinking there had to be more. Muzzle jump wasn’t significant, report could be classified the same and recoil was on par with some of my lesser cartridge handguns. I went on to put 18 rounds of mixed ammo into 4″ at 25 yards from a two hand supported standing position. The best groups came from Hornady and Federal Fusion, both under 2 ” at 25 yards. GoldDot was close at than 2 ½”.

The first shot with 185 grain Precision Cartridge frangible loads left me thinking there had to be more. Muzzle jump wasn’t significant, report could be classified the same and recoil was on par with some of my lesser cartridge handguns. I went on to put 18 rounds of mixed ammo into 4″ at 25 yards from a two hand supported standing position. The best groups came from Hornady and Federal Fusion, both under 2 ” at 25 yards. GoldDot was close at than 2 ½”.

Hornady and Federal Classic raised the ante on the three basic firearm food groups; report, recoil and muzzle blast. Ambient temperature was 40°F, my fingers were less than flexible and I began to experience a stinging, numbing sensation in my trigger finger. Still, the soft rubber grips, for as narrow as they are, absorbed recoil and there was no discomfort felt in my wrist or arm. The gun remained very controllable. Federal Fusion reminded me that the 44 Remington Magnum was not a trivial cartridge. Muzzle blast was still manageable, report was upped a little, but recoil was ratcheted up a bit and I began to feel the hard edge of the narrow grip against the palm of my hand with each subsequent shot. I thought it might be accumulative smacking, but the Speer 270 grain that followed felt quite mild, recoiling about the same as the 180 grain Hornady ammo.

After 100+ rounds the Taurus was as tight as when it came out of the box. No screws shot loose, the rear sight adjustment was positive and it stayed put. The barrel vents sort of toasted the sides of the front sight, but not the bright orange ramp; sight visibility was very good. The ejector rod stopped 3/8″ short of case length, always leaving the inside 3 cases to be pulled out the rest of the way, the outside 3 always fell free. Cylinder gap increased to 0.004″, or +0.001″ after the first 20 rounds or so, but grew no greater. Trigger pull and feel began as excellent and ended the same.

I really like this gun. more than other revolvers I own, including my Ruger SA gun, however, I still like my 1911 type guns better because I can’t shoot the 44 magnum as well. This 44 Mag is more friendly to shoot than a small alloy from S&W 38 Special. I’m looking forward to shooting the Taurus a whole lot more and I believe my double action shooting will greatly improve.

Deaf deer? My shooting is so bad she felt safe? My shooting was so good I wouldn’t accidentally hit her? Wildlife can be unpredictable. I was knocking off shots in pretty rapid succession when my wife tapped me on the shoulder and pointed to the deer that was causally feeding just above the low dirt backstop. She seemed absolutely not phased by the noise or the motion and was nice enough to pose while I took this picture. Then someone opened and closed a car door in the parking lot and she bolted. Go figure. I’m not sure what kind of range they are operating is Los Altos. Deer run past the 100 yard targets during live fire and flocks of turkey cross in the parking lot. Very strange indeed, being outdoors and encountering animals.

Deaf deer? My shooting is so bad she felt safe? My shooting was so good I wouldn’t accidentally hit her? Wildlife can be unpredictable. I was knocking off shots in pretty rapid succession when my wife tapped me on the shoulder and pointed to the deer that was causally feeding just above the low dirt backstop. She seemed absolutely not phased by the noise or the motion and was nice enough to pose while I took this picture. Then someone opened and closed a car door in the parking lot and she bolted. Go figure. I’m not sure what kind of range they are operating is Los Altos. Deer run past the 100 yard targets during live fire and flocks of turkey cross in the parking lot. Very strange indeed, being outdoors and encountering animals.

My wife and I spend a lot of time at the range together. We complain about our children, express happiness with our perfect grandchildren and get a break from other pressing matters. Diane had a chance to empty a few cylinders of 44 mag and she liked the heft and balance of the Taurus also. I’ve lost ownership of more guns that way.

I have three holsters, mostly because I don’t use my handguns enough in a fashion that warrants this further investment; a great shoulder holster rig for a very nice 1911, a paddle holster for my P229 SIG and now a tactical holster for the Taurus purchased from West Woods Landing. For $57 I received a lined nylon belt holster with adjustable thumb break and tactical leg straps. I think it will make a great field rig that offers protection to the revolver, but won’t require opening a coat in the dead of winter to get to the gun. The holster set up is sturdy, but very light and requires no maintenance. Best of all it fits the Taurus like a glove. I placed an order, received an email confirmation and three days later it showed up via Priority mail, following the adjustment instructions the set up was ready to go in a few minutes. The holster can also be secured directly to the belt if I get tired of the TAC carry. Now if I can just get status on the fancy wood grips I ordered from Hogue the same day as I ordered the holster…

A man in need of a plan…

Warning: The following material may be confusing, wandering, rambling, and possibly frightening. It is a transcription of me thinking out loud as I try to navigate from ride home from the range to the next trip with handloads.

A word or term will always come to mind that represents the substance of a project. The previous project was “Noamo”, which we of course know is Spanish for “without ammunition”. The term for this project is “counter intuitive”. It is my belief power begins with velocity; double the velocity and the resulting energy is quadrupled. Plus, brief time in flight means extended point blank range, a bullet that thumbs its nose at gravity so my inability to judge distances won’t be so obvious. Therein lies the dilemma; a short barrel handgun and stubby cartridge hardly coexist comfortably with the descriptive terms “high velocity”, “flat shooting” or even “hard hitting”.

A word or term will always come to mind that represents the substance of a project. The previous project was “Noamo”, which we of course know is Spanish for “without ammunition”. The term for this project is “counter intuitive”. It is my belief power begins with velocity; double the velocity and the resulting energy is quadrupled. Plus, brief time in flight means extended point blank range, a bullet that thumbs its nose at gravity so my inability to judge distances won’t be so obvious. Therein lies the dilemma; a short barrel handgun and stubby cartridge hardly coexist comfortably with the descriptive terms “high velocity”, “flat shooting” or even “hard hitting”.

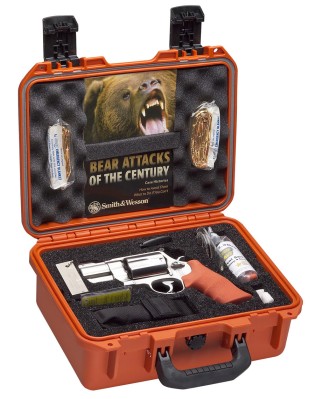

There is nothing wrong with having fun, and the recreational use of handguns has no specific firearm performance requirement. I indicated in the first of this series I felt the 44 Remington Magnum was the upper limit for a relatively short barrel revolver. The $1,400 piece of marketing wonder, pictured right, is the type of extreme I wanted to avoid. The S&W 500ES is a 55 ounce revolver with a 2 ¾” barrel, chambered for the 500 S&W magnum. Most people would associate the 63 grain capacity case, about 6 grains greater than the 308 Winchester, with an 18″-20″ minimum barrel length. I began the paragraph with the comment there is nothing wrong with having fun, but I can’t help but feel the overall packaging of this firearm, with whistle, signal mirror, stories of bear attacks and mostly worthless paraphernalia would be more embarrassing for a gun owner than entertaining. Everything about the firearm is the opposite of what is required for a cartridge of this type to serve any purpose. I have no idea where the trend of 2 ½” big bore revolvers labeled “Alaskan” came from, other than (as Wayne Campbell might say) from marketing department personnel shooting monkeys out of their collective butts. Unless the proud X Frame owner intends to toast a bear to death, or put himself out of his own misery while being mauled by a 1000 pound bear, how would this stubby gun work ? This is where I felt the project was drifting with the 4″ barrel Taurus. For as much as I liked the idea of a 4″ revolver with the power of a 44 Magnum, preliminary range data and a pile of handload data was telling me the combination could not outshoot my 460 Rowland autoloader. Perhaps it was the anxiety of reality was sinking in. I own no rifles chambered for Weatherby cartridges with less than 26″ barrels, I would not build a 375 H&H with a 20″ barrel, and the big pick up with a long barrel gun chambered for a magnum cartridge is heavy bullet performance, not barrel frying lightweights. Hmm…could it be the same laws of physics apply to rifles AND handguns? All great thoughts, which I immediately set aside, mostly because they conflicted with what I would rather believe. Living in denial is sometimes the most important component of handloading.

All I wanted was a useful firearm & cartridge combination that did not blind me with muzzle flash and frighten wildlife. I wanted to maybe even use it for a black bear or hog hunt, I wanted to use it when out hiking and taking pictures and maybe for some enjoyable recreational target shooting that would not result in my arm being wrapped in a sling. More so, despite the many miles of print that have been written regarding this type of combination, I needed to pick and poke at the subject for myself until I understood the dynamics and I could arrive at my own conclusions. Yes, I know I could have just asked NRA Life Time Member, Taffypull47 on the message boards at pookiebear.com, but I was not really looking for an instant answer from an anonymous source, I was looking forward to the enjoyment of gaining experience with a firearm-cartridge combination that is new to me, and the satisfaction of figuring it out for myself. Brain cells – use ’em or lose ’em. And so I pressed on in my long journey into tedium and minutia…

Brass selection is critical…

I like Starline brand brass. Like any good gasket material it’s appropriately soft, expands and seals well, recovers malleability when annealed, resizes without a fuss, and holds up to high pressures. Still, without much deliberation, I purchased Remington brass because it was on sale. As a practical matter, brass from any mainstream manufacturer will work as well. C26000 alloy, cartridge brass, with very minor variations is 67-70% copper, 30-33 % Zinc, with a trace content of lead and iron. Variation amongst manufacturers usually relates to material and process hardness.

I like Starline brand brass. Like any good gasket material it’s appropriately soft, expands and seals well, recovers malleability when annealed, resizes without a fuss, and holds up to high pressures. Still, without much deliberation, I purchased Remington brass because it was on sale. As a practical matter, brass from any mainstream manufacturer will work as well. C26000 alloy, cartridge brass, with very minor variations is 67-70% copper, 30-33 % Zinc, with a trace content of lead and iron. Variation amongst manufacturers usually relates to material and process hardness.

The nominal dimensions for the 44 Remington Magnum are: 1.285″ long, 0.457″ diameter immediately ahead of the rim and 0.456″ at the case mouth. The new Remington brass measured 1.279″ long, 0.453″ ahead of the rim and 0.453″ at the case mouth and well within any tolerance identified on a SAAMI drawing. Of course, these dimensions only needed to be close as the brass would be hammered mercilessly under many thousands of pounds of pressure until it conformed with the inside dimensions of one of the six chambers of the Taurus and, hopefully, not much more. To put this last comment in context, fresh Hornady cartridges measure 0.454″ forward of the rim, 0.453″ at the case mouth and 1.270″ in length. A fired version of the same measured 0.455″ forward of the rim, 0.458″ at the case mouth and 1.265″ in length. Of course all of this doesn’t matter, once again, because fired brass is reconstituted by a sizer die to the minimum end of the case dimensional spec, and the whole cycle begins all over again. Sort of like the movie “Ground Hog Day”, only without Bill Murray but, probably, with greater entertainment value. Gees that movie was a stinker.

The historical reason given for the 0.120″ increase in the 44 Magnum case over the 44 Special is that the extra length prevents the magnum from being chambered in weaker 44 Special firearms. The increase volume over the original Special was unnecessary as the Special was considered to have more than enough capacity for any reasonable powder charge. That may have been true when Elmer Keith was pushing 17 – 18 grains of 2400 through guns designed for 44 Special pressure levels, but this capacity would not have been enough for magnum loads of W296 or H110 in firearms designed specifically for the 44 Remington Magnum. The 44 Magnum case has an overflow capacity of approximately 39 grains, a net capacity of 22 grains under a long 300 grain bullet, 27 grains with a 240 grain bullet, 30 grains with a 180 grain bullet. By design, or fortunate circumstance, the 44 Magnum has enough capacity for the slowest useful powder for each bullet weight.

Weight watchers and handloading…

My preferred method of weighing brass is to stand on a bathroom scale, record the reading, then let an assistant hand me a bulk box of brass, then record the reading again. Then I have the assistant empty the brass from the box, hand the empty box to me, then record that reading. Then I count the brass and subtract and divide like crazy until I am pretty confident I have wasted enough time weighing brass and I move on to a more useful activity.

My preferred method of weighing brass is to stand on a bathroom scale, record the reading, then let an assistant hand me a bulk box of brass, then record the reading again. Then I have the assistant empty the brass from the box, hand the empty box to me, then record that reading. Then I count the brass and subtract and divide like crazy until I am pretty confident I have wasted enough time weighing brass and I move on to a more useful activity.

No one outside of a lab, or competitive shooter, or maybe one of those thousand round a day red mist varmint hunters, could ever tell me how to proceed after weighing and grouping 100 pieces of brass into 100 fraction grain differentiated categories, at least not in a manner that significantly impacted handload performance. Recorded pressure data has suggested there is no meaningful purpose served where these cases will receive a uniform powder charge and are then fired from a gun in the hands of a shooter who can’t hold a two inch group at 25 yards. Yes, a critical visual and dimensional check of all brass should always be conducted. Sorting brass by manufacturer where capacity variations can be significant is also essential. Tracking and grouping brass by number of times fired, more so with maximum loads and bottleneck cartridges, is also important. No, not so much to forecast case failure, as visual cues will do the same, but rather because exposing brass to cycles of pressure increasingly work hardens the material and elevates pressure without increasing charges.

Bullets ? By all means…

My experience with handloading has taught me the use of bullets is almost essential, and nothing I’ve encountered during this project has altered that opinion. On a quick scan of common retail products, I was able to identify 73 different bullets of .429″ and .430″ diameter; 86 if I include rubber, shot capsules and some rather odd cast bullets I can only presume are for silhouette shooting. I don’t like to use cast lead bullets. Beyond the fact they are not particularly inexpensive anymore, and indoor ranges frequently bar their use, lead absorption through touch and inhalation has a detrimental effect on short term memory. I hate not remembering how to get home from the range…or my name. Did I mention I don’t like to use lead cast bullets?

|

|

||||||

| Mfg. | Type | Grains | Diameter “ | Length “ | Impact Velocity | Unit Cost | |

| Remington | SJHP | 180 | 0.430 | 0.580 | 750 – 1400 | .14 | |

| Hornady | JHP | 240 | 0.430 | 0.710 | 900 – 2200 | .17 | |

| Remington | SJHP | 240 | 0.430 | 0.726 | 800 – 1600 | .15 | |

| Speer | JSP | 270 | 0.429 | 0.775 | 900 – 1800 | .22 | |

| Sierra | JSP | 300 | 0.429 | 0.891 | 800 – 1800 | .23 | |

| Hornady | JHP | 300 | 0.430 | 0.857 | 850 – 1900 | .22 | |

Setting aside preconceived notions regarding acceptable bullet weights, I picked six specific bullet types from 180 to 300 grains in weight, appearing left to right and tabled up to down. I selected these because they are made by reputable companies, they are spec’d for impact velocities consistent with anticipated velocity, they are readily available, and they are not priced for snob appeal. Swift bullets that I have used frequently for heavy magnum rifle loads, in my opinion, are excessive in cost for the 44 Magnum at 88 cents per. Nosler Partition 250 grain at 80 cents are not far behind. Barnes XPB bullets, that are nothing to write home about when it comes to handguns, top the charts at 90 cents per. There is absolutely nothing wrong with less expensive bullets for self defense or hunting as applicable and I will hold onto that opinion until a big hog, shot six times, chases me up a tree.

Powder Selection – Hurry up and slow down…

I don’t know how many times I’ve heard or read the comment, “Use fast powder for short barrel gun handloads because you’ll get more complete burn”. Well, that is true, slow powder may not completely burn, but that doesn’t mean that fast powder performance will be better. A charge of Bullseye may burn more completely than a charge of AA 9 when loaded to similar maximum pressures and fired through a 4″ barrel. In addition, fast burning Bullseye will generate approximately 4,640 PSI of chamber pressure per grain of powder, while AA 9 will generate only 2,165 PSI per grain. For the sake of discussion, establish the Bullseye charge as 8.0 grains and the AA 9 charge as 17.7. The increased charge weight of AA 9 would increased persistence of pressure, and ultimately generate higher velocity, however, each individual grain of AA 9 would make a less significant contribution toward pressure than each individual grain of Bullseye. Subsequently, some loss of energy to grains of unburned AA 9 propellant would not have as significant an impact on pressure and velocity as unburned Bullseye, and the larger amount of AA 9 that did burn would generate more gross energy than the Bullseye charge. Tortured logic, presented with excessive verbosity, are the earmarks of some of my favorite theories.

By mathematical estimation, the Bullseye load will hit peak pressure in 0.223 milliseconds, approximately 0.300″ down the barrel, and exit with 6,834 PSI of muzzle pressure. AA 9 will hit peak pressure in only 0.194 milliseconds, approximately the same distance down the barrel, and will have 12,300 PSI of residual pressure at the muzzle. A Bullseye propelled bullet would hit 336 fps at max pressure and exit at 904 fps from a 4″ barrel. An AA 9 propelled bullet would hit 436 fps at max pressure and exit at 1170 fps. 100% of the Bullseye would be consumed in this example, only 92% of the AA 9. If I added two inches to the barrel length, the Bullseye load would increase by approximately 70 fps, the AA 9 performance would bump up approximately 100 fps, underscoring the greater unused potential of the slower powder.

As a first run at this, I selected Accurate #9, Alliant 2400, Hodgdon Lil’Gun, and Ramshot Enforcer – in order of fast to slow. Normally, for larger handgun cartridges, H110 and W296 would occupy a slot after Enforcer and Lil’Gun. This time I wanted to build some experience with Lil’Gun and heavy bullets and anything lighter should be handled by the other powders. That said, my commitment to an H110-less world didn’t survive me writing this paragraph so a supply is lurking out of sight, but not out of mind and will make an appearance in the final piece. Based on prior experience and for the sake of consistency, all loads were assembled with CCI 350 Magnum primers.

As a first run at this, I selected Accurate #9, Alliant 2400, Hodgdon Lil’Gun, and Ramshot Enforcer – in order of fast to slow. Normally, for larger handgun cartridges, H110 and W296 would occupy a slot after Enforcer and Lil’Gun. This time I wanted to build some experience with Lil’Gun and heavy bullets and anything lighter should be handled by the other powders. That said, my commitment to an H110-less world didn’t survive me writing this paragraph so a supply is lurking out of sight, but not out of mind and will make an appearance in the final piece. Based on prior experience and for the sake of consistency, all loads were assembled with CCI 350 Magnum primers.

Sometimes source selection for material becomes habitual and good opportunities are overlooked. I do not buy smokeless powder locally. There is something about $23/lb, plus tax, just doesn’t do it for me and local retail almost never stocks what I need. Lock Stock & Barrel has been pretty good, Midway USA prices were high, now lower, but by the time Midway USA gets done adding special handling charges and separate $20 hazmat charges for powder and primers there is no deal to be found here. Graf & Sons is usually pretty good, but a little high in price at the moment. Powder Valley was great in this instance; below MidwayUSA dealer price, lowest shipping & handling, and same day ship with 3 days in transit through FedEx Ground. Impressive and I will use them again.

Reloading Dies

I’ve been traveling a lot these days, so I put together a very compact, but full featured set up that I can work with when I am away from the shop. A Lee Precision 4 Hole Turret has been working well for me, including when assembly lots of 7 WSM handloads for recent projects, so there was little reason to make a change. To cover the volume of handgun loads I would be building, I added a Lee Pro Auto-Disk powder measure and the Lee Safety Prime System. This is one of the few powder measures I’ve found that consistently throws charges and the priming system is fast and keeps staged primers away from sources of press and handling contamination. The 4 piece Deluxe carbide die set #90966 is capable of loading both 44 Special and 44 Remington Magnum cartridges. The 0.120″ length difference between the two cases is compensated for during the set up adjustment of the seating and expanding die by backing out an additional 1 ¾ turns for the magnum handloads.

Differences in quality die sets are usually pretty subtle. The Lee Precision set is unique in several ways. The decapping rod is collet secured and plain shanked for easy adjustment. The expander is a pass through charging die, allowing powder to be manually dispensed through a funnel affixed to the top of the die, or with an Auto Disk or Pro Auto Disk powder measure that can be attached and actuated by the motion of the die when lowered over a case. The cartridge crimping step is separated from the seating die; nice touch. It is easier to set up both operations individually and the last, the factory crimp die, also keeps loaded case mouth diameter in spec to insure proper chambering of the finished round. This equipment will be used for the duration of the project.

Regrets? I’ve had a few, But then again…

Thanks Frank. The Taurus as a 4″ or similar revolver chambered for the 44 Remington Magnum is terrific. Fit and finish is as good or better than any S&W brand revolver I’ve seen in recent times, the trigger is excellent, double and single action, and the sights are crispy cream…I mean crisp and clean. Sorry… lunch time. The muzzle vent ports, combined with the integral expansion chamber work well in that muzzle jump is modest, noise levels do not seem elevated at all and, even though the last inch of the barrel is full of vent holes and uniformly groove diameter as an expansion chamber, the gun’s velocity performance is closer to that of a 4″ rather than a 3″ barrel revolver. The expansion chamber allows gases to expand, cool and lose velocity before being further diverted through the barrel vents. The full underlug barrel adds useful recoil dampening heft and gives the revolver a balanced feel. The Model 44 single lock cylinder stayed firmly in place regardless the severity of load being fired, as did

Thanks Frank. The Taurus as a 4″ or similar revolver chambered for the 44 Remington Magnum is terrific. Fit and finish is as good or better than any S&W brand revolver I’ve seen in recent times, the trigger is excellent, double and single action, and the sights are crispy cream…I mean crisp and clean. Sorry… lunch time. The muzzle vent ports, combined with the integral expansion chamber work well in that muzzle jump is modest, noise levels do not seem elevated at all and, even though the last inch of the barrel is full of vent holes and uniformly groove diameter as an expansion chamber, the gun’s velocity performance is closer to that of a 4″ rather than a 3″ barrel revolver. The expansion chamber allows gases to expand, cool and lose velocity before being further diverted through the barrel vents. The full underlug barrel adds useful recoil dampening heft and gives the revolver a balanced feel. The Model 44 single lock cylinder stayed firmly in place regardless the severity of load being fired, as did  all of the other parts of the revolver. The matte finish stainless, beyond being durable, looked even better with use. The grips, despite narrow profile do a good job of absorbing recoil and make for a comfortable hold. The revolver’s ergonomic design puts everything that needs to be operated; trigger, hammer, cylinder release, and ejector rod within the natural span of hands and fingers making the Model 44 a very comfortable gun to shoot. Secured in the West Woods Landing holster the Taurus is compact, out of the way and light enough to feel like a more modest powered carry gun.

all of the other parts of the revolver. The matte finish stainless, beyond being durable, looked even better with use. The grips, despite narrow profile do a good job of absorbing recoil and make for a comfortable hold. The revolver’s ergonomic design puts everything that needs to be operated; trigger, hammer, cylinder release, and ejector rod within the natural span of hands and fingers making the Model 44 a very comfortable gun to shoot. Secured in the West Woods Landing holster the Taurus is compact, out of the way and light enough to feel like a more modest powered carry gun.

For the intended purpose, the jury is still out on the notion of a 4″ barrel 44 Remington Magnum. In this combination it is not unmanageable, nor even unpleasant to shoot. It is certainly much more accurate than I anticipated. That said, it would need to deliver superior ballistics to warrant replacing a revolver chambered for the 45 Colt or hyper version of the 45 ACP. The next and last installment will be a detailed rundown with handload results and overall conclusions.

For more on the Taurus and 44 Magnum revolver handloads –

When Longevity Trumps New…gevity Part I

When Longevity Trumps New…gevity Part II

When Longevity Trumps New…gevity Part III

44 Remington Magnum Handload Data

If you’re looking for a handgun, rifle or shotgun, check availability at RGI – Maine Guns, we ship to all 50 states and offer competitive prices, new guns and full factory warranties.

Thanks,

Joe

Email Notification