I was disappointed with both Ruger and Hornady during the introduction of the new 375 Ruger cartridge and firearms. I felt both companies were less than helpful by withholding basic specs and performance data, after sending out product announcement information and shipping production rifles in December 2006. Sort of like a PR agency working for a vacuous movie star; the agency gets the press to show up for what is suppose to be an important announcement, but when the press arrives the star wants only to complain about her loss of privacy and being dogged by the press. I lost interest in the product and the companies after writing an initial speculation piece in December 2006, sold the early production rifle I had in my possession and went on to other projects. Nine months later, with SAAMI cartridge homogulation completed and factory ammo and brass on the shelves, I thought it was time to stop grumping and examine the merits of the product.

The Rifles

I went with the obvious comparison, each gun typical and optimal for its respective cartridge, the CZ 550 African Safari 375 H&H (above-top) and the Ruger Hawkeye African. I wanted the longer barrel Ruger, as nearly every article I’ve read on the 375 Ruger begins by noting the very short barrel of the Alaskan, them immediately speculates how the three inch longer barrel African would have generated much more muzzle velocity. As you can see by the picture above, there are no losers on the table. Both are wonderfully executed products, quite different in philosophy, but each something special in their own right.

| Indices | CZ 550 Safari | Ruger Hawkeye African |

|---|---|---|

| Chamber | 375 H&H | 375 Ruger |

| Magazine Capacity | 5 | 3 |

| Weight – Lbs | 9.25 | 8.0 |

| Overall Length | 46″ | 43.5″ |

| Barrel Length | 25 “ | 23″ |

| Pull Length | 14″ | 13.5″ |

| CG from recoil pad | 21″ | 20 1/2″ |

| Bolt Stroke | 5.25″ | 4.50″ |

| Trigger Pull | 3 1/2 lbs/1lb Set | 5 1/2 lbs / no set |

General observations…

Appearances are deceiving. The CZ feels well balanced so the additional weight is not obvious. Since the stock change and clean up, it is a tack driver. Its balance makes it easy to follow a moving target, the gun has a natural point and, between the Decelerator recoil pad and added heft, there are no closed eyes, bracing or gritted teeth preceding each shot. The Ruger looks too small for its chamber and feels nose heavy by comparison. The recoil pad looks like it was selected to prevent scuffing, not absorb impact and it is efficiently plain. That said, the Ruger is also a tack driver, easy to point and track to a target after a few rounds of practice and the recoil from the lighter gun appears to be no greater than the CZ. Ammo shot was the same bullet weight and full up charges. After firing both guns, I came away with an appreciation for both.

The Ruger appears an exercise in simplicity, but it has its own buried engineered system of distributing recoil to metal and wood parts just as does the CZ. If you’d like to see some of the disassembled specifics for each gun please set the early CZ 550 Safari and Ruger Africancoverage. I love the Express sights on the CZ, I’ll accept the rear sight on the Ruger, but not the front. Should be hooded for protection at least. In reality, I doubt either will be used on many occasions…make that on no occasions, and the express sight is probably more of a romantic notion than a practical piece of hardware.

Both guns have keyed scope mounts that serve as combination bases and rings. The Ruger is cross keyed front and rear, the CZ rear has a prominent downward extended tab. I doubt either would move under fire. Ruger is thoughtful enough to provide rings with their rifles, CZ is not. Rather than spend another $40 with CZ for a pedestrian set of their rings, I selected a set of Warne Maxima steel rings which are specific to this application. Details appeared previously for both the CZand the Ruger. The target at the left was good for entertainment and probably the equivalent of hitting a hole in one for a golfer. I laser bore sighted both guns, took one shot with each to the same point of impact with this result. Not a bullet diameter separation.

Both guns have keyed scope mounts that serve as combination bases and rings. The Ruger is cross keyed front and rear, the CZ rear has a prominent downward extended tab. I doubt either would move under fire. Ruger is thoughtful enough to provide rings with their rifles, CZ is not. Rather than spend another $40 with CZ for a pedestrian set of their rings, I selected a set of Warne Maxima steel rings which are specific to this application. Details appeared previously for both the CZand the Ruger. The target at the left was good for entertainment and probably the equivalent of hitting a hole in one for a golfer. I laser bore sighted both guns, took one shot with each to the same point of impact with this result. Not a bullet diameter separation.

You will find, during this project rifle flogging process, there are no premium (spell that “e-x-p-e-n-s-i-v-e”) optics on either rifle. Both the Mueller and the Bushnell scopes are relatively inexpensive, both have held up to a lot of recoil abuse and semi skilled installations and both can put the bullet pretty much where I choose. The deficiency in both scopes is a less than generous, but still adequate, amount of eye relief. Why the low cost scopes, Joe? I can’t see putting $1,000 worth of glass on a rifle that will get pounded during handload development and never see more than a paper target during the process. Over all the years I’ve been shooting, I’ve honestly had only one scope croak on me and that was an expensive scope mounted on a 338-378 Weatherby.

Cartridge Comparisons

These are the case dimensions for both cartridges, as indicated by SAAMI, with esoteric references removed. The Ruger case; beltless, substantially larger in diameter, approximately 6 grains larger in calculated capacity as 98 grains, compared to the H&H at 92 grains. In checking water capacity of once fired, but neck sized cases, the H&H came in at 96 grains, the Ruger case at 101.5 grains.

The fact that the Ruger Hawkeye holds three rounds and the CZ 550 holds five is not a function of oversized case diameter like the WSM and UM series cartridges forcing a capacity limitation, but rather the standard magnum configuration of the respective firearm. The Ruger case is the same diameter as the H&H belt and a CZ 550 magazine will hold five rounds of 375 Ruger, just like it holds five 375 H&H rounds.

The 375 Ruger cartridge length is 0.760″ greater than its case length. The 375 H&H difference is 0.750″. Seat a 300 grain Sierra boat tail in the 375 Ruger and you have net capacity of roughly 83.8 grains. Seat the same in a 375 H&H and net capacity is 78.8. The 375 Ruger does not suffer from any of the “long bullet – lost case capacity” woes of the WSM and SAUM cartridges. I never understood why the extremes in case length from Ultra to Short when manufacturers were looking to replace the H&H series, and why the burning desire for a short action gun when the world was saturated in 30-06 length actions and related manufacturing tooling and designs.

The 375 Ruger cartridge length is 0.760″ greater than its case length. The 375 H&H difference is 0.750″. Seat a 300 grain Sierra boat tail in the 375 Ruger and you have net capacity of roughly 83.8 grains. Seat the same in a 375 H&H and net capacity is 78.8. The 375 Ruger does not suffer from any of the “long bullet – lost case capacity” woes of the WSM and SAUM cartridges. I never understood why the extremes in case length from Ultra to Short when manufacturers were looking to replace the H&H series, and why the burning desire for a short action gun when the world was saturated in 30-06 length actions and related manufacturing tooling and designs.

Tedium is gathering data…

I use Stoney Point gages, or LNL gauges as Hornady has branded them, to determine shoulder location and sizer die setting and to establish a safe and optimal cartridge overall length for a cartridge/firearm combination. I make my modified cases for the gages from brass fired in the applicable firearm’s chamber, as these most closely approximate what the rifle will see dimensionally from handloaded ammunition. If you’d like to see more on the use of these gages and the subject of establishing proper COL, you might want to check out some prior coverage.

I use Stoney Point gages, or LNL gauges as Hornady has branded them, to determine shoulder location and sizer die setting and to establish a safe and optimal cartridge overall length for a cartridge/firearm combination. I make my modified cases for the gages from brass fired in the applicable firearm’s chamber, as these most closely approximate what the rifle will see dimensionally from handloaded ammunition. If you’d like to see more on the use of these gages and the subject of establishing proper COL, you might want to check out some prior coverage.

Making modified cases is pretty easy – Run a drill through the primer pocket, something close to 0.281″, then run a 5/16×36 tap through the hole. I run my sizing die’s expander down to open the case neck without sizing the case neck, then polish the inside of the neck so checking bullets can slip in and out without wobbling or sticking to the gun’s rifling with contact. If you have a hard time locating a tap, try Enco.

Making modified cases is pretty easy – Run a drill through the primer pocket, something close to 0.281″, then run a 5/16×36 tap through the hole. I run my sizing die’s expander down to open the case neck without sizing the case neck, then polish the inside of the neck so checking bullets can slip in and out without wobbling or sticking to the gun’s rifling with contact. If you have a hard time locating a tap, try Enco.

I sorted through a number of bullets, these are the seven that made the final cut. There are many, many…many bullets for the .375″ so these represent only my preferences. I split the weight range down the middle and intentionally looked for lightweight bullets that would put the guns in the field more often. If you can load the 45-70 Gov’t for everything from rabbits to buffalo, why limit the .375″ to only two weights; 270 and 300 grain loads. This is one area where I believe the 375 Ruger Alaskan and African comparatively light weight is a big plus for use during for deer season.

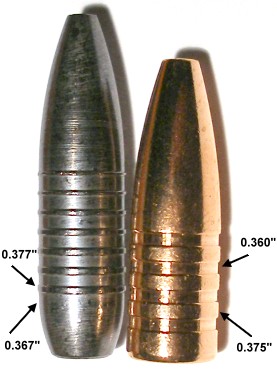

The Barnes bullet probably is the low end delineation between thin skinned large animals and big tough and dangerous animals, if you can consider 235 grains at 3,000 fps the low end of anything. The GS bullet, for those who have not used them, is something quite special. They are of solid copper construction but, unlike the Barnes bullet with grooves cut into the shank, the GS bullet shank is wrapped in a series of groove+ diameter thin driving bands. The result is a very low bore friction bullet that can outperform any other type of bullet at the same weight, while being highly accurate and penetrate and expand appropriately. I’ve used them in .257″ and .458″ firearms with universally excellent performance. Both the Ruger and CZ 550 have a 1:12″ RH twist which is beneficial for these long GS Custom bullet and bullets of similar length. GS Custom indicates 1:13.2″ is optimal for this bullet and 1:15.75″ as a minimal requirement for stability.

|

Bullet Selection |

Company | ID # | Material | BC | Weight Grains |

Length Inches |

Shank Dia. Inches |

|

Hornady | 3706 | SPFB | 0.320 | 225 | 1.129 | 0.3749 |

|

Speer | 2471 | SPFB | 0.301 | 235 | 1.058 | 0.3754 |

|

Barnes | 37552 | TSXFB | 0.270 | 235 | 1.223 | 0.3748 |

|

Nosler | 54413 | SPBT | 0.473 | 260 | 1.386 | 0.3746 |

|

GS Custom | 2657 | HVBT | – | 265 | 1.446 | 0.3768* |

|

Sierra | 3000 | SPBT | 0.480 | 300 | 1.370 | 0.3750 |

|

Woodleigh | W46C | PPFB | 0.400 | 350 | 1.407 | 0.3750 |

| *GC Custom employs raised driving bands, diameter between bands on shank measures 0.3668″ | |||||||

Exceptional tedium is gathering COL and comparator data…

There are many reasons for using a comparator to establish cartridge length…besides trying to create a false impression of an intellectual bent and considered thought invested into your handloading efforts. Comparators draw from a stable reference point on the bullet ogive (ō-jīve), the forward tapered portion of the bullet, rather than from the tip of a soft lead bullet tip that may vary in length from one bullet to the next. The comparator measures from the face of the case rim to the point of diameter on the bullet that equals the diameter of the raised rifling in a barrel; two points you do not want to intersect when you close the bolt on your rifle. Seating out to within a few thousandths of rifling in a sporting firearm offers virtually no return on time investment and loss of safety margin. Seating a bullet out as far as possible has also been attributed with gaining useful case capacity. Move a .375″ slug out by 0.100, which is a ton, and all you get back in capacity is 2.8 grains. Best bet is to locate the bullet were it is safe, where it is recommended, where you run across an applicable cannalure, where it assures adequate neck holding contact and stability, where it doesn’t waste capacity. This is the product of six hours, marathon measuring and checking of two guns and some semi-obsolete html coding –

| Bullet | Cartridge Overall Length |

Comparator Length |

Net Case Capacity |

||||

| Company | ID# | H&H | Ruger | H&H | Ruger | H&H | Ruger |

| Hornady | 3706 | 3.555* | 3.300 | 2.890 | 2.637 | 83.8 | 89.9 |

| Speer | 2471 | 3.600 | 3.255** | 3.030 | 2.676 | 86.7 | 90.2 |

| Barnes | 37552 | 3.700 | 3.400 | 3.113 | 2.814 | 83.6 | 88.4 |

| Nosler | 54413 | 3.600* | 3.340 | 2.936 | 2.673 | 77.8 | 83.8 |

| GS Custom | 2657 | 3.700* | 3.400 | 3.084 | 2.792 | 80.2 | 85.0 |

| Sierra | 3000 | 3.680* | 3.400 | 3.103 | 2.818 | 81.0 | 86.4 |

| Woodleigh | W46C | 3.600* | 3.340* | 3.085 | 2.832 | 76.7 | 82.6 |

|

*Seated to accommodate cannalure and/or minimum neck engagement. |

|||||||

Exceptional, exceptional tedium is developing handload data…

Neither cartridge is particularly behemoth in size. Pictures left to right – 375 Ultra Mag, 375 H&H and 375 Ruger. Both cartridges are easy to handload Not as easy as a .458″ gun where you don’t need a funnel to load powder, but close enough. It is the process that makes development tedious, not the cartridge. The new H&H brass was Remington with an average case weight of 255.5 grains, the Ruger was Hornady brass with an average weight of 259.6 grains. The length of sized Remington brass ran from 2.842″ – 2.848″ and all were trimmed to 2.840″. The Hornady brass ran from 2.574″ – 2.580″ and all examples were trimmed to 2.573″.

Neither cartridge is particularly behemoth in size. Pictures left to right – 375 Ultra Mag, 375 H&H and 375 Ruger. Both cartridges are easy to handload Not as easy as a .458″ gun where you don’t need a funnel to load powder, but close enough. It is the process that makes development tedious, not the cartridge. The new H&H brass was Remington with an average case weight of 255.5 grains, the Ruger was Hornady brass with an average weight of 259.6 grains. The length of sized Remington brass ran from 2.842″ – 2.848″ and all were trimmed to 2.840″. The Hornady brass ran from 2.574″ – 2.580″ and all examples were trimmed to 2.573″.

I always assemble and shoot a single example of each load as a final live functional check to address the more pressing issues – Will the gun remain in one piece? Will the bolt close? Will a loaded cartridge eject? Will the bullet fit with all of that powder in there? The usual. These are not precisely assembled cartridges as it is difficult to set up for single round loads and get the reloading press to settle down along with the person loading. Consequently 0.002″ – 0.003″ of variation in comparator measured length is pretty common, at least for me. Second time reloading with stable brass and runs of greater quantities typically come in much more uniformly.

All loads we assembled with CCI #250 Magnum Primers in APS strips. It is a clean system, fast and I have never had a primer misfire. Come to think of it, I’ve never had any supply of new primers of any major brand fail as long as I did my job and properly seated them. Sometimes I see these dramatic stories of failed primers in large numbers attributed to product failure and I can’t help but wonder if someone isn’t fully seating primers. It’s been a lot of years and it has never happened to me.

All of the charges were weighed with a mechanical scale for accuracy. Some of the charges are pretty heavy in comparison to some of the load data I checked against, but also much of the checking data was loaded to relatively low levels. I am not sure why the cut off at 48,000 to 52,000 PSI, even on recently revised data from many sources, as the 375 H&H is a 62,000 PSI CIP cartridge. The Ruger, of course, had very little reference material to work with. I used an existing set of RCBS reloading dies for the 375 H&H and a, early set of Hornady dies for the 375 Ruger. The Ruger cartridge dies are currently produced by Hornady, RCBS and Redding; handloaders are not without a choice. The shell holders for both are the same.

Notes of some consequence…

GS Custom HV product is unique in respect to performance, design and handloading practices. As I noted earlier, the GS bullet, far left, has an undersize shank and slightly over caliber diameter, and very narrow, driving bands. As a result, they offer very little resistance when being driven through rifling and start pressure are extraordinarily low. Load data for the GS bullet is not interchangeable with any bullet of same caliber and similar weight; not moly, not dry coated, nada. If you like the performance of these bullets, and I assume you would, you need to buy the product from GS Custom. There is no performance or loading relationship between the GS Custom product and the Barnes Triple Shock. The Barnes bullet is basically a Barnes X bullet with several grooves cut into a conventional bullet shank. Load data for the Barnes is only slightly hotter than the standard Barnes X and does not even approach the levels of the Barnes dry lubed XLC series. You might want to drop by the GS Custom web site and review the technical data for the HV and their other products and get a sense for how they perform on tough game. Impressive.

GS Custom HV product is unique in respect to performance, design and handloading practices. As I noted earlier, the GS bullet, far left, has an undersize shank and slightly over caliber diameter, and very narrow, driving bands. As a result, they offer very little resistance when being driven through rifling and start pressure are extraordinarily low. Load data for the GS bullet is not interchangeable with any bullet of same caliber and similar weight; not moly, not dry coated, nada. If you like the performance of these bullets, and I assume you would, you need to buy the product from GS Custom. There is no performance or loading relationship between the GS Custom product and the Barnes Triple Shock. The Barnes bullet is basically a Barnes X bullet with several grooves cut into a conventional bullet shank. Load data for the Barnes is only slightly hotter than the standard Barnes X and does not even approach the levels of the Barnes dry lubed XLC series. You might want to drop by the GS Custom web site and review the technical data for the HV and their other products and get a sense for how they perform on tough game. Impressive.

QuickLOAD is an exceptional product and one very useful tool where there needs to be a collection of several. Powder burn is not typically linear in response to pressure under confinement. Where pressure may build uniformly and predictably at pressure levels intended for a particular type powder, it can very well spike and go through the roof when pushed higher, and possibly lower. QuickLOAD assumes normal operating pressures and does not, could not, take into consideration products used out of typical application, however, QuickLOAD, as well as a significant number of data references, were considered when new loads were defined. The loads I initially tested were fired from a mechanical rest with a hydraulic trigger actuator. Each gun was examined and critical areas measured after each discharge, and brass was checked for typical signs of excessive pressure. That said, these are not light loads, they are not loads with a good deal of margin for error for variations that would be the norm for other firearms. Feel free to use this data for reference as one piece of information, but I strongly advise against taking this data as is and applying it to your own handloads, my intent was to draw a less subjective comparison between the Holland & Holland and Ruger cartridges.

Part I Summary

In terms of hunting logistics, the 375 H&H firearm currently has an edge. Ammo is available just about everywhere, as are handloading components and firearms. The person selecting the 375 H&H also has the benefit of a significant number of manufacturers and rifle models to choose from. Most firearms for the cartridge are hefty, have a large cartridge capacity and softer recoil.

The genius of the 375 Ruger design is in the 30-06 case length and in the unbelted case that does not exceed H&H belted magnum diameter. If you haven’t noticed, there is a premium affixed to long action guns suitable for use with full length belted magnums. There is also a weight penalty for all of that extra metal and wood. The 375 Ruger can be a re-barrel on even the lowest cost Mauser type rifles on the market today, and certainly invited the use of a wide array of standard actions to choose from. I think anyone who is familiar with the demise of the 300 H&H in the face of the shorter 300 Winchester Magnum knows the reality of that situation. What will matter is the installed base of firearms, the number of manufacturers other than Ruger that will embrace the new cartridge and how many shops will carry the new Ruger rifle and cartridge until the product grows legs. This is one time when I won’t ridicule a new release based on product compromise or lack of purpose. The 375 Ruger is a real deal and has lots of reasons to justify its existence.

If there is an area of hype in the products extended by Ruger, I believe it is the short barreled Alaskan. Based upon the case capacity, potential of the cartridge and application of such a firearm, every inch of barrel loss further takes away the cartridge’s logical reason for being. My guess is this gun is to placate the same crowd that believes the 2 1/2″ barreled 500 S&W makes sense in bear country. Does a loss of 3″ barrel length cripple the cartridges performance? No, it just lessons it. Sort of like putting a 1000 horse power big block in your truck and driving around with a plug wire disconnected.

Next up, ballistic data and some cautions on powder selection.

375 H&H Vs 375 Ruger Part I of II

375 H&H Vs 375 Ruger Part II of II

Thanks,

Joe

Email Notification