I realize the .500 Jeffery is a major departure from my needs as a hunter, and clearly more than I want to shoot recreationally on a routine basis. It is, however, one of those bigger than life cartridges that got me interested in firearms when I was very young, and spending more time daydreaming than in useful pursuits. In writing this, some of my earliest impressions had to come to grips with an adult reality. Fortunately, the two weren’t that far apart.

I realize the .500 Jeffery is a major departure from my needs as a hunter, and clearly more than I want to shoot recreationally on a routine basis. It is, however, one of those bigger than life cartridges that got me interested in firearms when I was very young, and spending more time daydreaming than in useful pursuits. In writing this, some of my earliest impressions had to come to grips with an adult reality. Fortunately, the two weren’t that far apart.

The Jeffery has been with us for a very long time, yet there is not a great deal of detailed information available for technical research. In fact, much of it is the same basic data restated over and over in slightly different ways. The Jeffery is not a cartridge utilized by thousands of shooters who wish to share their collective wisdom. Published original data comes predominately from independent sources and frequently in conjunction with the promotion of a rifle, cartridge component or ammunition. Subsequently, working with the .500 Jeffery requires a sense of enterprise…sort of like Star Trek, but without Captain Kirk, but maybe with a little Spock.

The Jeffery’s operating pressure by current standards is modest. The round is extremely flexible, predictable and well-mannered. In a rifle of modern manufacture, the Jeffery can be nudged to comfortably outperform the higher pressure 460 Weatherby and keep pace with an even higher pressure .500 A-Square. The Jeffery, loaded even to 30-06 Springfield pressure levels, is able to push a 600 grain bullet to 2,500 fps and generate over 8,100 ft-lbs of kinetic energy. It can just as easily be loaded to reduced pressure levels and made into a spectacular plinker; 350 – 400 grain cast bullets at 1,400 – 1,600 fps. With the right bullet, and in pursuit of appropriate game, it can be quite flat shooting while hanging on to enormous levels of energy. Relying too much on published data and software simulation results will tend to mask the cartridge’s potential.

Bullet points…

I could not construct the definitive list of hunting bullets for the .500 Jeffery. Quite frankly, only a hunter with lots of kill experience with this combination would have enough anecdotal evidence to render an opinion and then only if they had been paying close attention to the way hunts played out, animals expired and the condition of recovered bullets. Bullet manufacturers get lots of feedback on their products, both positive and negative, and potentially have the greatest collective wisdom to offer customers. Unfortunately, but understandably, these companies are in business to sell bullets, not to consult, so they tend to make the best case for their own products. Sometimes the message is slightly disingenuous. Ever see a product that had been widely and expensively touted for six months by a manufacturer as the “best of the best” and their biggest seller suddenly disappear from their catalogue with little fanfare? In preparation to making bullet selections, I read articles written by experienced hunters that didn’t look like thinly disguised ads – the stories not the hunters, and reread some very enjoyable novels that included credible firearm and ammunition referenced. I also checked products for marketplace longevity and I attempted to analyze the logic presented by each bullet manufacturer within their product description while stripping away as many of the superfluous adjectives as possible. Finally, I called manufacturers and asked questions about specific products, and effort that I found to be the least rewarding. These days the tendency is to put a marketing intern on the phone who can only restate what the marketing department wrote and will fold like a deck of cards when challenged.

I could not construct the definitive list of hunting bullets for the .500 Jeffery. Quite frankly, only a hunter with lots of kill experience with this combination would have enough anecdotal evidence to render an opinion and then only if they had been paying close attention to the way hunts played out, animals expired and the condition of recovered bullets. Bullet manufacturers get lots of feedback on their products, both positive and negative, and potentially have the greatest collective wisdom to offer customers. Unfortunately, but understandably, these companies are in business to sell bullets, not to consult, so they tend to make the best case for their own products. Sometimes the message is slightly disingenuous. Ever see a product that had been widely and expensively touted for six months by a manufacturer as the “best of the best” and their biggest seller suddenly disappear from their catalogue with little fanfare? In preparation to making bullet selections, I read articles written by experienced hunters that didn’t look like thinly disguised ads – the stories not the hunters, and reread some very enjoyable novels that included credible firearm and ammunition referenced. I also checked products for marketplace longevity and I attempted to analyze the logic presented by each bullet manufacturer within their product description while stripping away as many of the superfluous adjectives as possible. Finally, I called manufacturers and asked questions about specific products, and effort that I found to be the least rewarding. These days the tendency is to put a marketing intern on the phone who can only restate what the marketing department wrote and will fold like a deck of cards when challenged.

Generally speaking, or I guess that should be generally writing, bullet weights intended for .500 Jeffery applications weigh 600 or 535 grains. Bullets lighter than this weight are usually intended for the .50-110 WCF or .50 Alaskan and too fragile in construction for the .500 Jeffery. Bullets that fall between and beyond these weights are typically intended for the .500 Nitro Express. The real heavy weights in this caliber, those that hover around the 750 grain mark, are intended for use with the .50 BMG. Bullets for the .500 Jeffery and the .500 Nitro Express can be used when assembling .500 Jeffery handloads if the intended rifle has sufficient freebore and magazine length to accommodate a longer than standard COL. Performance of these loaded rounds will fall into the designed impact velocity of either type of bullets.

Best seats in the house…

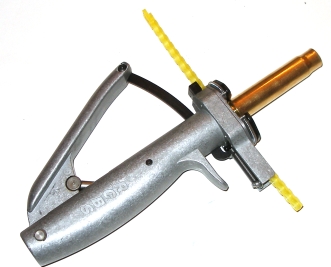

Bullets intended for the .500 Nitro Express, a cartridge with a 3.750″ COL, are longer than Jeffery bullets and will extend further into a Jeffery case when seated to a functional length. The yellow line in the picture indicates the case mouth position for the handloads I assembled. The 570 grain bullet, right, is catalogued for the .500 Nitro Express. Seating the bullet out to take advantage of available SC 550 freebore and magazine length, reduced this bullet’s intrusion into the case. If I had loaded to .500 Jeffery COL specification, intrusion would have been 0.142″ greater. Doesn’t sound like much but this difference equates to 12 grains of available case capacity and 11,000 PSI of chamber pressure. Utilizing this extra space by seating the bullet out further yielded an additional 50 fps in some loads.

Bullets intended for the .500 Nitro Express, a cartridge with a 3.750″ COL, are longer than Jeffery bullets and will extend further into a Jeffery case when seated to a functional length. The yellow line in the picture indicates the case mouth position for the handloads I assembled. The 570 grain bullet, right, is catalogued for the .500 Nitro Express. Seating the bullet out to take advantage of available SC 550 freebore and magazine length, reduced this bullet’s intrusion into the case. If I had loaded to .500 Jeffery COL specification, intrusion would have been 0.142″ greater. Doesn’t sound like much but this difference equates to 12 grains of available case capacity and 11,000 PSI of chamber pressure. Utilizing this extra space by seating the bullet out further yielded an additional 50 fps in some loads.

If a firearm will not accommodate a longer than specification cartridge overall length, maximum velocity won’t be achieved and 570 grain bullets intended for the .500 Nitro Express will max out at a lower velocity than a 600 grain bullet designed specifically for the .500 Jeffery. The Jeffery’s CIP drawing references a cartridge overall length of 3.468″ with consideration given to blunt round nose bullets. The same drawing vectors to a projected length of 3.624″. The SC 550 does not have work hard to accommodate this cartridge. The magazine has no problem with bullets seated out to a COL of 3.975″, however, the throat could not accommodate the same. I set my maximum COL at 3.700″ for all of the long bullets spec’d for the .500 Nitro Express. Both Barnes bullets loaded with room to spare. Not only did the banded flat nosed solid easily function at that length, it also offered the greatest net case capacity of the heavier weights.

If a firearm will not accommodate a longer than specification cartridge overall length, maximum velocity won’t be achieved and 570 grain bullets intended for the .500 Nitro Express will max out at a lower velocity than a 600 grain bullet designed specifically for the .500 Jeffery. The Jeffery’s CIP drawing references a cartridge overall length of 3.468″ with consideration given to blunt round nose bullets. The same drawing vectors to a projected length of 3.624″. The SC 550 does not have work hard to accommodate this cartridge. The magazine has no problem with bullets seated out to a COL of 3.975″, however, the throat could not accommodate the same. I set my maximum COL at 3.700″ for all of the long bullets spec’d for the .500 Nitro Express. Both Barnes bullets loaded with room to spare. Not only did the banded flat nosed solid easily function at that length, it also offered the greatest net case capacity of the heavier weights.

Two sizes fit all…

Big bore non-expanding solids are typically manufactured undersize. The objective is to reduce bore friction caused by a bullet that does not take rifling as easily as a more malleable jacketed lead core type. A solid’s diameter is one or two thousandths of an inch smaller than caliber and they are often banded where the surface of the bullet’s shank alternates between rifling groove and land diameter. The reduced contact surface area and friction cut fouling and boosts the bullet’s potential velocity. I always marvel at the discussion regarding the Triple Shock Barnes and it’s comparison to the original Barnes X and the effect on game. I bet I won’t be too far off if I guess the Triple Shock is no more than bands added to the X bullet to reduce a bore fouling problem and to get away from the expensive secondary dry lube process that was tried on their now defunct but really terrific XLC products.

In addition to undersize non-expanding solids, there is a big bore tradition of solid / jacketed companion bullets. While I can’t speak from first hand experience, there is an often expressed need to follow a jacketed bullet load with a solid bullet load in a gun’s magazine when hunting dangerous game. The concept advanced is that if the expanding bullet doesn’t do its job, the solid would be a convincing finisher. I believe the logic behind that theory escapes me. If the solid is the clean and sure killer, wouldn’t it make more sense to just begin and end with a solid? Anyway, for those who love folklore, British accents and dangerous game mysticism, the solid and expanding bullets are of the same weight to insure no shift in point of impact….which also makes little sense because there are numerous factors that control point of impact, bullet weight being only one of them.

Ah yes, if only ad copy could kill. The hunter would walk up to the cape buffalo, posture a bit, then flash a copy of the bullet manufacturer’s ad appearing in the latest issue of “Shooting and Hunting” magazine. The buffalo, after reading about the bullet’s devastating striking power, would become deeply depressed over the threat, stop working out and eventually die from high cholesterol.

|

Product |

Mfg. | Grains | D “* | L”* | Type |

Notes |

|

Woodleigh | 600 | 0.510 | 1.268 | Soft Nose, Protected Point | Woodleigh lists this bullet for use on large dangerous game including cape buffalo, large cats and large plains species. The FMJ version is recommended for elephant. S.D. .330, B.C. .350. Soft point expansion, Protected point against recoil damage in magazines.. 1,800-2,250 fps impact velocity range. $1.50/per |

|

Woodleigh | 535 | 0.510 | 1.165 | Soft Nose, Protected Point | Same as above, except light for bore weight and for large and dangerous thin skinned game. S.D. .294 B.C. .310 1800-2200 fps impact velocity range. $1.50/per |

|

535 |

0.510 |

1.269 | Soft Nose | Soft copper jacket and soft lead, designed to expand and not fragment. Options on jacket thickness and cannelure placement. This version has a 0.065″ jacket for use on heavy dangerous game. S.D. .294 approx B.C. .368. Same type holds up well with .416 Weatherby and 2000 fps impact velocity. $1.90/per. | |

|

Barnes | 570 | 0.508 | 1.415″ | Solid Copper and Zinc Solid | The Barnes banded solid is made of copper/zinc alloy for the 500 Nitro Express and weight matched to the Triple Shock bullet below. There is a 535 grain banded solid made specifically for the Jeffery, however, there is no corresponding Triple Shock .314 SD .243 BC $1.45/per |

|

Barnes | 570 | 0.508 | 1.560″ | Solid Copper, Hollow Point | Made for the .500 Nitro Express, this bullet is considerably longer than most Jeffery length bullets which results in the least available case capacity even when seated to greater than spec length. .314 SD .369 BC $1.40/per |

|

Lehigh | 471 | 0.510 | 1.300″ | Solid Copper Hollow Point | Custom product from Lehigh bullets, made for the .510-338 Lapua with a nose cut to expand properly in a cartridge with 2,400 fps of muzzle velocity. It’s design is not intended for the .500 Jeffery, however, it was worth loading to check weight range and twist rate performance |

|

Lehigh | 462 | 0.510 | 1.132″ | Solid Copper Flat Nose | Custom product from Lehigh bullets, made for the .50 Alaskan, a cartridge that operates in the 2,100 – 2,200 fps range. It’s design is not intended for the .500 Jeffery, however, it was worth loading to check weight range twist rate performance. |

|

Cast Performance | 410 | .511 | 0.827 | Cast LFNPB |

This bullet weight is not in production at this time, but very similar are available. With a Brinell hardness of 18-21 they don’t really require gas checks at the velocity loaded and the lube is good for 3,100 fps. |

|

Cast Performance | 350 | .511 | 0.724 | Cast WFNGC | Made for the 50-110 and 50 Alaskan. Low recoil and require little powder to churn up a ton of energy. Available in 350, 435 and 500 grain versions. $.05/per. $.11/per, $.12/per respectively. |

| * Dimension as measured | ||||||

Some of my scribbles on bullets…

Woodleigh: These probably have the best credentials for this type of cartridge. Long standing successes, loaded in factory specialty performance ammunition. Cannelure placement insures a loaded 600 grain round will slightly exceed the .500 Jeffery maximum COL, however, as a practical matter, this is not a functional problem in the SC 550. The need for a 535 grain bullet is suspect. While recoil is reduced from horrendous to just terrible with this lighter bullet, it would probably make more sense to just begin with a less powerful cartridge.

Hawk Bullets: I like these a lot and have used them in the .416 Weatherby and very heavy .45-70 Gov’t loads. On pigs and deer with thin jackets they grow to about three times their size and make a deep large wound channel without shedding much weight. With a 0.065″ jacket, they are tough and still fly straight. They penetrate deeper, but still expand as the jackets are very malleable, as is the soft lead core. Big plus, they have a great organization. Hawk knows how their bullets perform within an application and they can customize the products they sell. Try doing that at Woodleigh or Barnes.

Barnes: The banded Barnes bullet is interesting. Listed as 0.509″ in shank diameter, all of the bullets I loaded were actually 0.508″ at the bands, 0.490″ between the bands, and 0.495″ from the front band forward to the onset of the ogive. Not unlike one of their Bore Rider products and not unlike Remington‘s Golden Saber design where a banded shank provides pressure seal and a bore diameter nose rides on the lands to reduce bore friction. The Barnes Triple Shock bullets also had a shank and band diameter of 0.508″, however the tip is traditional in shape and size. I suspect the Triple Shock design is intended to reduce the shock of finding major bore fouling more than increasing the shock to the game they hit.

Lehigh Bullet: I included these bullets specifically because they fall within a lighter than typical weight range for the Jeffery. As indicated from the onset by David Fricke at Lehigh Bullets, these are not intended for the Jeffery and are a custom design not carried in the Lehigh catalogue. When you take a quick look at them, they seem quite pedestrian as bullets go, but when you break out a mic, the subtleties of the design become more obvious. Both bullets are “bore rider” type designs – smaller diameter forward of the driving bands. The lower hollow point is cut to promote expansion at a velocity approximately 400 fps lower than what was achieved with the Jeffery. Within a population of bullets both types were very uniform in dimension and weight. They are a quality product. Even though used out of application, both held up well and delivered good accuracy. I am looking forward to trying their catalogue products with the .50 Beowulf and some of the more popular cartridges.

Lehigh Bullet: I included these bullets specifically because they fall within a lighter than typical weight range for the Jeffery. As indicated from the onset by David Fricke at Lehigh Bullets, these are not intended for the Jeffery and are a custom design not carried in the Lehigh catalogue. When you take a quick look at them, they seem quite pedestrian as bullets go, but when you break out a mic, the subtleties of the design become more obvious. Both bullets are “bore rider” type designs – smaller diameter forward of the driving bands. The lower hollow point is cut to promote expansion at a velocity approximately 400 fps lower than what was achieved with the Jeffery. Within a population of bullets both types were very uniform in dimension and weight. They are a quality product. Even though used out of application, both held up well and delivered good accuracy. I am looking forward to trying their catalogue products with the .50 Beowulf and some of the more popular cartridges.

Cast Performance: Cheap and hard cast. Weight was fairly uniform +/- a few tenths, a little sloppy with obvious parting lines minor casting voids. Did I mention they are cheap? Accuracy was good. Did I mentioned they are cheap? Honestly, while Cast Performance product is typically very good, this specific stock was not. Large parting lines and casting voids were typical and weight variances were greater than typical.

Notes on brass….literally

I think the term “big cartridge” can be aptly applied to the .500 Jeffery as I was able to write my load notes and performance results for each round right on the cartridge case. The overall experience with Bertram brass wasn’t exciting, not for $5 per case. The rims were thin, the extractor groove cuts varied from undersize to too large to fit into the correct shell holder. After one firing, the brass was so work-hardened it rang like a bell, a condition that was corrected with careful annealing. I know, from recent communications with Norma, the company still intends to ship the .500 Jeffery as part of their PH product line and that it will be distributed by Black Hills. It would be great if Norma would also supply brass for handloaders as they make a first rate product. A side note, all of the Bertram cases were badly tarnished as received, so they were rinsed in Iosso before loading. This should be done infrequently as the process strips zinc from the alloy and weakens the case over time, but I want a clean case to ensure stress cracks aren’t hiding under tarnish and carbon deposits.

I think the term “big cartridge” can be aptly applied to the .500 Jeffery as I was able to write my load notes and performance results for each round right on the cartridge case. The overall experience with Bertram brass wasn’t exciting, not for $5 per case. The rims were thin, the extractor groove cuts varied from undersize to too large to fit into the correct shell holder. After one firing, the brass was so work-hardened it rang like a bell, a condition that was corrected with careful annealing. I know, from recent communications with Norma, the company still intends to ship the .500 Jeffery as part of their PH product line and that it will be distributed by Black Hills. It would be great if Norma would also supply brass for handloaders as they make a first rate product. A side note, all of the Bertram cases were badly tarnished as received, so they were rinsed in Iosso before loading. This should be done infrequently as the process strips zinc from the alloy and weakens the case over time, but I want a clean case to ensure stress cracks aren’t hiding under tarnish and carbon deposits.

|

Firing pressure caused only minor dimensional changes, particularly when viewed as a percentage of change in comparison to virgin brass. No brass gave out after three cycles of loading and there were no signs of distress from excessive pressure. Case head diameter stabilized after the first use and did not continue to expand to the degree noted in the table. Use of the expander die’s flair function is necessary or the very thin shoulder material will buckle under even light pressure when seating bullets. The thin brass showed up as a further problem with compressed loads, a condition that is relatively common with the Jeffery. Some cartridges with 105% compressed charges of H4350 deformed so badly the case below the shoulder looked like cellulite through stretch pants and had to be disassembled and resized.

Relax, you only need to pick two, or three…maybe four…tops

After sifting through lots of Alliant, Hodgdon, IMR, Ramshot, and Winchester powder, I settled on a handful that fit in the case and burned as slowly as possible. The slowest powders burned inefficiently in the 22.9″ of barrel remaining ahead of a chambered round, perhaps in the range of 89% to 92%. The faster stuff did well from the standpoint of burn completion, as high as 99%. H4350 set the speed records for the heavy bullets, Re 15 for the lighter. I could not get enough of the slowest powders I tried into the case to hit pressure goals or velocity potential. I believe H4350 and Re 15 are optimal for the cartridge, IMR 4350 for some reason worked well with the long .500 Nitro express type bullets. A late addition to the project was Winchester 760 which also proved useful. Powders not included because I felt they lacked sufficient pressure persistence: H380, Varget, Accurate 2700, Accurate 4064, and RamShot Big Game.

Handloading hardware, an all RCBS solution…

I attempted to put together a multi-vendor solution for handloading the .500 Jeffery, the best of each piece of equipment and tools from their respective manufacturer. In the case of the .500 Jeffery, and most of the other big bore dangerous game cartridges, most vendors do not service this market and a few provide only a single piece of the required overall system with nothing to support the rest. There is little point in buying a set of oversize dies from a vendor that does not supply an applicable press, or buying a press when dies are not available. The handloader is left with the task of trying to find adapters and odd pieced to make it all work. Worse, mixed vendor systems make technical support…sketchy. RCBS was the only company that could supply a well-integrated solution and at a reasonable price as outlined in Part I. Additionally, not so mainstream cartridges lead to not so mainstream technical questions and a call to RCBS tech support always resulted in a clear and concise response. Nice people who know their product line inside and out.

A few comments before lunch…

A yellow APS strip designates large rifle primers, red designates large rifle magnum. I ultimately elected to use CCI 250 large rifle magnum primers. These worked fine with no misfires or odd ignition problems. The decision was represents only an assurance as I had no misfires or degradation in performance with CCI 200 large rifle primers.

I personally use an RCBS bench APS press for production runs and a hand APS priming tool for development work. I assumed the big Jeffery case would not fit in the hand primer’s universal jaws, but I was wrong. Even the oversize brass popped right in and the task of priming was routine.

RCBS does not leave AmmoMaster users in the lurch if they do not use the APS system. Each press is supplied with a ram priming unit for use with box packaged primers. Basically, a priming rod assembly mounts to the press ram and a priming body that mounts a shell holder screws into the 7/8″ bushing in the top of the press. The operator can seat primers by feel, or to a positive stop where mechanical adjustment controls primer seating depth. The press accessory is actually easy to set up and works well for short runs also. I think the APS system is faster and cleaner.

RCBS does not leave AmmoMaster users in the lurch if they do not use the APS system. Each press is supplied with a ram priming unit for use with box packaged primers. Basically, a priming rod assembly mounts to the press ram and a priming body that mounts a shell holder screws into the 7/8″ bushing in the top of the press. The operator can seat primers by feel, or to a positive stop where mechanical adjustment controls primer seating depth. The press accessory is actually easy to set up and works well for short runs also. I think the APS system is faster and cleaner.

As outlined in Part I, the RCBS dies are a three piece set and come with a bushing that reduces the press top plate from 1 ½” to 1″. The dies set up routinely and, even with the mechanical advantage of the big press, I could feel enough resistance in operation to know if things were proceeding correctly.

| Dimension | Virgin brass | Once fired | Sized |

| Case length | 2.735 | 2.735 | 2.745 |

| Neck OD | 0.533 | 0.538 | 0.526 |

| Shoulder OD | 0.600 | 0.610 | .605 |

| Case head OD | 0.616 | 0.618 | .0617 |

The sizer formed cases to provide proper neck tension for bullet seating and to ensure adequate clearance for chambering under field conditions without overworking the brass. The idea is not to have a little grit on a cartridge or in a chamber cause a feed or extraction jam that might lead to something big, ugly, angry and possibly hungry, sitting on the hunter’s chest. The expander die in this set, covered previously, worked well; not opening the case neck excessively and reducing tension for bullet retention and with just enough mouth flare to facilitate bullet seating. The seater was held tight dimension in cartridge overall length and roll crimping. While the seater plug is contoured for round nose bullets, all bullet types used in the project seated without being deformed. RCBS, as is the case with most die manufacturers, will make plugs for specific bullets at a customer’s request.

Oops! Sometimes it happens…

Like most adventures into handloading, eventually a bullet will need to come out of a case without the benefit of ignited smokeless powder. You can forget hammer-like inertial pullers, the case won’t come close to fitting in even a multi collet models. There is no need to spend $240 for a 0.510″ collet puller designed for the 50 BMG when a $32 for a standard 7/8″-14 puller and 50 caliber collet will work just fine, even on the long nose 600 grain bullets. I pulled a few of this type out and the effort was low with the big Ammo Master press. Long spitzer type bullets might require rework of the collet as the nose recess in this standard collet would be too shallow.

The .500 Jeffery requires a standard #37 RCBS shell holder, the same as the .416 Rigby. Unfortunately, only five of twenty Bertram cases fit correctly into the shell holder. Head scratch, puzzled expression on face, followed by semi-audible muttering. The shell holder measured .500″ between the retention edges. The brass that fit measured .494″ at the extractor groove, however, the brass that did not fit measured an out of spec .505″. A quick hit with a 1/4″ aluminum oxide stone and Dremel opened the shell holder to .506″ and allowed it to work with both in and out of specification brass. Fortunately, the oversized brass chambered and ejected normally when cycled through the rifle.

The oversize ram has a 7/8″x14 internal thread, the same size as a conventional die. When the press isn’t being used to handload the .50 BMG, the shell holder adapter that is supplied with the press is secured with two Allen head screws to the top of the ram. The adapter permits the use of standard slip in shell holders. When setup to load the .50 BMG cartridge, the adapter is removed and a $25 shell holder made specifically for this application screws directly into the 7/8″x14 internal ram threads. When decapping, regardless the shell holder type, the spent primers drop into the ram and out through a port that is located about 4″ down on its side and into a primer catcher.

The oversize ram has a 7/8″x14 internal thread, the same size as a conventional die. When the press isn’t being used to handload the .50 BMG, the shell holder adapter that is supplied with the press is secured with two Allen head screws to the top of the ram. The adapter permits the use of standard slip in shell holders. When setup to load the .50 BMG cartridge, the adapter is removed and a $25 shell holder made specifically for this application screws directly into the 7/8″x14 internal ram threads. When decapping, regardless the shell holder type, the spent primers drop into the ram and out through a port that is located about 4″ down on its side and into a primer catcher.

Big cartridge, big press, big bench?

The AmmoMaster II is not an unwieldy piece of equipment. The press has a lot of capacity for cartridge size, it has a lot of mechanical advantage for easy of operation, but it is big only where “big” means strength. The ram is 1 ½”, the cast base plate is 0.640″ thick at it’s reinforcing ribs and 0.400″ at the recesses. The triangular mounting pad provides a great deal of mechanical advantage in opposing force generated by the actuating handle. The top die plate uniformly 0.770″ thick, each of the three support rods are 0.690″ in diameter. The linkage arms are huge at 0.400″x1.10″, all steel parts have a black oxide finish for durability. Because the press also has a simple design with an emphasis on function, all of those heavy parts combine for only 18.7 lb. I often mount presses on simple wood roll carts, rather than drill my main workbenches full of holes for a temporary setup. The AmmoMaster was no exception. A few boxes of bullets and powder on the shelves for ballast and I could crank out ammo effortlessly. I should notch the shelf and set the press back so the load is more evenly distributed over all wheels.

The handload strategy – Bolt thrust and other ways to get into trouble…

In its early form, the .500 Jeffery pushed a soft nose 535 grain bullet to approximately 2,300 fps, which is actually pretty spiffy. In modern loading, the Norma African PH version propels a 570 grain bullet to 2,200 fps; both loads coming in at 6,100 – 6,200 ft-lbs of kinetic energy. There is no SAAMI recommended pressure range for the Jeffery. The 1998 CIP standardization is 46,000 PSI, a pressure limit that was established with 1920-something metallurgy and between war machine tooling, conditions that don’t apply today. Today, the .500 Jeffery is surpassed in performance by the .500 A-Square and .460 Weatherby Magnum, not because of lesser case capacity, case geometry or rifle strength, but rather by pressure levels based on specification. The .460 Weatherby, with 14% less capacity than the Jeffery, operates at a maximum 63,817 PSI. The .500 A-Square with a similar capacity differential operates at the same pressure level of it’s parent case, the .460 Weatherby, or 63,817 PSI. The Jeffery hasn’t been surpassed, it just isn’t generally available in a modern loadings.

I tend to let firearms live up to their potential when I handload. In a modern rifle that can handle 50,000 PSI, I won’t limit a 45-70 Gov’t round to a Springfield Trapdoor limit of 28,000 PSI. I didn’t say I carelessly handload cases full of powder and hope a rifle can handle the load, nor did I say I loaded up until some telltale sign of nose bleed pressures made itself known. The Mauser magnum action is pretty tough. The bolt lugs and chamber walls were not being overly stressed by the .500 Jeffery’s 46,412 PSI CIP pressure standard and the bolt thrust of the big cartridge is actually pretty mild in relative terms.

460 Weatherby 12,123 psi

458 Lott 10,986 psi

500 Jeffery 10,612 psi

505 Gibbs 9,605 psi

416 Rigby 9,228 psi

While the case head diameter above the extractor groove is quite large, the internal case head planar surface, the surface parallel to the rim, is only .495″. The .500 Jeffery, for all of its size, is only mid-range in bolt thrust compared to other cartridges that have routinely made their way into use with the CZ 550 magnum action. Additionally, the .500 Jeffery is 0.021″ smaller in case diameter than the .505 rimless magnum (Gibbs), another cartridge chamber routinely used in conjunction with the CZ 550 magnum. This difference interprets into 19% greater wall thickness and increased resistance to stress that works on chamber walls.

While the case head diameter above the extractor groove is quite large, the internal case head planar surface, the surface parallel to the rim, is only .495″. The .500 Jeffery, for all of its size, is only mid-range in bolt thrust compared to other cartridges that have routinely made their way into use with the CZ 550 magnum action. Additionally, the .500 Jeffery is 0.021″ smaller in case diameter than the .505 rimless magnum (Gibbs), another cartridge chamber routinely used in conjunction with the CZ 550 magnum. This difference interprets into 19% greater wall thickness and increased resistance to stress that works on chamber walls.

Based on history, current chambering and some technical assessment of the firearm, somewhere below 57,000 PSI became my maximum pressure goal. I am not recommending this load level to anyone, not as an issue of liability, but rather I don’t recommend the approach unless the handloader has a way to closely control and measure progress. Predictive software such as QuickLOAD alone won’t get you there. While it is OK for preliminary assessments, it won’t replace a strain gauge or piezo transducer pressure check of a specific firearm, nor will it replace a good chronograph. In comparison to preliminary assumptions arrived at with QuickLOAD, chronograph and pressure data read approximately +/- 10% – 14%.

Handload results, the “Good Grief” part…

| Bullet Type | Bullet Weight |

Bullet Diameter |

C.O.L. | Net Water Capacity |

Powder Type |

Charge | Primer Type |

Muzzle Velocity |

Muzzle Energy |

| Lehigh Solid | 465 | .510″ | 3.417″ | 144.0 | Re15 | 123.0 | CCI 250 | 2551 | 6721 |

| Lehigh Solid | 465 | .510″ | 3.417″ | 144.0 | Re15 | 129.0 | CCI 250 | 2666 | 7341 |

| Lehigh Solid | 465 | .510″ | 3.417″ | 144.0 | H414 | 132.0 | CCI 250 | 2477 | 6337 |

| Lehigh Solid | 465 | .510″ | 3.417″ | 144.0 | H414 | 138.0 | CCI 250 | 2627 | 7127 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | Re15 | 123.0 | CCI 250 | 2556 | 6834 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | Re15 | 129.0 | CCI 250 | 2670 | 7458 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | H4350 | 130.0 | CCI 250 | 2481 | 6439 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | H4350 | 136.0 | CCI 250 | 2593 | 7034 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | H414 | 130.0 | CCI 250 | 2363 | 5841 |

| Lehigh HP | 471 | .510″ | 3.600″ | 141.7 | H414 | 136.0 | CCI 250 | 2493 | 6502 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | Re15 | 120.0 | CCI 250 | 2497 | 7409 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | Re15 | 126.0 | CCI 250 | 2549 | 7721 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | H4350 | 132.0 | CCI 250 | 2462 | 7203 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | H4350 | 139.0 | CCI 250 | 2593 | 7989 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | H414 | 130.0 | CCI 250 | 2379 | 6725 |

| Hawk SP | 535 | .510″ | 3.600″ | 144.8 | H414 | 136.0 | CCI 250 | 2492 | 7379 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | Re15 | 118.0 | CCI 250 | 2431 | 7022 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | Re15 | 124.0 | CCI 250 | 2538 | 7654 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | H4350 | 129.0 | CCI 250 | 2489 | 7361 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | H4350 | 135.0 | CCI 250 | 2604 | 8057 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | H414 | 126.0 | CCI 250 | 2385 | 6757 |

| Woodleigh PP | 535 | .510″ | 3.492″ | 143.1 | H414 | 132.0 | CCI 250 | 2475 | 7279 |

| Barnes TSX | 570 | .509 | 3.700″ | 133.4 | Win760 | 122.0 | CCI 250 | 2439 | 7531 |

| Barnes TSX | 570 | .509 | 3.700″ | 133.4 | Win760 | 128.0 | CCI 250 | 2507 | 7957 |

| Barnes TSX | 570 | .509 | 3.700″ | 133.4 | IMR 4350 | 120.0 | CCI 250 | 2415 | 7384 |

| Barnes TSX | 570 | .509 | 3.700″ | 133.4 | IMR 4350 | 126.0 | CCI 250 | 2522 | 8052 |

| Barnes Banded | 570 | .509 | 3.700″ | 140.9 | Win760 | 125.0 | CCI 250 | 2390 | 7231 |

| Barnes Banded | 570 | .509 | 3.700″ | 140.9 | Win760 | 132.0 | CCI 250 | 2524 | 8065 |

| Barnes Banded | 570 | .509 | 3.700″ | 140.9 | IMR 4350 | 123.0 | CCI 250 | 2406 | 7329 |

| Barnes Banded | 570 | .509 | 3.700″ | 140.9 | IMR 4350 | 130.1 | CCI 250 | 2519 | 8033 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | Re15 | 112.0 | CCI 250 | 2350 | 7359 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | Re15 | 117.0 | CCI 250 | 2421 | 7811 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | Re22 | 131.0 | CCI 250 | 2177 | 6316 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | Re22 | 138.0 | CCI 250 | 2319 | 7167 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | H4350 | 122.0 | CCI 250 | 2383 | 7568 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | H4350 | 128.0 | CCI 250 | 2468 | 8117 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | H414 | 121.0 | CCI 250 | 2305 | 7080 |

| Woodleigh PP | 600 | .510″ | 3.490″ | 137.1 | H414 | 127.0 | CCI 250 | 2414 | 7766 |

| Cast Bullet Loads – Light Loads | |||||||||

| Cast Performance | 350 | .511″ | 3.106″ | 146.0 | 2400 | 40.0 | CCI 250 | 1496 | 1740 |

| Cast Performance | 350 | .511″ | 3.106″ | 146.0 | 2400 | 45.0 | CCI 250 | 1642 | 2096 |

| Cast Performance | 410 | .511″ | 3.159 | 143.4 | 2400 | 40.0 | CCI 250 | 1454 | 1925 |

| Cast Performance | 410 | .511″ | 3.159 | 143.4 | 2400 | 45.00 | CCI 250 | 1618 | 2384 |

Joe, what does all of this mean?

Funny, I was thinking exactly the same thing. The .500 Jeffery is a very powerful cartridge and a convincing stopper. I am not sure the difference between this cartridge and the 460 Weatherby or .458 Lott justifies the dramatic cost difference for ammunition and handloading components. While the cartridge can be flexibly loaded for lighter and longer range duty, I don’t know if this serves a practical purpose. Light loading does not particularly diminish the cost of ammunition and handload components, nor does it remove weight from a rifle that is necessarily heavy to handle full up loads and not beat the shooter to a pulp. Light loading the Jeffery would be like paying $100,000 for a 500 horse power SUV then driving at exactly 55 miles per hour to save on gas. I think if I were prepping to go hunting for the largest game, or of I just liked handloading big bores and understood the associated cost and limitations, the Jeffery would be a great cartridge selection. If I needed something to do double duty and cover both heavy and medium size game, I’d probably look elsewhere. There is nothing in North America that warrants this cartridge and I don’t think there are many people who would want to haul a 10 lb gun around in pursuit of brown bear. It would seem for African dangerous game hunting there are also more modern, even if subordinate, cartridges.

As a ballistic note, the .500 Jeffery is fairly flat shooting. A Barnes 570 grain TSX can be zeroed at 200 yards and shoot that same distance point blank. Even at 300 yards, bullet drop is only 10″ and the bullet is still moving like a runaway freight train with 4,300 ft-lbs of energy. That is pretty spectacular big game cartridge performance.

| .500 Jeffery 570 Grain Barnes TSX | |||||||

| Indices | Range | ||||||

| Range – yds. | 0 | 50 | 100 | 150 | 200 | 250 | 300 |

| Velocity – ft./sec. | 2500 | 2384 | 2271 | 2162 | 2055 | 1952 | 1852 |

| Energy – ft.-lbs. | 7909 | 7192 | 6528 | 5913 | 5346 | 4824 | 4343 |

| Path – in. | -1.5 | 1.3 | 2.6 | 2.2 | -0.0 | -4.3 | -10.9 |

On the other hand, the recoil even in the 10 lb SC 550 is a concern. I shoot a lot of heavy rifles, but the Jeffery is sincerely not fun after a few rounds at the bench. An initial smile is quickly replaced with a grimace and a search for soft things to put between the rifle and shooter’s shoulder takes priority. Recoil while hunting, where shooting is limited to a shooting a few rounds through an adrenaline haze, would not be a big deal or distracting enough to have a negative effect on accuracy. A day of development handloads is another story.

Accuracy of the CZ SC 550 and .500 Jeffery isn’t bad, even without a scope on the rifle to optimize group size. I was able to put together a number of 1 ½” three shot groups at 100 yards with the factory installed express sights. I am a good shot, but my eyes aren’t, so that’s impressive performance for me. Shooting a rifle of this type for accuracy is different than shooting more typical smaller bore high velocity magnums. With 140 – 150 ft-lbs of recoil, on discharge there is significant rifle movement, there is significant shooter movement, there is significant shooting bench movement and, I’m pretty sure, the ground moves just a little bit. My point is that it takes a lot more to get the gun back to it’s original point of aim after each shot which is not conducive to optimal group sizes.

I’m glad CZ-USA is producing these types of rifles and covering the really big bores at a price that is not out of reach…even if requiring some determined stretching. I think we are all fortunate that RCBS is producing quality equipment and tools for these cartridges so we can all pursue our enthusiasm for these rounds and maybe preserve a little part of firearm history.

The 500 Jeffery Project – Part I – When Way Too Much Is Just Enough

The 500 Jeffery Project Part II – Handloads and Range Results – Good Grief!

The CZ SC550 Safari Classic Part I

The CZ SC550 Safari Classic Part II

Email Notification