It might be a good idea to begin with Part II of my articles before reading Part I. Part I contains my creative theories and conjecture. Part II contains all of the post live fire corrections. If not outright corrections, certainly revised opinion.

It might be a good idea to begin with Part II of my articles before reading Part I. Part I contains my creative theories and conjecture. Part II contains all of the post live fire corrections. If not outright corrections, certainly revised opinion.

Part I cast aspersions on what I referred to as the stock’s “reddish tint”. I stood the rifle against a shop wall and every FedEx and UPS guy that came into the office commented favorably on the appearance of the rifle. Customers and people who work at Real Guns did the same, as did my wife, just before she left to visit the grandkids in California…which I assume was an unrelated act. So let’s revise my observations of the gun’s aesthetics to “It’s a good looking rifle that has a…comfortable look about it and the checkering adds a nice touch of elegance”.

The plastic magazine follower that was disparaged in Part I has a high level of lubricity so loaded cartridges scoot across the surface when being chambered like…cartridges scooting across a really slippery surface. The worst analogy I ever attempted. CZ currently ships with a steel magazine follower and will change out the plastic part free of charge.

Through all of the heavy handloads and hot barrel sessions, the CZ 550 never burped, belched or sighed to signal a mechanical breakdown. In fact, the action got smoother, the bolt stayed tight without all of the wobble typically associated with Mauser actions, and that floating barrel and aft support proved to be an active contributor to the gun’s accuracy.

The set trigger came in handy. I was near the 150 round mark of test firing and began using the set function when shooting three shot groups. It took some trigger finger / brain adjustment for optimal control, but it was easy to see field situations where the light release would help a winded or muscle stressed hunter.

The scope mount system delivered. An inexpensive Simmons ProHunter scope was mounted and both the CZ mount system and scope did an admirable job throughout the project. Motion resulting from less than adequate mounting systems is at the core of most scope failures. The CZ combination of dovetail and locating lug really anchors the optics so this type of problem doesn’t develop. The scope held zero, the Simmons’ design minimized parallax and there was more than enough eye relief to make head position comfortable regardless shooting position.

Metric rehab, the .30-06 Springfield

Gratuitous comments to follow -The .30-06 Springfield is often neglected. It is a ‘tween round; not big enough to get pulled along by our fascination with magnums and too long to get picked up in our celebration of all things short. It does little to stoke the imagination of the first time gun buyer and it does little for those who think rifles are an extension of…boot size. For people who actually like to hunt, and don’t require peer collaboration to make a firearm buying decision, the .30-06 Springfield is one of the most practical cartridges in use today and up to the task of bringing down the largest of North America game.

Gratuitous comments to follow -The .30-06 Springfield is often neglected. It is a ‘tween round; not big enough to get pulled along by our fascination with magnums and too long to get picked up in our celebration of all things short. It does little to stoke the imagination of the first time gun buyer and it does little for those who think rifles are an extension of…boot size. For people who actually like to hunt, and don’t require peer collaboration to make a firearm buying decision, the .30-06 Springfield is one of the most practical cartridges in use today and up to the task of bringing down the largest of North America game.

The history of the .30-06 Springfield is tough to write about in a way that would be meaningful. The corollaries are old enough to occupy a point in time predating the memory of most readers. If I said that I have fired literally thousands of rounds of CMP supplied ball ammo through Garand, Springfield and Enfield rifles, there would be lots of folks thinking, “What’s a CMP?”, “What’s a Garand?”, and “Did I turn the coffee pot off before I left the house?”. The .30-06 Springfield use to be the cartridge of my father’s war. Now it is the cartridge of your great grandfather’s war but, like many other near hundred year old cartridges, not much better has ever come along.

The name is pronounced thirty “aught” six. Not thirty “oh” six, thirty “zero” six or trenta “zero” sei. Aught means zero, a number of insignificant value, or at least it did so when the cartridge was named and engineers did calculations with slide rules. If you have a need to appear Euro or to be a citizen of the world rather than the U.S., buy a man purse, pretend you’re from France, but please leave the name of the thirty aught six as it was intended.

The round other cartridges are almost as good as…

The .308 Winchester can almost match the performance of the .30-06 Springfield. In a world where second best is held in high regard, that would be a ringing endorsement of the .308 Winchester. In fact, the .308 Winchester wasn’t even a shooter’s choice, it was a government purchasing and logistics choice. The .308 Winchester, compared to the 30-06 Springfield, uses less brass, less powder and weighs less, which makes it less costly to manufacturer and cheaper to transport. Additionally, rifles chambered for the .308 Winchester can utilize a shorter action, which again means less material and lower cost. The penalty for enjoying these strategic cost advantages is compromised performance, without an upside for the shooter, as the .30-06 Springfield outperforms the .308 Winchester in every way. For the consumer, a rifle chambered for the .308 Winchester will not cost less, nor will it weigh less. It will only shoot to a level of performance approximately 100 – 150 fps below the .30-06 Springfield with comparable bullets. Yes, the .308 Winchester is almost as good as the .30-06 Springfield…and I almost have hair.

The .30-06 Springfield in context…

At the age of twelve, I had a choice of a .30-30 WCF or a .30-06 Springfield as my first center fire rifle. I picked the .30-30 WCF. Unfortunately, in making that decision, I left behind 800 fps of muzzle velocity, nearly twice as much kinetic energy and 80 additional yards of point blank range. Tradition has its price and youth has its ignorance. Apparently I was young for a very long time.

At the age of twelve, I had a choice of a .30-30 WCF or a .30-06 Springfield as my first center fire rifle. I picked the .30-30 WCF. Unfortunately, in making that decision, I left behind 800 fps of muzzle velocity, nearly twice as much kinetic energy and 80 additional yards of point blank range. Tradition has its price and youth has its ignorance. Apparently I was young for a very long time.

.300 Winchester magnums, regular and short, attempt to out perform the .30-06 by increasing case capacity from 68 grains to 88 and 81 grains respectively. With this extra powder, the .300 Winchester Magnum’s 165 grain performance can be matched with Hornady .30-06 Light Magnum ammo. The WSM’s 100 fps velocity edge equates to a 3% bump. A lot more recoil and a lot more cost for little gain.

If measureable ballistic superiority is desired, something on the order of the 30-30 WCF to .30-06 Springfield differential, the .300 Remington Ultra Mag is probably the next meaningful increment. 600 fps and 60 yards of additional point blank range can be gained over the .30-06 Springfield with reasonably priced rifles and ammunition. Barrel lengths being equal, no H&H based .308″ magnum cartridge can match this performance, including the venerable .300 Weatherby Magnum. Yes, really.

If measureable ballistic superiority is desired, something on the order of the 30-30 WCF to .30-06 Springfield differential, the .300 Remington Ultra Mag is probably the next meaningful increment. 600 fps and 60 yards of additional point blank range can be gained over the .30-06 Springfield with reasonably priced rifles and ammunition. Barrel lengths being equal, no H&H based .308″ magnum cartridge can match this performance, including the venerable .300 Weatherby Magnum. Yes, really.

For as much as I like super high velocities, as a practical matter, the requirement is very limited and the performance improvements come with significant tradeoffs. On one hand there are 60 yards and significant increased in kinetic energy to be found, on the other – a 6 lb. 30-06 with a 22″ – 24″ barrel, modest recoil, $20 box ammo, and rifle price tags in the $300 – $500 range. The wisdom of the .30-06 Springfield begins to loom large. Additionally, the .30-06 Springfield is available in bolt action, lever action, pump action, and autoloader form. The 30-06 Springfield is at home on Midwest prairies, the dense woods of Maine, the rolling Black Hills of South Dakota, or costal areas of Alaska, or…

If you can’t find an appropriate bullet, you must be in Bolivia

It took about five minutes to round up this cast of characters from bench stock. .308″ bullet are like Tribbles, they can be found anywhere and everywhere. Some are more useful than others, all are worth a look, each gives the .30-06 Springfield a slightly different personality and capability. Some just provide a great deal of entertainment value at a very low cost.

| Primary Bullets Selected for Project Left – Right | |||

| Bullet | Weight | Length | Max COL |

| Hornady RN | 110 | 0.680 | 3.015 |

| Remington PSP | 125 | 0.814 | 3.038 |

| Barnes TTSX | 130 | 1.173 | 3.250 |

| Hornady | 150 | 1.100 | 3.230 |

| Winchester | 150 | 1.047 | 3.120 |

| Barnes TTSX BT | 150 | 1.300 | 3.320 |

| Privi PSPBT | 165 | 1.170 | 3.200 |

| Sierra Spitzer | 165 | 1.180 | 3.165 |

| Barnes TTSXBT | 168 | 1.414 | 3.380 |

| Nosler Ballistic Silvertip | 168 | 1.310 | 3.300 |

| True Shot cast RNFPGC | 170 | 0.976 | 2.950 |

| Nosler Partition | 180 | 1.268 | 3.270 |

| Sierra Spitzer | 180 | 1.203 | 3.270 |

| Barnes TTXBT | 180 | 1.478 | 3.317 |

| Hornady BTSP | 190 | 1.332 | 3.295 |

| Nosler Accubond | 200 | 1.504 | 3.355 |

| Dimensions stated as measured | |||

Within this group construction varies. All copper Barnes bullets are plastic tipped with an expansion cavity. The shank is grooved to reduce bore friction and fouling. The Nosler Partition is an “H” jacketed type bullet, an early bullet design intended to promote high sectional density with expansion limited to the forward lead core and more fragile jacket of the forward compartment. The balance of the jacketed bullets are single core, tapered jacket. The lead cast is an inexpensive gas check design with sufficient weight to make it a serious bullet, but very low in cost and flat tipped for an intended .30-30 WCF application. The 110 grain Hornady is probably more at home as a .30 caliber carbine bullet.

Light weight within these selections does not necessarily mean fragile and low penetrating bullets. The Barnes 130 grain is substantial enough for antelope and deer. The Remington 125 grain PSP, however, has a fragile jacket and is intended for thin skinned light game.

The maximum cartridge overall length as established by SAAMI for the .30-06 Springfield is 3.340″. A Hornady COL gauge and bullet comparator was used to establish maximum cartridge overall length for the project handloads specifically in concert with the CZ 550 American. In two cases I exceeded SAAMI maximum because I was able to get a performance gain, while maintaining .030″ of chambered round to rifling clearance. Bullet length was taken from direct measurement which, on occasion varied by as much as 0.020″ from other published data while consistent from one bullet to the next.

Handloads – The Grue and the Flat Primer Society…

I like taking pictures for the site. I can look at them and remember where I spent the prior forty hours of my life. The sixteenth load, a 165 grain Hornady, is covered in the first installment of the CZ 550 Project. Nothing really eventful about the process. There were only a few compressed loads as cleverly indicated by the “C” designation next to the powder charge. The 190 grain Hornady load COL was set after checking with a COL gauge to get a little more room for powder and were not located to the cannelure. The only bullets crimped were the cast 170 grain loads.

| Bullet Type | Bullet Weight | Net Water Capacity | COL | Powder Type | Powder Charge | Muzzle Velocity |

| Hornady RN | 110 | 65.9 | 3.015 | 2400 | 22.0 | 2200 |

| IMR3031 | 58.5 | 3618 | ||||

| Varget | 61.0 | 3528 | ||||

| Remington PSP | 125 | 63.1 | 3.038 | Re 15 | 59.0 | 3330 |

| IMR4895 | 57.5 | 3341 | ||||

| Varget | 58.0 | 3349 | ||||

| Barnes TTSXBT | 130 | 60.6 | 3.250 | Re 15 | 56.0 | 3140 |

| BL-C2 | 57.5 | 3296 | ||||

| IMR4895 | 55.5 | 3268 | ||||

| Hornady BTSP | 150 | 62.8 | 3.230 | Re 15 | 56.0 | 3086 |

| BL-C2 | 58.0 | 3012 | ||||

| IMR4350 | 61.0C | 3003 | ||||

| Winchester | 150 | 60.2 | 3.120 | IMR4350 | 59.0 | 2916 |

| H414 | 59.0 | 3003 | ||||

| Barnes TTSXBT | 150 | 59.5 | 3.320 | BL-C2 | 56.0 | 3008 |

| H414 | 59.0 | 3019 | ||||

| Privi PSPBT | 165 | 59.8 | 3.200 | Varget | 53.0 | 2994 |

| IMR4350 | 57.5 | 2842 | ||||

| Sierra Spitzer | 165 | 59.3 | 3.165 | IMR4895 | 52.0 | 2964 |

| IMR4350 | 57.0 | 2863 | ||||

| Barnes TTSXBT | 168 | 58.5 | 3.380 | BL-C2 | 53.0 | 2983 |

| IMR4350 | 56.5 | 2858 | ||||

| H414 | 56.5 | 2902 | ||||

| Nosler Ballistic Silvertip | 168 | 59.0 | 3.300 | BL-C2 | 54.5 | 2936 |

| IMR4895 | 52.0 | 2916 | ||||

| IMR4350 | 57.0 | 2840 | ||||

| True Shot Cast RNFPGC | 170 | 58.4 | 2.950 | 2400 | 24.0 | 1866 |

| Re 15 | 50.0 | 2617 | ||||

| Varget | 48.0 | 2636 | ||||

| Nosler Partition SP | 180 | 58.9 | 3.270 | Re 19 | 59.0C | 2743 |

| IMR4350 | 55.5 | 2738 | ||||

| Sierra Spitzer | 180 | 61.5 | 3.270 | IMR4831 | 58.5C | 2785 |

| IMR4350 | 57.0 | 2800 | ||||

| Barnes TTSXBT | 180 | 56.1 | 3.317 | IMR4350 | 54.0 | 2794 |

| H414 | 54.0 | 2777 | ||||

| Win 760 | 55.0 | 2800 | ||||

| Hornady BTSP | 190 | 59.0 | 3.295 | Re 19 | 58.5 | 2817 |

| BL-C2 | 52.5 | 2858 | ||||

| IMR4831 | 56.0 | 2714 | ||||

| IMR4350 | 55.0 | 2736 | ||||

| Nosler Accubond | 200 | 59.0 | 3.295 | Re 19 | 56.0 | 2577 |

| IMR4350 | 52.5 | 2628 |

Results…

We’ll, that was a lot of fun. After working with a lot of short case cartridges, it was nice to handload something that didn’t run out of capacity with most powders, and could handle long bullets without worrying about action or magazine length.

We’ll, that was a lot of fun. After working with a lot of short case cartridges, it was nice to handload something that didn’t run out of capacity with most powders, and could handle long bullets without worrying about action or magazine length.

The range of bullet weights, flexibility of handloads and the range of performance that could be produced were…impressive. I don’t believe I’ve worked with many rounds that could double bullet weight in a comfortable operating range.

The CZ 550 American performed well. It didn’t shake loose in use, accuracy was excellent and even things like a heated barrel had little impact on performance.

Tougher than a bucket of rocks…

When I collect data, I back up the chronograph with a target at about 15 yards with a five gallon plastic bucket filled with ½” drip line stone and wet construction sand. Approximately one part stone to three parts sand seems to work best. The polystyrene bucket is almost self healing so material doesn’t pour out as the target is hit and the filler material confines lead fragments while letting virtually nothing pass through. I am sure the approach violates someone’s sensibilities, but I have not had any problems with this set up. When one spot gets shot up a bit; ten or twelve rounds, I rotate the bucket to a fresh spot. If the lid is on tight, a bucket will last for more than one hundred rounds.

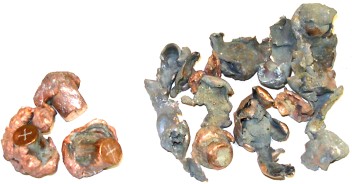

The condition of collected bullets was unscientifically interesting. Pictured right are approximately 30 slugs removed from the bucket. Most are no more than shards of jacket material and ribbons of cast lead. The only three bullets that remain relatively intact were the Barnes TTSX bullets. They began life as 130, 168 and 180 grain and ended their brief carrier at 106, 146 and 163 grains respectively. Not bad for running into rock above 3,000 FPS at 15 yards. Barnes bullets recovered from more appropriate test medium at one hundred yards mushroomed in very similar fashion but retained 96% to 99% of their original weight. That performance is a big deal to me as I have taken far more deer and wild hogs inside of fifty yards than I have at 200. I’m paying a lot more attention to recovered bullets these days and finding a need for revised perspectives.

The condition of collected bullets was unscientifically interesting. Pictured right are approximately 30 slugs removed from the bucket. Most are no more than shards of jacket material and ribbons of cast lead. The only three bullets that remain relatively intact were the Barnes TTSX bullets. They began life as 130, 168 and 180 grain and ended their brief carrier at 106, 146 and 163 grains respectively. Not bad for running into rock above 3,000 FPS at 15 yards. Barnes bullets recovered from more appropriate test medium at one hundred yards mushroomed in very similar fashion but retained 96% to 99% of their original weight. That performance is a big deal to me as I have taken far more deer and wild hogs inside of fifty yards than I have at 200. I’m paying a lot more attention to recovered bullets these days and finding a need for revised perspectives.

Other bullet performance…

The very light bullets and cast bullets were a blast to shoot at reduced velocity. Virtually no recoil, but flat enough shooting for one hundred yards or so. I have no doubt the 170 grain cast flat nose would do fine on deer even at the reduced velocity. The little 110 grain Hornady expanding round nose loads would do fine on small game and they had very low report at reduced loads. It was fun to push the 110 grain bullets above 3,600 fps, but they have a BC like a barn door so there is little benefit to stuffing these rounds full of powder. I use 2400 for most reduced loads. I picked up the habit of using this powder when loading reduced cast loads for the 500 Jeffery. The powder doesn’t seem to be sensitive to low density charges and doesn’t require case filler. Shot to shot performance is very uniform.

The 125 grain Remington bullets are cheap and great for varmints. While I am sure the .224″ guns are more adaptable for long range chucks, the 125 grain wasn’t a slouch either. A little low in sectional density for the .308″ bullet, but 300 yards would not be a problem and, in today’s over congested world, that’s a long ways off. A suitable antelope and deer bullet began at the 130 grain mark with Barnes TTSX bullets, probably at the 150 grain mark for the lead core material. 165 and 168 grain are all serious deer, elk, moose, and black bear loads; flat shooting, hard hitting, tough jackets and bullets that hold together. I’d guess the 180, 190 and 200 grain bullets would be substantial enough for large bear and a little more margin of kill power for other large game. Personally, outside of the 180 grain Barnes, the other heavier seemed a little fragile. The Nosler Partition held up at the shank but fragmented at the nose and the single lead core jacketed bullets had a lot less latitude for expansion velocity than I would have imagined.

The CZ 550 American, after the dust settled…

The CZ 550 American has some very specific things working for it that have practical benefits for the hunter and handloader. There is a lot of room in the magazine box, so even max COL rounds have over .300″ clearance with a smooth transition to the gun’s feed ramp. The gun locked up tightly and demonstrated no signs of excessive pressure during the handloading exercise; flat primers, bright spots, etc. Headspace for the .30-06 Springfield from a .375″ diameter shoulder reference diameter to the flat of the case head is 2.0526″ – 0.0070″. New brass measured 2.0350″ and grew to 2.0400″ maximum with no change being the norm. Good stuff. Brass last longer when it isn’t stretched unnecessarily and there is less chance of case head separation. Spec for shoulder diameter is 0.4410″ +0.0020″. Fired cartridges consistently measure 0.4430″. No overly tight chamber and max case capacity while maintaining spec. I think the chamber dimensions and care in machining showed in accuracy.

Bullet stability and accuracy…

I was concerned the 10″ twist would not stabilize heavy long bullets. The Nosler 200 grain Accubond and Barnes 180 grain TTSX at 1.504″ and 1.478″ respectively were the primary concerns. These are both excellent bullets just not typical of the norm for these weights. Most manufacturers fatten up the ogive and give up good BC numbers as bullets increase toward the heavy end of a caliber’s weight spectrum, usually concluding with a round nose. Nosler elected to hold onto a good BC so the weight could only be accommodated by making the bullet longer. The Barnes bullet is all copper construction, less dense than lead, so longer than a lead filled bullet of corresponding weight. In actuality, the 10″ twist rate of the CZ had no problem handling these longer bullets.

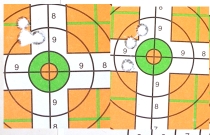

The CZ 550 American is a shooter. Between the very rigid action, the floating barrel and a solid spot glass bedding job, the small group measured ½”, a Barnes 168 grain TTSX, the big group was a hair over 1″, a Nosler 180 grain partition. Of the powder types and charges deemed acceptable, there were lots of 1″ groups and slightly under. The Barnes 168 TTSX shot consistently the best and I think it is an optimal weight for the .30-06 Springfield for large game. If I wanted to load 5 boxes of hunting ammo for routine use, this would be the bullet.

Every once in a while, someone will write and ask how I am able to get such good groups out of what amounts to factory rifles and all of my handloads perform so well. That’s an easy answer, I don’t on both counts. If I start a project on a gun that won’t shoot straight, I run it through the routines of checking bedding, barrel channels, loose fasteners and ammo. I think I’ve had one rifle that didn’t respond to this approach so it did not make it to a project. With all of the improvements in manufacturing tools and techniques, it’s tough to make a bad mass produced rifle these days.

Approximately 25% of the time handloads work out really well. About 60% are not great, but big game hunting worthy and about 40% are loads that will never see my bench again. I publish the best of what I assemble. Why don’t I publish all of the data? I only need to make a couple of each round to see which leave the barrel for points unknow and I can quickly set those aside. Then I need to make a couple more of each to set aside the best 25%. Then I need to assemble a good number of each of these to validate pressure and accuracy. If I were to publish the inaccurate load data, I would have to invest as much time to make sure they are safe and consistent in performance as I do for the best loads and all I would be publish is data for save, but very inaccurate ammunition. A waste of time and a waste of money. What you see here is the best of what I was able to assemble.

Good looks and great personality…

Rifles always seem to have three aspects that form a lasting impression. The first is appearance, the second is shooting personality, the third is the human organization behind the product. The first two items have been covered, so I will address the third. I made a number of calls at various times to check details and verify assumptions. I just called their web site listed tech support line and got whoever answered the phone. They don’t know me and I represent myself as a customer, and sometimes not a very bright one at that. They know their products, they chase down answers and are actually polite. If you do a search on Google or in popular message boards that cover their products, I bet you won’t find anyone who doesn’t have a good word about CZ product support or has a hard time figuring out who to contact when problems arise. I think you’ll find they get big points for being accessible and for being candid in addressing product issues.

If you’re looking for a solid, well made and reliable rifle at a great price and a cartridge that will cover virtually any North American hunting, you probably don’t have to look further than the CZ 550 American and the .30-06 Springfield.

More CZ 550 American and .30-06 Springfield information:

The CZ 550 American – A Classic .30-06

The CZ 550 American Part II – Metric Rehab – Handloads for the 30-06 Springfield

Handloads for the .30-06 Springfield

Email Notification