My first thought, for a photo that would best illustrate handloading, was an image of a giant river otter. Otters always seem to be having fun, floating around on their collective otter backs and eating fish all day. And handloading is all about fun…although maybe not so much about floating around and eating fish… but definitely about fun. Eventually, I woke from my nap and decided to go with an over crowded reloading bench and clear evidence of out of control spending on colorful equipment and non-essential gadgets. And that otter do it…

Galileo, Galileo…

Firearm and associated industries were built on a foundation of inventors and experimenters, each with the ability to see a horizon that was just a little further out there than most others could see. Many of the cartridges that remain popular today were developed by wildcatters, gunsmiths, or small cottage industry gun shops well before the availability of pressure testing equipment, electronic chronographs or personal computers ladened with simulation software. I am not suggesting that modern manufacturers haven’t since taken these same cartridges and refined them and defined them and hammered them into enhanced commercial products, but I am saying that many cartridges have served us well for the past one hundred years that originated with the efforts of these early enthusiasts.

Handloading will always be driven by pickers and pokers, and hunters and shooters, and pirates and cowboys, and other people who need to know what happens when they combine some things with other things, and measure the results of incremental changes of 0.001″. Handloading is not in the reserve of the technocrat, or lab rat or overly articulate message board poster who has earned the ranking of “super nimrod” by over talking and out posting every other board participant. No one’s permission is required to handload and a committee is not required to measure the results. Handloading is a freedom, self expression, competition, learning and understanding. Handloading is an opportunity for a man to exercise his right to hide in his home shop and pretend he is doing something important.

The intersection of Easy Street and Obsessing Alley…

Ninety five percent of handloading is derivative. It is based on data published by credible sources and finessed to completion with: results from an inexpensive chronograph, the feel of empty case extraction from a firearm, listening to report, and observing the appearances and dimensional changes from handload to fired brass. The remaining five percent is commercial product validation, wildcat cartridge development and/or handload dynamics analysis done under the auspices of simulation software, strain gauge and piezo transducer test equipment. If the batteries in my test equipment croaked, and/or I couldn’t find an AC outlet, the resources would be missed, but this wouldn’t mark the end. Technology is fun and educational, but not essential to handloading. Although I am pretty fond of smokeless powder…

Sometimes, particularly when a cartridge will see use in a narrow application, developing a good handload requires no more than referencing a copy of a manufacturer’s reloading manual. Dimensional specifications are provided, relative performance expectations are defined and there is the benefit of having access to knowledge gleaned from the use of very expensive equipment and a highly skilled technical staff. Powder of preference can be selected from the listed recipes and it is easy to begin with light loads and work up until accuracy and muzzle velocity are optimized. Potential improvement over factory ammunition could be an increase in accuracy, significantly lower cost and a better combination of components not available elsewhere.

Sometimes, particularly when a cartridge will see use in a narrow application, developing a good handload requires no more than referencing a copy of a manufacturer’s reloading manual. Dimensional specifications are provided, relative performance expectations are defined and there is the benefit of having access to knowledge gleaned from the use of very expensive equipment and a highly skilled technical staff. Powder of preference can be selected from the listed recipes and it is easy to begin with light loads and work up until accuracy and muzzle velocity are optimized. Potential improvement over factory ammunition could be an increase in accuracy, significantly lower cost and a better combination of components not available elsewhere.

This is my routine for this type of load refinement. Three powder types out of perhaps a dozen listed in the manual are selected. Following the manual’s assembly dimensions and instructions, three rounds of each are assembled to a midrange charge within the charge the range listed. Maximum charges are not used for obvious safety reasons, and minimum charges are not used because they tend not to be reflective of a powder’s potential and performance tends to be a little erratic. The powder type that produces the best three shot groups and chronographs closest to the manual’s listed velocity is the one that gets further refinement.

A second batch of ammo is assembled, all to the same dimensions and instructions, beginning with the minimum, progressing to maximum charge. Half grain increments are applied until the last grain where increments are reduced to two tenths of a grain. Based on typical charge ranges provided in manuals, twelve rounds will be required to cover the charge increments and three samples of each increment are loaded. Because accuracy is almost always the overriding objective, the most accurate becomes the favored recipe and another eighteen rounds are loads and shot to verify accuracy and velocity consistency. All done.

Nine rounds for powder selection

Thirty-six rounds to identify most accurate charge

Eighteen rounds for verification

Sixty-three rounds in total expended

Once fired brass of the same manufacture is used for all loads for the most consistent charge volume, no further brass sorting is done. Brass is always trimmed to consistent length and, as powder, primer and bullet lots change, a handload of this type is rechecked during routine recreational shooting. This is usually enough to find a sub MOA load from any rifle that has sub MOA potential. The performance improvement is found in tuning a handload into mechanical harmony with a specific firearm. If a change in brass, powder, primers or wear and tear on a guns chamber or barrel cause a loss in performance, the process needs to be rerun to reestablish an optimal load.

Sometimes handloading isn’t about finding that one great whitetail load for the fall hunting season. Sometimes handloading is an end unto itself providing the enjoyment of working with an unfamiliar firearm and cartridge combination and exercising curiosity and conducting a detailed cause and effect analysis. I am not a competitive shooter, and I am not a year round hunter. Like a lot of folks, I just like firearms and recreational shooting and I find learning more about ballistics and how firearms and cartridges work to be a rewarding use of time.

In the world of handloading, the firearm sets the rules…

The opportunity to work with a unique firearm and cartridge combination come to us in many ways. Personally, I usually go with “Hey! Neato gun. Now that I own it, I wonder what I’ll do with it?” Sometimes that process results in a .25-06 Remington with an 16½” barrel, but sometimes it results in a CZ-550 FS chambered for the 9.3x62mm that is destined to become one of my favorite combinations.

The CZ 550 FS is moderately light, compact and fast handling. The 9.3x62mm is a very flexible cartridges to handload, probably second only to the .45-70 Gov’t in this regard. The round can be light loaded for deer, nudged up for moose and heavily loaded for big bear and even cape buffalo. Despite that potential, each firearm chambered for the round brings its own set of performance limitations that have to be incorporated into handload expectations.

With virtually all published data for the cartridge based on a 26″ barrel length, handload velocity for a 20.5″ gun would always be less than listed in reloading manuals. Consequently, pressure levels as a product of velocity could not be inferred. Additionally, the slowest powder types applicable to this cartridge would not be useful unless the intention was to concurrently shoot and BBQ game. At some point in time, heavy charges of slow burning powder end up as so much muzzle flash and unburned residue.

Using light for bore bullets for the purpose of attaining significantly higher velocity might not be practical with a short barreled gun, as short barreled guns tend to narrow velocity spread driven by bullet weight and charge variations. Light bullets and heavy powder charges generally produce significantly higher muzzle velocity when there is enough barrel length and bore capacity to contain a more persistent gas generating charge. With a 26″ barreled gun, the velocity spread from a 232 grain bullet to a 325 grain bullet may be in excess of 600 fps, making it well worthwhile to exploit the potential of lighter bullets. From a 20.5″ barrel gun, the spread may realistically be half that amount. Subsequently, it often makes more sense to shoot heavier bullets from a short barreled gun and to moderate bullet construction and charge levels to match up with the game on the hunting agenda.

My point is that all rifles chambered for the same cartridge will not deliver the same absolute ballistic performance and this should be noted and accepted before attempting to load a 20″ barrel gun up to run along side a 26″ gun in muzzle velocity performance. Components can be juggled to play to the positive attributes of a rifle. The trade off for a short rifle is light weight and fast handling in dense cover where shooting is over shorter ranges. In exchange, the shooter can’t expect to pop field mice at 900 yards. But then the 9.3x62mm was never intended to be a long range shooter regardless barrel length. See where I am going here? If you do, send me an email and let me know, because I’m lost right about now… I think the point is that good handloads consider the unique aspects of a firearm.

When in doubt, cut them up….

Bullets seem a good starting point when handloading as, at the end of the day, they are chartered to complete an assignment and they do a great job of keeping powder in a case. Following a manufacturers’ recommendations for matching bullets with cartridge generally assures a cannelure will be in the right place and the cartridge will assemble to an appropriate cartridge overall length. Additionally, the bullet will be constructed to deform to the degree the manufacturer intended within the cartridge’s velocity range.

The 9.3mm bullets pictured right are quite different in some respects and very much redundant in others. They were the preliminary selection when the objective was to find a lightly constructed bullet for deer, hogs and black bear, a tougher bullet for heavy bodied large game like moose and elk and a still tougher bullet for large bear. Finally, there was a need for a heavy hitting solid for the cape buffalo I plan to hunt. Based on budget constraints, the trip isn’t penciled in on my calendar until 2049, but I can hardly wait.

Yeah, I know, not milling machine art, but enough metal removal to peek inside some of the selected bullets. Marketing spec data is very helpful but bullet recovery, or taking a peek inside, tells a lot about a bullet as there are variations in jacket thickness within the same product line. The 250 grain Barnes Triple Shock, far left, flies in opposition to the Third Law of Short Barrel-Heavy Bullet Blah Blah. Barnes suggests the bullet may be used for everything from Elk to Cape Buffalo. In testing, the bullet expanded to near double diameter, retained almost all of its original weight and penetrated to a depth somewhere between that of a tough lead core bullet and a banded solid. Just because a bullet is light doesn’t mean it has to travel at 5,000 fps to leave an impression. It was selected for toughness, not velocity.

The inexpensive 286 grain Prvi bullet with thick jacket material and core locking rings is impressive. Maybe not a construction ideally suited for whitetail deer, but a good heavyweight for moose and elk and bear. It would also make for a good practice load as the cost makes these very affordable. Nosler’s Partition 286 grain is an “H” design which always leads to a certain amount of ambivalence on my part. The nose rapidly and easily expands, the aft portion hangs together and drives for deep penetration. When they are recovered, they are typically two thirds their original weight and the jacket cross bridge and aft portion are almost always intact. They drop game consistently so maybe the picture perfect mushroom we often envision is not worth more than a nice picture. The Norma heavyweight with tapered jacket thickness, is an expander. The forward jacket is quite thin at the nose, thickening as it moves aft and very thick where the cup forms. It might seem like a bullet with a nose that upsets too easily, but at 325 grains it does not move along at cruise missile speeds so much heavier construction would make it into a game piercing round.

It appears as though the 320 grain Woodleigh, left, is inline with the Prvi pictured above in terms of a tough jacket and controlled expansion. A very good bullet, but redundant in performance and passed over because of high cost and short supply.

It appears as though the 320 grain Woodleigh, left, is inline with the Prvi pictured above in terms of a tough jacket and controlled expansion. A very good bullet, but redundant in performance and passed over because of high cost and short supply.

The Hornady, right, is actually made for a slightly slower 9.3x72R cartridge. It has a relatively light jacket and simple one piece core. It is low in cost which makes it a good choice for practice shooting and, based on construction, it could be loaded down for deer hunting.

Virtually every bullet listed is designed to expand reliably between 1,600 and 2,200 fps of impact velocity, however, suitability for this particular application is only conjecture until a bullet is recovered from game or test medium and a proper assessment is made.

Bullet tie breaking…

Ultimately, when there are several similar types of bullets delivering good accuracy and velocity, the final selection could be based on bullets recovered from test medium shot at game taking distances. After trying ballistic gel and paraffin based test medium and working through the huge expense and substantial mess, I’ve learned two things. The first is that shooting into any substance at closer than game killing distances and at elevated velocity is pretty much a waste of time. Bullets that blow apart at twenty yards in test medium may very well perform admirably at all reasonably hunting distances. Second, home brewed medium is virtually free compared to commercial test medium and performs at least as accurately as commercial products in predicting bullet expansion in game. The following is a useful formula –

Fill a five gallon bucket 3/4 full with dry softwood sawdust.

Add 1″ of fine construction sand.

Fill to top with shredded newspaper.

Gradually add two gallons of water.

Stir with power paint mixture until blended.

Final consistency is about the same as firm oatmeal

Lined up end to end at 100 yards, the pails are large enough in diameter to hit pretty easily…or at least they should be. Three in a row will pretty much catch anything, except Barnes Banded Solids and hard cast bullets. Four pails generally take care of those. Unlike commercial bullet recovery medium, multiple shots can be fired and recovered without interruption as long as the bullets can be differentiated. As an example, five or six distinctly different types of bullets are pretty easy to extract and identify. Because the material closes behind a penetrating bullet, there is no change of overlapping “wound channels” and hitting another bullet in all of that muck is a rarity.

These are examples of bullets pulled from the gunk, err… scientifically formulated test media during .45-70 Gov’t load development. It was easy to measure comparative penetration and expansion of full tilt loads by handloading all bullets tested to a common velocity.

Cartridge Overall Length…as a two part story

| Bullet | Weight | Length | Cannelure Height |

Seating Depth |

Calculated COL | Mfg COL |

Case Full Capacity |

Net Capacity |

| Barnes TSX | 250 | 1.372 | NA | 0.607 | NA | 3.205 | 77.9 | 61.8 |

| Hornady SP/RP | 286 | 1.318 | 0.600 | 0.600 | 3.158 | NA | 77.9 | 62.1 |

| Nosler Partition | 286 | 1.372 | 0.580 | 0.580 | 3.232 | NA | 77.9 | 62.5 |

| Barnes Banded Solid | 286 | 1.405 | NA | 0.695 | NA | 3.150 | 77.9 | 59.5 |

| Prvi Partizan | 285 | 1.245 | 0.400* | 0.400 | 3.285 | NA | 77.9 | 67.3 |

| Woodleigh PP SN | 320 | 1.449 | 0.635 | 0.635 | 3.254 | NA | 77.9 | 61.1 |

| Norma Oryx | 325 | 1.411 | NA | 0.623 | NA | 3.228 | 77.9 | 61.4 |

| * Loaded to aft cannelure | ||||||||

After measuring cases, bullets, cannelure locations, and checking manufacturer’s recommendations this table was constructed to reflect a first cut at proper cartridge overall length. “Calculated COL” just means there was no manufacturer’s COL recommendation, so COL was determined using the bullets cannelure for a dimensional reference. “Mfg COL” means the manufacturer supplied a recommendation for the cartridge and specific bullet. All of the COL entries are within SAAMI or CIP maximum length specification for the 9.3x62mm cartridge, but this does not guarantee each round will chamber properly in the intended rifle.

Rifles have feelings too…

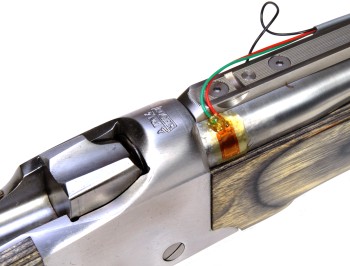

Sometimes, even after checking and double checking that all cartridge and bullet dimensions are within spec, an assembled cartridge won’t chamber. This phenomena is technically termed an “Uh Oh!”. As a safeguard against this type of surprise (I know, who doesn’t like a surprise) it is easy to determine the COL limitations for a specific type bullet in a specific rifle, with great…specificity using an inexpensive Hornady COL gauge. I apologize for using .243 Winchester images for this example, but I have only so many barrels lying around to give to my milling machine… which often seems like the giant hungry plant in “The Little Shop of Horrors” – “Feed me!”.

Basically, what we have here is a test cartridge on a stick; a free floating bullet and a pushrod that is used to press the bullet up against the firearm’s rifling. Simple and it works extremely well. Only one gauge is required for bolt action firearms and one modified case for each cartridge type to be tested.

Can I get a modified cartridge gauge for the 20mmx82mm MG151?

Well of course you can! And there really is a Wizard of Oz and the King is still playing Vegas. Actually, modified cases for the COL gauge are generally available for SAAMI spec cartridges, and Hornady will fabricate non-standards for a small fee if a customer provides brass. At $6 – $11 each, I usually just buy modified cases from a quality supplier such as Sinclair International. Sometimes, if a modified case is not available and I don’t have time to wait for a custom to be produced, and I am looking for an excuse to get out of doing something else, I make my own. It’s actually pretty easy.

Modified cases can be made from brass in the same state it will be in when it is handloaded. In my case, that would be Maine, or a once fired, full length resized 9.3×62 casing.

A 9/32″ drill is passed all the way through the primer pocket and the resulting opening is threaded with a 5/16-32 tap. As bullets need to travel freely in and out of the case mouth when checking clearance, without a lot of slop, the case mouth needs to be reworked to create a slip fit for standard diameter bullets.

A .375 H&H expander can be run through the 9.3x62mm case mouth, which will open it up to approximately 0.370″, then the empty case can be chambered in a rifle which reduces the 0.370″ down to 0.368″…which is just about right.

Finally, a 40 caliber bronze cleaning brush is chucked into a drill and used to burnish the inside of the case neck. A dramatic photo of the required tools and finished product appear right.

Hurry up and slow down…

Powder selection is always a big deal as it pretty much defines the personality of a cartridge. Some of the high strung big overbore cartridges will only run on the very slowest powders that is metered by the scoopful. Some of the small bottleneck cartridges have room only for a few grains of fast ball powder, and those charges are often compressed. The 9.3x62mm is a cartridge that could probably run on diesel fuel and cow flatulence. Relatively heavy bullets, sufficient case capacity and relatively little case mouth to body diameter differential make the round right for almost any moderate speed powder, however, the velocity attained from one powder type to another can vary by as much as 10%. So it is worth the effort to build and test, and build and test some more.

I am always totally blown away by the fact that sometimes the most attractively packaged products perform poorly and some of the most conservative packaging, as above, seems to consistently deliver the goods. Some day I intend to plot this packaging – performance curvilinear correlation…but not today. With the understanding newly released powders may not be listed, its often helpful to lay all of the manuals out on a table and looks for a powder type that shows consistently good results across all publications. Usually there will be a common standout or two that will shorten the assessment time and cost.

I have tried to use QuickLOAD to model various powders types, however, this does not seem to be a realistic approach as actual muzzle velocity runs from within a couple of fps of QuickLOAD projections to off by 10%-15%. In the case of the 9.3x62mm where H414 looked like a winner, BC-C(2) was the big guy, just behind RL15. In other situations, H414 has been excellent. With all of the lot to lot changes in powder, and without taking into consideration many of the variables at play when a cartridge is discharged, QuickLOAD does a pretty commendable job, but it the results are not absolute and it won’t work in an information vacuum.

Data collection…

|

Cartridge: 9.3x62mm |

Bullet: Nosler Partition |

Live Fire Date: |

|||||||||

| Control # |

Primer Type |

Powder Type |

Charge Grains |

MV fps |

Ambient Temp F | Percent Humidity |

Barrel Temp F | Primer Read |

Case Head | Case Diameter |

Bolt Op |

| 1 | CCI 200 | RL15 | 54.5 | 2170 | 76 | 37 | 76.5 | ok | ok | 0.4742 | ok |

| 2 | CCI 200 | RL15 | 55.0 | 2185 | 76 | 37 | – | ok | ok | 0.4742 | ok |

| 3 | CCI 200 | RL15 | 55.5 | 2224 | 76 | 37 | 81.8 | ok | ok | 0.4742 | ok |

| 4 | CCI 200 | RL15 | 56.0 | 2247 | 79 | 37 | 83.0 | ok | ok | 0.4743 | ok |

| 5 | CCI 200 | RL15 | 56.5 | 2272 | 79 | 35 | – | ok | ok | 0.4745 | ok |

| 6 | CCI 200 | RL15 | 57.0 | 2287 | 79 | 35 | – | ok | ok | 0.4745 | ok |

| 7 | CCI 200 | RL15 | 57.5 | 2304 | 77 | 39 | 92 | ok | ok | 0.4742 | ok |

| 8 | CCI 200 | RL15 | 58.0 | 2347 | 77 | 39 | – | ok | ok | 0.4742 | ok |

| 9 | CCI 200 | RL15 | 58.2 | 2335 | 77 | 37 | 94 | ok | ok | 0.4744 | ok |

| 10 | CCI 200 | RL15 | 58.4 | 2352 | 77 | 37 | 97 | ok | ok | 0.4742 | ok |

| 11 | CCI 200 | RL15 | 58.6 | 2359 | 78 | 37 | 99 | ok | ok | 0.4745 | ok |

| 12 | CCI 200 | RL15 | 58.8 | 2366 | 78 | 37 | – | ok | ok | 0.4742 | ok |

| 13 | CCI 200 | RL15 | 59.0 | 2381 | 78 | 37 | 102 | ok | ok | 0.4742 | ok |

| Primer read = OK or (F)lat Case head=OK or (B)right Spot Case Increase=0.000″ Bolt Op=OK or (S)ticky Powder charge MIN MAX |

|||||||||||

Data collection sheets are a fact of life, and they can be created for specific purposes. Sometimes, if it isn’t practical to bring along a lot of equipment, data logs can be created with programs like Excel and used in hard copy form to log data at the range. These days I tend to create my data logs on a small netbook that fits in my shooting box and has enough battery life to easily handle a day at the range. It sure beats sifting through handwritten notes a week or a year after the fact, especially when it comes to me trying to read my own chicken scratch.

The problem with data collection is that what data needs to be collected isn’t always so obvious. Consequently, when I begin with a new cartridge and I am unfamiliar with its idiosyncrasies I end up collecting lots of useless data until I get it all sorted out. Eventually, 90% of it will be found not useful. Everyone I know records temperature and humidity when they take a new batch of handloads to the range. Not one of them has ever used that data to make an adjustment in rifle sighting or handloads, nor have I. Could be we are all just lousy shots and can’t resolve our shooting to that degree of finesse.

The problem with data collection is that what data needs to be collected isn’t always so obvious. Consequently, when I begin with a new cartridge and I am unfamiliar with its idiosyncrasies I end up collecting lots of useless data until I get it all sorted out. Eventually, 90% of it will be found not useful. Everyone I know records temperature and humidity when they take a new batch of handloads to the range. Not one of them has ever used that data to make an adjustment in rifle sighting or handloads, nor have I. Could be we are all just lousy shots and can’t resolve our shooting to that degree of finesse.

Case capacity and seating depth measurements are watched closely, and changes in either are reason to alter or re-baseline a load as there is a direct correlation between changes in these dimensions and pressure and velocity. As an example, the calculating standard for QuickLOAD uses a case capacity of 77.8 grains for the 9.3x62mm. RCBSLoad uses a standard of 72.8 grains. The actual measured capacity of the once fired brass used in the 9.3x62mm exercise was 74.3. Each capacity would result in a different pressure level if loaded with an identical powder charge, a spread of approximately 14,000 PSI from the lowest to the highest. When new or different brass is introduced into the process, brass is wet checked for capacity and appropriate adjustments are made when loading.

Don’t they look like they are about to roll?

With a pressure spread of approximately 15,000 PSI from minimum to maximum 9.3x62mm loads there is not a flat primer or bright spot on a case head nor has a case expanded in excess of 0.0003″ at the diameter just above the extractor groove. And yet I stopped pumping in powder, primarily because the charges reached maximum as gauged by any of the many reference manuals kept in the shop library and some of the cases expanded 0.0003″ above the extractor groove and that is about my limit. Most of the other classic symptoms of pressure are way over the top for routine reliance with this relatively low pressure cartridge.

Material under pressure changes states. Ordinarily metal is in an elastic state; it will yield to tensile strain and recover when no longer stressed. Apply additional strain, and metal can change from elastic to plastic, a strain point where metal will flow and will not return to its original dimension. When primer cups flow (not flatten), or brass flows into a breech face extractor/ejector groove, when cases expand at the base of the web in excess of 0.0004″, when cases expand to the point a bolt in a bolt action rifle has to be forced open, pressure is already at the ragged edge of firearm mechanical failure. None of these indications are early signs of slightly excessive pressure. Additionally, excessive pressure can be a relative problem rather than absolute.

The pressure standard for the 9.3x62mm is approximately 56,565 PSI. 62,000 PSI would be considered a gross pressure excess for this round, however, in the world of modern firearms 62,000 PSI is below the normal peak pressure of many cartridges. 62,000 PSI would not be enough to produce any of the hard excessive pressure symptoms noted above, yet the pressure would be in excessive of design parameters for the cartridge. Perhaps this is not a pressure level that will blow out a barrel, but it might be high enough to shear a lug, or fracture a smallish ring receiver on an older firearm that was intended to provide safe operation below maximum spec pressure. I am not trying to construct a message to cause concern, I am trying to construct the message that subtle warning are sometimes as important to heed than warning that shout, “Duck!”.

Alchemy or technology?

Strain gauges are handy and industrial strength units can be quite accurate, however, consumer versions are quite different. Neither actually measure pressure directly, they measure tinsel strain by reacting to a change in the physical dimensions of a barrel that is experienced when a cartridge is discharged. This test equipment typically sees strain as a change in resistance, then outputs a voltage which is interpreted by someone’s creative software into an approximation of chamber pressure.

Strain gauges are handy and industrial strength units can be quite accurate, however, consumer versions are quite different. Neither actually measure pressure directly, they measure tinsel strain by reacting to a change in the physical dimensions of a barrel that is experienced when a cartridge is discharged. This test equipment typically sees strain as a change in resistance, then outputs a voltage which is interpreted by someone’s creative software into an approximation of chamber pressure.

The product’s output is lots of colorful arts and charts with impressive lab type data sheets. Unfortunately, all of this only masks the fact that the method is prone to inaccuracy. Not selecting precisely the correct position over the subject firearm’s chamber, or not precisely measuring the chamber wall thickness at that point, not having a perfect bond between gauge and barrel, calculations based on a barrel steel different from the subject gun, the wrong offset to account for brass case variations, poor grounding, cable noise, and no standard test cartridge combine to make this equipment with a limited application. These days they cost between $800 and $1,000 for equipment and a start supply of gauges and consumable materials. They may not be precise in measuring pressure, but they do provide insight into dynamics of change when working up handloads. The charts and data will impress your friends.

Piezo transducers, usually conformal transducers, are made to work with standardized test barrels, a charge amplifier and a standalone or computer based oscilloscope . A .45 Colt test barrel with conformal transducer is pictured, right. In this case, direct pressure is still not being measured, but rather the effect of pressure acting on a cartridge case. There are transducers that read direct pressure by being inserted through a test barrel and through a hole in the side of a subject cartridge. In the most common method, conformal transducer, reference ammunition must be obtained from several certified sources to calibrate and validate results.

Piezo transducers, usually conformal transducers, are made to work with standardized test barrels, a charge amplifier and a standalone or computer based oscilloscope . A .45 Colt test barrel with conformal transducer is pictured, right. In this case, direct pressure is still not being measured, but rather the effect of pressure acting on a cartridge case. There are transducers that read direct pressure by being inserted through a test barrel and through a hole in the side of a subject cartridge. In the most common method, conformal transducer, reference ammunition must be obtained from several certified sources to calibrate and validate results.

It is easy to put $25,000 into a universal receiver, adjustable carriage, charge amplifier, cables and software oscilloscope. Then another couple thousand more for each cartridge type to be tested as a function of test barrel, transducers, cables. Throw in lots more for calibration capabilities, or setup as a lab and swap lab test ammo with a few other labs and learn statistics. If you manufacture ammo it’s a pretty good deal because the pressure data collected reflects cartridge performance only in concert with your test equipment. Put the same ammo in another firearm and the pressure results will be different. Again, very interesting equipment and a great way to isolate variable when developing loads or to qualify ammunition manufactured in lots. Some labs get pretty snooty about the results from this equipment to the point they begin to suggest handload development can’t be done without it. Which of course makes me wonder how they got by the thirty years prior to installation of the lab equipment.

Closing arguments…

I have been handloading, on and off, for at least several decades, and I intend to keep at it until I get it right. With all fingers and toes intact, I’ve not had the experience of: a burst primer, an unexpected detonation of a charge, damaged firearms, damaged equipment, or even a lodged bullet in a barrel as the result of a squib charge. Maybe I’m just not trying hard enough, but I think it is more a case of knowing my limitations and following the safety instructions that are packaged with every piece of handloading equipment, component and related publication.

Ninety five percent of my handload development is derivative, based on established data. The progression is guided only by: inexpensive chronograph results, the feel of empty case extraction, the sound of a discharging cartridge, and by observing the subtle appearances and dimensional changes to fired casings. With a little attention given to obvious cautions and some basic laws of physics, anyone can work up handloads successfully and never experience rapid and unexpected firearm disassembly or other unpleasant side effects.

Email Notification