It’s not like I’ve had a lot of exposure to the .22 Hornet. I’d always intended to own one but, in fact, I’ve had only two contacts with firearms chambered for this round. The first through my fleeting association with B-52’s during the ’66-’70 time frame, when the little fold up bolt action H&R M4 rifle was still loaded into ejection seat packs and…now.

Most everything I’ve seen written in Internet reference regarding the history of the .22 Hornet is plagiarized from Cartridges of the Worldwithout the formality of crediting that source and, ironically, that material is lacking historical detail. However, an original piece written by Layne Simpson for “Shooting Times“, does an excellent job of providing Hornet background.

Pictured right, are opposite ends of the centerfire varmint cartridge spectrum and an illustration of what a difference of 1,500 fps looks like in terms of cartridge design and appearance. The diminutive 2,700 fps .22 Hornet, a moderate range cartridge, works well in more densely populated areas where noise levels and overreach are concerns. The 4,200 fps .220 Swift is more suitable for targets that are classified as being within driving distance and where knowledge of having neighbors is predominately theoretical.

Pictured right, are opposite ends of the centerfire varmint cartridge spectrum and an illustration of what a difference of 1,500 fps looks like in terms of cartridge design and appearance. The diminutive 2,700 fps .22 Hornet, a moderate range cartridge, works well in more densely populated areas where noise levels and overreach are concerns. The 4,200 fps .220 Swift is more suitable for targets that are classified as being within driving distance and where knowledge of having neighbors is predominately theoretical.

The Swift’s afterburner performance comes at a premium; more fuel is required, there is significantly higher muzzle blast and bullet evaporating performance on close-in targets is to be expected. Whatever the Swift is, the Hornet clearly isn’t, which means it has a small capacity case, generates low report and offers solid close-in performance. The Hornet, more suited to a setting that is becoming more common each day, is not about to retire even after eighty years of service.

| 22 Hornet Rifle Comparisons | |||||

| Manufacturer | Ruger | Ruger | Browning | CZ-USA | Savage |

| Model | 77/22RH | K77/22VHZ | Micro Hunter | 527 American | 40 Varmint |

| Magazine Capacity | 6 | 6 | 3 | 5 | 1 |

| Overall Length “ | 39 ⅝ | 43 ⅝ | 41 ½ | 40 ½ | 42 ¼ |

| Length of Pull “ | 13 ⅝ | 13 ⅝ | 13 5/16 | 13 ½ | – |

| Barrel length “ | 20 | 24 | 22 | 21.9 | 24 |

| Twist Rate “ | 1:14 | 1:14 | 1:16 | 1:16 | 1:14 |

| Weight – Lbs | 6¼ | 7½ | 6½ | 6¼ | 7¾ |

| Trigger Pull – Lbs | 4 ¼ | – | – | – | – |

| MSRP | $754 | $836 | $799 | $751 | $560 |

| RGI Retail | $557 | $616 | $670 | $655 | $475 |

| Maroon – Less than Optimal Specification | |||||

After handling and shooting a number of Hornet chambered firearms, I selected the Ruger Model 77/22RH for this project because it is an elegant rifle of traditional design and I felt it was ideally suited for the .22 Hornet cartridge.

A case for skinny barrels…

Rifles with heavy profile barrels and tactical/target type stocks are great, but not many situations. Their barrels are tuned and their stocks are ergonomically designed for precision, repeatable shot placement over very long distances. When a two inch target is critical at 100 yards and remains so at 400 yards, both the firearm and shooter need all the specialized firearm features they can get to work within those parameters.

The .22 Hornet, by trajectory table assessment alone, can be defined as an inside 300 yard cartridge. Downrange kinetic energy levels, acceptable point blank range and 2,000 fps levels of velocity to minimize cross wind deflection reduce the effective range to something closer to 200 yards. A sporter weight rifle like the Ruger 17/22RH can produce better than MOA accuracy with a little rifle turning and careful handloading, which is more than enough accuracy for this range…unless the quarry du jour on a small game safari is field mice…very small field mice.

I am not sure I have a good understanding of the industry’s treatment of twist rate and the .22 Hornet. A 1:16″ twist is tied to the Hornet’s early commercial loading and this is reported as not optimal 45+ grain bullets. I am not quite sure why the current firearm twist rate isn’t 1:12″ if not 1:10″. At 2,700 fps a 14″ twist will spin a bullet to 138,000 RPM. Many accurate loads are in the 200,000+ RPM range. Even pushed to 3,100 fps, RPM is still sub 160,000. A 10″ twist would produce 194,000 and 232,000 RPMs at 2,700 and 3,100 fps respectively. Putting away the calculators and conjecture, the Ruger is a very accurate rifle with a 14″ twist, so clearly there is some dynamic I don’t fully understand. That happens a lot.

What the heck are those parts doing in there?

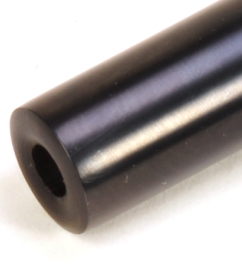

Externally, the Ruger Model 77/22RH Hornet and the Ruger Model’s 77/22 and 77/17 bolt action rimfire rifles seem very similar in appearance. They do share some common parts, however, centerfire and rimfire models actually differ significantly to accommodate the centerfire’s higher pressure stresses and central firing pin mechanism. Of the 80 pieces or so that comprise each model, 53 parts of the Hornet version are distinctly different from the rimfire versions. Some differences are minor, like the changes in rotary magazines to accommodate a variety of cartridges. Some differences are major, like a threaded barrel shank for the Hornet versus a wedge or V block barrel retention systems for the rimfire models. The result of all of this shuffling of parts and design makes the Model 77/22RH Hornet an extremely strong, yet lightweight… big boy’s rifle.

Above, the trigger guard’s forward assembly provides aft support for the detachable magazine and release latch. The Ruger’s trigger is good, however, nonadjustable. I wish Ruger would go to an adjustable trigger. Trigger pull is such a subjective setting and I believe consumer’s like to know determination is within their control. I know I like to crank these adjustments up and down and then eventually leave them at the original factory setting…because I wanted to, not because I had to. Grow up, Joe. No, you grow up. No, YOU…

A little better view of the bolt construction, above. The action locks up on two opposing lugs denoted by double arrows on the aft receiver ring. The bolt head diameter is 0.903 inches, cross lug measurement. Lug width is 0.313″, bolt rotation to unlock is 90°. The bolt rails forward of the locking lugs guide and locate the breech block assembly within the gun’s receiver. The underside of the bolt is cut away, however, the Hornet case head is fully supported with the exception of a small pie shaped cut that represents the ejector path. With a CIP Pmax pressure of 43,511 PSI and a SAAMI MAP of 43.000 CUP, there is plenty of lug area and case head support for any reasonable factory ammo and handloads. The Ruger M77/22RH is a thoughtfully engineered gun.

The gun was cleanly finished, outside, inside and in between. The stock inletting was precise, the walnut was sealed in all areas to guard against moisture causing wood to change dimensionally and the barrel floated in the barrel channel with the exception of the lone support bump and inch in from the tip of the forearm. Metal finish and quality of parts exposed on disassembly were as nicely finished as the show parts.

The gun’s safety is three position; “Fire”, “Safe and load/unload” and “Safe”. “Safe” locks the bolt closed. The second permits bolt cycling to clear a chamber of a loaded round or to single load a round. The position is not intended to be a primary “Safe” position. My personal preference would be a fourth position which would provide cable TV service.

There are no metallic sights on M77/22RH, however, Ruger provided three locations to mount their supplied proprietary scope rings. The extra mount location was provided out of a sense of guilt for not providing metallic sights. Kidding. As a guy who has to put on his reading glasses to make adjustment to metallic sights, I don’t miss the little speed bumps at all. OK, a second, and less interesting alternative theory is that the extra ring location provides greater latitude to accommodate scopes of varying lengths and control placement.

Overall, the rifle is very neatly laid out and, again, cleanly executed. Thanks to the rotary magazine nothing projects down from the bottom of the stock except for the trigger guard. The inletting is close fit and parts are surface level. The bottom of the stock is cut flat, which feels comfortable while shooting from virtually any position. The walnut stock had a good deal of figure which was nice in contrast to its very traditional cut. Checkering patterns and panels are just right. Nice gun.

A very interesting cartridge to handload…

I want to make a note here, because I think it is important. Ruger publishes within their product manual that they warrant, and recommend the use of their product only in concert with factory ammunition loaded to U.S. industry standards. I absolutely understand that a manufacturer would not want to be held responsible by the individual standards of every handloader or an ammunition manufacturer who is out of compliance with industry standards. What follows is an independent effort on my part, that in no way reflects Ruger practices, policies or recommendations. There, now I’m free to be an independent handloader.

When putting together material for this project, brass was in short supply, which is not the case at this point in time. Consequently, I had to go with Remington nickel plated product, which I refer to as “brass for fancy lads”. Plating tends to flake after some use and the hard material is rough on loading dies, not to mention it is bright and shiny in the field. I picked some popular weight bullets in the 40 grain to 50 grain range as this is about all of the weight the Hornet can propel at velocity levels that would be of interest to me.

The Hornet is an example of why it’s good to read the cartridge narratives preceding load data in reloading manuals before putting the data to use. Narratives set the stage for what follows and it highlights any cartridge idiosyncrasies that need to be taken into consideration while assembling ammunition. As an example, Hornady data utilizes small rifle primers, Sierra data utilizes small rifle match primers and Speer went with CCI small pistol primers because the Hornet uses primarily slow pistol powder. Speer goes on to caution that substituting small rifle primers for use with their data could result in unsafe pressure levels. Speer also underscores that most Hornet rifles and SAAMI chamber drawing for this cartridge, do not have freebore. Speer advises that where some modern production does incorporate freebore, these firearms often exhibit accuracy problems that can be resolved by seating out to a COL greater than the 1.723″ SAAMI spec, the exact length to be determined by COL gauge. The final caution is that increasing COL in these rifles beyond SAAMI maximum specification may result in a round that will not fit and/or feed from some rifle magazines. The Hodgdon site has load data with both SAAMI spec and 1.850″ COL without footnote. In total, I was left asking myself, “Huh?” So let me take a shot at making all of this worse.

Bullets for the Hornet – picky, picky, picky...

As represented in The Standard Catalogue of Winchester, Krause Publications, in 1932 the initial production of .22 Hornet ammunition was Winchester Staynless 45 grain and, in 1933, Winchester Super Speed 40 grain.

As represented in The Standard Catalogue of Winchester, Krause Publications, in 1932 the initial production of .22 Hornet ammunition was Winchester Staynless 45 grain and, in 1933, Winchester Super Speed 40 grain.

Today’s Hornet utilizes 0.224″ bullets and 0.224″ bullets come in many sizes and shapes. Pictured left, weights from 40 – 80 grains. Only the first two bullets, the 40 grain Sierra Blitz and the Berger 50 grain Varmint work correctly with a Hornet. This is not a failing on the part of the various manufacturers, as most bullets represented were not intended for Hornet applications. Bullets like the 80 grain Hornady Match, far right, are too long. Seated to a spec maximum cartridge overall length of 1.723″ there would be little room left for powder. Even if it were possible to seat a bullet of this type far forward in the case, the Hornet’s gross case capacity of 14.5 grains would be insufficient to provide useful velocity other than perhaps serving as a nail gun..

Some bullets that fall within an acceptable weight and length range still won’t work because of the shape of the bullet’s ogive. As an example, where the Berger 50 grain works well, the 50 grain green tipped Sierra #1450 will not, as its shank is too short. Seated to an appropriate depth to achieve proper COL, the #1450’s ogive begins to taper down well inside the case mouth, which is not acceptable…and it makes for pretty ugly handloads. However, Sierra offers three other 50 grain bullets that will work just fine: #1320, #1330 and #1340 each with a profile that would be appropriately positioned when seated in the Hornet case.

I am not suggesting this is a major problem, however, I am saying it is important to select bullet specifically for the Hornet and it is important to check the bullet product numbers when a manufacturer offers multiple part numbers for a common weight. If you are doing more speculative reloading with bulk bullets from one of the major manufacturers, again, check for Hornet application before jumping in; weight, length, ogive, and cannelure placement. It’s a little bit like .30-30 WCF bullets being a subset of 0.308″ bullets with a geometry that accommodates their probable use in tubular magazines.

Other handloading considerations…

The SAAMI chamber drawing for the Hornet does not indicate a freebore, only a transition taper from chamber to rifling. Not particularly unique as this is a relatively common approach for cartridges intended for use with light, short ogive bullets. The Ruger M77/22RH is designed for SAAMI spec cartridges, however, it will chamber ammunition assembled to a somewhat greater overall length if proper bullets are selected. The Ruger’s magazine, however, taps out at 1.810″. Allowing for some less than perfect cartridge assemblies, and a little field debris, the working maximum COL limit was 1.790″, or 0.067″ greater than spec. I used CCI BR4 small rifle primers in all loads. They produce no more energy than standard small rifle primers, but they are held to a tighter performance standard. All handloads listed cycled normally and reliably through the Ruger’s magazine.

Handloading was straight forward. A very heavy duty T7 Redding Turret and set of Lee Precision Dies made the sizing, seating and crimp operations relatively effortless. The Redding is the shop press these days for 99% of the reloading activity. The Lee Precision dies were inexpensive, available and of good quality. I like the factory crimp die included with the set and, yes, I don’t mind having a shell holder supplied with the die set I can keep with the dies when they are put up.

Handloading was straight forward. A very heavy duty T7 Redding Turret and set of Lee Precision Dies made the sizing, seating and crimp operations relatively effortless. The Redding is the shop press these days for 99% of the reloading activity. The Lee Precision dies were inexpensive, available and of good quality. I like the factory crimp die included with the set and, yes, I don’t mind having a shell holder supplied with the die set I can keep with the dies when they are put up.

The CCI Bench rest primers were inserted with an RCBS APS hand press, The same universal shell holder that work for the .416 Rigby and .45-70 work well with the Hornet also. This is an inexpensive tool that has proven to be indispensable. An RCBS ChargeMaster was used for all loads, either as a standalone scale or for auto metering. Even these little charges of ball powder were consistently accurate and the auto function was a real time saver. No special handling was required during any operation. It’s interesting how tools, equipment and material flow over a reloading bench over an extended period of time. Eventually, what works remains and what doesn’t helps to hold down those bottom shelves.

Results…

|

.22 Hornet Handloads – 20″ Barrel Ruger M77/22RH |

||||||||||

| Bullet Mfg | Bullet # | Weight Grains |

Length “ |

COL “ |

Powder Type |

Powder Charge |

Calculated Velocity |

Actual Velocity |

Muzzle Energy |

3 Shot Group |

| Sierra | 1385 | 40 | 0.568 | 1.720 | Win296 | 11.8 | 2859 | 2931 | 763 | 1.1 |

| L’il Gun | 11.5 | 2866 | 2930 | 763 | 0.7 | |||||

| H110 | 12.0 | 2843 | 2977 | 787 | 1.2 | |||||

| Sierra | 1385 | 40 | 0.568 | 1.790* | L’il Gun | 12.2 | 2964 | 3119 | 864 | 0.5 |

| Remington | 22956 | 45 | 0.518 | 1.720* | L’il Gun | 11.5 | 2760 | 3052 | 931 | 0.6 |

| H110 | 11.8 | 2701 | 2945 | 867 | 0.9 | |||||

| Hornady | 2240 | 50 | 0.780 | 1.720 | Win 296 | 10.6 | 2554 | 2684 | 800 | 1.3 |

| L’il Gun | 10.5 | 2587 | 2671 | 792 | 0.8 | |||||

| H110 | 10.7 | 2518 | 2655 | 783 | 1.2 | |||||

| Berger | 22307 | 50 | 0.718 | 1.720* | Win 296 | 10.2 | 2515 | 2710 | 816 | 1.2 |

| L’il Gun | 10.2 | 2575 | 2695 | 807 | 0.7 | |||||

| H110 | 10.4 | 2506 | 2653 | 782 | 1.0 | |||||

| Berger | 22307 | 50 | 0.718 | 1.790* | Win 296 | 10.7 | 2582 | 2718 | 820 | 0.8 |

| L’il Gun | 10.5 | 2592 | 2729 | 827 | 0.4 | |||||

| H110 | 10.7 | 2523 | 2764 | 848 | 0.6 | |||||

| COL reflects bullet manufacturer’s recommendations or (*) maximum mechanical COL permitted. | ||||||||||

Pictured as intact bullets above, left to right, as they appear on the table in descending order. One of the things that really impressed me about the Hornet was the demonstrated durability of the selected bullets. The only jackets that really came apart were the 40 grain Sierra slugs when pushed to high velocities – which is what they were suppose to do. Nicely mushroomed bullets were all recovered from a bucket full of sand used to target backdrops.

Overall impressions…

With all of the great firearms I was able to work with so far this year, this was one was a genuine pleasure to shoot. Light weight, no recoil, low report, excellent accuracy…I caught myself smiling a lot when I was shooting. The M77/22RH makes an excellent rifle for any experienced shooter, and it would make an excellent choice for a first centerfire for a son or daughter…or grandson or granddaughter, one that they won’t outgrow.

Firearm function was reliable. The barrel stayed cool, even with extensive shooting. The gun was reliable and smooth in function. Trigger pull was fine, certainly light and crisp enough. The flat bottom forearm was very steady shooting from a rest or standing. The scope was set up in full forward and full aft ring positions which made head and eye position very comfortable. The medium rings supplied with the rifle were workable, but the large eyepiece scope could have used some additional bolt handle clearance higher mounts would have provided. Anyone purchasing a new Ruger can request a swap to higher/lower sizes if this is done shortly after receiving the firearm. Ruger can be contacted for details.

My wife took a few shots with the combination and we ended up spending the whole afternoon popping targets and competing for household bragging rights. She is an incredible shot and I am always glad to have her company. She’s the one with the sense of humor. Below, one of the 50′ small bore targets that was heavily perforated at 100 yards. And, yes, all the tiny groups were put together by my wife, because she’s…so much a better shot than me and, yes, she is the goddess of the range and I am not worthy. Geez, I hate losing these little contests.

Email Notification