I am a creature of habit. No, that’s not a B Movie reptilian creature with flippers and a couple of air sucking gills, but rather a guy who finds something that works, then sticks with it until there is a compelling and logical reason to change. Even more boring, if that’s possible, is our work place philosophy of purchasing only to situation and application. “It’s New!” and “It’s Zippy!”, do not constitute sufficient adjective substantiality for a product to find its place onto the RealGuns’ reloading bench. Really.

I am a creature of habit. No, that’s not a B Movie reptilian creature with flippers and a couple of air sucking gills, but rather a guy who finds something that works, then sticks with it until there is a compelling and logical reason to change. Even more boring, if that’s possible, is our work place philosophy of purchasing only to situation and application. “It’s New!” and “It’s Zippy!”, do not constitute sufficient adjective substantiality for a product to find its place onto the RealGuns’ reloading bench. Really.Short runs and experimental load development dominate handloading activity at Real Guns, situations and applications that are well served by a Redding T7 turret press. The T7 also can easily knock out the occasional couple hundred pieces of production. A more recent sharp increase in firearm review activity and recreational target shooting, however, drove consumption of a handful of cartridge types beyond manual turret press production capacity – A compelling and logical reason to search for an additional piece of equipment.

Intra office free climbing…

My first inclination was not to grab a catalogue and look for new equipment. I’m not cheap, I’m…frugal. When we take equipment out of service it’s cleaned, checked for proper operation, coated with preservative, and packed for extended storage. There is too much of an investment in press, operator familiarity and supporting tools and accessories to toss good equipment every time something new is introduced. So I climbed up into the RealGuns loft to see what equipment might be stowed away… which I hate to do as my socially dysfunctional coworkers tend to pull the loft ladder away and chant, “Jump, Joe, jump!”. They are such children.

There was lots of auto indexing progressive and turret equipment to be found, but nothing worth hauling down and re-commissioning into service. Every box I opened brought an immediate reminder of why each piece had been retired; too long of an operating stroke, less than durable construction, excessive operating effort, iffy powder dispensing, and priming systems that made no sense at all. Additionally and universally, speed of operation of the equipment was limited by too rapid acceleration of rotating mass; die heads jumped index or in-process cartridges barfed smokeless powder all over the press and bench during rapid cycling. The new higher levels of production would go on for the foreseeable future, so a commitment to more appropriate equipment would be needed.

Why is blue such an expensive color?

Already operationally experienced with equipment from other leading auto indexing equipment suppliers, I looked at Dillion’sXL650 and Hornady‘s Lock-N-Load AP. After working my way through Dillon equipment and prices, features and benefits and utilizing their equipment build up feature, I realized this was not a brand that would work for me. Too many basic components of their equipment were categorized as extra cost options and the tightly integrated and narrow design of their product created a demand for many proprietary accessories. So I shifted over and began working through the Hornady Lock-N-Load information; print, web site brochures and FAQ’s. Comparative pricing at discount retailers led to the impression that, at least ostensibly, the Hornady product was worth pursing.

Hornady die sets, culver powder measures and case prep and gauging tools have seen frequent use in the shop, right along side similar equipment from other leading suppliers. However, without a prior requirement, there has not been much of an opportunity to spend time with their reloading presses.

Hornady die sets, culver powder measures and case prep and gauging tools have seen frequent use in the shop, right along side similar equipment from other leading suppliers. However, without a prior requirement, there has not been much of an opportunity to spend time with their reloading presses.The Lock-N-Load AP press is unique, even in the way it is packaged for the consumer. The first genuinely nice surprise was that it arrived in the box almost completely assembled. No fifty bags of small hardware, nuts, bolts, brackets, and screws to sort through, no pile of sub assemblies to build up and adjust. Everything, including small tools were part of the kit.

Other than adding a set of standard dies, and associated shell plate, there are no other required purchases to get the press into operation. Priming systems and a powder measure with large and small metering drums are included. Documentation and support media is excellent; catalogs with applicable reference charts and accessories, a cleanly illustrated press manual with setup and operation instruction, a staple bound basic reloading guide and a very professionally produced and user friendly “How To” video DVD. The information on the DVD is well organized and indexed in chapter format. Quality video and audio clearly illustrate all aspects of the product from setup to operation of the Lock-N-Load Press, including an overview of the design elements employed.

Good design and manufacturing practices…

Hornady’s Lock-N-Load AP is a robust piece of production equipment that has been engineered and tempered over time into a very solid design. Typical weakness found on other auto indexing progressive equipment had been addressed and eliminated with Hornady’s design. I always get a kick out of Lee Precision budget equipment as their proprietary designs run from solid to just plain clever. The Lock-N-Load AP is the first premium grade product I’ve seen that demonstrates similar design innovation. If something is different, it is easy to see the obvious practical benefit.

Most press rams are solid body, or perhaps drilled for spent primer disposal. Hornady makes their ram double the typical size, utilizing oversized two inch diameter thick wall steel tubing. This allows the ram to withstand huge loads and still house and protect all of the press’ indexing drive bits and pieces. The spent primer disposal tube is located outside of the ram where it won’t get in the way.

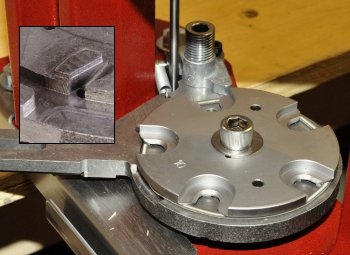

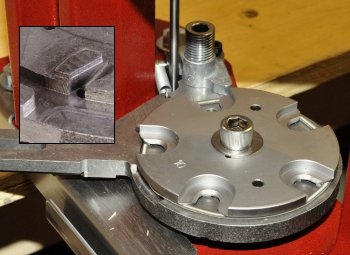

Most press rams are solid body, or perhaps drilled for spent primer disposal. Hornady makes their ram double the typical size, utilizing oversized two inch diameter thick wall steel tubing. This allows the ram to withstand huge loads and still house and protect all of the press’ indexing drive bits and pieces. The spent primer disposal tube is located outside of the ram where it won’t get in the way.Indexing actuation and control is done at the bottom of the press, rather than the top, which removes all of the complicated, fragile and intrusive brackets and pawls that too often clutter the work area of competing brands. The indexing function is simplified. Green arrows above and pictured in detail left – Two stationary, heavy duty pawls embedded in the toggle drive an robust steel index wheel. Nothing fragile to break and easy to adjust if the need arises.

Bearing and driven parts are big. The index wheel is keyed to a full half inch drive shaft which is sufficient to handle hundreds of times the torsional loading that would be experienced within the handloading process. The two inch diameter ram is supported at all times by 19 sq.in. of lubricated frame bearing surface and could support the weight of a bus…and me, even after lunch.

Notice the three grease fittings, two bottom at linkage pins and one for the ram. The ram has a grease groove reservoir; good practice for heavy duty machinery and applied in a way that keeps lubricant away from work surfaces, but dispenses an adequate amount to friction surfaces. The approach assures ease of operation and longevity of use. Nothing radical, but rather a design from people who understand how and where the equipment would be used.

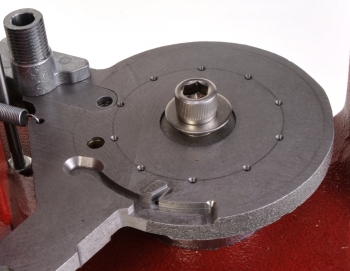

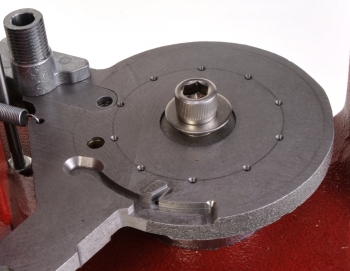

Directly above, the stage, or the “subplate” as nomenclatured by Hornady, is near solid surface. It is free of subassemblies and small parts related to shell plate drive and indexing, so there is no place for powder, brass and spent primer compound to accumulate and no fragile parts to break.

Interesting mix and use of alloys…

Rather than an all or nothing approach on materials, Hornady went with a “appropriate material for the appropriate purpose” approach. The parts marked with green arrows are formed with heavily gusseted high strength aluminum; very nice casting designs, uncompromising strength and much less parasitic weight. For the sake of context – Not unlike landing gear intended to support a large aircraft touching down at 250+ knots… but quite different from, say… Don Knotts. The blue arrows point to the ferrous parts, the links and yoke and the Lock-N-Load bushings pressed into the die locations at the top of the aluminum frame. The latter is a nice technique, like steel cylinders insert pressed into an aluminum big block Chevy or Ford race engine, the benefit of light weight and strength, and still with non-galling, long wearing load bearing surfaces. Neat. As a result of using multiple alloys in its construction, the Lock-N-Load scales only 27.5 lbs without powder measure in place. Not a lightweight, but a big press that is easily moved about as required.

Basic set up…

Sorry for the cluttered shot of the press. My reloading bench is…. intensely over utilized. The Lock-N-Load AP, as a multi station press, has a small foot print. The bulkiest portion of the frame is only 5″ wide and 8.5″ deep which makes it more narrow than my turret press. Approximately an hour was required to get the AP unpacked, assembled and ammo making operational. Again, excellent product support material included with the package.

Bench drilling and bolting down the press was a snap; two 5/16″ bolts and a press locating ledge secure the equipment. The side roll on the bracket that holds the ammo catch bin was too tall, which required the addition of one extra 5/16″ washer under the bracket to get adequate clearance. The press mount pad has approximately 20 sq. in. of bench clamping surface area, which makes the press feel rock solid and very precise in operation.

The powder measure requires disassembly and cleaning prior to use; lots of precision surfaces to protect while awaiting shipment to a customer. I didn’t have any on hand, but Hornady makes a One Shot product that cleans as a solvent and leaves a dry film and would be useful for this purpose. I generally detail disassemble, scrub with hot soapy water, dry with forced warm air, then dry lube – about $6/16 oz.

The powder measure is packaged with two rotors, one for larger powder charges, 5 – 100 grains, 5 grain adjustment per full metering plunger rotation. The smaller pistol unit dispenses 0.5 – 17 grains in roughly quarter grain increments. The rotors are easy to change with a spring loaded, “press to release” buttons on each. Case actuated linkage adjustment and charge calibration were simple tasks. Multiple drop tubes are included with the kit.

Quick note on production revisions…

Good products change over time. It is a sign of a company that keeps tabs on customer service issues and actually listens to comments from customers and this applies to the Lock-N-Load AP. All Lock-N-Load presses, regardless production date, can be fit with Hornady’s powered case feeder. The current Lock-N-Load press has mount bosses, for this purpose, cast integral to the frame. This change to the original product release eliminates the need for assorted mount brackets and hardware that re required when mounting the case feeder to earlier production presses. I believe the bosses were introduced with serial number 07279.

Good products change over time. It is a sign of a company that keeps tabs on customer service issues and actually listens to comments from customers and this applies to the Lock-N-Load AP. All Lock-N-Load presses, regardless production date, can be fit with Hornady’s powered case feeder. The current Lock-N-Load press has mount bosses, for this purpose, cast integral to the frame. This change to the original product release eliminates the need for assorted mount brackets and hardware that re required when mounting the case feeder to earlier production presses. I believe the bosses were introduced with serial number 07279.Current shell plates have a revised leading edge contour to further facilitate use of the powered case feeder, promoting more reliable feed. This version of the shell holder is packaged in plastic boxes as pictures, right. Additionally, a radial relief was added to the backside of the shell plate to support the current Lock-N-Load AP’s EZject feature as detailed in following text below. Current shell plates are backward compatible with earlier presses, however, early production shell plates will not work on current presses with the EZject feature.

Highlights and instant replays…

A major difference between the Hornady press and competing progressives is Hornady’s management of shell plate rotation. There are ten detent positions rather the more typical five employed with other five station progressive presses. The Hornady Lock-N-Load indexes half of a position with each up and each down stroke of the operating lever. This means there are fewer degrees of rotation and less abrupt shell plate starting and stopping. Complimented by the index wheel’s more gradual camming rate, movement is much gentler – no index overruns and no powder spills.

A major difference between the Hornady press and competing progressives is Hornady’s management of shell plate rotation. There are ten detent positions rather the more typical five employed with other five station progressive presses. The Hornady Lock-N-Load indexes half of a position with each up and each down stroke of the operating lever. This means there are fewer degrees of rotation and less abrupt shell plate starting and stopping. Complimented by the index wheel’s more gradual camming rate, movement is much gentler – no index overruns and no powder spills.

Shell plate and subplate are held together with one socket head screw. There are no small parts mounted inside of the subplate. The small spring running around the perimeter of the shell plate retain cases in the holder during process. Spring loaded detent balls are permanently swaged into each shell plate assuring that none will fall out and disappear into a workbench black hole. With the EZject system, no sprung fingers are required to eject finished ammo. A small pad cast into the subplate bumps the finished round out of the shell plate at the last station. The case retainer spring is a bit on the fragile side but, for a dollar and change, replacements are available.

For as much as I like RCBS APS primer strips and associated bench and hand held priming tools, that system does not adapt well to their RCBS Pro 2000 progressive press. That priming system is active feed all of the time so, shell casing in the shell holder or not, each handle stroke will pop a primer out of the APS strip and advance the carrier strip to the next location. Hornady employs a classic shuttle feed system with the Lock-N-Load AP that is passive; it offers up a primer but, if there is no case to accept it, the unused primer will drop back down into the primer slide and a follow on primer will not be dispensed.

The motion of the shuttle is controlled by a simple cam rod; a wheel on the shuttle follows the outline of the rod, which moves the shuttle in and out from under the press shell plate in the correct timing and sequence. Mechanically, changing over between large and small primers is a matter of unhooking a primer slide return spring and pulling out and replacing the slide. The primer seater punch is changed by raising the subplate and removing and replacing the threaded seater punch – a minute or two, tops. In operation primers are dispensed cleanly and reliably and primer seating has a good…feel.

The AP’s mechanical advantage is approximately 5.00:1+, making full length sizing a no stress deal. A counter balance compression spring, part of the primer punch assembly, provides enough artificial feel for consistent primer seating. Changing over to load 7mm-08 Remington rounds during the project, the press ran just as smoothly at this case size and geometry. The Hornady Lock-N-Load has a good deal of cartridge length capacity. There is 4¾” clearance above the shell plate for big case clearance and shell plates are available for everything from the diminutive 25 ACP to the gigundo .460 Weatherby Magnum. As a practical matter, I do not load for the .25 ACP and I don’t run production quantities of huge volume magnums, but I had no problem running a good number of mainstream pistol and rifle cartridges that fell between these extremes.

Good production, quickly…

It is typical for me to resign myself to making ugly ammo on the first outing with new equipment. That didn’t happen in this instance. I began with pistol loads and the Lock-N-Load AP, without any fuss, cranked out a bunch of .357 SIG ammo.

It is typical for me to resign myself to making ugly ammo on the first outing with new equipment. That didn’t happen in this instance. I began with pistol loads and the Lock-N-Load AP, without any fuss, cranked out a bunch of .357 SIG ammo.Primers seated uniformly, powder was dispensed within a few tenths of a grain for the duration of the session, and COL was extremely uniform from one cartridge to the next. As is the case with auto indexing equipment, every cycle of the handle concluded with a finished round being ejected into the ammo bin. No jams, not missed indexing, no spilled powder charges, and I remembered to insert bullets…good production.

The Hornady Lock-N-Load AP press is production rated at up to 500 rounds per hour, or 8 rounds per minute. With material properly positioned about the press, and muscles and limbs familiarized with required repetitive motion, this is a reasonable production expectation. Within a short period of time, a 250 round per hour rate, manually feeding cases and bullets, felt pretty natural and I’m uncoordinated. While I am not usually a fan of automation accessories on people powered presses, the Hornady powered case feeder is a worthwhile addition. With case feed taken care of, all that remains for manual material transport is bullet stuffing and paying greater attention to the overall process. This accessory requires more extensive coverage than I can dedicate here, but I will get to it in the near future.

The Lock-N-Load is a heavy duty piece of production equipment, designed to make lots of precise ammunition, and to do so over the long haul. As is the case with the very heavy duty Redding T7 turret, I didn’t feel as though my shoulder or elbow were going to fall off after extended production sessions, something that can’t be said for lighter presses that require greater and persistent operator effort. I know we all like to say budget equipment can so all the things more costly equipment can do, but that just isn’t realistic. There is a functional difference.

The Hornady Lock-N-Load is available for approximately $399 from quality reloading suppliers such as Sinclair International. The price includes the powder measure with two rotor sizes as well as small and large priming systems. Only a set of dies, a shell plate and cartridge components are needed to begin producing ammunition. The case feeder, with one feeder plate that adapts the unit to one of three general types of cartridge casings, can be purchased, retail, for approximately $300.By comparison, Dillon sells their XL650, a press of similar capability, for $529 in less complete form and the auto indexing Pro 2000 RCBS sells for approximately $530. The Hornady Lock-N-Load AP is an excellent press, representing an excellent value.

I am a creature of habit. No, that’s not a B Movie reptilian creature with flippers and a couple of air sucking gills, but rather a guy who finds something that works, then sticks with it until there is a compelling and logical reason to change. Even more boring, if that’s possible, is our work place philosophy of purchasing only to situation and application. “It’s New!” and “It’s Zippy!”, do not constitute sufficient adjective substantiality for a product to find its place onto the RealGuns’ reloading bench. Really.

I am a creature of habit. No, that’s not a B Movie reptilian creature with flippers and a couple of air sucking gills, but rather a guy who finds something that works, then sticks with it until there is a compelling and logical reason to change. Even more boring, if that’s possible, is our work place philosophy of purchasing only to situation and application. “It’s New!” and “It’s Zippy!”, do not constitute sufficient adjective substantiality for a product to find its place onto the RealGuns’ reloading bench. Really.

Hornady die sets, culver powder measures and case prep and gauging tools have seen frequent use in the shop, right along side similar equipment from other leading suppliers. However, without a prior requirement, there has not been much of an opportunity to spend time with their reloading presses.

Hornady die sets, culver powder measures and case prep and gauging tools have seen frequent use in the shop, right along side similar equipment from other leading suppliers. However, without a prior requirement, there has not been much of an opportunity to spend time with their reloading presses.

Most press rams are solid body, or perhaps drilled for spent primer disposal. Hornady makes their ram double the typical size, utilizing oversized two inch diameter thick wall steel tubing. This allows the ram to withstand huge loads and still house and protect all of the press’ indexing drive bits and pieces. The spent primer disposal tube is located outside of the ram where it won’t get in the way.

Most press rams are solid body, or perhaps drilled for spent primer disposal. Hornady makes their ram double the typical size, utilizing oversized two inch diameter thick wall steel tubing. This allows the ram to withstand huge loads and still house and protect all of the press’ indexing drive bits and pieces. The spent primer disposal tube is located outside of the ram where it won’t get in the way.

Good products change over time. It is a sign of a company that keeps tabs on customer service issues and actually listens to comments from customers and this applies to the Lock-N-Load AP. All Lock-N-Load presses, regardless production date, can be fit with Hornady’s powered case feeder. The current Lock-N-Load press has mount bosses, for this purpose, cast integral to the frame. This change to the original product release eliminates the need for assorted mount brackets and hardware that re required when mounting the case feeder to earlier production presses. I believe the bosses were introduced with serial number 07279.

Good products change over time. It is a sign of a company that keeps tabs on customer service issues and actually listens to comments from customers and this applies to the Lock-N-Load AP. All Lock-N-Load presses, regardless production date, can be fit with Hornady’s powered case feeder. The current Lock-N-Load press has mount bosses, for this purpose, cast integral to the frame. This change to the original product release eliminates the need for assorted mount brackets and hardware that re required when mounting the case feeder to earlier production presses. I believe the bosses were introduced with serial number 07279. A major difference between the Hornady press and competing progressives is Hornady’s management of shell plate rotation. There are ten detent positions rather the more typical five employed with other five station progressive presses. The Hornady Lock-N-Load indexes half of a position with each up and each down stroke of the operating lever. This means there are fewer degrees of rotation and less abrupt shell plate starting and stopping. Complimented by the index wheel’s more gradual camming rate, movement is much gentler – no index overruns and no powder spills.

A major difference between the Hornady press and competing progressives is Hornady’s management of shell plate rotation. There are ten detent positions rather the more typical five employed with other five station progressive presses. The Hornady Lock-N-Load indexes half of a position with each up and each down stroke of the operating lever. This means there are fewer degrees of rotation and less abrupt shell plate starting and stopping. Complimented by the index wheel’s more gradual camming rate, movement is much gentler – no index overruns and no powder spills.

It is typical for me to resign myself to making ugly ammo on the first outing with new equipment. That didn’t happen in this instance. I began with pistol loads and the Lock-N-Load AP, without any fuss, cranked out a bunch of .357 SIG ammo.

It is typical for me to resign myself to making ugly ammo on the first outing with new equipment. That didn’t happen in this instance. I began with pistol loads and the Lock-N-Load AP, without any fuss, cranked out a bunch of .357 SIG ammo.

Email Notification