Having had the opportunity to examine and shoot a good number of AR type firearms, and the opportunity to assemble a few from carefully selected piece parts and subassemblies, I’d have to say that “subtle technological evolution” is a term that best characterizes these types of firearms. Updating changes manifests themselves in functional design, manufacturing process, materials and an ever growing list of useful accessories… and if you’ve ever been manifested, or experienced manifestation, or even manifest destiny, you know how characterizing that can be. The tough part for manufacturers jumping on a product of this type, is to know what generation of features to include in an initial product release. Fortunately for Ruger, they appear to have had a better than average crystal ball when they launched their AR type standard bearer.

The Ruger SR-556 ships inclusive of purposeful…appurtenance. I didn’t select the word, that was my spell/context checker trying to make sense out of me typing “appaduperence”. Beyond the SR-556, as pictured above, the Ruger’s retail carton contained: three MAGPUL thirty round PMAG magazines, one PMAG cap, three Troy Picatinny rail covers with Ruger logo, and a very nice padded canvas carry case with well thought out interior accessory compartments.

External look and operating overview…

|

||||||||||||||||||||||||||||||||

Beyond holding up dishes, tables often obscure key points that differentiate one product from another, and such is the case with Ruger’s SR-556. Described as a “Gas-operated, piston-driven, box magazine fed, autoloading rifle”, the SR-556 is a bit like a premium traditional AR-15, upgraded to include: $400 – $550 AR gas piston operating system conversion, $280 adjustable Troy Battle Sights, $120 canvas case, $250 collapsible stock, $60 worth of 30 round poly magazines, etc. The cheapo items that owners frequently upgrade after purchasing a lesser AR-15 don’t exist on the SR-556. The upgrades are courtesy of the folks at Ruger.

The discoloration on the Parkerized parts is new gun…gunk and protective coating that was left on by a guy who didn’t wipe the gun down before a photo shoot. As you’ll see in forward photos, the finish is actually a uniform matte black. The flash suppressor (1) ahead of a peel washer is pretty much standard fare and the same as the flash suppressor on the current Mini-14 Tactical. The front sight mounted above the gas block (2), is a Troy Industries adjustable folding battle sight with HK Globe type brush guards. The gas regulator and gas block (3), is an all steel assembly with four indexed settings to adapt the gun to various types of shooting and ammunition. “0” position blocks all gas from entering the system and renders the SR-556 a single shot that must be manually cycled, Positions 1 through 3 allow progressively more gas flow with position 2 being the typical for factory ammunition.

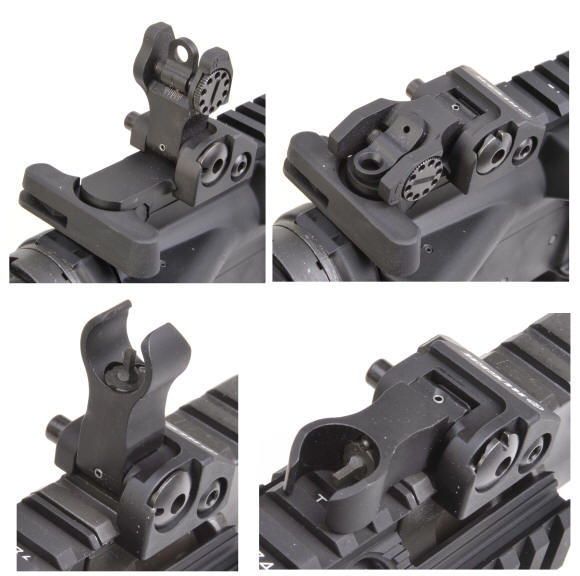

Folding battle sights…

The Troy Industry sights are a good selection. Easy to install and remove using the gun’s Picatinny rail system. They are very solid. Popped up for use, the front sight offers elevation adjustment in 1 MOA click increments, the rear sight provides 1/3 MOA incremental windage adjustment. Both sights fold to a compact 1/2″ height to place them out of the way of additional optical or electronic sighting systems that might be installed by those of us with 5 MOA eyesight.

A rail…y good way to mount stuff

The hard anodized and Teflon coated aluminum floating handguard (4), incorporates four Picatinny rails – 3, 6, 9, and 12 o’clock positions, each location marked with white alphanumeric identifiers to assist when installing and reinstalling optics and other accessories. The top rail blends into the Picatinny rail that is integral to the gun’s receiver; the top rail runs the length of the gun. A set of rail covers are supplied for three sides to provide a comfortable handhold when accessories are not installed at these sections of rail.

The hard anodized and Teflon coated aluminum floating handguard (4), incorporates four Picatinny rails – 3, 6, 9, and 12 o’clock positions, each location marked with white alphanumeric identifiers to assist when installing and reinstalling optics and other accessories. The top rail blends into the Picatinny rail that is integral to the gun’s receiver; the top rail runs the length of the gun. A set of rail covers are supplied for three sides to provide a comfortable handhold when accessories are not installed at these sections of rail.

Show above with sights popped up and rail covers in place, the layout of controls and placement of locating pins are all AR standard, so upgrade and newly developed bits, pieces and accessories can be added, as would be the case with any typical AR. As an example, an oversize cold weather trigger guard could be installed, a cushy palm swell grip, other standard AR magazines, and stocks suitable for differing applications. The exception to universal parts fit would be the non-standard handguard which is made to clear the Ruger’s adjustable gas block and to allow passage for the transfer rod and spring assembly that replaces the gas tube found on a conventional gas operated AR. As the SR-556’s handguard is of a very current and popular configuration, I couldn’t see the need to make a change to this part in the foreseeable future.

The Ruger has a well made collapsible stock that is adjusted by pushing up on the lower lever. Lock up is positive, the stock feels stable in use and the shooter may select one of six positions.

While the stock includes a sling swivel, the handguard does not, however, accessory sling swivels that attach to a Picatinny rail are easy to come by. Brownells offers a largeselection of this type of hardware at very reasonable prices.

Maintenance takedown…

Take down for routine cleaning and maintenance is easy. Pull out the charging handle, cock the hammer and rotate the safety to the “safe” position. The rear takedown pin is pushed out to the detent, I used a Delrin AR15 take down tool, then the upper assembly can be tipped down and the bolt carrier and charging handle can be removed. Push out the forward pivot pin, left to right just like the takedown pin, and the upper receiver can be removed from the lower.

The center of the SR-556 universe…

Conventional AR-15 type firearms have a gas block fixed some inches aft of the firearm’s muzzle, over an open orifice drilled in the gun’s barrel. A hollow tube runs from the gas block down the length of the barrel, under the cover of the gun’s handguard, through the face of the receiver and into the tubular receptacle of the bolt carrier key that sits atop the bolt carrier. When the firearm is discharged, gas is bled off from the barrel into the gas block, then into the gas tube and down to the bolt carrier key where pressure forces the bolt carrier open and cycles the gun. The gas is hot and contains powder residue which, combined, pumps miniscule debris into the gun’s receiver and elevates operating temperature. Additionally, on conventional ARs the gas flow is of fixed regulation and may be sensitive to ammunition power levels – lower pressure ammo may cause a failure to cycle and higher than standard pressure may promote excessive wear. The SR-556 gas operated piston system addresses both issues.

The Ruger SR-556 system utilizes a gas block with a barrel connecting orifice that permits gas to flow from the barrel to the block. However, instead of flowing directly into a tube and being carried to the bolt carrier, gas first flows through a metering body, a regulator, that offers four shooter selectable levels of flow. Labeled “Variable size gas ports” in the photo above, a smaller port is selected for higher pressure loads or to set the gun to single shot, manual cycle. Progressively larger ports are selected as ammunition load pressure diminishes. The parts are shown disassembled for the purpose of illustration as finger tip adjustments are made with the assembly installed, as pictured in inset. Maintenance of the Ruger assembly is easy to accomplish; the regular pin, #4 in the picture above, is pushed left to right to the detent position, the regulator is indexed to the gas block flat and the parts pull out with light finger pressure.

Another major feature of the SR-556 operating system is labeled #3 in the photo above, the piston that replaces the function of the AR standard gas tube. With the Ruger system, gas from the regulator acts on the piston and the piston drives a transfer rod that mechanically acts on the bolt carrier. Photo left illustrates the difference between a bolt carrier key to contain a gas tube versus the Ruger where a bushing driven by a transfer rod actuates the bolt carrier. The SR-556 system runs cooler during extended fire and there is no more powder residue passed to the bolt carrier through the gas tube.

Another major feature of the SR-556 operating system is labeled #3 in the photo above, the piston that replaces the function of the AR standard gas tube. With the Ruger system, gas from the regulator acts on the piston and the piston drives a transfer rod that mechanically acts on the bolt carrier. Photo left illustrates the difference between a bolt carrier key to contain a gas tube versus the Ruger where a bushing driven by a transfer rod actuates the bolt carrier. The SR-556 system runs cooler during extended fire and there is no more powder residue passed to the bolt carrier through the gas tube.

Third party conversion kits are offered to convert conventional AR guns to a similar operating system, however, I’ve not seen one with an adjustable regulator, most come with a utility grade handguard and the cost runs typically between $400 and $550.

Shooting and handling impressions…

I’ve read a number of times that the gas operated, piston driven system soften recoil and this appeared to be the case when shooting the Ruger in comparison to our Real Guns rusty, trusty High Standard AR-15 project rifle. Considering we have handguns shooting the same cartridge, recoil from an 8 pound plus rifle seemed negligible in single or slow fire with either gun, however, under rapid fire conditions dampened cycling made a difference when it came to staying on target and allowing accurate placement of shots. Considering the mission of the firearm, that is more than a subtle difference.

The Ruger was easy to shoot with the stock pulled full out and easy to carry with the stock pushed in. The six adjustment lengths made it easy to adapt to heavy winter clothing, or a thin vest. The forearm with rail covers in place made for a very comfortable hold. The metallic sights were a little low for me, so I found myself with my head rolled over a bit when I got to proper alignment. You can read that as “no drop at the comb of the stock”, just like its AR-15 brothers. With a scope on medium height mounts, eye alignment was very comfortable. With both guns left on a table in the shop for a couple of days so visitors, under supervision, could heft and handle them, everyone preferred the Ruger SR-556 over the AR-15. Most notably, the preference was based on compact size, stock adjustment and appreciation for more precise fit and feel.

The best hundred yard groups came with 70 grain Hornady factory ammunition, however, everything from 55 grain to 70 grains seemed to shoot fine. The 70 grain ammo shot 1″ – 1¼” – 16.1″ barrel! Remington UMC 223 Remington 55 Grain FMJ shot 2″, Remington Premier Match 223 Remington 62 Grain JHP shot under 1½”, Winchester USA Ammo 5.56×45 55 Grain FMJ shot between 1½” and 1¾”. I felt all of these groups were more than respectable.

The greatest discomfort while shooting was the SR-556’s heavy trigger pull. It began and ended at 8 lbs 12…13 ounces which, for me, is a bit too heavy and with a bit too much creep. Easy problem to correct and that would be probably the first and only modification I’d make to the SR-556. If I were using the rifle primarily for defense or security, I would probably leave it as shipped from the factory as this would not be a safe place for a very light trigger. All I know is whenever I picked up the SR-556 I felt I should push in the stock, move the gun to alert carry and go out an patrol the perimeter…any perimeter. The gun has a very intuitive feel.

Conclusions? I’ve had a few, but then again, too few to….

Interesting gun, Nicely put together and different enough in design to make it functionally better. From the standpoint of aesthetics and quality of build, it is head and shoulders above the greater majority of AR-15s being offered these days. For as much as I liked the gun “as is”, I’d really like to build a custom around this operating system, but I think we’ll have to save that for another time. For now, the Ruger SR-556 is a good choice for a compact premium autoloading shooter.

Email Notification