Generally, especially when it come to cartridges that are handloaded with some frequency, my bench top is clear except for the necessities; press, dies, a scale, a dial caliper, components, and something to hold the work in process so it doesn’t roll off the bench. However, when loading for a new firearm, or new cartridge, or where ammunition will serve a more critical mission, everything that will serve to document and refine handloads is put to use.

A concentricity gauge comes in handy when qualifying a new set of dies, bullets, brass or reloading press. It basically tells the operator if ammunition components are being assembled along a common longitudinal axis; is the center of the bullet in line with the center of the case so that, hopefully, all will end up in line with the centerline of a gun’s bore. Some products, as is the case with the Hornady tool, there is also the ability to put wayward bullets into concentric alignment.

An innovative approach….

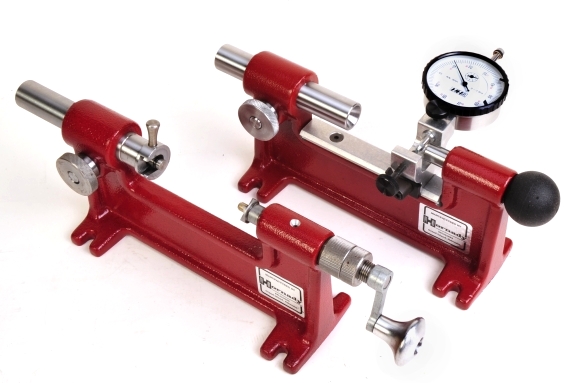

One of the things I enjoy most about firearms and related products is the head scratching engineering that is so prevalent. Virtually all other concentricity gauges are V block based; the cartridge floats on V blocks that support the case while a dial indicator rides on whatever surface the operator intends to measure. Sometimes the wobble picked up is no more than the case rocking on the V blocks as the operator applies uneven pressure while rotating the cartridge in the blocks.

The Hornady take a different approach by securing the case between a case head spindle and a spring loaded bullet spindle. If the cradle lock seems familiar, it probably should. The cradle slides side to side in the gauge frame attached to what amount to a Weaver or Picatinny style rail without the cross notches, locked in place with the type of fastener employed on a quick disconnect scope mount.

The case head is centered in the case head spindle by a conical recess cut into the face of the spindle. The surface auto aligns the case head at the back end which I thought, initially, might not be the best reference surface for concentricity. However, after checking a considerable number of cases representing rimmed, rebated and rimless cases, the chamfered rim edge was more consistent dimensionally then case bodies. This is a very adaptable design. As I am always looking for something wrong to write about to show how insightful I can be, I tried every cartridge on my bench from the ,222 Remington to the .500 Jeffery and they all fit without a problem… Yes, the .45-70 fits just fine also.

“O” rings on the plunger stem and the indicator position adjustment on the cradle allow the plunger tip to be set for a useful range of measurement. The spring loaded bullet spindle makes it easy to pop cartridges in and out of the fixture. Then by rotating a round to its lowest reading, the bullet straightener can be screwed in to press the out of concentric bullet into alignment.

The frame of the concentricity gauge, I’d guess, is made from the same casting as that used on the Hornady lathe trimmer with a couple of different secondary operations. The oiler hole is eliminated from the bullet spindle boss and the bridge where the carriage track mounts is radius drilled at both ends for mounting clearance. Personally, I like it when several tools share a common look and feel, plus they make the loading bench seem less… chaotic.

The kit includes the frame and fixtures, interchangeable bullet spindles and a dial indicator with a 1″ measurement range; 0.100″ face range, 0.001″ increments and a ten revolution counter. It takes a couple of second more to load the Hornady Lock-N-Load Concentricity Tool than a “V” block gauge, but then it takes several seconds less to get an accurate measurement and corrective action can be taken without having the move the cartridge to another fixture.

Nice piece of equipment. Feels substantial in use. Provides accurate measurement and correction to assembled cartridges as required. MSRP is $127. Typical price through discount retailer, $95 – $99.

Email Notification