05/05/2024 – Winter is gone, spring has sprung and the real work begins. Ordering fertilizer, potting soil, weed killer, and new mower blades from Amazon and Wally’s was exhausting. I am not sure how nutrients and chemicals will make it from bag to lawn, or potted plants will get repotted. Seems like a lot of work, but then, after 65 – 70 years of doing it all, you would think I would have a better feel for work.

The mower blades should be easy. I’ll just shackle the front end of the law mower to the tractor’s bucket loader and lift it up until I have access to the underside of the mower deck. I am a little concerned that the blade arbors are toast, based on the loud squealing coming from the deck when the clutch is engaged. Geez, only twenty two years of use and already things are going wrong.

Actually, I am really looking forward to lots of outdoor manual labor and playing with all of the machines that were stowed over the winter. Beats the heck out of being cooped up over the winter and having to rely on running like a frantic gerbil on the tread mill.

Thank you for sharing in my commitment

I promised the person who loaned the Ruger GP100 41 Special revolver, that I would handload some ammunition. Coincidentally, the .41 Special wildcat creates an opportunity to work through and illustrate various steps in the handloading process.

I had a hard time thinking how best to organize the work. I decided I would put the Hornady equipment on the floor next to the photo table, mount the press to the table, then pull out the kit content as required. I will then be able to identify what steps in the handloading process are covered, and which steps needed additional equipment or substitution for personal preference.

The Hornady Lock-N-Load Classic Press

As you might have noticed, the Lock-N-Load Classic was joined by an Inline Fabrication press stand. This Ultramount stand, #15, is 9 3/4″ tall. The legs are 3/16″ steel, the top plate is 1/4″ steel, the press retaining studs are 3/8″. The top plates are interchangeable and available as purchased accessories. $85 from Inline, free shipping. I bought this one from Grafs.Com for this project. Between business discounts and UPS exorbitant shipping costs, the price was about the same.

The stand is not necessary, it is a personal preference. I handload standing in front of my bench and I like a more direct view of the area where the cartridge is being processed. The stand also raises the press handle, making it easier and more comfortable to cycle.

If there is a nit to pick, the press mount holes should be located approximately 1″ further back on plate to fully support the press’s mount surface. If I have time, I will drill and tap a couple of holes at the optimal points. In all fairness, the press is stoutly supported as is, it just could be better if the unpainted machined surface were pushed back flush against the stand’s top plate.

So this is not an omission from the Hornady Lock-N-Load Classic kit. I could have just bolted the press at the edge of the bench top. Alternatively, I could have gone with a Hornady Quick Detach Mounting Plate System Item #399697. It is a good choice for a neat bench, providing a single mount point for essentially all Hornady bench mounted gear. The system runs approximately $80, with additional plates available for approximately $25

Lock-N-Load Bushings and dies of a different color

Some reloaders maintain a bench comprised of a preferred manufacturer’s equipment colors. Others opt for a more eclectic selection driven by best of equipment type. Then there is the issue of no single manufacturer producing all things.

The Lock-N-Load Classic Kit Deluxe does not include dies, because the press and kit will facilitate reloading virtually any metallic cartridge. So the customer gets to supply dies for their specific application. In this case, dies for reloading the wildcat .41 Special revolver cartridge were available from Lee, with longer lead time and with a custom die fee, or Redding as a standard set and shipped from stock. Impatient and appreciative of quality dies, Redding was my choice.

The press kit comes with six Lock-N-Load bushings. Each Redding die was screwed into one of the three bushing. Side note: The press die station has 1 1/4″-12 female threads. A Lock-N-Load press bushing has corresponding male threads, and inside 7/8″-14 female threads.

The Hornady Classic Press could be converted from the Lock-N-Load systems to a conventionally threaded die system by replacing the Lock-N-Load press bushing with an RCBS PN 709138press bushing. No, I do not know what anyone would want to make this conversion.

However, traditionally bushed reloading presses, with a 1-1/4″-12 inside threads, can be converted to the Lock-N-Load bushing system with Hornady Lock-N-Load® Conversion Kit Item #044099. The kit includes the conversion press bushing and three Lock-N-Load die bushing.

The Hornady Classic Press with Redding sizer die installed with the Hornady Lock-N-Load bushing system. This will work with any 7/8″-14 threaded die. Any shell holder from a mainstream equipment manufacturer will fit the end of the press’s ram. In this case, the shell holder (arrow) is a Lee Precision piece. If you Google “shell holder conversion chart” you’ll see a multitude of charts that list corresponding shell holder numbers.

While shell holders have common outside profile dimensions, the center hole may vary. As an example, while other brand shell holder will mount to the press ram, they will not work in trimmers, power or manual. These pieces of equipment utilize use a cam locking system to secure the cartridge case, where an anvil passes through the larger center hole of the Hornady shell holder. I’ll break that out further when we get to trimmers.

The path forward…

The plan is to conduct two reloading projects, one for the straight wall handgun .41 Special and one for the small bottle neck .22 Hornet rifle cartridge, and detailing each step. Yes, I am dragging you through the sometimes tedium of the process me, because some folks may not be familiar with the process and are considering handloading/reloading. I also think experienced readers can read along and comment, bringing some of their skill to others.

Subsequently, because the .41 Special wildcat cartridge requires reworking brass from a different cartridge, the .41 Remington Magnum, the process will begin with case modification. More specifically, case length trimming. In fact, a good deal of repetitive trimming.

.41 Special case prep… But first a word from our shell holders

I mentioned, previously, that Hornady shell holders have a larger center hole, to facilitate use with Hornady equipment using the Hornady Cam Lock method of securing a case/cartridge while performing an operation… like trimming. The pin gauges through the shell holders above illustrate the hole size difference.

The 0.257″ shell holder center hole is pretty much the standard for Lee, Lyman, RCBS, and Redding.The 0.299″ is standard for Hornady and a set of shell holders are included in the Hornady Lock-N-Load Class Press Deluxe. So nothing to buy here for any common cartridges.

Trimmers… Just a little off the top please

A trimmer is not included in the Lock-N-Load® Classic™ Kit Deluxe, but one is necessary to get quality results. There are hand tools, lathe type trimmers as pictured below, and a wide variety of powered trimming equipment.

A manual, lathe type trimmer will suffice on the bench for the great majority of reloading efforts, but there is definitely a place for powered equipment. I do not think choosing one over the other is a matter of quality of output, as much as it is production quantity and amount of material removed.

The Hornady Cam Lock trimmer can be found at discount retailers for approximately $145. Not that bad of an investment considering it will last just about forever. It is supplied with an assortment of pilots that center the cartridge case while cutting is underway. Shell holders that are used in this type of equipment, as well as on reloading presses are normally sold separately, but are included in the Lock-N-Load Classic Kit Deluxe.

One of the things that separates the Hornady unit from other lathe trimmer tools is the Cam Lock method of securing a case being trimmed. The shell lock, the part in my hand, with a shell holder installed, goes over the spindle, the threaded doohickey above my hand.

A casing is inserted into the shell holder, the shell lock handle is turned clockwise. The end of the spindle passes through the hole in the shell holder and presses against the case, locking it in position. The case is positioned centered and squared to the cutter.

The spindle diameter, where it contacts the casehead is 0.290″, significantly larger than a 0.210″ large primer pocket, so there is a good deal of clamping contact surface. The cutter is 0.640″ in diameter, again, considerably larger than cases that will be trimmed.

There is a Hornady adapter, Item #050145, that replaces the crank handle with an adapter that can be driven by a battery powered screw driver. The adapter sells for approximately $25 from discount retailers.

When trimming is more than casual, a buzz cut…

The .41 Special is a wildcat. Therefore, it has not undergone standard’s agency homologation, and does not have formal specifications used by reloading tool & die companies, ammunition makers, or firearm makers.

There is, however, enough .41 Special anecdotal evidence in the form of chamber reamers, custom die sets and custom firearms, to conclude that whacking precisely one-eighth inch (0.125″) off of a .41 Remington Magnum case yields the proper dimensions. Pictured Left-Right .41 Rem Mag, .41 Special (1.165″)made from a .41 Rem Mag case (1.290″)

Not long ago, Starline brass made a run of .41 Special with the proper headstamp, but has since ceased production. So, if you want brass, you have to make it. It can be made, in short quantities, with a manual case trimmer, but a power trimmer offers a less coma inducing process for the longer haul.

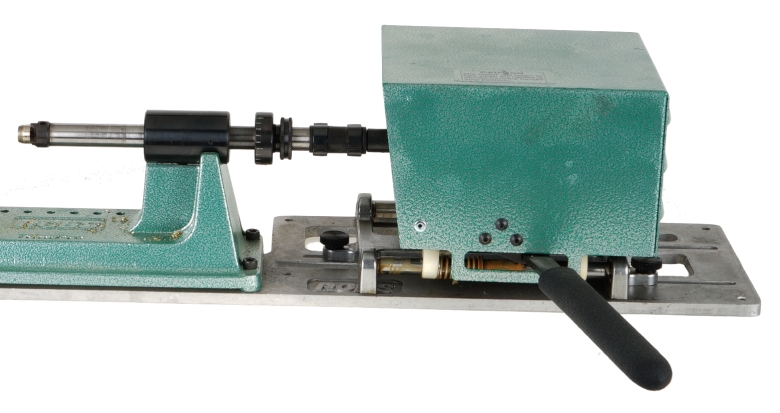

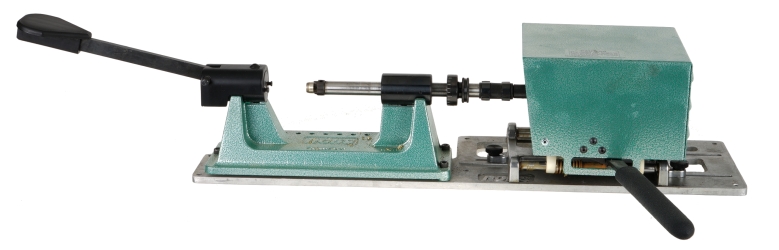

Do not mock me for having a relic on my bench. This RCBS power trimmer has seen many, many… many miles of brass cutting, and it has done a good job. At $428 for a replacement, I will continue to extract the benefits of this… vintage machine.

There are a couple of weak points in this design. The RCBS trimmer uses flat plate shell holders that serve no other equipment purpose. The clamping action is provided by spring tension on the pins that hold the shell plate and pull the shell holder and case against the head stock.

Locating the case mouth to the cutting head is accomplished with a caliber specific pilot inserted into the cutter face. If care is not taken when releasing the drive and moving the cutter to the case mouth, the case will often turn in the shell holder. If the case being trimmed has been fired and expanded under pressure, the case can wobble on the pilot and move the case mouth off square to the cutter.

The trimmer and powered drive are mounted on a common plate to insure alignment and the depth of cut is consistently precise. Pressure to cut is applied by releasing the lever on the drive motor and allowing that whole assembly to move forward on rails, moving the cutter spindle forward and into contact with the case being trimmed under hefty spring pressure. To stop, the lever is pulled back and locked into a detent.

Unfortunately the drive is connected to the cutter spindle with a piece of clamped rubber tubing. Unless carefully eased into the brass cutting, the shaft from the drive will sometimes spin inside the tubing and not drive the cutter. Additionally, the motor is relatively low powered and will occasionally stall while cutting, and irritatingly hum.

I started this reloading project with the RCBS unit but, between cases spinning in the shell holder, the drive shaft spinning in the tubing, and the motor stalling, on the average it was taking a minute per case to process. To avoid standing in front of the trimmer all day, I switched to something better.

The Hornady Lock-N-Load Case Prep Center, AKA The BAT

The Hornady Lock-N-Load Case Prep Center is a vertical, rather than horizontal operation. Compared to the RCBS unit, it takes up less space on the bench, it has a motor with great torque and it gear driven. In addition, the powered tools mounted at the front deburr, chamfer, clean primer pockets, etc. So as a case is trimmed, it can be cleaned up on the same equipment.

Where the RCBS trimmer applies the load during thew cutting operation, the Hornady requires the operator’s effort at attention to feed the cutter. So it is not possible to perform clean up on post trimmed cases during the cutting step.

The trimmer incorporates the Hornady Cam Lock system to secure cases. Both an assortment of cutting head pilots and shell holders are included and cover most popular cartridges. The .41 Special utilizes the shell holder and pilot designated for the .41 Remington Magnum, a less than popular cartridge, so a Hornady #17 pilot and shell holder #29 shell holder needed to be purchased.

The price for power and versatility is approximately $625 through retail outlets.

Intermission

So far, a trimmer was added to the Hornady’s Lock-N-Load Classic Kit Deluxe. Additionally, $15 for a shell holder and trimmer pilot. The trimmer type was my choice, as it fit my applications, it will last a long time, and it will save me a good deal of time.

If the work was more assembling a hundred rounds or so each month, a $25 hand held trimmer, or a $145 lathe type trimmer would have been a better fit. I’m going to break here and make some brass. Die set up is next.

Definitely liking this new series of articles. I sit while reloading, but wholeheartedly agree on making the effort to get the press and other tools at a comfortable height and solidly mounted.

Exactly. There is so much that could be done to get to an accommodating layout.

So far so good. Project is interesting. Especially the 41 special.

More on the way, David.