Right now, I am mostly feeling guilty. I keep sitting down to write a firearm related article and I can’t. Some very long term industry contacts have been reassigned in respective organizational reshuffling, or they retired, or they moved out of the industry. Unfortunately, they have been replaced with new wave marketing types, that are not really firearm enthusiasts, or firearm enthusiastic.

So the process went from a discussion about current and future firearm innovation and a no strings loan of a product to evaluate, to some yammering marketing type that makes my nose bleed. That has temporarily killed my interest in firearms, beyond my personal use and related projects. At the moment I am building a powered rimfire shooting gallery for the backyard.

Over the past few weeks I have taken out, taken apart and cleaned and performed maintenance on every firearm I own. Scrubbing copper and lead residue from bores, touching up gun metal and stocks, sifting through scopes and sight systems. I have not had an interest in buying or building anything new. I like the guns I have. The kind few seem to make anymore.

Hunting handloads have been assembled and shrink wrapped ahead of the coming deer season. I am prepared, in the event I decide to kill one of the three large whitetail bucks that reside in back acreage. I was not sure which firearm I would use, so I put together a supply of 44 Mag, 243 Winchester and 7×57 Mauser ammunition.

Past due projects fill the vacuum

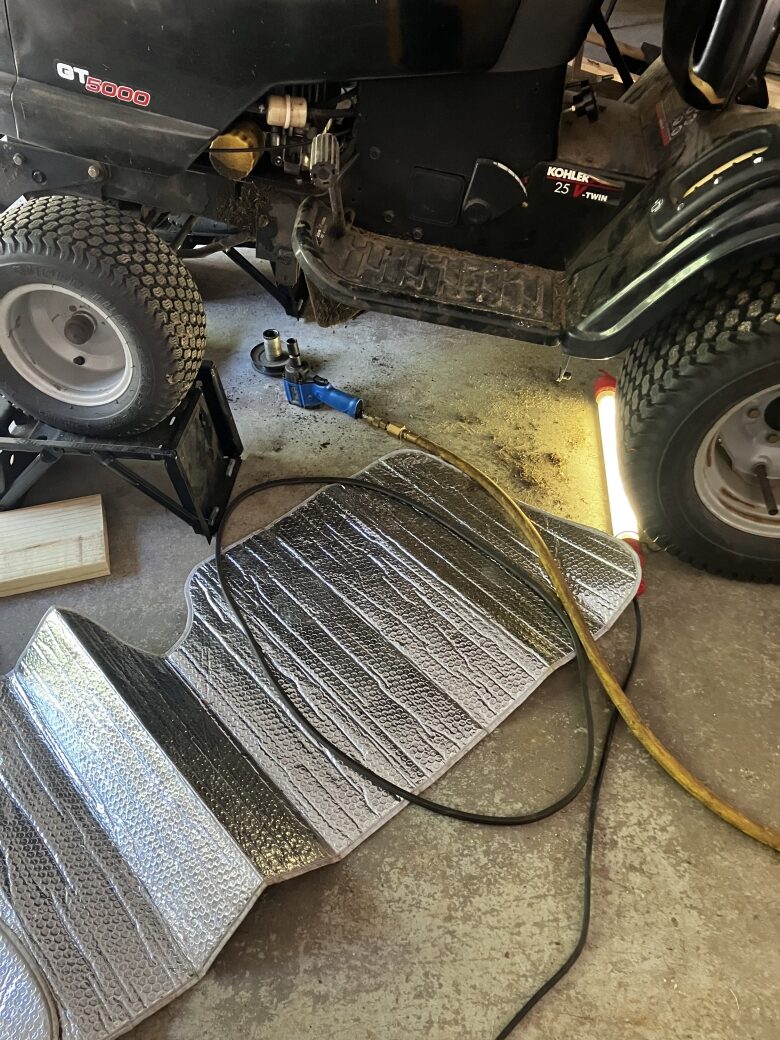

Living in a rural setting, equipment gets a workout, and most of it serves a necessity. My old Craftsman GT5000 garden tractor, actually a Husqvarna tractor, has put in twenty years of summer and winter use; mowing, but also pulling behind it lots of landscaping implements, or pushing a snow blower.

Living in a rural setting, equipment gets a workout, and most of it serves a necessity. My old Craftsman GT5000 garden tractor, actually a Husqvarna tractor, has put in twenty years of summer and winter use; mowing, but also pulling behind it lots of landscaping implements, or pushing a snow blower.

A year and one half ago, the bulk of the workload was moved to a subcompact John Deere 1025R, and the Craftsman was relegated to mowing and hauling gardening tools or a twenty gallon sprayer tank filled with pesticide. A week ago, Craftsman quit moving at an awkward moment; mowing and halfway up a steep slope in the front yard. Gravity effortlessly got me down the hill, but huffing and puffing old man pushing power got it into the garage.

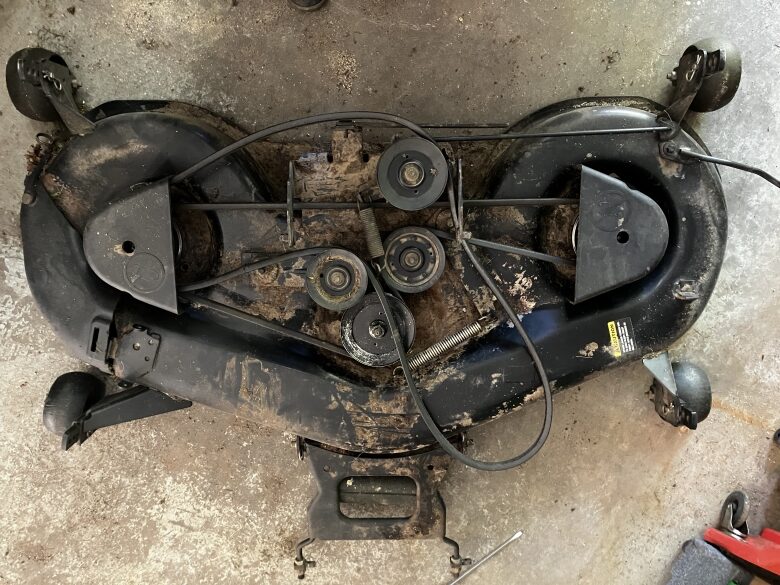

The problem turned out to be multi faceted. The drive belt had stretched to the point of sagging below/between drive pulleys, a tensioning pulley set was frozen, and the belt driving the deck and blade arbors were more of the same. I had all of the replacement belts on the shelf. I purchase these types of parts when I purchase equipment, because I know they will be obsolete by the time they are needed.

I checked YouTube for a possible belt changing tutorial, and found two. One was an eight part series that explained how to remove the rear tractor body and gas tank to thread the rear belt pulleys, the other was fifteen minutes of a guy talking about changing the belt on his tractor, but not covering how to accomplish the task. Who needs instructions?

I pulled the mower desk. I’ve done that many times, so that took ten minutes tops. Cleaning it up with a 6.5 HP shop vacuum took another ten minutes. Changing the primary and secondary deck belts took ten minutes. Getting my shin to stop bleeding, after dropping the edge of the deck on it, took about the same. So, forty minutes in total.

After releasing the belt tensioner, the transaxle and rear idler pulleys were remarkably easy to photograph with my phone, but no so easy to reach in to remove the old, and route the new belt. A spot of good luck, the fan is made of flexible rubber so lassoing it with the belt was relatively easy.

The only real disassembly was removing the electromagnetic clutch that drives attachments, that blocked access to the drive pulley. A pneumatic impact wrench loosened the bolt that secured it to the engine shaft, gravity put it into unexpected free fall, and the electrical wiring and connector gave it a surprisingly soft landing.

So I was twenty minutes into the belt installation, belt in place, and only the PTO clutch to reinstall. The vertical engine shaft has a key, the clutch center hub is slotted, but the hub floats in the assembly. Consequently, there is no commitment on its part to remain where you put it, when lifting the clutch assembly into place on the vertical engine shaft.

On the first attempt, the assembly went right on and into place. Unfortunately, the center bolt was sitting on the sand bin on the other side of the garage. Subsequent second, third and fourth attempts did not go as well. Each attempt separated by a coffee break, lunch or, at one point, watching First Amendment Auditors get arrested on YouTube. I really enjoy seeing pests get arrested.

With exhausting resolve, the clutch went on, the moving deck went on, and the tractor made three passes on a sharply pitched, hundred yard driveway, forward, reverse and drive away speeds. It was then that I realized how much performance had deteriorated prior to absolute failure. It was like new.

$50 worth of belts and I did not have to spend $3,500 – $5,000 for a comparable replacement tractor or zero turn mower.

No, this does not count as a firearm related article, and there will be more of those to follow. I just didn’t want anyone to think I left town. I will try not to write about the joys of perimeter pesticide selection next week.Maybe I will have my shooting gallery finished?

Oh, the silver windshield curtain in the tractor picture is used when I work on the cement floor, particularly in the winter, when there is not enough under vehicle height to use a creeper.

Joe, I feel your pain. I just spent $300 on my 54″ Cub Cadet with new blades, and new middle spindle, and oil change and filter. Fortunately, I have a Vietnam vet Marine that has a shop to do the work just up the road to do the work. I continue to work daily at 73 years. I mainly wanted to report that this past Friday I was able to order 1000 new Starline 41 Special brass straight from Starline. Midway and Graf’s had them, as well. I remain keenly interested on GP-100 in 41 Special. Like you, not much of the new firearms interest me. Hang in there, Buddy! Bob!

That is actually a pretty cost effective repair for that work. You’re fortunate to have that access.

Good news on the .41 Special brass. Starline did the original production run and it went out of stock. Nice that they made another run and put it at these large outlets.

You take care also, Bob.

Joe

It’s amazing how equipment performance can very slowly drop off sometimes, and the pleasant surprise when it’s restored. Very good foresight buying spares up front on the tractor and similar equipment!

You caught my attention with the mention of your new shooting gallery. Maybe that’s a future article on what you did? I’d certainly be interested. Hang in there Joe.

Scott

The buy parts in advance of obsolescence mentality came from years of racing old FE engine Fords, Scott. Yes, the plan is to turn the gallery into an RG projects. Fingers crossed.

Joe