You don’t have to be a precision handloader to benefit from incorporating a couple of inexpensive measurement tools into the handloading process. I am not, but any stretch of the imagination, a precision handloader. I don’t have the time, I don’t have the skill and I don’t own or shoot firearms with bench rest competition-like accuracy. However, I do try to concentrate on producing carefully and consistently assembled ammunition that will be perform reliably and predictably.

Two of the most useful tools on my bench are an inexpensive headspace gauge and a cartridge overall length gauge. The first makes it possible to keep reloaded brass near chamber size for a specific firearm. This chamber matching reduces cold working, which extends the useful life of cases and it reduces the pressure dampening effects of undersize brass being forced into conformance with larger chamber walls on initial discharge. The second gauge, the cartridge overall length gauge, helps maximize net case capacity and it keeps bullets close to rifling to enhance accuracy, while assuring sufficient clearance from rifling to prevent pressure spikes. These tools can be made even more useful with a little refinement.

Hornady’s Lock-N-Load headspace gauge bushings

![]()

The Hornady Lock-N-Load Headspace Gauge is comprised of a small adapter, or gauge body, that clamps to one jaw of a caliper and a bushing that configures the setup for use with a specific cartridge or series of cartridges. A set that includes a body and all five production bushings retails for approximately $36. Sinclair International lists this set as #HK66.

Hornady lists the gauge’s range of bushings as: A – 0.330″, B – 0.350″, C – 0.375″, D – 0.400″, and E – 0.420″ where the noted measurement is the inside diameter of the bushing. In some cases, this  dimension reflects the headspace reference diameter as noted on the SAAMI drawings for specific cartridges. This holds true for the 7mm-08 Remington, pictured right. The “D” bushing diameter matches the 243 Winchester and the 308 Winchester, however, the “D” bushing is also listed for the 300 Savage, a case with a smaller 0.3.968″ headspace reference diameter. Relative change in a Savage case’s length can be measured between new and fired case, however, a headspace dimension can not be inferred. The 6.5×55 Swedish Mauser has a similar circumstance. The Swedish Mauser falls into bushing category “C” with a 0.375″ through hole, while the 6.5x55mm headspace reference diameter is 0.365″.

dimension reflects the headspace reference diameter as noted on the SAAMI drawings for specific cartridges. This holds true for the 7mm-08 Remington, pictured right. The “D” bushing diameter matches the 243 Winchester and the 308 Winchester, however, the “D” bushing is also listed for the 300 Savage, a case with a smaller 0.3.968″ headspace reference diameter. Relative change in a Savage case’s length can be measured between new and fired case, however, a headspace dimension can not be inferred. The 6.5×55 Swedish Mauser has a similar circumstance. The Swedish Mauser falls into bushing category “C” with a 0.375″ through hole, while the 6.5x55mm headspace reference diameter is 0.365″.

Using a bushing with an opening larger than a cartridge’s headspace reference diameter will cause it to locate at a point too far down the slope of a case’s shoulder. This lower contact point is not consistent with the contact point within a firearm’s chamber. Consequently, the difference in measurement found between a fresh and fired case with an oversize bushing doesn’t translate directly to headspace or sizer die adjustment.

Using a bushing with an opening larger than a cartridge’s headspace reference diameter will cause it to locate at a point too far down the slope of a case’s shoulder. This lower contact point is not consistent with the contact point within a firearm’s chamber. Consequently, the difference in measurement found between a fresh and fired case with an oversize bushing doesn’t translate directly to headspace or sizer die adjustment.

OK, Joe, you’re making all of this up, right? Typically that might be true, but I offer into evidence… a 6.5×55 Swedish Mauser case, when fired in my rifle, measures 1.766″ when checked with a Lock-N-Load “C” bushing, the bushing listed for use with the 6.5x55mm cartridge. The same case measures 1.778″ when measure with a 0.365″ through hole bushing. The 6.5x55mm drawing call out a headspace length of 1.7793″ -0.007″. The proper bushing diameter brought the measurement inline with a real world headspace measurement, but more important was the difference in change that was detected between new and fired cases. The oversize bushing showed no difference between the two types of cases, masking a change of 0.002″ in headspace length that was detected by taking a measurement with a the correct size bushing, referencing the correct point on the case shoulder. A difference worth knowing when setting up dies, or perhaps checking for changes in a rifle’s mechanical condition. So where did I get the proper bushing? Glad you asked.

A good point for skilled machinists to stop reading…

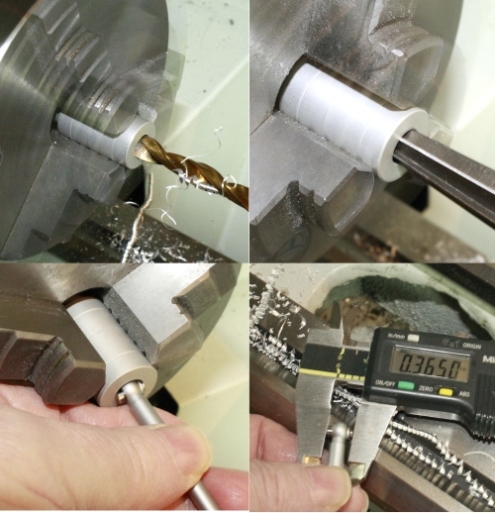

Fortunately, it is relatively easy to create a bushing that is a correct match or any cartridge, production or wildcat. Hornady offers blank bushings that are externally finished, but have only a small pilot through hole that can be opened to accommodate a maximum bore size of approximately 0.450″.

I chucked the blank bushing into the lathe (probably could have just as easily done with a drill press, but the lathe is more fun), case contact end facing the cutting tool and enlarged the pilot hole with a 23/64″ drill to a measured 0.356″. A 23/64″ drill is suppose to drill a 0.359″ hole but my drill set was imported from, I believe, Nauru, where the primary exports are bat guano and life preservers for ducks. What can I say, I’m… thrifty and I enjoy the excitement of unpredictable results.

My original intent was to finish the hole with a hand held adjustable reamer which, as luck has it, is a tool I apparently own; $13, also from Nauru. Accepting that the hole only needed to be very precise at the mouth of the gauge and not throughout the entire bore, the bore was taken to 0.363″ with the hand reamer, then a reamer with a shallow taper was used to get the mouth of the gauge to exactly 0.365″, the headspace reference diameter for the 6.5×55 Swedish Mauser.

My original intent was to finish the hole with a hand held adjustable reamer which, as luck has it, is a tool I apparently own; $13, also from Nauru. Accepting that the hole only needed to be very precise at the mouth of the gauge and not throughout the entire bore, the bore was taken to 0.363″ with the hand reamer, then a reamer with a shallow taper was used to get the mouth of the gauge to exactly 0.365″, the headspace reference diameter for the 6.5×55 Swedish Mauser.

One final note on this whole bushing deal… There is almost no liquid marking substance that will stick to the surface of these bushings. Subsequently, I’ve taken to stamping sizes on them so I am not spending my life fishing through a pile of bushings with an inside micrometer. A stamp set runs about $25 fromBrownells and it is a useful investment where work of this type is routine.

Since I was making things anyway…

Sinclair International lists the Hornady Lock-N-Load OAL gauge, CFG-2000, for approximately $35. There is also a curved version that fits through the ejection port of semi auto and lever action firearms that is similarly priced and accomplishes the same task. Hornady produces, and Sinclair International sells, for $7 – $8, modified cartridge cases for use with the Lock-N-Load OAL Gauge. A modified case is made from new brass, drilled and taped at the primer hole so it can be secured to the gauge. Additionally, the neck of the modified case is opened so a bullet will move freely within the case’s neck.

Modified case are suitable for meeting the intent of the OAL gauge, however, modified cases do not closely match the chamber of a specific firearm.

| 6.5×55 Mauser Case | Overall Length |

Headspace Length |

Body Diameter |

| Fresh Case | 2.156 | 1.778 | 0.432 |

| Fired – Full Length Sized | 2.161 | 1.777 | 0.440 |

| Fired – Neck Sized | 2.158 | 1.776 | 0.444 |

In other circumstances, modified cases may not be available to cover a newly released cartridge, a wildcat cartridge or less popular production cartridges. My personal favorite – it’s a weekend, a handloading project is underway and I forgot to order the applicable modified case.

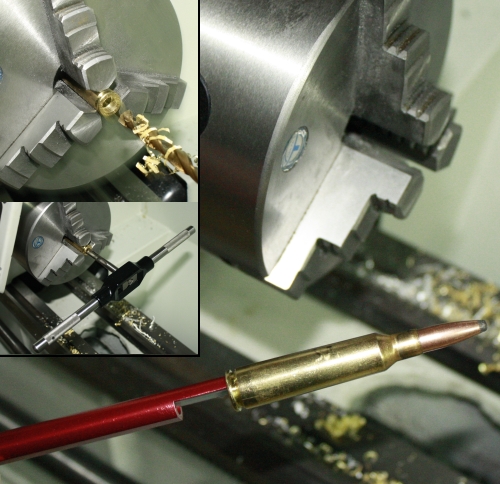

Few tools are required to fabricate a modified case for the OAL gauge from a fired case. A universal decapping die allows primer removal without sizing, which allows a bullet to move freely within the case’s neck. A 9/32″ drill bit is required to drill through the primer pocket in preparation for the next and last tool, a 5/16-36 tap, which is the gauge’s thread size where the modified case is affixed.

This case was drilled out on a lathe, but the same could be accomplished with a drill press or hand drill. In my experience, the lathe chuck tends to hold a case without causing distortion and without allowing the case to slip in the jaws and damage the case body. After drilling, the case was left in the chuck and hand tapped to finish. Tapping oil was used because brass tends to gall when tapped dry.

It took a lot longer to write about the pieces than it did to actually produce them, approximately one hour to make both.

Email Notification