News Bulletin: Fajen on the auction block

![]()

For a company that obviously has to manage a huge inventory, Brownells seems to always have everything in stock. I keep hoping they’ll get that online order site going so I can place orders during off hours. In the interim, the large, well organized, mail order catalog works just fine. I’ve used Brownells for everything from custom internals for my Colt autos, to specialty tools that are not generally available elsewhere. More recently, they’ve expanded quite a bit in handling a wide assortment of factory parts, from companies like: Browning, Colt, Remington, and S&W.

For a company that obviously has to manage a huge inventory, Brownells seems to always have everything in stock. I keep hoping they’ll get that online order site going so I can place orders during off hours. In the interim, the large, well organized, mail order catalog works just fine. I’ve used Brownells for everything from custom internals for my Colt autos, to specialty tools that are not generally available elsewhere. More recently, they’ve expanded quite a bit in handling a wide assortment of factory parts, from companies like: Browning, Colt, Remington, and S&W.

I ordered the other day from Brownells to pick up a Wichita rifle rest and Protektor bench rest bags. Why would I go all the way to Iowa to get these types of items ? Choice. The local stores started carrying a popular brand name’s rifle rest. From a distance, the rest looked massive. Unfortunately, as I got closer, I realized it was constructed entirely of wobbly plastic. A rest is suppose to be a rock steady substantial support for sighting in, or testing loads and rifles for accuracy. This local store product was clearly $5 worth of injection molding tossed in a $90 box.

Brownells, on the other hand, carries several models and brands of quality rests, with prices running from around $100 to some pretty fancy Ransom models at around $700. They have over a dozen shapes, sizes and styles of bench rest bags to choose from, and bags intended for use in the field. I got the narrow forearm bag made to fill the U shaped support in the rest, and a large rabbit ear bag to support the rear of the stock. The bags are all made of quality leather, won’t leak filler, and will probably outlast my rifles.

Brownells, on the other hand, carries several models and brands of quality rests, with prices running from around $100 to some pretty fancy Ransom models at around $700. They have over a dozen shapes, sizes and styles of bench rest bags to choose from, and bags intended for use in the field. I got the narrow forearm bag made to fill the U shaped support in the rest, and a large rabbit ear bag to support the rear of the stock. The bags are all made of quality leather, won’t leak filler, and will probably outlast my rifles.

The rest has adjustments for vertical height, leveling and a forearm stop to insure the rifle is returned to the original firing position. The rabbit ear bag is the correct height and angle for use with the the rest and will firmly locate the rifle at the toe of the stock. The idea, in using this equipment, is to eliminate as many rifle positioning variables as possible, and to keep the rifle trained on the same spot on the target.

“Big” just keep getting bigger…………..

loads for the 7 mm RM and the .338-378 WM – Part II

“Smooth” was not a word that came to mind as the week began. In preparation for assembly of test rounds, I was running 7 mm cases through the resizing die when I noticed this very subtle dimpling on some portions of the shoulder. Typically a sign of excess case lube, I started working down the amount of lube I was using, and exercising more care in selecting specific areas of application. Then I made my first serious mistake by wiping a case almost dry, before running it through the die.

I should have stopped pulling down on the press handle when the case started to bind. But I didn’t. I thought if I ran the press full stroke, the newly formed case would be easier to extract. I could have stopped when the case had been driven home, clearly wedged in the die. But a large press operating handle, unfounded confidence in the strength of a brass case rim, and an assessment of great potential, caused me to move on ahead. That’s when the case rim collapsed and folded over, released the shell plate and handle, which then traveled like a rocket to the full down position. The press handle hit home in a pretty spectacular fashion, with basically everything that had been resting on the bench going airborne, then rapidly returning under gravitational pull to random locations scattered about the room. In short, “It blow’d up real good”.

I compounded the problem by not being patient, and not using used a stuck case extractor. If I had, I may have lost the case, but would have probably not done any damage to the die or expander rod. A broken case extractor is actually a fairly simple device, sort of a mini-wheel puller.

I compounded the problem by not being patient, and not using used a stuck case extractor. If I had, I may have lost the case, but would have probably not done any damage to the die or expander rod. A broken case extractor is actually a fairly simple device, sort of a mini-wheel puller.

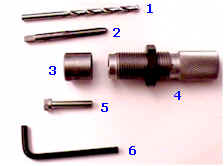

The die is removed from the press, and the extractor rod is backed out until it clears the primer hole. Then the drill (1) is used to open a hole in the primer pocket of the stuck case, a hole which is then threaded with the tap (2). The cap (3) is then slipped over the die housing (4) containing the stuck case, and the cap screw (5) is passed through the cap (3) and threaded into the opened hole in the case’s primer pocket. Then the Allen wrench (6) is used to screw the cap screw into the case, which in turn pulls the stuck case from the die and into the cap. The set cost only a few bucks, a lot less than it cost to replace dies or even an expander rod setup.

Unfortunately, pressed for time, I tried to take some shortcuts and use tools not specifically designed for this purpose. The results were not quite what I was looking for. In this picture, that step in the expander rod (1) is where the threads mounting the expander ball (3) were sheared off. The decapping pin was tweaked into a permanent semi U Turn, no longer aligning with the primer flash hole. (3) The hardened expander plug was just eaten in the case removal process. The resizing die came out in good shape, but the expander rod assembly had to be replaced. What did we learn from this anyway ? Well……

Unfortunately, pressed for time, I tried to take some shortcuts and use tools not specifically designed for this purpose. The results were not quite what I was looking for. In this picture, that step in the expander rod (1) is where the threads mounting the expander ball (3) were sheared off. The decapping pin was tweaked into a permanent semi U Turn, no longer aligning with the primer flash hole. (3) The hardened expander plug was just eaten in the case removal process. The resizing die came out in good shape, but the expander rod assembly had to be replaced. What did we learn from this anyway ? Well……

Stop if an operation requires excessive force, something is wrong. Now there’s a surprise.

Only apply case lube, sparingly, to the case sides. Brush a small amount of lube on the case mouth, or use dry lube if excess lube and powder contamination are a concern.

Do not press cases that are essentially dry through a full length resizing die.

Keep a case extractor handy. You will eventually need the services of one.

Keep some spare parts, like extractor rods and balls – they are not unbreakable and you probably can’t pick them up at the 7-11.

Try to elevate reloading to an art form by combining the ancient art of thinking, with the time honored traditions of quality reloading.

As a consequence of the broken die parts, and having to wait for a UPS delivery, the 7mm RM load development was placed on the back burner for a few days, and I moved on to the .338-378 WM.

My general approach here was to find the slowest burning powder load data, and work up my own loads from there. On this initial attempt, I restricted powder selection to IMR 7828 and Reloader 25. Both powders look very similar, both are cylindrical or stick powder, RL-25 granuals are slightly longer. Varying surface area of granules by varying length, creating an axial perforation, or applying a form of burn retardant are all methods of controlling smokeless powder burn rates.

My general approach here was to find the slowest burning powder load data, and work up my own loads from there. On this initial attempt, I restricted powder selection to IMR 7828 and Reloader 25. Both powders look very similar, both are cylindrical or stick powder, RL-25 granuals are slightly longer. Varying surface area of granules by varying length, creating an axial perforation, or applying a form of burn retardant are all methods of controlling smokeless powder burn rates.

Slower powder and large case capacity combinations typically require magnum primers. In this application, Federal 215’s were recommended. Some other suitable alternatives would be CCI 250, and Remington 9 1/2m. Magnum primers burn longer and produce hotter ignition. Standard large rifle primers may not be substituted.

I wasn’t very excited about the bullet selection I had to work with, as I didn’t think the Speer Grand Slam’s were representative of what I would eventually use for hunting. I just think that a lot of current bullet technology is unnecessary in features and cost. Unless the Speer’s bullets specifically had more uniform jackets, or weight, or some other tangible benefit, they just seemed over priced. Any well made spitzer soft point, of the correct weight, in a decent H or A frame jacket would have been fine. I originally planned to use 200, 225, or 250 grain bullets from Hornady, or the 215 and 250 grain spitzer boat tail from Sierra. I’m sure I will get back to these before this project is concluded.

The Grand Slam, on the right, has a flat tip. Hardly a good aerodynamic design. I believe this tip has a jacket that runs all the way to the end, offering more controlled expansion, and greater protection of the soft lead core. As I’ve never had a problem with expansion control in plain jacketed soft points, I’m not sure there was actually a problem to solve with this more advanced design. I get the feeling that practical bullet design reached its limits around 20 years ago, and the biggest change since have been product marketing.

The Grand Slam, on the right, has a flat tip. Hardly a good aerodynamic design. I believe this tip has a jacket that runs all the way to the end, offering more controlled expansion, and greater protection of the soft lead core. As I’ve never had a problem with expansion control in plain jacketed soft points, I’m not sure there was actually a problem to solve with this more advanced design. I get the feeling that practical bullet design reached its limits around 20 years ago, and the biggest change since have been product marketing.

I don’t need solid copper bullets. I have never seen objective data that would make me use moly coated bullets. I have no idea what I would do with a box of bullets, with color coded plastic tips, that made me feel like I was carrying a box of Crayons. Maybe I’m just a grumpy old guy who doesn’t need to be entertained by the ammo I carry. But there is a more practical reason why I don’t like Grand Slam bullets, some bullet seating dies just don’t like flat tipped bullets.

The Grand Slam flat tip would consistently catch on the face of the die’s bullet seating plug. I didn’t particularly want to locate, or fabricate a special plug, just for use with this bullet.

The Grand Slam flat tip would consistently catch on the face of the die’s bullet seating plug. I didn’t particularly want to locate, or fabricate a special plug, just for use with this bullet.

Beyond the bullet tips that looked like they had been chewed on by a small animal, this hang-up would cock the bullet in the die, causing the base of the bullet to catch the mouth of the case, in turn applying enough pressure to actually collapse the cartridge case neck, rendering these little $4 brass gems unusable. Note the deformed shoulder on the lower assembled case.

If there was ever a case to be made for single station manual, versus multi station auto progressive reloading operation, the oversized .338-378 would be at the center of it. Normally, my RCBS Ammo Master just clunks and clanks along, with little effort, and with a great deal of reliability, kicking out finished round, after finished round. Sizing cases, seating primers, dispensing powder, seating bullets, – pistol, rifle….. Not so with this Weatherby round. In fact, every time the expander plug cleared another case, the resulting motion slung powder from open cases and made accurate primer seating almost impossible.

The CH/4D resizing die was fine. It dropped right in, was easy to set up, and turned out cases right on the favorable side of spec. The die closely approximated my rifle’s chamber, so resizing effort was minimal. Only getting the cases to let go of the expander plug was a little bit of a task. The plug was smooth, appropriately tapered, and more than enough lube was used. Just a tight fit that was pounding the crap out of the press and the bench. So I elected to batch reload in single steps rather than try to turn this into a volume production exercise.

Unless something drastically changes with experience or setup, chances are the next time I attempt this task, I’ll be using a very heavy duty single stage press and meter out powder charges with an electric scale. There are just too many obstacles with each step to move smoothly from one to the next. In addition, I could never see loading more than 50 rounds of this cartridge at a time under any circumstance. That’s just not enough volume to bother with setting up for automatic operation.

Unless something drastically changes with experience or setup, chances are the next time I attempt this task, I’ll be using a very heavy duty single stage press and meter out powder charges with an electric scale. There are just too many obstacles with each step to move smoothly from one to the next. In addition, I could never see loading more than 50 rounds of this cartridge at a time under any circumstance. That’s just not enough volume to bother with setting up for automatic operation.

So, in single steps, I decapped and resized, trimmed to length, tumbled till clean in walnut husks and polish, wire brushed the primer pockets, then washed out and dried the cases. I primed each case, fed them powder and carefully seated each bullet. Each round was assigned a number, each was labeled with a waterproof marker, and critical measurements were logged for future reference.

![]() A micrometer that is accurate enough to measure in .0001 increments was used to take case head measurements, a standard dial caliper was used to record the rest. I am going to watch two locations on the case in looking for excessive expansion. The first location is the diameter of the belt, the second is just above the belt. Any expansion of .0005 or greater will be considered a sign of excessive pressure. From everything I’ve read, this method is much more reliable than checking for flat primers or brass flow to recesses or openings in the bolt face. This measurement applies only to cases fired more than once, but no more than 3 times.

A micrometer that is accurate enough to measure in .0001 increments was used to take case head measurements, a standard dial caliper was used to record the rest. I am going to watch two locations on the case in looking for excessive expansion. The first location is the diameter of the belt, the second is just above the belt. Any expansion of .0005 or greater will be considered a sign of excessive pressure. From everything I’ve read, this method is much more reliable than checking for flat primers or brass flow to recesses or openings in the bolt face. This measurement applies only to cases fired more than once, but no more than 3 times.

We loaded up Bob’s Blazer with guns, ammo, chronograph, cameras and a bunch of other gunk, then we woke Bob up to let him know he know he was going to the range. Seemed like the decent think to do. beside, there was a lot of crap to carry. We also brought Kachun Lee, the technical brains behind NewsGuy news service, because he likes to go to the range, and also because we needed a math guy to help interpret statistical results. Then we spent that day and the next watching the rain pour down, pour down some more, and pour down even more….. Next week, some results, honest.

Thanks

Joe

Email Notification