Anyone who has been a firearm enthusiast for any length of time eventually ends up with rifles that never see the light of day. A gun may fall out of style, or it might be missing a useful feature that makes it less than fun to take hunting. With a minimal expenditure of time, money and effort, these types of firearms can again see active service.

I don’t know what I was thinking when I bought a Winchester Super Shadow. I could have been distracted. The war in Pianosa was raging on. Disco was the new craze and me and my lady were spending most of our evenings at local clubs perfecting our Point and Hustle moves. 2005 was a quite a trip.

I don’t know what I was thinking when I bought a Winchester Super Shadow. I could have been distracted. The war in Pianosa was raging on. Disco was the new craze and me and my lady were spending most of our evenings at local clubs perfecting our Point and Hustle moves. 2005 was a quite a trip.

It’s not uncommon to have mixed emotions over the Super Shadow’s appearance. To some, the Shadow is the work of an artist… a very angry artist who was hell bent on sticking his or her thumb in the eye of every gun loving American. To others, the Super Shadow represents a very clever way for Winchester to deliver a light, accurate and durable rifle for under $500, with the hope of encouraging the shooting public to try Winchester’s Short and Super Short Magnum cartridges.

This .270 WSM Super Shadow is accurate and reliable, the cartridge produces stellar ballistics and the gun seems impervious to the effects of harsh weather and rough handling. The stock’s sweeping inset compound curves and raised forearm grip surface serve as external ribbing and give the inexpensive stock a substantial feel. The raised stippling provides a better grip and is less expensive to tool for manufacturing than impressed molded checkering. Unfortunately, the gun’s forearm is narrow, it has a blind magazine, the stippled surfaces are worn slick. Worse, the rifle looks dated.

The first thought was to just restock the gun with a replacement Winchester walnut featherweight stock, but that stock was priced at $350 with approximately another $400 required for new steel bottom metal and related floor plate pieces; more than the price of the gun when new. Locating a value priced, finished walnut replacement stock for the Winchester Model 70 was a bit of a challenge. Guns fall out of popularity, parts and accessories fall out of distribution, and this was the case with the Winchester. So a little head scratching thought was required.

Assessment and investigation… Too much Hawaii Five-O

The Super Shadow stock emulates a Model 70 with a two piece Winchester floorplate. Three screws anchor the barreled action to the stock and a fiber filled poly trigger guard is glued or sonic welded in place and the false floorplate is integral to the stock. I couldn’t figure out why Winchester would go to so much trouble to mold the floorplate in this form so I disassembled the gun for a better look. I also disassembled a current Columbia, SC manufactured 270 WSM Featherweight for the sake of comparison. I like to take at least two similar guns apart at the same time. My theory is that this gives me a 50-50 chance of getting at least one whole gun back together again.

Inside the stock were all of the magazine parts that would be in place for a conventional floorplate equipped model. By Winchester forming the synthetic stock to replicate the form and dimensions of a gun with a hinged floorplate, Winchester was able to utilize a common set of parts for both floorplate and blind magazine models.

Luck is where you find it…

The only real difference found was the use of two 1/4″x32 screws to secure the one piece bottom metal on the Columbia, SC manufactured Featherweight versus the three fasteners securing the Shadow’s stock to its barreled action. The plan was to use one piece bottom metal because it is looks cleaner, it’s more reliable in operation and it require fewer fasteners. Dimensionally, the magazines, followers and magazine springs were essentially the same.

Some mechanical differences were found between the older New Haven push feed action and the newer Columbus manufactured actions; bolts, trigger assemblies and trigger mounting and the thickness of the radius at the back of the feed port. The receivers do have identical three fastener locations and recoil lug thickness and depth is the same. I did try dropping the Shadow action into the newer generation Featherweight stock, but it didn’t fit. The Featherweight’s inletting for the new style trigger didn’t provide enough clearance for the older generation trigger assembly.

The result of empirical knowledge… or outhouse engineering

I had to do some digging for a replacement stock. Current generations of good synthetic stocks were too expensive for this project and most inexpensive replacement walnut stocks required finishing, clean up inletting and/or checkering. A Boyds’ Classic, PN 661-000, became the solution; finished inside and out, intended for use with a 1 piece floorplate and recoil pad and swivel studs were included. The ENG-060 option was selected, “Laser engraved classic checkering pattern #1”. For under $150 I had a complete stock assembly. Boyds cautioned that the stocks barrel channel might have to be reworked to accommodate the WSM barrel contour.

As illustrated below, or at least that’s what the attempt was, the Boyds stock has a longer pull and the pistol grip that is wider at the tang and set at a more sweeping angle. The forearm is extended and slightly flatter and wider that the Shadow’s factory stock for a better hold.

The Super Shadow barreled action dropped right in. The old style trigger cleared, the inletting tracked to the action and barrel channel contour was a perfect match so no rework was required. That was quite a relied as I do wood work like I do automotive body work.. sort of like a toddler left alone with a big block of wood and a chainsaw.

High school shop class all over again…

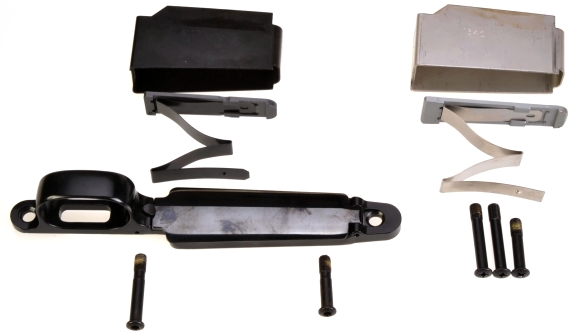

Winchester bottom metal is made of painted cast aluminum and the release catch is on the outside of the trigger guard and too easy to bump open. Brownells #954-000-018 Winchester Model 70 Bottom Metal, Short Action is a really clean machined steel piece with a satin finish. The floor plate release is inside the trigger guard bow, but it must be pushed deeper than the surface of the bow to release the floorplate would be opened accidentally.

The magazine spring is a replacement part purchased in anticipation of the spring being altered. I always try to keep unaltered factory parts so a gun I can restored a firearm to it original condition at a latter date, especially if there is a chance the firearm will be sold.

Like the original piece, the square corners of the spring made it difficult to feed the end into the floorplate’s retention grooves, so the corners were snipped and surfaces dressed with a stone to aid assembly.

Like the original piece, the square corners of the spring made it difficult to feed the end into the floorplate’s retention grooves, so the corners were snipped and surfaces dressed with a stone to aid assembly.

The follower spring can be installed at the aft end or at the middle of the floorplate, depending on cartridge and follower length. The WSM configuration puts the spring at the mid point as shown below.

With the barreled action in place in the stock, the assembled bottom metal was placed for a trial fit with the thought inletting would have to be touched up but, as was the case with the barreled action, the bottom metal was a close fitting drop in.

The nearly straight comb and heel of the new stock is very similar to the Super Shadow factory stock, which makes it ideal for scoped applications. Something that goes hand and hand with the .270 WSM cartridge.

The barrel channel spacing is business card thick and uniform. While the receiver is well anchored, between close inletting and the span of the bottom metal, the barrel floats the length of the channel with no pressure pad at the end. This rifle was exceptionally accurate at the onset of this project and it remained so when the project was completed.

There. That’s better…

The greatest obstacle to overcome was beginning with a short action Model 70 Winchester. Because of the rifle’s current lack of popularity, third party accessory and part manufacturers just aren’t offering as much as they once did. If this had been a Remington Model 700 project, I would have had a choice of several dozen types of stocks and bottom metal.

Like a lot of projects, the time was in researching materials; fit, function and cost, but that effort made all the difference in the world. The actual disassembly, minor fitting and assembly took less than an hour. Human response to appearance is subjective, but I think the new stock is a marked improvement and I really appreciate the hinged floorplate. The total project cost was approximately $350. Certainly a lot better than the $750 that would have been the cost using comparable factory parts and a lot less work.

Email Notification