So I got into it with some of my co-workers over my approach to dealing with firearms with bores in need of attention. Rule of thumb, when I’ve put 200 rounds through a firearm, I sell it and avoid the whole cleaning issue. It’s better than my previous approach, which was to turn guns into table lamps after the same usage, which is better then my original approach – bury them in the back yard.

So I got into it with some of my co-workers over my approach to dealing with firearms with bores in need of attention. Rule of thumb, when I’ve put 200 rounds through a firearm, I sell it and avoid the whole cleaning issue. It’s better than my previous approach, which was to turn guns into table lamps after the same usage, which is better then my original approach – bury them in the back yard.

The catalyst for the the discussion was my favorite beater/shooter rifle, a 1944 vintage Model 38 Mosin Nagant. I cleaned it, sort of, when I brought it home, but it never grouped good enough even for brush hunting and, more recently, it had begun to require a patterning target to catch all of its lead. On inspection, the gun’s bore appeared to be filled with a mixture of bituminous coal and Cheez Whiz; the bolt and its tracks had clearly been dipped in coal tar. So I did some baseline shooting, then dug out all of the cleaning gadgets and supplies and went at the Nagant hammer and cleaning rod – inspection, then cleaning.

Long as I can see the li-i-i-ight…

Generally speaking, old eyes need three times the light of young eyes. I’m at a point in my life where I need a 500 watt reading lamp, so I need lots of directed light sources to peek into bores, chambers, magazine wells, etc. Especially etc..

Lights, far left and far right, are inexpensive, AA battery powered, 1″ head flashlights. Both have “O” ring seals to protect them from bench spills and both have Krypton bulbs installed for brightness. Good shop lights, $10. Away from home, on a hunting trip, someplace where you can’t run out and buy another cheap replacement from a discount retailer, there are much better quality small lights available. Aluminum-bodied, waterproof, compact and high intensity beam Streamlight handheld LED flashlights are a good fit. Available in two sizes, Brownells #100-005-926 & #100-005-927. Both have three brightness settings and can run for many continuous hours; both lights are powered by 2 CR123A lithium batteries. About $50.

The two center lights are more specialized. The gooseneck light is Brownells # 531-322-500. The flex neck bends to a tight radius and holds form, the peanut bulb at the end of the neck is high intensity, powered by two AA batteries. The neck assembly is only 0.250″ at its largest diameter so it fits into mag wells, chambers and the bore size of any gun I’d admit owning. Under $20.

The second light, center right, is a Flexible LED Bore Light, Brownells, #622-000-001. Again, flexible neck, brilliant LED light this time, well made all metal body, “O” ring sealed case. The lamp head is 0.400″ in diameter, which makes for a great chamber checker and excellent bore illuminator. Just over $6. That’s like the price of chewing gum these days.

The fiber optic wands, on and off the flashlight to the right, are only 0.118″ in diameter and slip over virtually any flashlight with a 1″ head. Light is transmitted from the flashlight, through a very pure light pipe and to the tip of the wand. Wands come in 7″ and 20″ lengths and don’t obstruct the view when peeking into very tight spaces. They are non-conductive, non-magnetic, and non-electrical, and the cap is designed to prevent the flashlight from rolling off of a workbench. Under $10 from Nite Ize.

Geek gear…

Magnifying visors are essential for cleaning tasks and just about any other tasks where small parts and spaces are on the menu. There are lots of choices with all sorts of accessories, but it pays to go easy on magnification as the higher the magnification, the closer the object needs to be to your face.

|

The OptiVISOR product sold by Brownells allows the option of purchasing one visor and multiple ground and polished optical glass lens plates with any of the magnifications noted. The OptiVISOR dial adjustable headband is leather lined so there isn’t a piece of plastic causing you to sweat into your eyes and the visor tilts to fit both your noggin and work placement so you don’t have to work with you head in uncomfortable positions.

Other useful visor accessories are a pivoting 6x OptiLOUPE, Brownells #255-001-600 that mounts to the visor and can be flipped in and out of line of sight and the Visor Light, a hands free adjustable position light that clips onto the visor. The visor costs under $50, the loupe is another ten and change, the light is priced under $30. Compact handheld magnifiers are also useful, especially if they fold so you can keep them in a pocket. Brownells #345-534-002 is an inexpensive folding double lens magnifier, 2x and 6x or combined for 8x. About $15.

A Gradient Lens Borescope, with its $900 entry price, is a little outside of my budget, but it is an ideal tool for checking bore condition. One of these days I’ll make an investment in one with video and image capture capability so I can show more than tell about chamber and bore conditions. For now, a much more limited use tool that can at least spot copper and lead fouling in 6mm diameter bores and above, is a $100 – $150 mechanic’s borescope. The user looks through the unit’s manually focused eyepiece and a micro lens attached to the end of the unit’s flexible fiber optic shaft. A miniature bulb in the body of the unit sends light down the fiber optic shaft and illuminates the area ahead of the lens. An accessory 45° mirror that clips onto the end of the shaft allows a side view of the bore. Great idea, great price but the tool offers only very marginal image and illumination quality.

Heavy duty… duty

I keep lots of small brushes around for getting into bolt faces, ports, under extractors and inside bolt bodies. Pictured left, and angle mount nylon, bronze, stainless steel bristle set. Brownells #100-006-049. $8/set.

One of the best close space, but broad area cleaning tools, is an electric tooth brush. With a little solvent, they really scrub surfaces clean, they are excellent for polishing and light rust removal with the use of a little tooth paste.

Dewey Copper Eliminator Rods have aluminum hardware so there is no reaction to the ammonia that is present in most copper cleaners. Subsequently, no false readings on patches. The rods are nylon-coated steel, the handles are ball bearing mounted. Under $40, Brownells #234-000-087. All of the supporting pieces, brushes and jags also incorporate aluminum hardware. Where the Dewey brushes top out in size at 0.308″, Brownells nylon bristle on stainless hardware cover all handguns and rifles through 0.501″ and shotguns .410 bore to 10 gauge.

The Nagant’s bore was filthy to the point I had to do some preliminary cleaning just to see if and what more special treatment would be necessary.

There are many products on the market that do a good job, but sometimes the most basic still work the best for this type of initial clean up. Specialized copper and lead removers don’t usually do the best job of cutting through powder residue and gun oil to get to the fouling metal beneath the surface.

Pictured above right, the twelfth patch through the bore after solvent soaking and nylon brushing the bore. Black, orange and green coloration; powder residue, surface rust and accumulated copper. Some of the gunk was from recent use, but some of it was left over from inadequate cleaning when I first purchased the firearm. Shame on me. My rule of thumb “clean just until bore diameter is achieved” needed a rethink.

You dirty copper… Movie lines you’re too young to remember

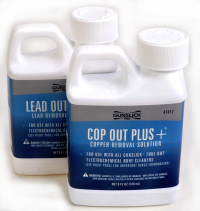

After preliminary cleaning, the Nagant’s bore looked pretty good. Shiny, no dark spots, crisp rifling. Then I looked closer with the borescope and found that the barrel was loaded with copper just at the intersection of lands and grooves, and it went on for most of the length of the barrel. Typically I use Montana X-Treme Copper Killer for routine copper removal, Brownells #100-005-021, and Copper Cream, Brownells #100-005-023 for more stubborn fouling. However, because of the age of the Nagant and evidence of minor bore pitting, I thought a better approach might be electrolytic plating, a process that would pull copper and lead out of even the light pitting.

The Outers Foul Out III system, Brownells #674-000-001 has a retail price of $140, but they come with enough chemicals to clean many firearms and the chemicals are sold separately when the original supply runs out. Probably the biggest justification for the expenditure is that they do a heck of a job pulling out lead and copper and they can do the job unattended except for occasional monitoring of the progress. With a good number of older military surplus rifles stacked up for project work, the Foul Out III seemed like a piece of equipment that could save a lot of project prep time.

The Foul Out comes with easy to follow instructions and it is straight forward to set up. The Foul Out III system includes two types of electrolyte, one for lead removal and one for copper. In use, the chamber end of the gun’s bore is plugged and half filled with the selected solution. Then a stainless steel rod, the electrode, is placed in the bore and insulated from contact with the bore by four small rubber “o” rings. Inserting the rod in the barrel displaces the solution, causing the solution to rise and fills the remainder of the bore. A control unit slips over the exposed portion of the rod and provides 0.3v of electricity to the stainless steel rod. There are three Indicator lights on the control unit: yellow – active cleaning, red – direct rod contact with the gun’s bore or other form of short, green – no more copper ions being transferred to the stainless rod, all done.

The Foul Out comes with easy to follow instructions and it is straight forward to set up. The Foul Out III system includes two types of electrolyte, one for lead removal and one for copper. In use, the chamber end of the gun’s bore is plugged and half filled with the selected solution. Then a stainless steel rod, the electrode, is placed in the bore and insulated from contact with the bore by four small rubber “o” rings. Inserting the rod in the barrel displaces the solution, causing the solution to rise and fills the remainder of the bore. A control unit slips over the exposed portion of the rod and provides 0.3v of electricity to the stainless steel rod. There are three Indicator lights on the control unit: yellow – active cleaning, red – direct rod contact with the gun’s bore or other form of short, green – no more copper ions being transferred to the stainless rod, all done.

Considerations – The gun’s bore needs to be free of any type of powder or petroleum residue to expose the copper or lead present in the bore. The stainless rod needs to be sandpaper surfaced and cleanly degreased. I’ve degreased with acetone and alcohol, but not well. Products like Brownells TCE is a much better and safer choice, #083-060-032. The electrolyte contains ammonium acetate so a thorough solvent cleaning and light oil is essential after the cleaning process is completed. The applied low voltage causes copper or lead transfer without disturbing barrel steel. Where rust is present in a bore, the system will tend to transfer iron ions to the electrode along with the copper or lead. This could contaminate the electrolyte and slow or stop the cleaning process. If bore rust is present, the cleaning solution will turn yellow within thirty minutes of starting the process.

OK, I smell like nitro solvent and smokeless powder, but…

All three 50 yard groups were shot with Winchester Metric 7.62 x 54 mm Russian, 180 grain soft point ammo, all from the same lot, Brownells #105-202-489. The first group was prior to cleaning, approximate group size was 2.10″. The second group was shot after solvent cleaning, approximate group size was 0.85″. The last group, after the Foul Out III treatment, measured 0.66″. I apologize for the last target, but I ran out of the other and those moles are fun to shoot.

Email Notification