I thought I’d jump right in with the heavy technology and flash some of the exotic equipment that made the .223 Remington workup possible. Here we have a picture of my pneumatically actuated, unidirectional coarse incrementing smokeless powder dispenser. It is manufactured by the famous Mustard company, as imprinted on the container. I have other’s from competing companies; Catsup and Ranch, but I believe Mustard makes a superior product.

I thought I’d jump right in with the heavy technology and flash some of the exotic equipment that made the .223 Remington workup possible. Here we have a picture of my pneumatically actuated, unidirectional coarse incrementing smokeless powder dispenser. It is manufactured by the famous Mustard company, as imprinted on the container. I have other’s from competing companies; Catsup and Ranch, but I believe Mustard makes a superior product.

It has been so long since I worked up loads for my .223 Remington Contender, I forgot how much fun it is to load for a small bore centerfire cartridge. I also forgot the plus and minus aspects of the same. I pretty much followed the process defined in Part II, with a couple of exceptions and a couple of discoveries. I thought I’d take a pre-range moment and document some of what transpired.

If there ever was a cartridge designed for “scoop powder until full” loading, it is the .223 Remington. With the exception of one powder type, and then only barely, all loads were compressed to come degree. At that point I realized the .223 case should be filled with a drop tube, or powder should be tricked into a funnel from a few inches above the case mouth. The resulting compaction makes better use of the case capacity and makes room for a couple more grains.

If there ever was a cartridge designed for “scoop powder until full” loading, it is the .223 Remington. With the exception of one powder type, and then only barely, all loads were compressed to come degree. At that point I realized the .223 case should be filled with a drop tube, or powder should be tricked into a funnel from a few inches above the case mouth. The resulting compaction makes better use of the case capacity and makes room for a couple more grains.

The other component effecting case capacity is bullet length, and relatively short COL standard of 2.260″. The result is that some of the longer bullets, like the Combined Technologies Ballistic Silvertip Boat Tail are seated deeply enough to crowd an already small powder chamber. This is a good point to determine exactly how long of an overall cartridge length your rifle will support.

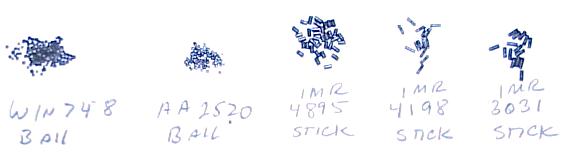

Powder selection could make a great deal of difference in attaining optimal performance, because large grain powder may consume more volume, generate less energy less can be fit in the case. The first two are ball powders, the next three are stick or cylindrical. I use quite a bit of 3031 in all reloading efforts and was hoping this would provide optimal results, and I would get savings from economy of scale – I have not yet reached a conclusion. I originally thought 4198 had the largest grain, until one got up and walked off. Win 748, by weight, fit more to the case, the rest followed in descending order.

I metered every charge with an RCBS electronic scale. They seem to be as or more accurate than a balance beam scale, although it takes time to be able to anticipate where exactly they will settle after computer lag issues a final reading.

I metered every charge with an RCBS electronic scale. They seem to be as or more accurate than a balance beam scale, although it takes time to be able to anticipate where exactly they will settle after computer lag issues a final reading.

I primed all cases, then charged them then, to minimize bullet seating adjustments, skipped around to do all same bullets at the same time. All loads and steps were done with a cartridge control log and all loading blocks are numbered to track to each case. It took a lot of ammo to cover all variables.

The handloads went together well. Bullet runout was between .001″ and .002″, overall length varied with the bullets selected, clockwise from top left:

The handloads went together well. Bullet runout was between .001″ and .002″, overall length varied with the bullets selected, clockwise from top left:

Speer TNT 50grain 2.235″ COL

Remington PSP bulk 55 grain 2.190″

Hornady SPSX 50 grain 2.200″

Combined Technology BST 50 grain 2.260″

The Ballistic Silvertip is at the COL limit for the .223 Remington cartridge. The TNT had such a sharply tapered ogive I don’t believe I could have seated it out much further than spec. I’m sure the Remington offers a bit of latitude for cartridge length, but I thought I would put that tinkering off until next time.

I used only case tension to retain the bullet, not utilizing a taper or rolled crimp, even when using the Remington bulk bullet which has a cannelure properly located for the .223. The case neck sized to .246″ OD, then expanded to .248″ when a bullet was seated, which appears to be enough tension to secure the bullet. The following is a typical log sheet I use to record performance of handloads at the range.

| Powder Type: | ||||||

|

Bullet Weight |

Bullet Type |

Load Source |

Powder Charge |

Muzzle Velocity |

Cartridge # |

Group Size |

|

50 |

Speer TNT |

Original |

1 |

|||

|

50 |

Speer TNT |

Original |

2 |

|||

|

50 |

Speer TNT |

Original |

3 |

|||

|

50 |

Hornady SPSX |

Original |

4 |

|||

|

50 |

Hornady SPSX |

Original |

5 |

|||

|

50 |

Hornady SPSX |

Original |

6 |

|||

|

50 |

CT Ballistic ST |

Original |

7 |

|||

|

50 |

CT Ballistic ST |

Original |

8 |

|||

|

50 |

CT Ballistic ST |

Original |

9 |

|||

|

55 |

Rem PSP |

Original |

10 |

|||

|

55 |

Rem PSP |

Original |

11 |

|||

|

55 |

Rem PSP |

Original |

12 |

|||

|

*CCI 450 small rifle magnum primers |

||||||

Thanks,

Joe

Email Notification