If there is one thing I’ve grown wary of, it’s four foot products that arrive in a one foot box. Why? Because it means the item purchased for enjoyment or entertainment or to ease a sense of being a beast of burden is going to require work… time… effort.

Three minutes later… I may have overreacted

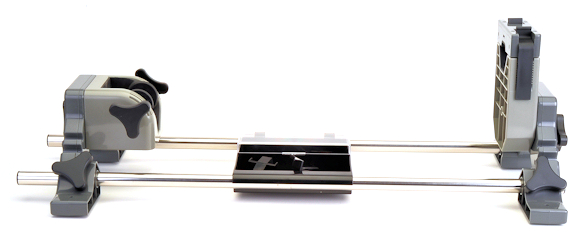

It would quickly become obvious, to most people, that there is only one way to assemble these parts. They are, for the most part, four subassemblies and a couple of chrome-plated and plastic-capped steel tubes that are screwed together to form guiderails.

We go through lots of gun vises at the shop. They just don’t work out and I don’t know why. Maybe because the companies that sell them try to make too much out of them and lose sight of the basic objective, a gun vise. Not a shooting box, not a cleaning rod holder, not a shooting rest, and not a place to stash nuts, bolts and anything else we’re too lazy to put away in its proper place. The Revolution is promising.

More than gratuitous pictures…

The Revolution is a relatively accommodating vise. The steel guide tubes are 36″ long. The thickness of the front and rear support bases make the net distance between support points 32″ which works for every conceivable long gun. The aft support can accommodate a thickness of 2 1/2″. The front vise, 3″, or 2 3/4″ if a gun’s barrel needs to be anchored.

The Revolution is a relatively accommodating vise. The steel guide tubes are 36″ long. The thickness of the front and rear support bases make the net distance between support points 32″ which works for every conceivable long gun. The aft support can accommodate a thickness of 2 1/2″. The front vise, 3″, or 2 3/4″ if a gun’s barrel needs to be anchored.

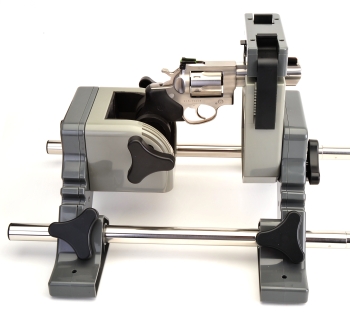

Removing the parts tray, which is suspended between the guide bars, allows the front support to be moved rearward for use with compact rifles or handguns. The handgun pictured here is a four inch barrel Ruger GP100. For a more permanent set up, the front and rear support bases can be bolted to a work bench.

By loosening the front locking knob, the entire carriage can be rotated 45° toward or away from the front of the work bench and it locks in that position. There is a plastic storage bin, half covered, half open, that slides along the guiderails to keep it out of the way. There are even notches in the front and rear mount to hold cleaning rods… or a fishing rod. Cleaning would be my guess.

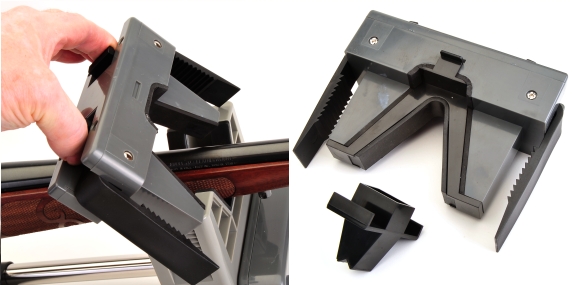

The rear and front lock up tightly. The rear, by turning the knobs on either side of the vise, the front by pushing down and allowing the top’s hinged flaps to engage the teeth on the lower support. A couple of plastic inserts are provided for the front vise to adapt it to most any firearm form. Below, inserts in place in front vise and closer view of the teeth on the straps that lock into the lower half of the front mount.

So what’s the real chance of this being used routinely?

On the plus side, the presence of the vise doesn’t overwhelm the firearm. The rails and mounts don’t obstruct the view of, or access to, the firearm and the rotating mounts position the rifle in any useful position. Movement is easy, lock up is firm and the overall vise is sturdy. I’ve used it during scope installation and I have used it when setting torque on bottom metal. I will use it for cleaning if I ever decide to clean my firearms… like that’s going to happen.

On the minus side, I believe there are two issues of consequence. The first is that the mounts at either end do not have vertical adjustment, so they rely on the buttstock of a rifle or the grip of a handgun being raised or lowered when clamed to level the firearm. The second, probably of greater significance, is the large warning at the conclusion of the manual, “Any chemical or bore solvent that is spilled on the vise should be cleaned as quickly as possible so as to not damage the vise”. Chemicals and solvents are to be expected around firearms and fixtures intended for their maintenance. Lyman surely could have selected a solvent resistant plastic, which is the case with most gun vises, especially with a $94.95 MSRP.

I like the Lyman Revolution for what it is and what it can do, but causing me to maintain a second vise to use for cleaning because the Revolution can’t be used for that purpose is a deal breaker for me.

Email Notification