An experiment in powder burn rates and barrel length ran off the road and into a ditch when the M91/30 Nagant with 28 3/4″ barrel and a M38 with 20 1/4″ barrel produced chronograph readings of 2,629 fps and 2,657 fps. The shorter barrel gun, by 8 1/2″, produced 28 fps higher velocity with the same factory ammunition.

Firing 10 rounds of the same ammunition through each gun yielded an average of 2,608 fps and 2,644 fps, for an average of 36 fps greater muzzle velocity from the short barrel gun. So I scratched my head and wondered what could have gotten into the M91/30’s bore that would cause this problem.

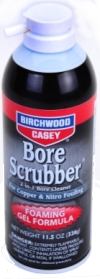

I broke out the soft lead sinkers and slugged each bore; 0.314″ for the rifle, 0.312 for the carbine. It would seem the 90/30’s bore was introducing excessive bore friction, but I wasn’t sure how as I’ve been religious in my 5 year/1,000 rounds, which ever comes first, bore cleaning regimen. Still, I ran Birchwood Casey Bore Scrubber, 2 in 1 Bore Cleaner, Copper & Nitro Fouling remover and scrubbed both gun’s bores until clean.

would seem the 90/30’s bore was introducing excessive bore friction, but I wasn’t sure how as I’ve been religious in my 5 year/1,000 rounds, which ever comes first, bore cleaning regimen. Still, I ran Birchwood Casey Bore Scrubber, 2 in 1 Bore Cleaner, Copper & Nitro Fouling remover and scrubbed both gun’s bores until clean.

The stuff is a gel so it doesn’t run out of the bore and it has ammonia so there is little chance of getting sleepy and nodding off while cleaning. Scrubbing with natural fiber bore brushes, lots of twill patches were pushed through on a jag… about 25 before they stopped coming out green, rustic red and bright yellow. And then it was back to the range. Factory ammo was fired for the sake of comparison and the results were the same as pre-cleaning.

How much powder?

I pulled a bullet from a factory cartridge and scale checked the powder at 46.5 grains of stick powder, or between approximately 5 and 10 grains less than handloads I had assembled, which suggested something with a burn rate a little faster than Re15 or Ram Shot TAC. My new theory was that moderate pressure loads of relatively fast burning powder has a significantly lower expansion factor than slower burning powders and bore friction negated any potential pick up from the extended barrel length. Unfortunately, pulling chronograph data from handloads with fast and slow powder demonstrated approximately the same velocity differential. Powder selection was not core to the problem of longer barrel – lower velocity.

The ultra high tech kinetic bore friction tester…

While bore slugging showed the long barrel rifle to have a 0.002″ larger groove diameter than the little carbine, that difference might have meant little in regard to velocity differences. The increase in bore volume of the rifle over the carbine was negligible and would not diminish bore pressure through increased volume. Recovered bullets showed full groove diameter contact in both rifles. Which all suggested that bore finish and resulting bore friction was killing velocity in the longer barreled rifle, but I needed some down and dirty way to quantify the difference between the two firearm bores.

Using a slightly oversize bore brush with resilient natural bristle, a piece of string and a Lyman trigger pull gauge, I measured the resistance of the brush being pulled from chamber to muzzle. A smooth, steady pull yielded readings that could be repeated with each respective firearm within 2 to 3 tenths of an ounce. The rifle averaged 4 lbs 14 ounces of resistance and the carbine averaged 3 lbs 3 ounces; a huge difference in terms of bore friction, approximately 53% greater resistance.

How does bore friction effect handload performance?

Warning: Bullet selections are specific, and loads are not valid with substitutions of different bullets of the same weight. Variations in bullet material and length will alter net case capacity, pressure and velocity results. Primer selection is specific and primer types are not interchangeable. These data represents maximum loads in our firearms and test equipment and may easily be excessive in other applications. All loads should be reduced by 3%, and developed following safe handloading practices as represented in established reloading manuals produced by component manufacturers. Presentation of these loads does not constitute a solicitation for their use, nor a recommendation.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The exception to the rule?

So if bore friction is the reason factory ammo and most handloads are slower when shot from the long barrel rifle in comparison to the short barrel carbine, how would I account for the first set of handloads being faster in the long barrel rifle? Bearing surface, or less of it. The 125 grain bullet has much less contact with a gun’s bore because of its short shank so there is less surface area in contact with the rough bore. My theory and I am sticking to it. When time is available it would be interesting to work on the rifle’s bore, clean it up further and see if the velocity can be recovered.

Oh, Those Wacky Nagants Part 1

Oh, Those Wacky Nagants Part 2

Email Notification