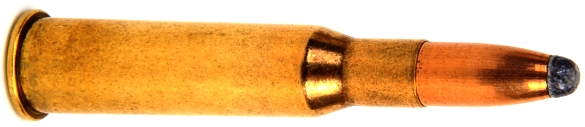

Experimenting with the 7.62x54R is always a treat. They are not unlike snow flakes in that it sometimes seems there are no two exactly alike. Terence W Lapin’s The Mosin-Nagant Rifle does a very good job of addressing the unique characteristics of each version of Mosin-Nagant rifle and carbine, but there is still variety to uncover. We find 0.308″ versus 0.312″ groove diameter are the two norms, however, uncovering groove diameter that can run +/- 0.003, within the two general bore sizes is always a treat. So we slug every gun, log the measurement and tag the rifle for future reference. The 91/30 pictured slugged 0.314″, the Model 38 slugged 0.312″ and I am now down two more lead sinkers I planned on using for lake trout fishing.

Experimenting with the 7.62x54R is always a treat. They are not unlike snow flakes in that it sometimes seems there are no two exactly alike. Terence W Lapin’s The Mosin-Nagant Rifle does a very good job of addressing the unique characteristics of each version of Mosin-Nagant rifle and carbine, but there is still variety to uncover. We find 0.308″ versus 0.312″ groove diameter are the two norms, however, uncovering groove diameter that can run +/- 0.003, within the two general bore sizes is always a treat. So we slug every gun, log the measurement and tag the rifle for future reference. The 91/30 pictured slugged 0.314″, the Model 38 slugged 0.312″ and I am now down two more lead sinkers I planned on using for lake trout fishing.

Another issue that arises from time to time is brass with undersized primer pockets. Factory ammo with boxer primers is shot, spent primers are popped out to facilitate reloading and then new large rifle primers can’t be inserted without a fight and the possibility of fireworks. The most common source of the problem is Czech Republic sourced ammunition, often sold under American brand names.

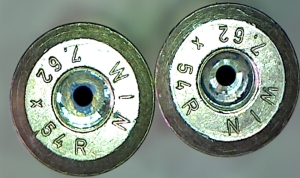

Below, a spent case from a box of Winchester Metric Calibers ammo which is made by Sellier & Bellot. The pocket is undersize in diameter and depth to U.S. primer standards and there is a sharp edged recess around the perimeter of the primer pocket that engages the leading edge of a new primer when attempting to seat them.

Of course our European friends are free to make ammunition to their own specifications and insist that anyone selling into their market falls into compliance. However, I do have a problem when foreign manufacturers sell into our market and refuse to comply with SAAMI standards, especially when sold as an American brand.

Sporting Arms and Ammunition Manufacturers’ Institute – SAAMI says…

There are a number of approaches that are acceptable for measuring a primer and the primer pocket. In this case, primer diameter was measured with a small hole gauge and then measurement was verified with a pin gauge. Depth was measured with a digital caliper. A standard depth micrometer contact tip couldn’t be used because the bottom of the primer pocket is concave to conform with the surface of a primer’s anvil and would cause an erroneous reading. The digital caliber’s depth probe was able to read from the outside edge of the primer pocket where the primer seats.

| Large Rifle Primer |

Diameter Inches | Depth Inches | ||

| Min | Max | Min | Max | |

| SAAMI Primer Spec | 0.2105 | 0.2130 | 0.123 | 0.133 |

| Measured Primer | 0.2115 | – | 0.129 | – |

| SAAMI Pocket Spec | 0.2085 | 0.2100 | 0.125 | 0.132 |

| Measured Pocket | 0.2075 | – | 0.121 | – |

Left – A simple cutaway illustration of a cartridge casehead. Spec for primer seating is flush to 0.008″ below the face of a case head, a dimension that could not be attained with the physical dimensions of a large rifle primer and unaltered 7.62x54R Winchester Metric Caliber brass.

The easiest way to clean up the primer pockets and to bring the dimensions into SAAMI spec is with a primer pocket uniformer and inside/outside case chamfering tool like the Lyman and RCBS products pictured below. Just about every manufacturer makes them and they all fundamentally work the same. Brownells carries them from manual operation budget to powered production ready.

The hardened steel depth stop above the cutting head prevents the tool from cutting too deeply and the four cutter head and cutter head diameter keeps the cutter square in the primer pocket. Material is removed at the outside of the pocket floor where the primer rests when seated. The case chamfering tool has a shallow enough angle to chamfer a lead all around the entrance to the primer pocket without cutting into the primer pocket’s flash hole. The brass pictured above left is reamed and chamfered. The brass right has a primer seated 0.006″ below the face of the case head.

One of the reasons a drill should not be used to clean out a primer pocket is that the tip of a standard drill will cut into the primer pocket flash hole (far right) and damage the concave floor of the primer pocket that conforms to the shape of the primer’s anvil. A drill also won’t remove material from the outside of the primer pocket floor that prevents primers from properly seating. Could a bottoming drill or end mill be mounted to a handle as an alternative to the Lyman tool? Sure, but the Lyman tool is a $10 purchase and it comes with handle and built in control to assure a proper outcome.

One of the reasons a drill should not be used to clean out a primer pocket is that the tip of a standard drill will cut into the primer pocket flash hole (far right) and damage the concave floor of the primer pocket that conforms to the shape of the primer’s anvil. A drill also won’t remove material from the outside of the primer pocket floor that prevents primers from properly seating. Could a bottoming drill or end mill be mounted to a handle as an alternative to the Lyman tool? Sure, but the Lyman tool is a $10 purchase and it comes with handle and built in control to assure a proper outcome.

Only once…

The rework only has to be accomplished once and there is no down side. Even brass that has been reloaded 6 or seven times and primers shows no signs of lose primers and priming is a safer operation. As far as required effort goes, a few minutes will clear a box of fired brass.

Oh, Those Wacky Nagants Part 1

Oh, Those Wacky Nagants Part 2

Email Notification