The world has become a complex place that jars our senses, made stress a fixed component of daily life and leaves us all too often with smiles absent from out faces. I know it leaves me with “brain jam” and I have a difficult time settling down and getting my thoughts into focus. So I wander over to YouTube and listen to my classics while I work and the world becomes a better place… for you… and me… wait and see.

In Part 1 We addressed the issue of shooting non-spec ammo in the Mini Thirty… Don’t, because you’re not supposed to run Russian and other similar poor quality Berdan primed ammo in your nice Mini Thirty. But what if you don’t listen, what if you don’t read, what if you don’t follow the rules? Is there a way to make the stuff work? Is there? Huh? Is there? Glad you asked.

In Part 1 We addressed the issue of shooting non-spec ammo in the Mini Thirty… Don’t, because you’re not supposed to run Russian and other similar poor quality Berdan primed ammo in your nice Mini Thirty. But what if you don’t listen, what if you don’t read, what if you don’t follow the rules? Is there a way to make the stuff work? Is there? Huh? Is there? Glad you asked.

The easiest way to clean up the occasional failure to fire with this lumpy ammo is to change to a higher rate hammer spring. Wolff Springs sells a +20% extra power hammer spring SKU #30351 for $7.49. It is also available from the nice folks at Brownells as 969-000-063WB

Mini-14/30 Hammer Spring. Dimensionally, both the Wolff and Ruger spring are the same length and outside diameter, however, the material is 0.0695″ in diameter, up from the stock springs 0.0650″.

While this may not be a legit modification, see “don’t shoot junk ammo in a nice rifle” above, it is an inexpensive mod, and easy to implement mod and it is very effective, but not without its down side.

Easy take down

Magazine out, empty chamber checked, action cocked, safety on – Put a 3/8″ punch through the hole in the trigger guard, pull up and the trigger group hooks are released, allowing the trigger group to be lifted out of the rifle.

The thing is, not only is the trigger group free to come out, but the stock will also be free to lift off of the barreled action. Like I said, easy to take apart.

Like most every other Ruger hammer spring strut, there is a hole in one end that is used to pin the spring in place to facilitate removal. So with the action cocked, a pin punch or small hex wrench is put through the hole, the hammer is eased forward, allowing the hammer spring to lift right out.

Any excuse to make tools…

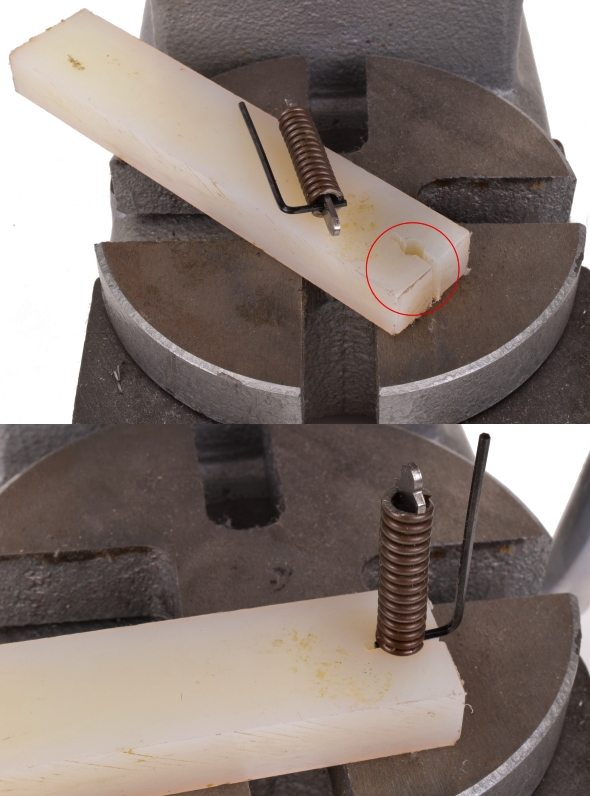

This was made from Nylon 66, but it could have just as easily been made from a piece of hardwood. A slot was cut with the bandsaw in about an inch or so, then a hole was drilled midpoint on the slot with a diameter the width of the strut. The idea is that the hole will allow the strut to pass though while retaining the spring and allowing it to be compressed. The slot allows whatever is used to pin the strut to pass through with the strut.

Using a small arbor press, the spring is compressed, the pin is pulled, then the handle is raised and the spring decompresses. Reverse the process to install a new spring and reinsert the pin in the whole in the strut to retain the spring in a compressed state. This little tool was actually made for working on Redhawks and Marlin lever guns, but it works well here too and keeps springs and struts out of the ceiling. No, I would not run out and buy an arbor press exclusively for this purpose, but if the tools are already in the shop, why not?

The new spring in place, the hammer is pulled down in the cocked position, the guard is popped back open and the trigger group is reinstalled in the rifle, the reverse of how it came out. Done.

Results of a 10 minute investment in time…

After reassembly, a hundred round of Herter’s International Select steel case, Berdan primed ammo was fired without a single failure. The ammunition failure rate in Part 1 was 2 of 15 rounds as a ratio failed to fire with a clean primer strike.

I mentioned at the beginning of this article that there was a downside, and there is. Trigger pull increased from the original factory 6 lbs 9 oz to 7 lbs 11 oz. Part of it is the increase in the hammer spring rate, part is the increased sensitivity to the rough contact surfaces on the trigger, primary and secondary sears and trigger side strut contact. Hence the “Part 1 ½” title.

The spring performed as intended, however, the trigger pull is no longer acceptable. A trigger job is in progress at this moment and we’ll see if we can get the benefit of the heavy hammer spring and a reasonable trigger. Next…

Ruger’s Mighty Mini Thirty… ish Part I

Ruger’s Mighty Mini Thirty… ish Part 1½

Ruger’s Mighty Mini Thirty… ish Part 2

Ruger’s Mighty Mini Thirty… ish Part 3

Ruger’s Mighty Mini Thirty… ish Part 4

Email Notification