It was about 3 AM, I was watching the second season of Green Wing on Hulu and thinking that Michelle Gomez played the best character, when it dawned on me that I was going about proving the “Component sort and control leads to accuracy” hypothesis in a convoluted and bewildering manner. Heavy emphasis on the “bewildering”. There weren’t missteps in Part I as much as the stated forward plan was poorly devised.

Two control groups were needed; one with uniformly prepped and documented by dimension and capacity brass, the other group comprised of mixed manufacture bras, untrimmed, but documented as well the prepped brass. All would receive the same moderate powder charge from the same container of powder, all would receive bullets of the same weight and length, all bullets seated to the same depth, verified with a comparator making brass the only variable.

Each round would be fired over a chronograph, velocity logged. Then a comparison between capacity and fps would be used to determine if controlling case volume would lead to a narrowed range of velocity readings and if those like velocities would result in common group sizes on target. Other factors such as dimension, brand and repetitions of use would also be considered for influence on result.

Components

Bullets were the first on the controlled component list as they would be a major factor in determining a suitable powder type and charge and key to setting velocity expectations.

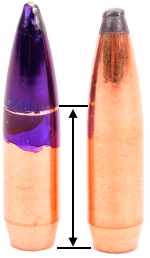

The SAAMI specified weight tolerance for bullets is ±2% < 100 grains and ±1.5% > 100 grains. The Speer 100 grain boat tail soft point bullets under consideration could vary ±1.5 grains or bullet weights between 98.5 grains and 101.5 grains. Weight checking, the Speer bullets varied in weight between 99.8 grains and 100.3 grains, a spread of 0.5 grains or one-half of one percent. The second bullet represented is an 80 grain Berger Varmint Flat Base Hollow Point. Because of its lesser weight, the weight tolerance is ±2% or 78.4 grains to 81.6 grains. Weight checking, the Berger bullets varied in weight between 79.8 grains and 80.1 grains, a spread of 0.3 grains or slightly less than three-tenths of one percent.

Measurements were taken with a micrometer that accurately measures to the 1/10000″ rather than a caliper that is accurate to 1/1000″. The bullet diameter specification for the .243 Winchester is 0.2430″ +0.0000″ – 0.0030″. The Speer bullets ran 0.2431″ to 0.2433″ for a +range of 0.0002″. Berger bullets checked 0.2436″ to 0.2439″ for a + range of 0.0003″. For me, bullet shank diameter was a wash, particularly since the moly coat would minimize the influence of friction, so bullet length, overall and from a reference point on the ogive to base was checked next.

Bullet tips are like politicians; they are deceptive in appearance and can’t be trusted…

If you look at the picture of the lead tipped bullets above, you will probably jump all over the fact that the tips are like the stripes of a zebra; no two are alike. Consequently, bullet tips are not a great point of reference for measurement, even though reloading recipes in mainstream manuals all reference COL; cartridge overall length. No, I do not know if the semicolon is appropriate punctuation, but it does make an excellent case for the use of a fragmented sentence to pass for proper grammar. Not only do I think soft lead tips are not the bastion of stability for measurement, neither do the guys who make the dies that seat the bullets in cases.

The seater plug located in the center of a sizer die is cut to allow a bullet to partially enter, until an angle cut in the plug comes to rest on a dimensionally stable location on the bullet’s ogive. Where, exactly along the bullet’s ogive varies with plugs and die maker, but in the case of RCBS and the plug used for the 0.243″ bullet, at a bullet diameter of 0.230″. Keep that number in mind. And so it follows that I never use the tip of a bullet as a point of dimensional reference, even though I list handloads with a COL as a term of common understanding and a reloading manual convention.

Within the context of this exercise in tuning ammunition for accuracy, uniform seating depth and bullet weight were needed to minimize the influence of bullets on pressure, friction and accuracy results, so it took a couple of relatively inexpensive tools and a couple of steps to get there.

The bullet seating two step… No, that is not like the Boot Scootin’ Boogie

A man was walking down the street late one night and saw his friend, under a street light, walking in circles and looking down at the ground. When queried as to why, the friend indicated a dollar had fallen out of his pocket. Offering assistance, the man asked where precisely it had fallen. “Across the street”. Puzzled, the man asked, “So why are you looking for it over here?”. “Because the light is better”, was the reply. Logic is not often the child of convenience.

The tools used for sorting bullets were a calibrated digital scale to check weight, a micrometer to check shank diameter and a caliper with comparator as pictured below. This is one of my relic Stoney Point fixtures, the red anvil and silver caliber bushing, which is now sold as Hornady’s Lock-N-Load® comparator. A comparator with 6 popular bushing sizes that can accommodate .224-.308 caliber retails at $36.65. Each part is also available separately and bushings are sold that range up to .50 caliber.

The proper comparator bushing for a 0.243″ or 6mm bullet is #3-24, which has a bore size of 0.230″, which happens to be the approximate size opening as the RCBS seater plug covered previously. The sizer plug applies pressure at a point on a bullet that offers a stable dimension and the comparator permits measurement from the same reference point to the heel of a bullet to facilitate consistent measurement and uniform seating depth.

The proper comparator bushing for a 0.243″ or 6mm bullet is #3-24, which has a bore size of 0.230″, which happens to be the approximate size opening as the RCBS seater plug covered previously. The sizer plug applies pressure at a point on a bullet that offers a stable dimension and the comparator permits measurement from the same reference point to the heel of a bullet to facilitate consistent measurement and uniform seating depth.

The table below indicates number of things. The Berger bullet demonstrated more dimensional and weight uniformity than the Speer bullets that were checked during a search for a good bullet for our tests. The table shows that all bullets are not created equal and, perhaps, why some bullets are priced at $22.99/100 and other are $32.99. At this stage, Speer was dropped… not from my life, not from my handloading bench and shooting activities, but from this project as they represented too many inconsistencies. The Berger bullet selected inventory was expanded to several hundred pieces and then moved into an inventory with other project components.

| Berger HPFB 80 Grain |

Speer SPBT 100 Grain |

||||||

|

# |

Weight Grains |

Overall Length “ |

Comparator Length” |

# |

Weight Grains |

Overall Length “ |

Comparator Length” |

| 1 | 80.0 | 0.915 | 0.472 | 1 | 100.0 | 1.062 | 0.621 |

| 2 | 79.8 | 0.914 | 0.471 | 2 | 100.0 | 1.035 | 0.621 |

| 3 | 80.1 | 0.915 | 0.471 | 3 | 100.1 | 1.053 | 0.621 |

| 4 | 79.9 | 0.913 | 0.472 | 4 | 99.9 | 1.046 | 0.616 |

| 5 | 80.0 | 0.914 | 0.471 | 5 | 99.8 | 1.060 | 0.616 |

| 6 | 79.9 | 0.914 | 0.472 | 6 | 99.8 | 1.047 | 0.616 |

| 7 | 79.8 | 0.916 | 0.472 | 7 | 99.8 | 1.032 | 0.620 |

| 8 | 80.0 | 0.914 | 0.472 | 8 | 99.9 | 1.062 | 0.620 |

| 9 | 80.0 | 0.916 | 0.472 | 9 | 99.9 | 1.054 | 0.616 |

| 10 | 79.9 | 0.913 | 0.472 | 10 | 99.9 | 1.060 | 0.616 |

| 11 | 80.0 | 0.912 | 0.471 | 11 | 99.8 | 1.060 | 0.618 |

| 12 | 79.9 | 0.912 | 0.472 | 12 | 99.9 | 1.050 | 0.618 |

| 13 | 79.9 | 0.913 | 0.472 | 13 | 99.9 | 1.035 | 0.617 |

| 14 | 79.9 | 0.911 | 0.472 | 14 | 100.1 | 1.053 | 0.621 |

| 15 | 80.0 | 0.912 | 0.472 | 15 | 100.1 | 1.065 | 0.621 |

| 16 | 79.9 | 0.914 | 0.472 | 16 | 100.1 | 1.048 | 0.621 |

| 17 | 79.9 | 0.916 | 0.472 | 17 | 99.8 | 1.062 | 0.619 |

| 18 | 80.0 | 0.915 | 0.472 | 18 | 100.0 | 1.049 | 0.620 |

| 19 | 79.9 | 0.912 | 0.471 | 19 | 99.9 | 1.032 | 0.620 |

| 20 | 79.9 | 0.916 | 0.470 | 20 | 99.8 | 1.044 | 0.619 |

| 21 | 80.1 | 0.915 | 0.471 | 21 | 100.0 | 1.051 | 0.622 |

| 22 | 79.9 | 0.913 | 0.471 | 22 | 100.0 | 1.045 | 0.620 |

| 23 | 79.9 | 0.914 | 0.472 | 23 | 100.1 | 1.032 | 0.619 |

| 24 | 79.9 | 0.914 | 0.471 | 24 | 99.8 | 1.028 | 0.619 |

| 25 | 79.8 | 0.916 | 0.471 | 25 | 100.3 | 1.062 | 0.622 |

| – | Weight Grains Variance |

Overall Length Variance |

Comparator Length Variance |

– | Weight Grains Variance |

Overall Length Variance |

Comparator Length Variance |

| – | 0.3 | 0.005 | 0.002 | – | 0.5 | 0.037 | 0.006 |

With the 80 grain Berger Varmint HPFB defined as the project bullet, cartridge length as measured with the bullet comparator could be determined. Using a OAL gauge and modified case with the Berger bullet identified to what depth the bullet needed to be seated to safely clear rifling. In traditional cartridge overall length terms, tip to casehead, maximum length to contact rifling was 2.668″ – 0.020″ for safety clearance for a 2.648″ COL. Measured with the comparator, maximum length was 2.224″ – 0.020″ for a margin of safety gave me a maximum length spec of 2.204″. This seated the bullet to a depth of 0.311″ with a nominal case capacity of 50.4 grains.

A quick check with the magazine assured a round assembled to that dimension would clear and, below, the comparator is used to measure the assembled test cartridge held in the AOL gauge..

A quick check with the magazine assured a round assembled to that dimension would clear and, below, the comparator is used to measure the assembled test cartridge held in the AOL gauge..

At this juncture, the bullet selection is Berger 80 grain HPFB, OAL for the round is specified as 2.204″ as measured with a comparator, CCI large Rifle primers were also selected as was 40.0 grains of IMR 4064 as the universal powder charge. At nominal case capacity pressure would come in at 56,000 PSI and would not exceed maximum pressure with the smallest case capacity anticipated.

If only it could make ice cream….

After calibration of the RCBS ChargeMaster, its hopper was wiped with a sheet of fabric softener to kill static electricity and a pound of powder was loaded. The ChargeMaster is actually pretty fast, considering it even runs the final trickle and is accurate to ± 0.01 grain… the same as a mechanical balance beam scale.

The key to accurate loading with the ChargeMaster is pretty much the same as any electronic scale; keep it level, keep it out of drafts and give it enough time to show a settled reading indication. Charging cartridges was uneventful, with each occupying approximately 95% case capacity. Hey, wait a minute. “Charge”? ChargeMaster? Now I get it. Whew! Right over my head….

Samples of preliminary handloads

| Prepped & Wet Checked Remington – Peters Brass |

No Prep – Wet Checked Mixed Brass |

||||||||

|

# |

Weight Grains Empty |

Weight Grains Full |

Capacity H2O |

Case Length “ |

# |

Weight Grains Empty |

Weight Grains Full |

Capacity H2O |

Case Length “ |

| 1 | 169.2 | 223.8 | 54.6 | 2.035 | 1 | PMC | |||

| 2 | 168.0 | 223.2 | 55.2 | 2.035 | 2 | 182.5 | 236.2 | 53.7 | 2.039 |

| 3 | 171.0 | 225.1 | 54.1 | 2.038 | 3 | 182.3 | 236.3 | 54.0 | 2.038 |

| 4 | 169.0 | 223.6 | 54.6 | 2.036 | 4 | 177.8 | 231.2 | 53.4 | 2.044 |

| 5 | 169.3 | 223.3 | 54.0 | 2.036 | 5 | 179.8 | 233.1 | 53.3 | 2.039 |

| 6 | 169.1 | 223.5 | 54.4 | 2.036 | 6 | 182.9 | 236.3 | 53.4 | 2.044 |

| 7 | 169.8 | 223.8 | 54.0 | 2.036 | 7 | Hornady | |||

| 8 | 167.8 | 222.1 | 54.3 | 2.036 | 8 | 162.2 | 218.4 | 56.2 | 2.042 |

| 9 | 166.6 | 221.8 | 55.2 | 2.036 | 9 | 163.1 | 219.3 | 56.2 | 2.036 |

| 10 | 169.3 | 223.7 | 54.4 | 2.036 | 10 | 162.4 | 218.4 | 56.0 | 2.040 |

| 11 | 170.0 | 224.2 | 54.2 | 2.037 | 11 | 162.3 | 219.0 | 56.7 | 2.044 |

| 12 | 170.4 | 224.7 | 54.3 | 2.036 | 12 | 162.0 | 218.3 | 56.3 | 2.037 |

| 13 | 170.6 | 224.7 | 54.1 | 2.036 | 13 | Winchester | |||

| 14 | 167.6 | 221.6 | 54.0 | 2.036 | 14 | 170.8 | 226.0 | 55.2 | 2.044 |

| 15 | 167.5 | 222.0 | 54.5 | 2.036 | 15 | 170.9 | 226.2 | 55.3 | 2.036 |

| 16 | 170.0 | 223.9 | 53.9 | 2.036 | 16 | 171.6 | 226.9 | 55.3 | 2.045 |

| 17 | 167.0 | 221.4 | 54.4 | 2.036 | 17 | 169.7 | 225.4 | 55.7 | 2.036 |

| 18 | 170.1 | 224.1 | 54.0 | 2.036 | 18 | 171.3 | 225.3 | 54.0 | 2.041 |

| 19 | 169.7 | 223.8 | 54.1 | 2.037 | 19 | W-W Super | |||

| 20 | 172.0 | 225.6 | 53.6 | 2.036 | 20 | 169.7 | 224.8 | 55.1 | 2.038 |

| 21 | 170.7 | 224.5 | 53.8 | 2.036 | 21 | 172.0 | 227.0 | 55.0 | 2.044 |

| 22 | 167.2 | 221.6 | 54.4 | 2.036 | 22 | 168.4 | 223.9 | 55.5 | 2.042 |

| 23 | 168.8 | 222.5 | 53.7 | 2.036 | 23 | 169.0 | 224.4 | 55.4 | 2.036 |

| 24 | 170.2 | 224.1 | 53.9 | 2.036 | 24 | 170.9 | 226.1 | 55.2 | 2.040 |

| 25 | 171.8 | 225.4 | 53.6 | 2.036 | 25 | – | – | – | – |

We’ll take a break here and finish logging ammo and structuring a shooting day while we tend to other projects. That should be a good head to head theoretical calculations versus reality. I apologize for dragging you through this process in this manner. It is just me thinking out loud and getting some answer to my own questions. Maybe the information will be useful to others, even if we all interpret the results differently.

Handloading… A Sorted Story Part I

Handloading… A Sorted Story Part II

Email Notification