I went back and read the article I wrote on the Weatherby .338-378, where I described it as “a rifle with moderate recoil”. What the heck was I thinking about ? Just got back from the range, 4 hours of fun and sun, resulting in a bruise on my shoulder the shape and size of New Jersey, and whiplash, from my head bobbing around, like one of those little spring necked dogs that sit up on the package tray of a car.

If you find yourself getting bored, and you want to play, “How much recoil did it have ?”, the formula for recoil is –

Recoil = [(Wb x Vm) + (4,700 x Wp) ]2

48 x Wr

Wr = Weight of the rifle in pounds

Wb = Weight of the bullet in pounds

Wp = Weight of the powder charge in pounds

Vm = Muzzle velocity in feet per second

| Cartridge | ft/lbs. recoil |

| .270 Win reference | 19 |

| 7mm RM reloads | 36 |

| .338-378 reloads | 92 |

Over 80 rounds of this 7mm RM and .338-378 ammo, leaning forward at a shooting bench, within a relatively short period of time, and I was pretty much ready to hang it up for the day. But at least I know both rounds can go fast, and be very accurate, even if not always at the same time. The goals of the project were to come up with reloads that would perform as a minimum –

7mm Remington Mag 145 grain bullet @ 3200 fps < .750″ groups

7mm Remington Mag 175 grain bullet @ 3000 fps < .750″ groups

.338-378 Weatherby Mag 250 grain bullet @ 3150 fps < 1.5″ groups (+450 .338 Win)

.338-378 Weatherby Mag 215 grain bullet @ 3300 fps < 1.5″ groups (+450 .338 Win)

All goals were met, some exceeded. You can skip to performance results tables near the end of each cartridge section, or read through some of the information I accumulated along the way. Please keep in mind these are my loads, in my rifle, under local weather conditions. The temperature ran between the high 30’s and mid 40’s (Fahrenheit) while I was testing loads. I will note my starting point next to final loads, and I wouldn’t touch a single load without backing off 5% or so just as a precaution. Disclaimer, Disclaimer, don’t try this at home, based on anything I’ve written.

I did not encounter a single sign of excessive pressure in any of these loads, as a function of physical case measurement, visual inspection through an eye loop, or difficulty in working a bolt to chamber a round or extract an empty. I stopped adding powder to the .338-378 215 grain loads when the cases started to fill up. No guts, and I felt I wanted more experience with this round in a more varied environment, before I pressed on further.

Prior to getting to the range

Last installment, I was left trying to diagnose a pressure problem that had developed with the Weatherby .338-378, at lighter loads than anticipated. I was waiting for a replacement expander rod assembly to show up from RCBS for for my 7mm RM resizing die.

Last installment, I was left trying to diagnose a pressure problem that had developed with the Weatherby .338-378, at lighter loads than anticipated. I was waiting for a replacement expander rod assembly to show up from RCBS for for my 7mm RM resizing die.

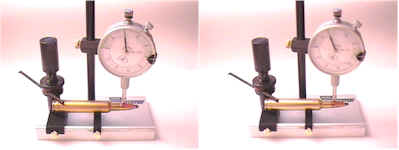

When I was sorting out the high pressure problem, I picked up an RCBS Case Master Gauging Tool. That would be a brand name for a dial indicator, a couple of V blocks and a proper fixture for taking several critical measurements from cartridges. One of these measurements is bullet run out, or how much the centerline of the bullet, is out of alignment with the centerline of the case.

Bullet run out for the problem .338-378 reloads ran as high as .017″, or about 3 times greater than what would be considered cause for checking further. None of the factory rounds exceeded .004″, with most running .002″ or less. This tipped bullet position was causing an already excessively long cartridge to make early contact with the entrance to the bore, spiking chamber pressures. So backtracked through the reloading steps to see of I could find where the run out problem was originating.

With the second set of RCBS .338-378 dies I had picked up through Midway USA, I was able to run some brass through dies made by both RCBS and CH/4D, and then compare the output. The obvious difference in use between the CH/4D and RCBS setups, was the very high effort required with the CH/4D sizer die when dragging the expander ball back through the case opening after sizing. Running cases through the RCBS set was effortless.

With the second set of RCBS .338-378 dies I had picked up through Midway USA, I was able to run some brass through dies made by both RCBS and CH/4D, and then compare the output. The obvious difference in use between the CH/4D and RCBS setups, was the very high effort required with the CH/4D sizer die when dragging the expander ball back through the case opening after sizing. Running cases through the RCBS set was effortless.

So I pulled the expander balls from the dies, resized a couple of cases, and found the CH/4D die was resizing the necks .007″ smaller than the RCBS die. The CH/4D inside neck measured .323″ or .015″ under bullet diameter after sizing, the expander ball was .336″, and the bullets measured .338″. I actually had been pointed to look to this area by CH/4D.

When I first mentioned a bullet run out problem to them, the initial response was, “If the sizer is not reducing the case neck more than .004″ smaller than required to hold the bullet, you should be able to hold within…” No substitute for experience works, and that was the clue I needed to check further. The sizer dies went back to CH/4D to be polished out to decrease neck size reduction. I’m hoping to get these back soon as they more closely match up to the chamber in my rifle.

As the first pass at .338-378 reloads exhibited signs of excessive pressure as a result of assembly problems, I disassembled whatever was left over from this batch, recovered components, and verified powder charges, etc. The .338-378 is an oversized case, and it will not fit into a standard inertial (hammer type) bullet puller, which is designed to max out on .375 H&H derivative cases, so I used a press mounted collet puller.

If you’re unfamiliar with this approach, a puller is screwed into place on the press die plate. The puller is fitted with an internal collet that matched the bullet size. The loaded round is placed in the shell plate, raised until the bullet fully enters the collet, then the collet is tightened securely to the bullet. The press handle is then raised, and the bullet is easily and smoothly extracted from the case, without damaging the bullet.

Since all of the cartridges had been serialized and logged, as they were assembled, there was no problem returning all components, including powder, to their original containers. All of the cases were cleaned (not tumbled), re-measured and logged again.

Since all of the cartridges had been serialized and logged, as they were assembled, there was no problem returning all components, including powder, to their original containers. All of the cases were cleaned (not tumbled), re-measured and logged again.

Now, finding myself at the start of the process again, I had a chance to re-examine some of my initial choices. It was at this point I decided to set aside the 250 grain Speer Grand Slam bullets in favor of reloading with a Sierra 250 grain spitzer boat tail. There were several reasons for making the change.

Improved ballistic performance – The Sierra bullet has a higher ballistic coefficient, offers improved down range trajectory and higher retained energy. The ballistic coefficient for the Sierra bullet is .593 versus .431 for the Speer Grand Slam. The shape of the heel also lends itself to less force required in bullet seating.

Improved ballistic performance – The Sierra bullet has a higher ballistic coefficient, offers improved down range trajectory and higher retained energy. The ballistic coefficient for the Sierra bullet is .593 versus .431 for the Speer Grand Slam. The shape of the heel also lends itself to less force required in bullet seating.

Improved control over throat clearance – While the boat tail is longer, it’s seated deeper, and the ogive is tapered more sharply, improving throat clearance at an overall cartridges length of 3.700″. The boat tail overall length is 1.443″, the Grand Slam 1.335″, but the portion of the boat tail held by the case neck, and projecting forward, is only 1.235, a full 1/10″ shorter than the Speer bullet.

The final issue is one of quality control. I like Sierra bullets. They are consistent in weight and, if you check them for out of round, you can’t get a nudge out of a dial indicator. I like Speer Hot-Core in center fire rifle cartridges and Gold Dots in handguns. They are reasonable in price and provide excellent performance. In fact, this positive experience led me to purchase Speer Grand Slam product.

The final issue is one of quality control. I like Sierra bullets. They are consistent in weight and, if you check them for out of round, you can’t get a nudge out of a dial indicator. I like Speer Hot-Core in center fire rifle cartridges and Gold Dots in handguns. They are reasonable in price and provide excellent performance. In fact, this positive experience led me to purchase Speer Grand Slam product.

I’m pretty much convinced Speer Grand Slam bullets are a “tourist” product, or a very average product, overpriced to attract people who make selections based on price alone. I was going to say they should spend as much time developing the product as they did on the packaging, until I saw the typo on the label that reads .388″ rather than .338″. At over 50 cents a bullet, That’s half a buck per bullet, I think customers deserve more than a reject quality box and bullets that are perhaps inferior to those costing less than half as much.

I’m pretty much convinced Speer Grand Slam bullets are a “tourist” product, or a very average product, overpriced to attract people who make selections based on price alone. I was going to say they should spend as much time developing the product as they did on the packaging, until I saw the typo on the label that reads .388″ rather than .338″. At over 50 cents a bullet, That’s half a buck per bullet, I think customers deserve more than a reject quality box and bullets that are perhaps inferior to those costing less than half as much.

A label typo on a box of expensive bullets, that come packed with a self congratulatory message packed inside is ironic and trivial, but inconsistent bullet weights are unacceptable. I scale weighed 10 bullets each from a box of Grand Slam 250 grain .338 bullets and 10 Game King Sierra 250 grain .338 bullets. The Grand Slam’s cost $29.00 at a local outlet, the Game King’s cost $13.90, both in quantity 50. The scale I used for weighing the bullets is an RCBS 10-10, a product of the same company that owns Speer.

Speer Sierra

Grand Slam Game King

249.1 249.7

250.0 249.6

250.0 249.6

250.0 249.7

249.6 249.6

249.7 249.6

249.2 249.6

250.1 249.7

250.1 249.7

250.0 249.6

I went on to weigh 6mm and 7mm Speer Hot Cores, and 7mm Sierra’s in 175 grain. Then I weighed 9mm and 10mm Speer Gold Dots and Hornady 10mm bullets. Nothing else went more than one or two tenths of a grain in total deviation, regardless manufacturer, including Speer. So why does the expensive Speer Grand Slam deviate in weight ten times as much as the low cost bullets ? If at least some of that extra price isn’t going to improved process or quality control, or to improved materials, where would it go besides raw profit ? My conclusion – Grand Slam’s are for tourists. And, no, I don’t think a bear or moose will know the difference if I use a lower cost bullets, but they may have a better chance of being hit.

In addition to the 250 grain, I also thought I’d add something a little lighter. I selected the Sierra 215 grain for this purpose. Same basic style of bullet, just a little shorter in overall length. I thought I’d be able to get around 3,300 feet per second, in a really flat shooting lighter load.

Upon inspection of the brass from the cartridges I had disassembled, I found quite a bit of variation in case dimensions. None were out of limits, but there was enough of a variation to possibly show up in performance measurement. So I purchased a couple of boxes of unprimed brass. I always thought Weatherby brass was ridiculously expensive, but now, thanks to the really crazy prices charged by other ammo manufacturers for their new “premium” stuff, Weatherby is looking pretty inexpensive.

Weatherby unprimed brass, available just about anywhere Weatherby ammo is sold, is produced by Norma Precision AB of Sweden. That would be a 100+ year old company, with a 40 year history with the same customer. Norma indicates on its web site, they are recognized as a “purveyor of ammunition to His Majesty The King of Sweden”. Hey, it’s good enough for Carl, it’s good enough for me.

Weatherby unprimed brass, available just about anywhere Weatherby ammo is sold, is produced by Norma Precision AB of Sweden. That would be a 100+ year old company, with a 40 year history with the same customer. Norma indicates on its web site, they are recognized as a “purveyor of ammunition to His Majesty The King of Sweden”. Hey, it’s good enough for Carl, it’s good enough for me.

A dial indicator(1) was used to measure neck run out and bullet run out, after loading. A micrometer (2) measured accurately in increments as small as .0001. This will be used to check case pressure expansion after the first reload cycle. (3) A hole locator mic with a small radius pin, and normal anvil, was used to accurately measure neck wall thickness. A dial caliper (4) was used anywhere a .001″ measurement was close enough, including outside, inside with no radius, and depth with the extending depth gauge.

A dial indicator(1) was used to measure neck run out and bullet run out, after loading. A micrometer (2) measured accurately in increments as small as .0001. This will be used to check case pressure expansion after the first reload cycle. (3) A hole locator mic with a small radius pin, and normal anvil, was used to accurately measure neck wall thickness. A dial caliper (4) was used anywhere a .001″ measurement was close enough, including outside, inside with no radius, and depth with the extending depth gauge.

Case length was measured with the RCBS Case Master. A flat tip was placed on the dial indicator, the face was zeroed at 2.900″ and each case was placed under the gauge. It was pretty fast and measurements were spot verified with a mic or caliper.

Case length was measured with the RCBS Case Master. A flat tip was placed on the dial indicator, the face was zeroed at 2.900″ and each case was placed under the gauge. It was pretty fast and measurements were spot verified with a mic or caliper.

Within the contents of one box, I found cases that measured a range of 2.903″ – 2.910″. Rather than subject this first controlled batch to trimming, I swapped the contents of a couple boxes around until the length range closed to within .003″, almost. With these first measurements, these cases would now remain together, barring damage, for all future use.

I don’t know what the actual spec is for the .338-378 case length. I’ve never seen it published, and the case has yet to hit any hard copy reloading manuals that I am aware of. The load data I’ve seen published at various places seem to list an overall loaded cartridge length, but not for an empty. I do know, however, the parent .378 case is 2.908″ and the trim to length is 2.898, which is that’s pretty much in line with the new unprimed cases I received, as well as the loaded factory ammo I’ve been using.

Even “brand new” brass doesn’t mean perfect. All cases were cleaned to remove any factory glop that might remain from the manufacturing process, all primer pockets were wire brushed to remove any oxidation and flecks of brass that might hamper primer seating. Without cleaning primer pockets, the seating pressure was so high, I believe I would have worn ear protectors while reloading. Wire brushing is a lot easier, safer and quiet. I also took the opportunity to inside/outside chamfer all case mouths.

I made a decision to make a permanent switch to the APS priming system. It’s just too smooth to use, and too consistent in results, for me to go back to reloading press priming of these large cartridges. When comparing reloading press and APS press installed primers, I was able to really see the variation in seating depth on the primers seated on the reloading press. The touch on the APS is lighter, but more sensitive, and there were no perceptible variations in primer seating depth.

Bullet seating with the Sierra boat tail was really easy. I found even pressure on the press handle, particularly at the bottom of the stroke where the ram tends to wander around, could yield very uniform overall cartridge length and relatively small amounts of bullet runout. The following is a sample of the first 20 .338-378 reloads on the new brass and Sierra bullets-

# Case L COL Bullet RO

01 2.905 3.701 .001

02 2.905 3.700 .002

03 2.904 3.702 .002

04 2.905 3.699 .004

05 2.903 3.700 .001

06 2.904 3.704 .003

07 2.903 3.701 .002

08 2.905 3.700 .003

09 2.904 3.701 .002

10 2.905 3.699 .002

11 2.904 3.702 .002

12 2.908 3.704 .003

13 2.904 3.695 .003

14 2.905 3.698 .002

15 2.905 3.700 .002

16 2.904 3.698 .002

17 2.905 3.698 .002

18 2.905 3.702 .001

19 2.905 3.700 .001

20 2.905 3.700 .001Spec.

Case L*=2.898″ – 2.910″

C.O.L.*=3.645″ – 3.705″

Bullet run out=0.000″ – .005″

*Not factory specs, referenced specs developed for this specific rifle and application.

I went on to load rounds based on the Sierra 215 grain SPBT. There is a considerable difference between the 250grain and 215 grain, even though they are of the same basic design. You can see how the 215 on the right has a much shorter heel and base as a method of reducing bullet weight. The 215 also has a corresponding drop in it ballistic coefficient rating, .485.

I went on to load rounds based on the Sierra 215 grain SPBT. There is a considerable difference between the 250grain and 215 grain, even though they are of the same basic design. You can see how the 215 on the right has a much shorter heel and base as a method of reducing bullet weight. The 215 also has a corresponding drop in it ballistic coefficient rating, .485.

# Case L COL Bullet RO

01 2.904 3.668 .002

02 2.906 3.665 .003

03 2.907 3.667 .002

04 2.904 3.668 .004

05 2.905 3.670 .001

06 2.905 3.670 .001

07 2.909 3.668 .001

08 2.910 3.668 .002

09 2.910 3.669 .002

10 2.904 3.671 .003

11 2.901 3.667 .002

12 2.906 3.701 .003

Since I was testing some relatively heavy charges, I wanted to double check that I had enough throat clearance to prevent pressure spikes from having a bullet sitting on the rifling. On the left is the factory load with the dial indicator reading zero. It is sitting on the start of the ogive slope where it drops from a .336 diameter. On the right, the Sierra boat tail has a .008″ smaller diameter, at the same reference point, as measured from the cartridge case head.

To get to a .336 diameter on the Sierra round, I had to move the indicator back toward the case head an additional .015″, for .015″ greater throat clearance than the factory load. Something to think about. I made up a custom gauge to measure throat clearance out of relatively common hardware. Maybe I’ll use this for the subject of a future article.

All powder charges were weighed, and cases manually charged. My press mounted powder measure would not handle the large increments, and either IMR 7828 and Reloader 25 tend to bridge in a dispenser.

All powder charges were weighed, and cases manually charged. My press mounted powder measure would not handle the large increments, and either IMR 7828 and Reloader 25 tend to bridge in a dispenser.

On the right is a measured amount for the Weatherby round, and probably the reason handguns have become so popular. At 100+ grains of expensive slow burning powder, I can load approx. 65 rounds of .338-378, or 100 rounds of 7mm RM. The same pound of powder, 7000 grains, will yield about 1,000 rounds for my .357 SIG, or .45 auto. 40 cents a round or 2 cents a round ?

I guess I could go slower in powder selection when available, or I can always borrow from one of the guys who loads for the .50 BMG round. Neither the IMR or Alliant powders came within .250″ of the case shoulder with 250 loads. I was hoping I would have a full case of slow burning powder, at max charges, that would yield the best accuracy and velocity.

I was able to come very close with the 215 grain loads, with Reloader 25 filling into the entrance to the case neck. I was interested in the Reloader 25 loads because Alliant seems to be able to get more velocity at lower pressures, and I’ve had very good luck with their products in my handgun loads. In fact, in all reloads, RL25 yielded extremely consistent cartridge to cartridge bullet velocity, and uniform grain increase / velocity increase increments. Might just be me, but when I start clocking rounds that don’t measure greater than 5 fps difference (for same loads), I get impressed.

Calipers open to 1″, groups are obviously not. Seems I just read that big Weatherby’s are inaccurate and belted magnum’s are out of style. I guess I never thought of ballistics as a style. I had a good feeling about this rifle the first time I picked it up. Now I know why.

I think both powders did a pretty good job, however, I would use RL 25 as a general purpose powder for the .338-378. I shot many more groups and collected much more data than I was able to include in this article, but Reloader 25 offered many more combinations of speed and excellent accuracy than I could achieve with IMR 7828.

RL 25 ran cooler barrel temperatures, with most of the heat coming about 8″ from the muzzle. I was pretty surprised by the accuracy the Weatherby rifle could deliver. With these loads I could shoot those types of small group repeatedly. Point of impact shift when loads changed were significant. Shots didn’t move along a vertical line, but as much as 3″ – 4″ side to side. Within the same load, consistency was incredible.

Cost savings with the Weatherby round was excellent. I figured my cost to be less than $14.00 per box, compared to $85.00 for factory loads. I was also able to beat factory velocity and accuracy pretty easily. The brass didn’t take a beating, even in heavy loads, so I don’t anticipate short case life. I’m gong to load up a couple of boxes of the best loads and look forward to a little hunting.

7 MM Remington Magnum progress and results

RCBS delivered a replacement warranty expander rod assembly, in fact they delivered two. I was able to repair the resizing die I had killed two weeks earlier, and move ahead with loading. Using once fired brass for the 7mm RM loads, the issue of case trimming came up. Case length increases as a function of brass flow induced by chamber pressure, as well as in the resizing step of reloading. When a case grows beyond spec, it needs to be trimmed back to a trim spec.

I took a few moments to measure cases before and after resizing. I had cases shrink a maximum of .002 and grow a maximum of .014 during the operation. Probably not a good sign considering the entire range, from case trim length spec to max length spec for the 7mm mag, is only .010. The greatest contributor to excessive case length seems to be routine resizing. Maybe RCBS, with their X sizer die approach to controlling case length, has a really good idea. I also think neck resizing and bushing resizing may be better methods than traditional full length.

I took a few moments to measure cases before and after resizing. I had cases shrink a maximum of .002 and grow a maximum of .014 during the operation. Probably not a good sign considering the entire range, from case trim length spec to max length spec for the 7mm mag, is only .010. The greatest contributor to excessive case length seems to be routine resizing. Maybe RCBS, with their X sizer die approach to controlling case length, has a really good idea. I also think neck resizing and bushing resizing may be better methods than traditional full length.

I’m starting to question if auto progressive reloading, for larger capacity rifle cartridges, is all that reasonable for quality reloads, at least for my purposes. The basic reload steps in this type of setup are decap and resize, prime, powder charge and seat a bullet. You can’t trim on the press, you can clean primer pockets on the press and, much of the time, you can’t reliably throw large stick powder charges from the press. So you end up using two press stations, and they don’t represent a progression.

Beyond the lack of efficiency, there is the lack of precise operation with a progressive press. For all the steel bars that locate the die plate to the press body, and for the giant sized rams that hold rotating shell plates and provided vertical movement, there is only a small indentation on the light shell plate mount casting, controlling the critical alignment between the shell plate holding a case, and the dies located above. I’m not sure how to get precise reloads out of a very un-precise tool.

I’m sure this range of movement, by design, was intended to make the press self aligning. – I.E. slightly out of index cases would rock a little so they would start in a resizing die, case heads would shift enough to start over a slightly misaligned primer, and a bullet that starts off a little crooked can find its way to general alignment. But that also means if the operator isn’t right on, there will be raised primers, high run out bullets and wide variations in case length and overall cartridge length.

Short case handgun ammo, small rifle cartridges with small charges of fast burning powders ? Progressive is great and allows me to reload a lot of volume, with a lot of quality control and consistency. But I think I think I’ll be adding a heavy duty single station press, and maybe an electric scale and dispenser combination for large rifle case work.

I felt I didn’t do as good a job with the 145 or 175 grain 7mm loads as I did with the .338-378. The 7mm loads were made with fired brass, had the added step of trimming, and I used a combination of flat based and SP boat tail bullets – In this case, the very long boat tail tapered base didn’t seem to help all that much in case/bullet alignment. I included the case D measurements because, in this once used brass, these can be used for pressure checks. These are the first 20 cartridges.

# Case D Case L COL Bullet RO

01 .5113 2.489 3.285 .005

02 .5115 2.489 3.275 .003

03 .5123 2.490 3.280 .007

04 .5117 2.489 3.281 .005

05 .5124 2.491 3.281 .005

06 .5122 2.492 3.281 .004

07 .5118 2.488 3.277 .007

08 .5118 2.487 3.279 .003

09 .5115 2.490 3.281 .001

10 .5114 2.491 3.281 .004

11 .5119 2.492 3.285 .004

12 .5114 2.493 3.280 .008

13 .5114 2.489 3.284 .002

14 .5117 2.488 3.279 .001

15 .5115 2.490 3.283 .003

16 .5121 2.488 3.280 .005

17 .5120 2.488 3.284 .001

18 .5119 2.489 3.279 .006

19 .5116 2.488 3.283 .007

20 .5116 2.492 3.276 .003

Spec.

Case D=.5131″

Case L=2.490″ – 2.500″

C.O.L.=3.280″ – 3.290″

Bullet run out=0.000″ – .005″

Before I reload another box of these, I’ll check out the seating plug profile and be more careful in the seating stoke to see if I can bring these into closer tolerances. I’m pretty convinced this is pilot error. All and all, it seems the quality must have been okay.

These 145 grain and 175 grain bullets had a more dramatic difference than the two bullets used in the .338-378 loads. The 145 grain Speer has a ballistic coefficient of .457 and the 175 grain Sierra .600.

These 145 grain and 175 grain bullets had a more dramatic difference than the two bullets used in the .338-378 loads. The 145 grain Speer has a ballistic coefficient of .457 and the 175 grain Sierra .600.

In shorter ranges the 145 holds the edge in velocity, but way out there, they are not much different in trajectory, and the high sectional density of the 175 holds on to a lot more energy. Both bullets seemed to offer comparable 100 yard accuracy, but I don’t know what that would look like further down range in cross or gusting winds.

Caliper set to 1″. Bottom center and right are, respectively, 175 grain and 150 grain Winchester factory loads. The rest are pictures of these handloads that I now carry around in wallet size. These were shot from a 24″ sporter weight 700 BDL Remington from a rest.

I started my 175 grain loads at 64 grains of IMR 7828 and 66 grains of Reloader 25. These powder types for the 175 grain held that difference throughout the range. The 145 grain started at 65 grains for IMR 7828 and 68 grains of Reloader 25. I was surprised that Reloader 25 worked so well in a smaller case and a light bullet.

I had good speed and / or accuracy with both types of powder, both types of bullets, etc. Didn’t seem to matter if the barrel was hot or cold and I actually had more than 8 groups that were less than .250″. This particular rifle has always been very accurate with even most factory ammo. It’s interesting to see the heavy bullet in the .338-378 offers flatter trajectory and much, much more retained energy.

The cost per box of highly accurate ammo that easily beat factory ammo performance was about $8, or about 1/4 the cost of the new premium ammo. At no time did the rifle exhibit signs of excessive pressure, including brass flow, sticking bolt or excessive change in case dimensions. I do need to get a new recoil pad for this gun. At less than half the actual recoil, it’s much worse than the Weatherby, particularly after a box or two of 175 grain loads.

Conclusion

I think reloading in this regard is a cost savings but, more so, a refinement.. I like the feeling of being able to control the accuracy and performance of the ammo I use, and not have to settle for substandard factory ammo, or pay high prices for special brands. The reloading process is interesting and educational, and it’s a lot of relaxation after a stressful work day.

I believe the goals were met, I think that these cartridges cover anything I’d be hunting for, and they are very enjoyable for recreational shooting. I may take a break from writing about reloading, and try relaxing and doing some shooting. During this break I’ll try to hit on a different subject or two, then see if we can come back with some fresh information and another reloading project.

I’m thinking a few boxes of this ammo, including equipment and labor, is now running right around….$6,500 a box. But you know, it’s a lot of fun and I wouldn’t have it any other way – except maybe for those “one size fits none” plastic ammo boxes.

I’m thinking a few boxes of this ammo, including equipment and labor, is now running right around….$6,500 a box. But you know, it’s a lot of fun and I wouldn’t have it any other way – except maybe for those “one size fits none” plastic ammo boxes.

In 7mm mag size, I can’t put them in base side down, they don’t fit. Tip down, they fall all over the place. But I have a lot of them, all color coded to size, and they fit absolutely nothing. Anybody have any cardboard ammo boxes. ?

Thanks

Joe

Email Notification