Twenty four hours of Maine sunshine. Up late clearing. Homes are not close and all are set back quite a bit from the road, but we have roads that connect to our little mountain road. It was a little surreal hearing so much noisy exhaust and seeing all of those sets of small tractor headlights through the snowblower spray up and down the hill so late at night. Finishing up this morning with roof rakes and smaller equipment getting three foot drifts off the porch and from around utilities. Also was able to clear enough to get some twenty five yard shooting out of the way.

The 45 Colt is an exceptional cartridge. Factory produced or handloaded to original power levels, recoil is modest but, loaded with the proper bullets, it is terrific for self defense and/or close range hunting of medium size game. In firearms of adequate design, with modern high pressure ammunition and appropriate bullet type, the 45 Colt can drop anything living in the Americas.

Four bullets that see a lot of work around Real Guns in performance 45 Colt handloads: Hornady HP/XTP 250 grain, Speer JHP 260 grain, Hornady XTP/Mag, 300 grain, Oregon Trail, Cast FN 300 grain. The bad news is, the common denominator is that they have the flight characteristics of a barn door, soaring through the air… flat side out. They all have a ballistic coefficient of less than 0.145. The good news is that, compared to 0.451″ to 0.452″ spire tipped bullets of a significantly higher ballistic coefficient, there is no notable performance difference within the cartridges working range.

| 45 Colt Hornady HP/XTP 250 grain Point Blank 128 Yards | |||||

| Yards | 0 | 50 | 100 | 150 | 200 |

| Velocity – fps | 1400 | 1233 | 1108 | 1019 | 954 |

| Energy – ft.-lbs. | 1088 | 844 | 681 | 576 | 505 |

| Momentum – lbs-sec | 1.55 | 1.36 | 1.23 | 1.13 | 1.06 |

| Path – in. | -1.5 | 2.6 | 1.1 | -7.6 | -24.6 |

| 45 Colt Barnes TMZ 250 Grains Point Blank 134 Yards | |||||

| Yards | 0 | 50 | 100 | 150 | 200 |

| Velocity – fps | 1400 | 1276 | 1174 | 1093 | 1030 |

| Energy – ft.-lbs. | 1088 | 904 | 765 | 663 | 589 |

| Momentum – lbs-sec | 1.55 | 1.41 | 1.30 | 1.21 | 1.14 |

| Path – in. | -1.5 | 2.7 | 1.5 | -6.0 | -20.7 |

Left to right: Barnes Spitfire MZ 245 grains, Hornady SST 250 grains, Barnes Spitfire TMZ 250 grains, Hornady SST 300 grains. A recent rifle project utilizing 0.451″ and 0.452″ spire tipped bullets and a 1:16″ twist reduced spread hand size groups with stubby pistol bullets, to 1″ to 1 1/2″ groups with the bullets pictured above. The project rifle was a Ruger American Ranch Rifle in 450 Bushmaster where velocity was quite high. The pictured bullets, while components of sabot loads for precision muzzleloader applications, improved accuracy and offer good controlled expansion characteristics.

The enigmatic muzzleloader sabot bullet – centerfire cartridge coalition…

Sounds like the name of a band from the 1960’s. Wrapping up a traditional handgun bullet handload project for the Ruger Blackhawk Bisley, and noting the 1:16″ twist and elevated 45 Colt velocity, I couldn’t stop without at least trying to see if spire tipped ammo could be assembled for the Ruger and, if so, would there be any measurable benefits. There were a few concerns at the onset. Would the bullets’ parallel shank surfaces allow a cartridge overall length that would fit within the Ruger’s 1.7″ long cylinder while presenting a crimping surface? Would resulting net case capacity allow the use of anything other than fast pistol powder in support of relatively heavy bullets? Did the muzzleloader bullets have exceptional bearing surface that would sharply increase bore friction and pressure.

| Bullet | Bullet Type |

Weight Grains |

Bullet Length” |

Bullet Diameter “ |

B.C. | Bearing Surface Sq. In.* |

Cartridge COL” |

Net Case Grains |

| Barnes Spitfire MZ | HPBT | 245 | 0.968 | 0.4504 | 0.203 | 0.70 | 1.700 | 20.5 |

| Hornady SST | PTFB | 250 | 0.955 | 0.4517 | 0.210 | 0.93 | 1.700 | 20.5 |

| Barnes Spitfire TMZ | PTBT | 250 | 1.110 | 0.4506 | 0.210 | 0.83 | 1.700 | 14.8 |

| Hornady SST | PTFB | 300 | 1.080 | 0.4518 | 0.250 | 1.06 | 1.700 | 15.4 |

| * By comparison, the average 45 caliber handgun bullet in these weight classes have a 1.08 sq. in. bearing surface |

||||||||

Bearing surfaces were not an issue with the long ogive bullets as all were less than their traditional bullet counterparts. Getting acceptable seating depth and crimping surface proved a bit more problematic. Of course…

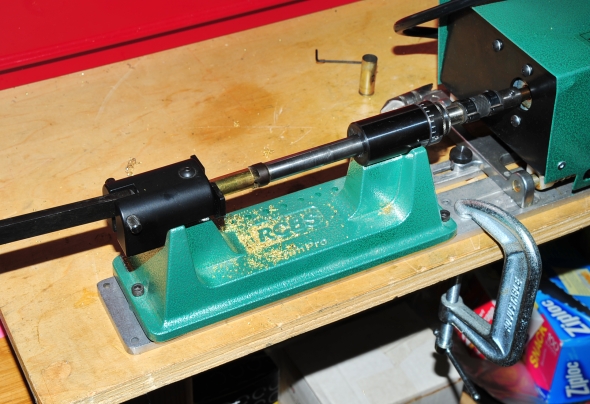

Taking a page from Hornady’s approach to their 45 Colt FTX load, but working to a COL of 1.7″, cases were reduced in length until all bullets would present a parallel surface at the case mouth. The RCBS powered case trimmer got a work out, as did an inside/outside case reamer, but eventually a 1.170″ case length did the job. By comparison, Hornady FTX brass measures 1.235″ and standard 45 Colt length is 1.275″

As the maximum COL set bullet depth, which determined net case capacity, trimming the case had no bearing on the cases capacity. There are penalties for case trimming to this degree. Cut a case too short and there is a chance the heel of a bullet will contact the internal case wall thickness taper and distort the case. In this case, all of the bullets cleared the internal case web and taper. The second concern is the case mouth seeing an oversize chamber. Contrary to what things would seem, straight wall cases are not straight.

The 45 Colt chamber entry is 0.4807″ -0.0000″/+0.0040″. At the case mouth, the diameter is reduced to 0.4742″ -0.0000″/+0.0040″ for a 0.0065″ taper. Cutting back exposes the case mouth to an approximately 0.002″ larger chamber. Not the same as firing a 38 Special round in a 357 Magnum chamber where the chamber/cartridge taper is only 0.0006″. How much of an effect does that lack of trimmed case mouth support have on accuracy. At this juncture; beats me, but we will soon find out.

R-r-r-r-r-r, eke-eke-eke

That is the sound of the power trimmer from start to “all done. Trimming at the shop is generally done with a manual trimmer of varying manufacturer, but this powered trimmer has been in use approximately 35 years with no more maintenance than replacing the cutter every 5 years or 50,000 miles… which ever comes first. It works great when a good deal of material needs to be removed from cases, or there are a lot of cases to trim. It has no on/off switch which complicates the set up sequence a bit, but one set, it will chunk out clean, trim cases all day. What do you do when tediously trimming cases? Alexa, play Dylan’s “Watch Tower”.

Originally, the plan was to determine cartridge COL, then cut cannelures in the bullets to accept a roll crimp. Fortunately, the jackets are relatively soft to expand at muzzleloader velocities, so using a Lee crimp die was enough to coin the jacket and roll crimp tightly without distorting bullets. Assembled, the loaded ammo looks a lot like this:

There were only two issues of note when reloading this combination of components. The cases, as cut, are too short for the standard 45 Colt expander so, initially, a universal expander was used. However, trimming back and running each case through a sizer die, and then subjecting the cases to inside/outside chamfering, permitted bullet seating without the expander step. The seater plug needed to be relieved to make contact on the bullet and not the soft poly tip, or the results looked like the round pictured left.

There were only two issues of note when reloading this combination of components. The cases, as cut, are too short for the standard 45 Colt expander so, initially, a universal expander was used. However, trimming back and running each case through a sizer die, and then subjecting the cases to inside/outside chamfering, permitted bullet seating without the expander step. The seater plug needed to be relieved to make contact on the bullet and not the soft poly tip, or the results looked like the round pictured left.

Going in, the thought was to use H110 or Win 296, or even Lil’ Gun powder. Unfortunately, the low case capacity and relatively high bullet weight left only Alliant 2400 and No.9 as the viable, popular powder candidates. Standard large pistol primers were utilized. Pressure goals were in the mid to high 20kpsi range, velocity considerably higher than standard pressure 45 Colt loads, but lower than “put your fingers in your ears and wait for the flying parts” handloads. The feeling was that if accuracy was exceptional, velocity could always be improved and if the accuracy wasn’t there, pushing velocity was pointless as that could be done with traditional bullets.

|

Warning: Bullet selections are specific, and loads are not valid with substitutions of different bullets of the same weight. Variations in bullet material and length will alter net case capacity, pressure and velocity results. Primer selection is specific and primer types are not interchangeable. These data represents maximum loads in our firearms and test equipment and may easily be excessive in other applications. All loads should be reduced by 3%, and developed following safe handloading practices as represented in established reloading manuals produced by component manufacturers. Presentation of these loads does not constitute a solicitation for their use, nor a recommendation.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sometimes even a bad outcome is educational…

Was anything proven? Certainly. Stuck in the wilderness with 50 caliber muzzleloader sabots, 0.451″ or 0.452″ projectiles, reloading equipment and other components, with an out of ammo 45 Colt Ruger Blackhawk, all can be placed into a bag, shaken up and out will pop a mediocre to poor performing combination of ammunition and firearm. Accuracy wasn’t bad, but velocity was low. There was no performance gain for either hunting or self defense and a lot of brass was ruined in the process. Perhaps someone with a little more time and patience might hit on a better combination.

Of greater importance I have to apologize to the Ruger Company, 45 Colt Ruger owners everywhere and, specifically, the Ruger Blackhawk Bisley for diminishing its performance while I played “What if?”, just to see what I could see. The deal breakers here were the obvious; too long of a projectile, too little case capacity. Now I can be content getting back to a zillion existing handloads with traditional handgun bullets or any number of factory performance loads.

*A little masterpiece from George Harrison circa 1969

Email Notification