My first encounter with the original Caldwell Lead Sled came just about twelve years ago. I was in the middle of a .500 Jeffery handload development project that involved pushing handloads; 600 grains, just under 2,500 feet per second of muzzle velocity and generating just a tad over 8,000 foot pounds of muzzle energy, fired from an 8.5 pound bolt action rifle without a muzzle brake. With a conventional front rest and rear shooting bag, every squeeze of the trigger resulted in face slapping, shoulder pounding, retina and rotator cuff stretching recoil. The effects of roughly 170 foot pounds of recoil.

Setting aside the physical punishment of firing 300 to 400 rounds to gather velocity and pressure data, there was the task of assessing accuracy for the combination… which is difficult to accomplish while squinting, blinking, bracing and getting tossed around. On the schedule ahead of me, only more big bore rifles of similar and even greater power, so I checked my ego and bought a Caldwell Lead Sled, plopped it on the shooting bench and weighted it down with four, twenty five pound bags of lead shot.

The Lead Sled didn’t eliminate the 500 Jeffery’s felt recoil, but it did reduce it to something less than a .308 Winchester mid-weight sporter. My focus and control returned, I got through the handloading project and I learned that well made big bore rifles could group like a varmint rifle. Projects passed and I’ve found the Lead Sled allows me to collect good data without ill effects and I am able to provide a more credible representation of a rifle’s potential, regardless the caliber and level of recoil.

The Lead Sled is not made to build field marksmanship skills or condition a shooter to handle heavy recoiling firearms. A hunter needs to learn how to shoot from a variety of positions and how to manage a rifle’s recoil in doses consistent with hunting. That said, the Caldwell Lead Sled, and now the Caldwell Lead Sled DFT 2, is a valuable piece of equipment, that serves many common purposes.

The original Caldwell Lead Sled

My original Caldwell Lead Sled, despite constant, frequent use over a dozen years, actually shows little wear and tear. It never broke and, other than the occasional retightening of hardware, it sits on my shooting bench as is there when needed. There are, however, some design elements within the old style Lead Sled that are less than exciting.

The windage adjustment system is placed at the front of the cradle assembly. The top plate that supports the firearm is anchored to the windage adjustment assembly with a single rear fastener. The front bushing that is the windage adjustment contact surface floats between the adjustment and backing screws. The cradle is actually a very fragile assembly that pops out of place under even modest recoil and works loose so that it has a semi permanent wobble.

Additionally, the dual frame rail spacing was narrow enough to prevent extended magazines from pass through which meant shooting with a magazine removed or raising a rifle exceptionally high. The sliding block that positions the front cradle relative to the rear rest is really stiff, requiring a good deal of effort to adjust..

Caldwell’s Lead Sled® DFT™ 2

Refinements to the current DFT 2 Assembly come in many forms. The bearings that float the elevation wheel are now steel caged ball bearings rather than plastic mounted. The ram lock is tipped with a tension key and spring to firmly secure the ram. The ram is hard chromed for corrosion resistance and wear resistance. The slide blocks move a lot more freely than the original version, but lock up as well.

The current cradle assembly is much more robust, tied to a beefy ram block with a gib, socketed and secured to the ram with a central M6 fastener. The windage adjustment is made with a lead screw that passes through the ram block and drives the cradle side to side.

More pieces in place. The ram fastener is central and the underside of the cradle assembly is cylindrically recessed to slip over the end of the ram for increased stability.

Finally, the front rest is secured at four points, a union reinforced with two steel clamping bars in the lower outside compressions cells. A very resilient forend strap keeps muzzle climbers in check.

Other improvements over the original

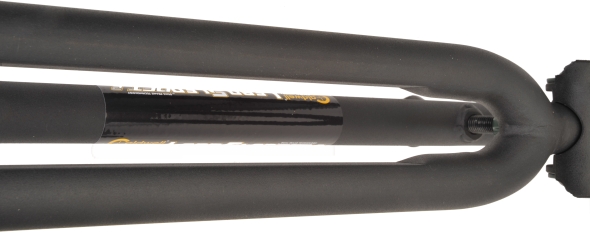

The DFT2, Dual Frame Technology, puts two frame rails above and rail one below. The top rails are pancaked on the inside for extended magazine clearance. The three tube system makes for a rigid, but still shock dampening assembly. The result is that the rest absorbs even big time recoil, but the resistance isn’t so unyielding that it would result in split wood rifle stocks.

The rear rest, compared to the original, is formed from heavier gauge steel, it has a non-marring liner and a thick, resilient front and rear facing pad. The fine elevation adjusting foot is larger is diameter which adds to overall rest stability and it doesn’t dig into my cloth covered shooting bench.

A couple of closing notes

The Caldwell Lead Sled DFT 2 is packed partially assembled. It took twenty minutes to assemble, including a few minutes chasing down songs on YouTube. All of the parts were as described in clear instructions furnished with the rest and all tools needed for assembly are included.. although an electric driver was used to minimize assembly tedium.

The only thing I would change about assembly is very minor and an issue of sequence. The instructions indicate the front rest is installed and secured before the forend strap is fed under it and back over the front rest. Secured, the bottom of the front rest bellies into the windage cradle and blocks the path of the strap. It is easier to start the front rest hardware, slip the strap beneath and into position and then tighten the front rest hardware.

Unlike many shooting accessories that suggest a good deal of utility, but end up under a work bench or up in a loft, the Lead Sled in our shop sees constant use; setting up scopes, sighting in, fine tuning new factory and custom rifle accuracy, identifying a rifle’s accuracy potential, shooting hundreds of rounds of ammunition during handload development Compared to the decades of service a Caldwell Lead Sled DFT 2 can deliver, the price is a bargain. MSRP is $259, however, they can be found online from discount retailers for $200 +/- a few dollars. Check out the Caldwell site for further information.

Accommodating different shooting requirements

For folks looking for a rest, but not with all of the features of the Lead Sled DFT 2, there are other Caldwell shooting rests like the new Lead Sled 3. The Lead Sled 3 is a single frame tube product with front and rear rest elevation adjustment, but no windage adjustment and with fixed front/rear rest spacing. It does have the same 100 pounds of lead shot capacity for recoil dampening. Pictured below, the Lead Sled 3 sells for approximately $100 less than the Lead Sled DFT 2.

The Stinger Shooting Rest pictured below is geared toward range use, but without a recoil dampening feature. The Stinger has twin frame tube construction, front and rear rest separation adjustment, vertical front and rear adjustment and an MSRP of only $119. A nice range rest for any type of long gun, including AR types with extended lower appendages.

For those of us who like traditional, portable simplicity for general purpose range applications, The Rock Shooting Rest and Rear Bag Combo offers good value and it is a very versatile set up. With the right bags a product like this can not only work with long guns, but handguns as well.

Email Notification