First….8x57mm JS

There are some variables to handloading the 8×57 JS, the first being it’s name. Sometimes it is referred to the 7.9x57mm, or 7.92×57, or 8mm Mauser, or 8x57mm JS Mauser, or the 8x57mm IS Mauser. They are all the same. The cartridge is a derivative of the German Military Commission and is not a product of Peter Paul Mauser. The only issue of any consequence to a modern day shooter is the 1903 change over from the “J” .318″ diameter bullet to the “JS” .323 diameter bullet.

There are some variables to handloading the 8×57 JS, the first being it’s name. Sometimes it is referred to the 7.9x57mm, or 7.92×57, or 8mm Mauser, or 8x57mm JS Mauser, or the 8x57mm IS Mauser. They are all the same. The cartridge is a derivative of the German Military Commission and is not a product of Peter Paul Mauser. The only issue of any consequence to a modern day shooter is the 1903 change over from the “J” .318″ diameter bullet to the “JS” .323 diameter bullet.

The 8mm JS shares shell holders with the .30-06, and components are readily available, particularly bullets and at human consumption prices. I did have to lathe polish a trimmer pilot, the .320″ standard is too large to use on sized cases.

Before working up and handloads I slugged the barrel. Bore dimensions vary as do chamber reamers and degrees of wear and tear, so there has to be a baseline, a starting point. I do not hammer oversized lead cylinders into barrels. Sometimes I wonder, when I see wide reports of blunderbuss like muzzle dimensions of the person didn’t create the condition by hammering a hard lead slug into muzzle. I start with a .458 soft lead bullet, turn a section of it to size on a lathe to slightly undersize of the specific rifle’s groove diameter. In this case, the bore measured near the muzzle was .312″, the groove diameter was .323″ so I turned the slug to .319″. The slug, coated with high pressure wheel bearing grease expanded to fill the bore as it was started into the barrel, verified by the lathe tool marks being wiped by groove contact. The reading taken from the slug indicated .323″ groove diameter and 312″ bore diameter when run the full length of the barrel.

In addition to the bore slugging, I also did a short chamber cast to capture the neck, throat and rifling just ahead of the chamber. I got .323″ groove diameter, .311″ bore. The neck diameter measured .361″. There is no flare at the muzzle, and there is really no erosion at the throat, just a porous chamber cast. A new Lothar Walther 8x57IS Model 98 replacement stepped barrel is 7.89/8.20 mm , or .311″/.323″ land/groove diameter so I was pretty happy about the gun’s bore. As a side note, the twist rate is 1:240mm or 1:9.5″, the same as the new replacement barrel. This is more than enough to stabilize even the very long 1.360″ 250 grain Woodleigh bullet as verified with ourtwist rate calculator. I assume the rotational speed for the 154 grain JS military bullet at 2,880 fps was not considered excessive.

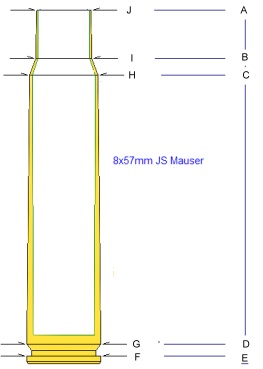

Comparative Chamber – Case Dimensions

|

Ref | ANSI Chamber |

ANSI Case |

New Brass |

Fired Brass |

Resized Brass |

| A | 2.247″ | 2.240″ | 2.238″ | 2.231″* | 2.230″* | |

| B | 1.923″ | 1.933″ | 1.946″ | 1.934″ | 1.933″ | |

| C | 1.814″ | 1.827″ | 1.835″ | 1.815″ | 1.823″ | |

| D | N/A | 0.125″ | 1.240″ | 1.130″ | 0.125″ | |

| E | N/A | 0.049″ | 0.046″ | 0.046″ | 0.049″ | |

| F | 0.475″ | 0.473″ | 0.468″ | 0.467″ | 0.473″ | |

| G | 0.471″ | 0.472″ | 0.466″ | 0.467″ | 0.472″ | |

| H | 0.433″ | 0.431″ | 0.427″ | 0.438″ | 0.431″ | |

| I | 0.358″ | 0.350″ | 0.343″ | 0.361″ | 0.350″ | |

| J | 0.357″ | 0.343″ | 0.346″ | 0.360″ | 0.343″ | |

| K | N/A | 0.013″ | 0.013″ | 0.013″ | 0.013″ |

Notes On Chamber Checking

The magenta boxes, or TP to some of you, are areas out of cartridge spec. My first clue that I might have a chamber cut oversize was when I attempted to start a fresh bullet in a once fired case for a photo mockup, and the bullet dropped cleanly to the bottom of the case. The reason I didn’t make a full chamber cast was because I did not have to; pump brass up with about 10k PSI and it will form to the chamber, then spring back 0.002″ generally, so it makes a good print of the chamber. Concerned that radial stresses increased or blew out the chamber, I measure a couple of hundred rounds of one fired brass and they were all the same, from number 1 to number 200 in terms if brass growth and neck diameter. A good reason to number all preliminary handloads and for not tossing notes and data collected.

The magenta boxes, or TP to some of you, are areas out of cartridge spec. My first clue that I might have a chamber cut oversize was when I attempted to start a fresh bullet in a once fired case for a photo mockup, and the bullet dropped cleanly to the bottom of the case. The reason I didn’t make a full chamber cast was because I did not have to; pump brass up with about 10k PSI and it will form to the chamber, then spring back 0.002″ generally, so it makes a good print of the chamber. Concerned that radial stresses increased or blew out the chamber, I measure a couple of hundred rounds of one fired brass and they were all the same, from number 1 to number 200 in terms if brass growth and neck diameter. A good reason to number all preliminary handloads and for not tossing notes and data collected.

Cerrosafe for chamber casting takes a little work and, no, I am not going to post pictures of funnels and brass tubes and other dramatic low temperature casting. Chamber casts are a lot easier to take with the barreled action removed from the stock; the chamber and casting pour tools need to be kept warm and a torch is the easiest way to accomplish the task. Chambers and casting area should be very clean and preferable coated with a release agent like graphite. Don’t over heat the medium, it will separate and be ruined. Get a good joint between a funnel and pour tube, if a tube is required. Don’t chat while pouring, the stuff can wrap itself around anything and be very difficult to retrieve. Other than following the packages instructions, casting chambers is a snap and very worthwhile.

If you pick up headspace gauges, you may read about early and later chambers having different shoulder angles. This mostly applies to early US factory rifle production and chambers cut by gunsmiths for the 8mm Mauser that were made to the same 28° 48′ shoulder angle as the cartridge. The chamber shoulder angle specification is actually 19°. This condition does not apply to military Mausers, the standard modern headspace gauge with a 19° is correct. Forster Precision Productscarries both, something I believe I mentioned in an earlier segment. They are really nice folks who don’t mind helping fellow gun enthusiasts, and their web site carries the full explanation of the headspace gage sets and application.

Cartridge Handloading Notes

The 8mm Mauser, like the Russian round, uses relatively fast powder most effectively. Powders like Re19 and IMR 7828 are really too slow for this application, even with heavy bullet weights. That said, there are probably more good powders in his range than in others.

I used standard large rifle primers with extruded powders and magnum primers with ball/spherical powders. The latter is a little harder to uniformly ignite and burn, the use of magnum primers was the recommendation of virtually all mainstream handloading manual publishers, and there were a number of compressed loads; use of magnum primers in these applications wasn’t much of a controversy.

The sized case mouth was too far under to use the .320″ trimmer pilot so I polished one undersize for this specific purpose.

Handloading for this round is routine with no idiosyncrasies I am aware of. I loaded to CIP pressure limits, 56,565 PSI, using software as a factor in load development, and validating with published handloads from recognized handloading manual publishers. SAAMI maximum average pressure is only 35,000 as a protection against .323″ bullets being fired in old .318″ barrels, and the resulting performance is a waste of a good gun and cartridge. None of the loads showed excessive pressure, the bolt never became difficult to turn, nor did extraction require notable effort. There is relatively complete powder burn, so I don’t think the round is all that barrel length sensitive. I do think the need to use somewhat fast powder and most loads coming close to capacity, if not compressed, means not much opportunity for very slow powder for heavy bullets. Consequently, or fortunately, depending how you want to look at it, there is not a lot of velocity separation from 185 grain through 200 grain bullets. I did not get the opportunity to try the heavy Woodleigh bullets, but I will at some point. 250 grain .323″ bullets have a sectional density of .342 compared to .233 for a 170 grain Speer. I have a feeling the long length would be hard to stabilize in a barrel with a twist rate intended for a 150 grain bullet, and it would be hard to push it to much more than 2,400 fps.

The Handload data table is a little large in presentation scale so I linked it here – 8x57mm JS Handloads. Again, these are European standard level loads, not SAAMI loads and they run approximately 20,000 PSI higher. They are only useful in a firearm in verified good shape and able to handle pressure levels in excess of 56k PSI. This is a terrific round, accurate and a wide range of 8mm bullets that exist perhaps not for the benefit of 8x57mm IS shooters. I did what I believe to be a pretty thorough search and was able to uncover only one manufacturer still producing guns chambered for this cartridge, HEYM of Germany. Most manufacturers, domestic and International seem to have settled on the .308 Winchester or 30-06 Springfield as the cartridge in this ballistic range.

And then….7.62x54R (Russian)

This is the new Real Guns bore cleaning system, AKA, Ziploc Easy Zipper bag. It’s not that we are cheap…well, actually we are pretty cheap, but they catch patches and solvent without dissolving and cleanup is a snap.

This is the new Real Guns bore cleaning system, AKA, Ziploc Easy Zipper bag. It’s not that we are cheap…well, actually we are pretty cheap, but they catch patches and solvent without dissolving and cleanup is a snap.

I need to make a public apology to the spirit of the Model 1891/30 Mosin Nagant for misrepresenting its accuracy potential as well as the condition of the bore. Unhappy with the gun’s performance during its initial outing, I loaded the bore with some nuclear bore cleaner, let it sit for an hour, then hit it with a wire brush. I have never seen a bore so dirty in all of my years of reluctant gun cleaning. After the soak, the brush and rod were covered with black dissolved debris, it took approximately 6 coarse patches before I could see patch through what looked like black axle grease. Three more bronze brush attacks, 30 – 40 more patches and I could see bright metal. and a relatively decent bore.

While aggressively cleaning, I also discovered movement of the action in the stock that I traced back to a loose guard screw. I do not know if this was loose before the first range day, or shot loose during the session. Since the gun produced uniformly bad results from first shot to last, I have to assume it was loose at the onset of the session. Subsequent shooting resulted in sub 1″ shot groups at 50 yards with metallic sights, which of course leaves me feeling happy and perhaps a little dumb. Duh.

In the context of size, the 7.62x54R is close to a 308 Winchester, 56 and 60 grains of capacity respectively. Pictured right: 8mmx57 JS, 25-06, 7.62x54R, 30-30 WCF. Since I mostly own rifles that shoot weird cartridges, that’s about as close as I can get to popular reference ammo.

In the context of size, the 7.62x54R is close to a 308 Winchester, 56 and 60 grains of capacity respectively. Pictured right: 8mmx57 JS, 25-06, 7.62x54R, 30-30 WCF. Since I mostly own rifles that shoot weird cartridges, that’s about as close as I can get to popular reference ammo.

The Russian round has a pronounced rim, beveled and .038″ smaller than a 45-70. I don’t know why the big rim design, maybe it represents a big chunk of metal for an extractor to grab in a land where field dirt and inclement weather are expected. Sometimes weird rims are employed to facilitate use in specialized firearms like automatic weapons, I think this was just done to toughen up Russian troops by forcing them to clear magazine and stripper clip jams while under live fire. Just a theory. Despite it’s odd appearance, it is relatively easy to handload.

The Russian round has a pronounced rim, beveled and .038″ smaller than a 45-70. I don’t know why the big rim design, maybe it represents a big chunk of metal for an extractor to grab in a land where field dirt and inclement weather are expected. Sometimes weird rims are employed to facilitate use in specialized firearms like automatic weapons, I think this was just done to toughen up Russian troops by forcing them to clear magazine and stripper clip jams while under live fire. Just a theory. Despite it’s odd appearance, it is relatively easy to handload.

The bore in both Mosin Nagant firearms, measured .311″ under controlled conditions with the carbine counterbored to about 1″ inside the muzzle. I have seen some specialty sites note Soviet made guns sometimes run a little oversize in groove diameter, as much as .314″, however this was not the case with these particular rifles. The twist rate was the same as the 8mm Mauser, 1:9.5″ and has the same match up with bullet weights and velocity potential.

The bore in both Mosin Nagant firearms, measured .311″ under controlled conditions with the carbine counterbored to about 1″ inside the muzzle. I have seen some specialty sites note Soviet made guns sometimes run a little oversize in groove diameter, as much as .314″, however this was not the case with these particular rifles. The twist rate was the same as the 8mm Mauser, 1:9.5″ and has the same match up with bullet weights and velocity potential.

It’s a little disconcerting to find a bullet category on retail sites selling handload components labeled “303 Caliber, 7.7mm Japanese, 7.62x39mm (.310-.312)” such as the one that appears on MidwayUSA. I don’t know if that means they believe people who handload for military surplus firearms are an intelligent bunch and it is assumed they can pick the right bullet, or they just gave into the notion that some of these gun makers were less precise in barrel making so a size selection would be required. .310″ and .311″ seem to shoot equally as well. I did not load .312″, there were more than enough of the other with a good weight and construction selection and I am not a big fan of using bullets over measured groove diameter even though the CIP spec for bullet diameter is .312″.

It’s a little disconcerting to find a bullet category on retail sites selling handload components labeled “303 Caliber, 7.7mm Japanese, 7.62x39mm (.310-.312)” such as the one that appears on MidwayUSA. I don’t know if that means they believe people who handload for military surplus firearms are an intelligent bunch and it is assumed they can pick the right bullet, or they just gave into the notion that some of these gun makers were less precise in barrel making so a size selection would be required. .310″ and .311″ seem to shoot equally as well. I did not load .312″, there were more than enough of the other with a good weight and construction selection and I am not a big fan of using bullets over measured groove diameter even though the CIP spec for bullet diameter is .312″.

Mainstream handload data is virtually nonexistent for the 7.62x54R and there is a good deal of inconsistency between US sourced case drawings and European sourced drawings. In fact, “The Handloader’s Manual of Cartridge Conversions” show this as a .308″ bore and 59 grains of capacity which applies loosely to Finnish versions of the cartridge and firearms. As my rifle and carbine are Soviet produced and .311″ bore, I went with my .311″ bullet selections and CIP reference pressures in the 56,000 PSI range. Both guns digested handloads with no visible signs of excessive pressure with the exception of slight cratering; extraction was easy and case appearance was normal. All of the loads I put together for this cartridge that had decent results in terms of accuracy can be found listed on the Real Guns 7.62x54R handload page.

I hope this was helpful, I know it was a departure for me, but a lot of fun. I look forward to more projects based on these firearms.

More “What could be more fun than $75 rifles….”

![]() What could be more fun than $75 rifles…. Part I

What could be more fun than $75 rifles…. Part I

![]() What could be more fun than $75 rifles…. Part II

What could be more fun than $75 rifles…. Part II

![]() Handload Data 7.62x54R

Handload Data 7.62x54R

![]() Handload Data 8x57mm JS

Handload Data 8x57mm JS

Thanks,

Joe

Email Notification