I noticed priming isn’t always that easy to accomplish in a progressive reloading press, particularly when trying to concentrate on a powder measure that isn’t dropping charges cleanly, or cases that require a little extra leverage at a resizing station. That primer seating “feel” can be lost to all of the other simultaneous activities. So I thought I’d take a look at the RCBS APS priming system, and some related accessories.

The idea behind APS (Automatic Priming System) is that primers are purchased, mounted in color coded plastic strips. The plastic strips are fed directly into the APS, either bench or press mounted, and cases are primed without the operator handling, and possibly contaminating, the primer at any step. Strips may be locked together to make a strip as long, or as short, as applicable to the reloading session.

APS is suppose to also be a more reliable system of feeding and seating primers, which is why plastic strips may be purchased separately and, with the help of a strip loader, hands off loaded from a supply of conventionally packaged primers.

The actual APS press is small and compact. It’s designed to be mounted directly to a bench, or to the RCBS accessory base plate. The base plate allows one spot on the bench to be used for quick mounting numerous pieces of RCBS equipment, without covering your bench top with mount holes for each one.

The actual APS press is small and compact. It’s designed to be mounted directly to a bench, or to the RCBS accessory base plate. The base plate allows one spot on the bench to be used for quick mounting numerous pieces of RCBS equipment, without covering your bench top with mount holes for each one.

Personally, I don’t use a base plate. I do, however, have a bench that looks like Swiss cheese and has several cracks, mostly around press mounting points, and they run the length of the bench. When the bench collapses, which will be very soon, and I head to the garage to build a new one, I’ll definitely get an accessory base. I think half the problems that originate in sizing and priming are directly related to poor press mounting, and counter tops that flex too much when applying leverage to an operation.

In any case, the retail price of the APS bench mounted unit is around $85, about $15 less at most discount chain stores, $75 from Midway – they pay freight, and there’s no sales tax. The accessory base plate 2, don’t know what happened to 1, is $22.95.

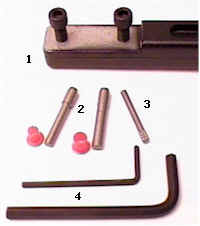

The press comes with most of what is needed to get started: 1) Press handle 2) Large and small primer plugs and bushing 3) Cam lock 4) hex keys used for assembly and routine adjustments. There was also this little booklet that was packed in the box. Not sure what purpose it serves, but I’m sure I’ll take a look when I get a chance.

The press comes with most of what is needed to get started: 1) Press handle 2) Large and small primer plugs and bushing 3) Cam lock 4) hex keys used for assembly and routine adjustments. There was also this little booklet that was packed in the box. Not sure what purpose it serves, but I’m sure I’ll take a look when I get a chance.

Unfortunately, you need to buy more things that were not included. I use an Automaster Press with shell plates, rather than shell holders, so I needed to buy a set of standard shell holders to cover the cartridges I’ll be priming. At $5 a pop, for me, $20 were added to the cost of APS to cover approximately 7 cartridges.

Unfortunately, you need to buy more things that were not included. I use an Automaster Press with shell plates, rather than shell holders, so I needed to buy a set of standard shell holders to cover the cartridges I’ll be priming. At $5 a pop, for me, $20 were added to the cost of APS to cover approximately 7 cartridges.

Of course, if your local retailer isn’t convinced APS is the wave of the priming future and doesn’t stock those new high energy magnum rifle primers in APL strips, or you have a favorite primer other than CCI, you can purchase an APS Strip Loader, a bunch of color coded plastic strips (SP, LP, LPM, LR, etc.) and load your own. The strip loader retails for about $21.95 and the plastic strips, in packs of 8 (25 primers per strip) at $6.95 per pack.

Of course, if your local retailer isn’t convinced APS is the wave of the priming future and doesn’t stock those new high energy magnum rifle primers in APL strips, or you have a favorite primer other than CCI, you can purchase an APS Strip Loader, a bunch of color coded plastic strips (SP, LP, LPM, LR, etc.) and load your own. The strip loader retails for about $21.95 and the plastic strips, in packs of 8 (25 primers per strip) at $6.95 per pack.

For this article, I’m going to use Federal 215 primers in the APS large magnum rifle strips. But I will have to work withthe system for several weeks before there is a determination of keeping the APS system on the bench for frequent use, or storing it in the “cabinet of no return”. That’s basically where I store everything I ever bought, for a good reason, a good reason that didn’t seem to hold up in actual use. As an example, that’s where I keep my extra .40 S&W barrel for my .357 SIG.

These strips are kind of fun to work with, Lego’s for gunners. In short form, you dump a bunch of primers into the strip loader, shake the primers into holes in the plastic strips, press the lever down, and pull the finished strip out. It takes a lot less time to do than describe.

These strips are kind of fun to work with, Lego’s for gunners. In short form, you dump a bunch of primers into the strip loader, shake the primers into holes in the plastic strips, press the lever down, and pull the finished strip out. It takes a lot less time to do than describe.

The ends of the strips can interlock to form long strips of primers to feed into the APS press. There is also a protective tape cover that can be used where the intention is to store strips for later use.

|

Primer Strip Coding |

|

| White | Large and small pistol |

| Red | Large and small magnum pistol |

| Yellow | Large and small rifle |

| Blue | Large and small magnum rifle |

| Black | Large and small bench rest rifle |

| Orange | Military 7.62mm and 5.56mm |

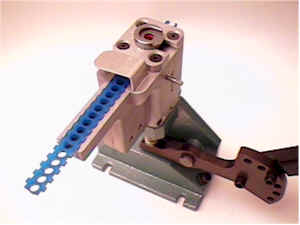

This is the press, assembled, with shell holder and bushing in place, empty primer strip correctly inserted, and the handle adjusted to a comfortable angle.

This is the press, assembled, with shell holder and bushing in place, empty primer strip correctly inserted, and the handle adjusted to a comfortable angle.

The pin sticking out of the side, below the shell holder, halts the feed of primers while seating depth is being adjusted. Seating depth is controlled by a simple mechanical stop at the base of the press.

For adequate arm travel, the press must be mounted at the edge of the bench. I keep thinking by bench is going to roll over if it gets anymore weight along the leading edge. I assume it would be easy enough to mount the press to a block and raise it off the bench enough to……..

Top view of the press with a loaded strip, a primed round and another in place in the shell holder. It was really nice to use. The perceived pressure for seating was very light, but I was definitely able to feel the primer as it seated.

Top view of the press with a loaded strip, a primed round and another in place in the shell holder. It was really nice to use. The perceived pressure for seating was very light, but I was definitely able to feel the primer as it seated.

The press was easy to unload, anywhere in the process, by simply pulling the plastic strip to the right. Even without buying primers preset in strips, the strip loader was easier to use than loading a press feed tube, and I didn’t end the priming operation by having to pull a tube and chase primers around on the floor.

The bench press fits in with my plans to go to a single stage reloading press for low volume, large rifle ammo. I’ll probably pick up a press mounted APS for my pistol and small rifle reloads on the Ammo Master. Nice product, very useful, and nice not to have to worry about misfed primers or a jammed primer shuttle. I think this one will stay out on the bench.

Thanks

Joe

Email Notification