I have to admit I’m growing fond of Tula 1943r; it was touch and go for a while. Everyone talks about the 7.62x38R Russian Nagant Revolver, but I don’t know how many people have actually seen one, at least one with ammo. Starline advertises the sale of new cases in 100, 500 and 1,000 piece quantities, but they are always out of stock and/or down in production while attempting to modify the case to make it more durable for reloading; certainly a worthwhile goal. MidwayUSA lists brass as “Out of Stock. Backorder Not OK”.

I have to admit I’m growing fond of Tula 1943r; it was touch and go for a while. Everyone talks about the 7.62x38R Russian Nagant Revolver, but I don’t know how many people have actually seen one, at least one with ammo. Starline advertises the sale of new cases in 100, 500 and 1,000 piece quantities, but they are always out of stock and/or down in production while attempting to modify the case to make it more durable for reloading; certainly a worthwhile goal. MidwayUSA lists brass as “Out of Stock. Backorder Not OK”.

On the reloading die front, Lee Precision, one of the most committed reloading equipment providers, makes dies specifically for forming 7.62x38R brass from 32-20 brass, but not specifically for reloading factory 7.62 brass. RCBS makes proper dies, but they are special order and require a shell holder that is face stamped with cartridge ID and not identified with the typical little number stamped on the side. Panicked over a Midway USA product notation “Only 2 left” I grabbed an RCBS set without considering the possibility that this notation was in place since 1955, and one of the aforementioned shell holders. The die set cost only slightly more than the gun.

7.62 Nagant reloading data is virtually non-existent. I’m not sure why. Brass for this cartridge has sort of an odd taper, or two…or three, but nothing that difficult to deal with, but it is heavily worked when fired. So it does not lend itself to frequent reloading and is at best a player in a symbiotic relationship with a revolver though by many as mostly suited to weighting paper. Yet, there are these cheap and relatively accurate guns, with only occasionally available Fiocchi factory ammo and, perhaps, some highly corrosive, Berdan primed, dunked in grease, steel cased surplus ammo from the wars over Nacho Grande. If there was ever a need for reloading, this is it.

If it’s so easy, why…

The biggest problem with the 7.62 Nagant is that it is an “innie”. In factory ammo, the bullet resides inside the case, behind a shoulder. Upon firing, the case opens up ahead of the projectile and straightens the shoulder until the case is cylindrical. Consequently, the brass is heavily worked and hardens very quickly, which leads to short case life. Out of necessity due to shortages of ammo, some handloaders convert 32-20 cases which end up being too short and of the wrong rim thickness. Starline brass is in and out of production for this case as they attempt to find an optimal case length and increased case longevity.

The biggest problem with the 7.62 Nagant is that it is an “innie”. In factory ammo, the bullet resides inside the case, behind a shoulder. Upon firing, the case opens up ahead of the projectile and straightens the shoulder until the case is cylindrical. Consequently, the brass is heavily worked and hardens very quickly, which leads to short case life. Out of necessity due to shortages of ammo, some handloaders convert 32-20 cases which end up being too short and of the wrong rim thickness. Starline brass is in and out of production for this case as they attempt to find an optimal case length and increased case longevity.

Bullet selection is limited to .308″ in diameter and short enough in length to allow room for a proper powder charge. Bullets also have to be of a design that will provide proper expansion on impact at the anemic velocity this cartridge typically generates. Through the Chrony, factory ammo ran between 671 and 687 fps. I pulled the trigger and I swear I could hear the sound of a bowling ball rolling down an ally…slowly, very slowly. The Handloader’s manual of Cartridge Conversion indicates a .306″ bore. In any event, the bore is not sufficient size for anything larger, like the 32 ACP cartridge cylinders that are frequently sold. I even read where some guy routinely shot 32 H&R ammo through his Nagant revolver; a cartridge with the wrong diameter bullet and operating at twice the pressure of the 7.62 Nagant spec. I’ll have to remember that approach the next time I run low on 270 WSM ammo, but have 7 WSM rounds handy.

Extending case life beyond a single reload

I ran the brass though universal decap and vibratory cleaner. The once fired factory brass was thin and pinged like an empty tin can, so I annealed the case mouths. Annealing, a highly technical process based on holding a case at mid point while rotating between the fingers and heating the case mouth at the tip of a propane flame until the pain reaches your brain and you are forced to let go. The case then falls into a pan of water waiting below. If you find your fingers will not let go of the brass, you have overheated the cases. Overheating will softening the case head and diminish its ability to properly seal against and contain pressure.

Subject to a Little Interpretation

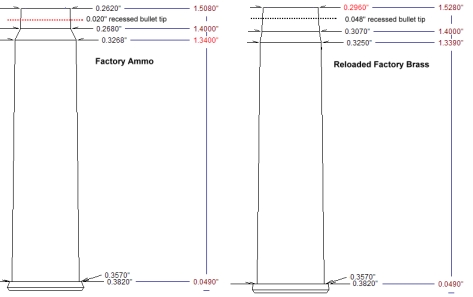

A case drawing for the 7.62x38R Russian Nagant Revolver looks a lot like the drawing on the right. The factory ammo is quite different. In both, the case capacity is the same and the bullet is positioned approximately the same distance above the case web. The primary difference is the factory fodder has a sharp shoulder and the neck is pulled in over the bullet, forming angles that make the COL slightly shorter than a handload. The reference drawings and subsequent handloads don’t really have a distinctive shoulder, but rather a series of tapers that accomplish the same thing, while leaving the COL a little longer. What I found to be critical is that the case length on a finished handload can not exceed 1.520″ and the mouth diameter cannot exceed 0.296″. The 1.520″ will assure cylinder rotation with lots of room to spare, but this length and the 0.296″ diameter mouth are necessary to allow the gas sealing cylinder to move forward into place when the hammer is cocked. Any longer or larger in diameter and the hammer will be blocked from full rearward travel.

Generally, there is nothing particularly exciting about loading this case through sizing. The sizer die, because the case is not straight walled, does not have a carbide forming insert; case lube is necessary. The forming effort is minimal and dies are set up in typical fashion; raise ram, tighten dies to surface of shell holder, and maybe just a little bit more. because there is no bottleneck and die expander ball in the sizer, a separate expander die is employed, which is also handled in a typical fashion; left with a minor flair of the case mouth to facilitate bullet seating.

If there is something to consider at this point, it is anchoring the case when priming. That rim only projects 0.012″ from the case. If I didn’t hold the case back all the way into the shell holder while priming, the case would pop out well before adequate pressure was applied. I use an APS, but any primer set up works fine. I use a Lee Classic Turret Press for the balance of the operations because it is small and out of the way on the bench and easy to switch between auto index and manual. RCBS dies work fine if the lock rings are changed over to the Lee type. The set screws in RCBS lock rings protrude and prevent adjacent dies from being locked n place.

Inside the numbers

The table below probably best illustrates the transition the case goes through from factory new to handload. I would make the assumption the most stress the cases sees is at the initial firing. Note, COL is really less than case length; bullet tip to case head.

| Round | Case Length “ | COL “ | Rim D “ | Shoulder D” | Mouth D | Neck Length “ |

| Factory | 1.509 | 1.488 | .382 | .328 | .276 | .110 |

| Fired | 1.511 | NA | .382 | .333 | .330 | NA |

| Sized | 1.518 | NA | .382 | .320 | .320 | NA |

| Loaded | 1.514 | 1.480 | .382 | .325 | .296 | NA |

There is quite a difference between the handload, left, and the factory load in appearance. Functionally there is no difference. I loaded Hornady 90 grain XTP hollow points. I seated the bullet to the proper height, backed out the seating plug, ran the die down until it rolled the case mouth to .296″, then ran the seater plug down and locked it in place. The rest of the handloads came out just like the first. I thought the factory neck might be required to secure the bullet, but this was not the case. After sizing and roll crimping the case, 4 raps with an inertial puller did not disturb the bullet and nothing moved under recoil.

Powder selections

I had great ideas for powder selections based on the size of the case and my stubborn notion I could load this like a small rifle case and use stick powder intended for moderate capacity rifle cartridges. Unfortunately, like many of my brilliant conclusions based on an obscure but entertaining theory, none of these ideas panned out. They did all outperform factory ammo, some were very mild to shoot, but there was just nothing significant to be gained from their use. Moving to more suitable powder selection, the best were pretty good and the gun became considerably more authoritative in report and performance. All of the loads were built from a baseline understanding. The Nagant has a very low max pressure of only 11,000 PSI, barely more than enough pressure to form brass to cylinder walls. Setting aside the metallurgical differences that might exist between the Nagant and more modern firearms, I did some comparisons amongst various firearms, cartridges and operating pressures. Yes, I realize 1943 Russia could have produced guns made from old tuna cans.

The S&W Model 37 Airweight has 0.059″ cylinder walls; a 5 shot with the notches between cylinders so the walls are not thinned over the chamber. The Nagant has roughly 0.112″ walls with a notch 0.033″ directly over the chamber, yielding a net thickness of 0.079″. The little M37 has an alloy frame, the Nagant hefty carbon steel. The Nagant top strap is slightly thinner above the cylinder notches as a result of the larger cylinder diameter at that location. SAAMI max pressure for the 38 Special is 17,000 PSI and the guns are quite similar in apparent strength.

The Model 37 is not a good candidate for +P loads, however, that pressure rating would only add another 1,500 PSI to the useful pressure range. If I move to Europe, CIP suggests just under 22,000 PSI is OK but, until I can speak French… In any event, I believe the Nagant has a little latitude for pressure, however, not much latitude, low as its operating pressure might seem. With a little software assessment, some cartridge comparisons and the use of the “I can’t pry this empty out of the gun” statue of pressure limitations I worked up the following loads –

| Powder | Grains | Primer | Velocity fps |

| Factory Load | – | – | 680 |

| Re 7 | 11.5 | CCI 550 | 808 |

| Re10 | 12.0 | CCI 550 | 877 |

| Alliant 2400* | 7.5 | CCI 500 | 893 |

| Power Pistol | 4.5 | CCI 500 | 962 |

| Blue Dot* | 6.0 | CCI 500 | 1007 |

| RS Enforcer | 8.5 | CCI 500 | 993 |

| H110** | 10.0 | CCI 500 | 1079 |

I know, “What’s up with the 45-70 powder, Joe”. I don’t know, I was bored, but I also wanted to see if I could fill up a case and get decent velocity and accuracy. I did not. My guess is too light bullet weight for proper resistance to building pressure and powder not intended for very short volumes. Still not too bad. Blue Dot performance was good, I use it a lot in other handgun cartridges, but empties were hard to eject suggesting higher than desired pressure. H110 was the big surprise for me; loud, fast and empties just dropped out when the gate was opened and the barrel was tipped up. Accuracy was OK. At least good enough to keep a small ammo carton bouncing around in the backyard from 15 or 20 yards.

Conclusion

From a handloading standpoint, the results are mixed. Better performance is readily available and I could reload a 50 count box of ammo for approx $11 or a third of frequent factory ammo prices. Dies are a little stiff at $118. Still 6 boxes of ammo, if the brass holds up and your at break even. I’d like to do an accuracy test on short case loads. it might just be that cracked cases could be trimmed back 0.030″-0.040″ without a great loss. The cylinder will still move forward and close up the cylinder gap, only the contact gas seal would be missing. In regard to the forcing cone, some shooters clear rifling and create a throat or taper, and I think this would not be much different. I don’t know, yet.

At their selling price, these guns are a great bargain and could be a lot of fun for plinking. They are an oddity in shooting in that the heavy trigger pull is not a deterrent to accuracy and shot placement. The pull is predictable and there are enough places to take short breaks and steady the sights before hammer fall. The examples of Nagants we have sold run from the early 1900’s to just near WW II war end. They are in good shape, including bores and finish and interesting to say the least. They have virtually no recoil and they are relatively compact. If you haven’t had the opportunity, grab one and a box of factory ammo. I bet you like it.

Thanks

Joe

Email Notification