Here’s a combination that will make you smile every time you pull the trigger.

Here’s a combination that will make you smile every time you pull the trigger.

3 groups shot at 25 yards, 3 shots in each group:

1.00″ left, Cor-Bon 185 grain JHP +P

0.375″ center, .45 Super® 185 grain JHP

0.750″ right, 230 grain ball Winchester “white box”

The recoil with .45 Super® loads was controllable, but felt a lot like my 14″ barreled T/C Contender with heavy .30/30 loads. Noise was about the same as +P loads, although at one point there were 185 grain JHPs zipping along at about 1,400 fps. I think the ejecting empties may have knocked a few people unconscious, leading me to believe there’s may be a need for about 2 to 4 more lbs of recoil spring. But I’m getting ahead of myself.

Published data may yield “warm” results

Prior to loading any ammo, I went through all the .45 Super® information I could locate. There are actually quite a few articles floating around out there, unfortunately most seem to just copy data from the earliest published article, typographical errors and all. As an example, I couldn’t find one that didn’t overstate the overall length of the cartridge as 2.220″. So I started looking for some consistent load data that would put some of my concerns to rest, and make me feel as though I had a basis for a safe starting point.

For the sake of comparison, I dug up all of the .45 ACP, .45 ACP +P data I could find that referenced the same powder and bullets types as those appearing in the .45 Super® research information. I was looking for load stability in the form of a relatively linear increased progression of powder and resulting velocity. Each color listed below represents a different data source, none are load suggestions or reflect my own findings.

| Power Pistol | |||||||||||||||

|

Grains of Powder |

8.2 | 8.6 | 9.1 | 9.5 | 9.5 | 11.3 | |||||||||

|

Bullet Velocity |

185 gr | 939 | 1025 | 1075 | 1047 | 1105 | 1307 | ||||||||

| Velocity/ grain | 114.51 | 119.19 | 118.13 | 110.21 | 116.32 | 115.66 | |||||||||

| AA #7 | |||||||||||||||

|

Grains of Powder |

9.4 | 9.7 | 9.9 | 10.2 | 10.3 | 10.6 | 10.7 | 10.8 | 11.1 | 11.2 | 11.5 | 12 | 14 | 16 | |

|

Bullet Velocity |

185 gr | 800 | 750 | 850 | 800 | 900 | 850 | 950 | 825 | 900 | 1000 | 950 | 947 | 1199 | 1306 |

| Velocity/ grain | 85.11 | 77.32 | 85.86 | 78.43 | 87.38 | 80.19 | 88.79 | 76.39 | 81.08 | 89.29 | 82.61 | 78.92 | 85.64 | 81.63 | |

The Alliant Power Pistol loads are about what would be expected. .4 grains produced 86 more fps, then .5 yielded 50 fps, then the next .4 added lost 28 fps. It happens. Temperatures change, barrels and bullets vary in dimension, powder scales weigh a little different, chronograph screens are positioned plus or minus…. But the Accurate # 7 loads went a little beyond. In fact there were loads where adding .1 grain added 11% to MV, adding .1 lost 125 fps and subtracting .3 added lost 75 fps. So I decided to not only start at the light side of .45 Super® loads, I decided to start with the equivalent of .45 ACP standard loads and work my way all the way up to the top for .45 Super® using a single powder type and bullet weight.

Notes on loading

All of the loads were done using new .45 Super® brass from Starline. I have been using Starline for my .357 SIG and .40 S&W handloads for some time, and the product has been of consistently of high quality. In this instance, all I did for prep was wash the cases to make sure they were free of process lube, and ran a deburring tool over the case mouth.

All of the loads were done using new .45 Super® brass from Starline. I have been using Starline for my .357 SIG and .40 S&W handloads for some time, and the product has been of consistently of high quality. In this instance, all I did for prep was wash the cases to make sure they were free of process lube, and ran a deburring tool over the case mouth.

Priming was done as step away from the loading press. The APS system from RCBS represents a significant improvement in semi-automated priming. Insertion pressure and depth is uniform, primers stay out of oily hands and off of floors, and it doesn’t take a developed sense of feel to seat primers correctly.

I have to admit I like working with the single station Rock Chucker and a mechanical scale on these types of projects. I don’t have to rush, I’m only going to produce a handful of ammo, and I can spend a little more time producing some very uniform loads.

I have to admit I like working with the single station Rock Chucker and a mechanical scale on these types of projects. I don’t have to rush, I’m only going to produce a handful of ammo, and I can spend a little more time producing some very uniform loads.

When it comes to handguns, I find that I enjoy reloading in small lots making unique combinations, particularly relating to a new gun or cartridge. I volume load, but only when I can configure cartridges in a form not available over the counter.

Still, right about the time I get too comfortable with the notion of better than factory quality, I pull one of these gems off of the press and remind myself I can do some pretty lame stuff when I’m not concentrating on the work in front of me. When I taper crimp, I like to open the case mouth as little as possible. This is the brass letting me know that whatever I did, it was obviously incorrect. Actually, the problem was a combination of having the taper crimp die set too low and the expander die to high, followed with just a little too much press leverage and…

Still, right about the time I get too comfortable with the notion of better than factory quality, I pull one of these gems off of the press and remind myself I can do some pretty lame stuff when I’m not concentrating on the work in front of me. When I taper crimp, I like to open the case mouth as little as possible. This is the brass letting me know that whatever I did, it was obviously incorrect. Actually, the problem was a combination of having the taper crimp die set too low and the expander die to high, followed with just a little too much press leverage and…

It took about a two minutes to reset everything and lose the accordion crimp. Then I dumped the carcass in my “special draw”, the one I go to when I need to take a picture of the results of doing things the wrong way. You need to really work to screw up handloading a .45 auto cartridge, Super or otherwise. The .45 Super® of course is externally identical to the .45 ACP, is easy to load, and is assembled with all standard components and equipment with the exception of .45 Super® brass. I didn’t want to work with mixed brass on the bench, so I used this stronger case for all .45 ACP. +P and .45 Super® level handloads. Under no circumstance, can standard or +P .45 auto brass be used for .45 Super® loads.

I like the outdoor range at Lake Chabot. It’s well run, safe and clean, seems to attract very pleasant people, and you can shoot all day without having anyone bother you. The benches may be a little worn, the sand bags aren’t exactly high tech, but it’s just good to spend a little time outdoors and away from the politics of guns.

I like the outdoor range at Lake Chabot. It’s well run, safe and clean, seems to attract very pleasant people, and you can shoot all day without having anyone bother you. The benches may be a little worn, the sand bags aren’t exactly high tech, but it’s just good to spend a little time outdoors and away from the politics of guns.

I grabbed the last bench on this section of the range, fought off what I’m sure were killer bees, then set up shop with the chronograph and a piece of string marked off in one foot increments to measure empty case ejection distances.

I didn’t attempt to adjust the sights to the bulls eye. I wanted to see what the shift in point of impact would be across a range of loads from .45 ACP through .45 Super®. I also wanted to see how reliable the gun would function, pick up some MV readings, watch very closely for any signs of excess pressure, and check to see if I had made correct spring selections. The chronograph was approximately 10′ from the bench, and the temperature was 75ºF.

Spring rates and operating reliability

During the checkout I fired PMC and Winchester 230 grain ball, 185 grain JHP Cor-Bon, and 185 Speer Gold Dot and Remington 185 grain bulk JHP bullets in a variety of .45 ACP – .45 Super® loads. There was never a problem with extraction, ejection, or feed. The gun cycled perfectly from the lightest to the heaviest loads. I started with the 28 lb Wolff Colt Delta Elite replacement spring, and never dropped down to any of the lower rate springs I brought with me. The gun was fitted with a heavier firing pin spring that came as a set with the heavy recoil spring.

Outside of 2 flyers that went 10′, empty brass from every load tested stayed within a 6′ to 9′ ejection range. As a point of comparison – there was a guy two benches over, firing standard velocity 230 ball ammo from an unmodified stainless government model. His gun was tossing empties 15 feet. Personally, I would have liked to have had a choice of 30 lb and 32 lb springs to work with, although I felt the 28 lb was adequate for the task, up through any acceptable load levels.

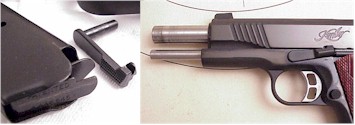

On two occasions the slide did not lock open on empty when firing the .45 Super® loads. I went to a heavier Wolff magazine spring and the problem cleared up. I reinstalled the original spring and the problem returned.

On two occasions the slide did not lock open on empty when firing the .45 Super® loads. I went to a heavier Wolff magazine spring and the problem cleared up. I reinstalled the original spring and the problem returned.

I had received a comment from a reader a very short time ago, suggesting a heavier mag spring be used as a part of the .45 Super® conversion to eliminate a possible feed problem. The gun didn’t demonstrate feed problems, however, I believe the cause of the slide not locking open is a similar and related timing issue. The left finger, or lower tab of the magazine follower is suppose to lift the slide stop actuating arm when there are no rounds in the magazine to limit the distance of the follower’s upward travel. The result should be as illustrated in the photo at the above right, the slide locked in the open position.

Typically, a slide not locking open is caused by too heavy of a recoil spring inhibiting rearward slide travel, or a fatigued magazine spring not moving the magazine follower fully into place under the slide stop. I believe a combination of heavy loads, a heavy recoil spring and a standard magazine spring can also cause the slide to not lock open on empty. The standard magazine spring rate isn’t able to keep up with the slide’s increased cycling velocity. As a result, the follower does not move up into position against the slide stop, and the stop does not engage the slide stop detent.

Pressure is a always a critical issue

The .45 Auto was not intended to be a high pressure cartridge. In previous installments, I noted the need to use only brass designed for the .45 Super®, which is properly head stamped as .45 Super, and is of heavier construction than a standard or +P .45 ACP. Industry spec for the .45 ACP is 21,000 psi, most of the +P loads come in around 23,000 psi and the .45 Super® between 26,000 and 28,000 psi – a hefty 33% increase over the original ACP.

Conversion pieces are typically guns that are all steel, have a full length slide, and are offered in the same basic model, in versions for the .38 Super and/or .40 S&W cartridges. These cartridges generate, respectively, 33,000 psi and 35,000 psi maximum average pressure. The prevailing logic is, if the gun could handle these pressures, handling the .45 Super® pressures should be a breeze. Maybe not. The outside diameter of .45 ACP barrel is approximately .580″, the same as the .40 and .38 versions. Both of these more minor calibers have thicker chamber and barrel walls to withstand higher pressure and their reduced base surface areas apply less direct load on the recoil face of the slide.

The most ragged ammo I shot came from an old box of Cor-Bon 185 JHP +P loads. They delivered the rated velocity, 1,130 – 1,150 fps, but showed more significant signs of pressure than any of the .45 Super® loads I tested. There was a distortion at the rim and some flattened primers. In all fairness, this was some relatively old ammo and probably not reflective of current Cor-Bon production.

The most ragged ammo I shot came from an old box of Cor-Bon 185 JHP +P loads. They delivered the rated velocity, 1,130 – 1,150 fps, but showed more significant signs of pressure than any of the .45 Super® loads I tested. There was a distortion at the rim and some flattened primers. In all fairness, this was some relatively old ammo and probably not reflective of current Cor-Bon production.

Without the minor rim distortion and signs of brass flow, I would have probably chalked the primer appearance up to primer smear or flow resulting from late firing pin return. I don’t know what type of powder Cor-Bon used in this ammo, but it wasn’t yielding much in exceptional velocity compared to the level of pressure apparently being generated.

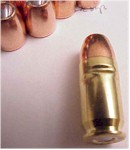

Oddly enough, higher velocity .45 Super® loads had very normal looking primers and case heads, with only the highest velocity selections demonstrating any signs of flattening primers. The dark spots on the primers are not holes, just reflection. Across of all versions of ammo fired, none showed truly excessive pressure signs. Right to Left: Winchester 850 fps 230 grain FMJ, 1300 fps 185 grain .45 Super® handload, 1400 fps 185 grain .45 Super® handload, 1137 fps 185 grain +P Cor-Bon.

I disassembled the gun on several occasions, both at the range and at the work bench, to monitor for any early signs of damage. I used a magnifying lens for the last inspection and there really was nothing to note.

I disassembled the gun on several occasions, both at the range and at the work bench, to monitor for any early signs of damage. I used a magnifying lens for the last inspection and there really was nothing to note.

The frame and slide rails and slots were clean without the least sign of battering, in fact, the session barely wore the bluing on the contact surfaces. There were no burrs or distortions anywhere, and the gun still had a new gun tight fit.

My conclusion is there was no excessive pressure or abusive cycling of the gun, but I could do more research on the issue of firing pin diameter, taper, weight, spring and hole diameter in the slide. I have a feeling this exercise would also help with similar problems I experience with my P229 .357 SIG. A lightweight titanium firing pin for the Kimber is a $10 part – pretty cheap if it will clean up the primer issue and add a margin of operational safety.

Group size and point of impact

As noted in my opening comments:

As noted in my opening comments:

1.00″ group (left) Cor-Bon 185 grain JHP +P

0.375″ (center) .45 Super® 185 grain JHP

0.750″ (right) 230 grain ball Winchester “white box”

From a sandbag rest: Winchester loads shot 2.5″ low and 1″ to the left, Cor-Bon’s shot 2″ low and 4″ to the left and .45 Super® top loads shot 3″ low and 2.5″ to the left. I think the general idea is the gun shot low and to the left out of the box. Probably of greater importance, at 25 yards I could easily put every load from standard velocity 230 grain ACP, to a high velocity 185 grain .45 Super®, into a 3″ circle.

.45 Super® Handload data

| Cartridge | Bullet | Powder | Weight Grains |

Primer | Average MV fps |

Average KE ft/lbs |

25 yard 3 shot Group |

| .45 Super® | 185 grain Speer GD | Power Pistol | 8.2 | Fed #150 | 1059 | 460 | .78 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 8.2 | Fed #150 | 1043 | 446 | .65 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 8.6 | Fed #150 | 1113 | 509 | .35 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 8.6 | Fed #150 | 1095 | 492 | 1.10 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 9.1 | Fed #150 | 1162 | 554 | 1.00 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 9.1 | Fed #150 | 1089 | 580 | .50 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 9.5 | Fed #150 | 1237 | 628 | .39 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 9.5 | Fed #150 | 1251 | 643 | 1.0 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 10.0 | Fed #150 | 1288 | 681 | .37 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 10.0 | Fed #150 | 1282 | 675 | .90 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 10.5 | Fed #150 | 1331 | 727 | .40 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 10.5 | Fed #150 | 1310 | 705 | .780 |

| .45 Super® | 185 grain Speer GD | Power Pistol | 11.3 | Fed #150 | 1403 | 808 | .38 |

| .45 Super® | 185 grain Rem JHP | Power Pistol | 11.3 | Fed #150 | 1387 | 790 | .65 |

| For Comparison Only | |||||||

| .45 ACP | 230 Win FMJ | NA | NA | NA | 807 | 267 | .750 |

| .45 ACP | 185 Cor-Bon +P | NA | NA | NA | 1125 | 520 | 1.00 |

I was topped out at the yellow entry. I did have loads in two tenth increments above that point, but these proved to be excessive with even this modest increase. There was also not enough gain to make this handload hair splitting necessary. The 11.3 grain load is widely distributed via articles in national publications, which only serves to underscore the point, “Don’t start with maximum loads”. The Kimber produced about 100 fps higher than published velocity. The physical differences in bullet were marginal. Gold Dots have a concave base, Remington bullets are flat. The Gold Dot’s were from the same lot, the Remington’s were from two different supply sources, with a six month separation in shipment dates. Ambient temperature wasn’t particularly high at 70°F – 75°F.

Summary

So what the heck does all of this mean ? I really like the Kimber, the .45 Super® is fun to shoot, potentially very accurate, and probably a significant notch up from the .357 SIG, .40 S&W or .45 ACP in terms of power. If I were going to do a lot of shooting with the combination I’d want to find a 10% – 20% stiffer recoil spring that would serve to define the other side (too heavy) of the spring rate range, and I’d want to resolve the firing pin/primer smearing issue. Not a big deal, but clearly lose ends.

There are some things I don’t like about the .45 Super®. I don’t like having three dimensionally identical types of brass around (.45 ACP, +P and Super) with the same external dimension, and only a head stamp to tell them apart. Particularly when one, loaded to the other’s spec, could blow the case out. For a time I thought I might just clear my stock, and shoot only Super brass in my reloads. Unfortunately at 2x the price, and with a ton of ACP and +P brass, that’s probably not reasonable. I think I’ll collect more information, try some AA# 7 loads, and see how I feel after I’ve gained a little more experience with the cartridge.

There is nothing I experienced within this project that would make me feel compelled to send my gun somewhere to be modified to .45 Super®. In fact, most of the modifications bundled into these conversion packages are already standard configurations on quality guns, and really have little to do with the .45 Super®. Required changes seem to be limited to a routine spring change, and maybe a light weight firing pin tapered to reduce primer flow. $17 – $20 tops. I think selecting the correct gun to start with is critical. Personally, I’d only use a steel, full length gun – no alloy, no plastic and no stamped steel slides. I’d also skip trying to covert a short barrel .45 for this purpose. Short barrels negate the whole premise of this round; pushing a .45 slug to a higher velocity.

As a side issue to this project, I’m glad I have a leftover selection of Wolff springs for my 1911 type and SIG pistols. I run a pretty wide spread of handloads, and even a modest selection of spring rates will allow me to tune more closely for each load and purpose. When you think of it, they represent some pretty inexpensive safety and reliability insurance.

More “A Kimber in .45 Super®1 for under $8?”:

A Kimber in .45 Super® for under $8 ? – Part I

A Kimber in .45 Super® for under $8 ? – Part II

A Kimber in .45 Super® for under $8 ? – Part III

Handload Data 45 Super®1

Thanks,

Joe

Email Notification