I’ve been trying to get this project to grow legs for some time, but some other priority always seemed to push it out. I finally concluded the best way to get on with it, was to sit down and start writing, so this is my initial effort at organizing my thoughts and the project steps. Eventually, I should get to some worthwhile information.

I’ve been trying to get this project to grow legs for some time, but some other priority always seemed to push it out. I finally concluded the best way to get on with it, was to sit down and start writing, so this is my initial effort at organizing my thoughts and the project steps. Eventually, I should get to some worthwhile information.

The basic premise for the .25 caliber project is that there is a need for flat shooting firepower that resides somewhere between the very effective, but limited range, deer dispatching .243, and the larger 7mm and .308″ bore cartridges. The hope of this .257″ bore selection is to retain the modest recoil, moderate report and low reloading component costs of the .243, while gaining significant reach and impact in hunting situations. Pictured, left to right: .243 Winchester, .25-06 Remingtonand .257 Weatherby Magnum.

The 7mm Remington Magnum offers a good deal more reach than the .243 Winchester, but with greater muzzle blast and three times the level of recoil; 30 ft/lbs and 10 ft/lbs respectively. Even the 7mm-08 Remington, which offers substantial close-in performance improvement over the .243 Winchester, has twice the recoil and adds little in longer range capability. It was consideration of all of these factors, combined with some level of field experience, that brought me to these two .257″ bore cartridges.

The .25-06 Remington began life in 1920 as an A.O. Niedner wildcat. In 1969 Remington standardized the cartridge as a straight neck down of the .30-06 Springfield to the .257″ bore, and a case capacity of 62 grains. This represents an approximately 20% greater capacity than the .308 Winchester case that serves as the basis for the .243 Winchester. The .257 Weatherby Magnum has been with us since 1944. Roy Weatherby shortened, blew out and necked down the .375 H&H Magnum case to the .25 caliber bore with 78 grains of capacity, or 26% greater than the .25-06. This became Weatherby’s first proprietary cartridge.

Originally labeled by many as grossly overbore and inefficient, newer generation smokeless powders such as Alliant’s RL-25 and IMR 7828 are helping both the .257 Weatherby Magnum and the .25-06 see new levels of performance. Higher velocities, combined with a wide selection of new bullet designs, have created tremendous potential for these rounds. Even in factory form, neither cartridge is a straggler. The .25-06 in 100 and 120 grain Remington loads carries muzzle velocities of 3230 fps and 2990 fps, respectively. Federal loads a 90 grain .25-06 at 3440 fps. Weatherby’s factory 87 grain load leaves the barrel at 3825 fps, their 100 grain at 3600 fps, the 115 grain at 3400, and finally a 120 grain bullet at 3300.

The .25-06 Remington & .257 Weatherby Magnum in Context

|

Cartridge |

Bullet |

Barrel Length |

Muzzle Velocity |

Muzzle |

Velocity |

Energy |

Drop |

Recoil |

|

243 Win |

100 |

24 |

2950 |

1932 |

2326 |

1210 |

-7.0 |

11 |

|

.25-06 Rem |

120 |

24 |

3050 |

2478 |

2384 |

1514 |

-6.6 |

17 |

|

.257 Weatherby |

120 |

26 |

3305 |

2910 |

2602 |

1804 |

-5.5 |

22 |

|

.270 Win |

150 |

24 |

3000 |

2997 |

2434 |

1973 |

-6.6 |

24 |

|

7mm-08 Rem |

150 |

24 |

2750 |

2518 |

2160 |

1554 |

-8.3 |

19 |

|

7mm Rem Mag |

175 |

24 |

3000 |

3497 |

2484 |

2397 |

-6.4 |

32 |

|

.308 Win |

180 |

24 |

2650 |

2806 |

2036 |

1656 |

-9.2 |

21 |

|

.30-06 Spfld |

180 |

24 |

2800 |

3133 |

2164 |

1872 |

-8.1 |

28 |

This table is not intended to represent interchangeability of these cartridges, or rate them in degrees of performance. The information is only to show the .257″ bore cartridges in relationship to other popular cartridges. In forward coverage, I hope to more clearly illustrate the almost 200 yard performance advantage the .257 bore holds over the .243.

The .257 bore is not a natural long range bore, in that it offers comparatively low sectional density, even at the upper end of practical bullet weight. Consequently, a 120 grain .25 caliber bullet will not retain velocity and energy as well as a 175 grain 7mm bullet, or a 300 grain .338″ match bullet. Consequently, .25 caliber cartridges have a need for disproportionately elevated muzzle velocities if they are to deliver exceptional downrange performance. This factor took cartridges like the .257 Roberts out of contention, at least within the confines of this project.

| Bore | Bullet Wt | SD | % MV Retained 300 yards | % ME Retained 300 Yards | Bullet Wt @ .375 SD | Grains @3000 fps |

| .243 | 100 | .242 | 78 | 63 | 155 | 106/120 |

| .257 | 120 | .260 | 78 | 62 | 175 | 108/120 |

| .277 | 150 | .279 | 81 | 65 | 200 | 112/120 |

| .284 | 175 | .310 | 83 | 68 | 210 | 114/120 |

| .308 | 180 | .271 | 77 | 60 | 250 | 116/120 |

| .338 | 300 | .375 | 88 | 77 | 300 | 120/120 |

This relationship of high sectional density to practical heavy bullet weight is best illustrated in the 7mm and .338 bores, where cartridges hold onto velocity and energy to a greater extent than calibers that bracket these bore sizes. The next to last column indicates what bullet weight for each bore size would be required to equal the .338″ match bullet in sectional density. The final column was a theoretical look at how much very slow powder, in a 120 grain net capacity case, would be required to drive this .375 SD bullet in each bore size to 3000 fps. I thought it was interesting that a 13% increase in powder could drive a 200% increase in bullet weight to the same velocities. Is there a point to all of this SD drivel? Sure, I’m just not sure what it is at this particular moment, but I’m sure I’ll get around to it.

Getting Organized

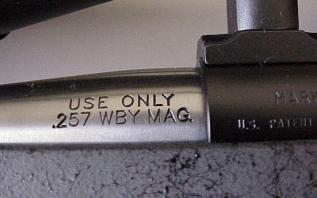

I’m approaching this project with two similar, but different types of rifles; the Remington Mountain rifle in .25-06 and the Weatherby Ultra Lightweight Mark V in .257 Weatherby Magnum. Both rifles weigh approximately the same, 6.5 – 6 3/4 lbs, but the Weatherby is considerably longer at 46 5/8″ than the 42 1/2″ Remington. The approximate 4″ difference can be almost directly attributed to Weatherby’s 26″ barrel length, compared to 22″ for the Mountain Rifle.

I’m approaching this project with two similar, but different types of rifles; the Remington Mountain rifle in .25-06 and the Weatherby Ultra Lightweight Mark V in .257 Weatherby Magnum. Both rifles weigh approximately the same, 6.5 – 6 3/4 lbs, but the Weatherby is considerably longer at 46 5/8″ than the 42 1/2″ Remington. The approximate 4″ difference can be almost directly attributed to Weatherby’s 26″ barrel length, compared to 22″ for the Mountain Rifle.

The Remington has a classic look; satin finished walnut stock with a straight comb and slightly raised cheek piece, all beaded blued exterior and 4 shot detachable magazine. Both guns have very slender barrels, each with a recessed crown and 1:10″ twist. The Remington pull is comfortable at 13 3/8″. The drop at the heel of only 3/8″ makes for a straight line from the receiver, and puts the shooter’s face higher up in line with a scope.

The Weatherby is built on a hand laminated fiberglass stock. The action is carbon steel, but the barrel is fluted stainless. The Weatherby’s Mark V action, and other related hardware, have been lightened in many ways to meet a sub 7 lb goal.

The Weatherby is built on a hand laminated fiberglass stock. The action is carbon steel, but the barrel is fluted stainless. The Weatherby’s Mark V action, and other related hardware, have been lightened in many ways to meet a sub 7 lb goal.

A top loader with a hinged floorplate, the rifle holds 3 rounds in the magazine well. The pull is slightly longer than the Remington at 13 5/8″, but the drop at the heel is huge at 1 1/2″, and there is a raised comb and cheek piece. Weatherby’s are all fitted with a Pachmayr Decelerator™ pads. The stock also has a degree of castoff. The result of this approach taken in stock design is that recoil is kept away from the shooter’s face, and rearward motion is converted to muzzle climbing motion, rather than a sharp shot at the shooter’s shoulder.

90% of the stock makers, and the vast majority of factories, believe the best way to deal with recoil is to track it in a straight line, and let the mass of the shoulder and upper body absorb the shock. I think this choice is habit more than beneficial. Personally, I’d rather have a gun that rises than one that comes straight back at the shooter.

90% of the stock makers, and the vast majority of factories, believe the best way to deal with recoil is to track it in a straight line, and let the mass of the shoulder and upper body absorb the shock. I think this choice is habit more than beneficial. Personally, I’d rather have a gun that rises than one that comes straight back at the shooter.

The design of the Ultra Lightweight stock is the same design that allows the big .40+ bore Weatherby’s to be shot from a bench without breaking any bones. My .257 Weatherby has less felt recoil than my .243 Winchester, and the .338-378 and .416 Weatherby’s are easier to handle on a long range day than a 7mm Remington Magnum from a straight stocked M700. I’m looking forward to seeing how the Remington Mountain Rifle compares to the Ultra Lightweight in felt recoil.

The Weatherby was about ready to go, the Remington still needed a few odds and ends, like a scope. My other scopes were already allocated to other firearms, and I wasn’t ready to make a commitment to permanent optics until I had a chance to work with the rifle.

The Weatherby was about ready to go, the Remington still needed a few odds and ends, like a scope. My other scopes were already allocated to other firearms, and I wasn’t ready to make a commitment to permanent optics until I had a chance to work with the rifle.

I dug around in my “where the heck did this stuff come from” cabinet and found a choice of Leupold or Warnes bases and rings, and a new Tasco scope I had picked up from MidwayUSA. The Tasco is a 3-9x 40mm World Class with a MIL-DOT reticle, very clear optics, decent eye relief; Midway sells them for $69.00, or about $20 less than the Warne mounts. The Warnes mounts came from Brownells, a company that does a good job of stocking the entire Warnes line, as well as just about everything else.

There is a degree of shame in explaining why the Tasco was sitting in “WTHDTSCF” storage, I’ve become a midrange price Leupold – Burris scope snob. Is there a reason to disparage scopes with the giant “TASCO” logo wrapped around the eye piece? Probably not. I have a 7mm magnum that has been wearing the same Tasco variable for at least 15 years, at it’s performance has been flawless. The new Tasco is light weight and matches the finish on the Remington, close enough.

The picture above probably best illustrates the good and bad points of Warne mount systems. The bases are very low profile, sturdy and clean looking. The cross slot and pin locating system of the rings, makes for a very strong and secure fit. The rings are split vertically and get a serious grip on both the scope tube and base and take little room on the scope tube.

The problem, if there is a problem, is that the Warne system seems overly engineered. The rings utilize two different size Allen head screws, the bases uses conventional cross slot screws, and each ring has a free fitting locating pin. That’s seems like a lot to fall off during a hunting trip. In all fairness, I have a Warne Quick Release set up on a Model 7 and it is rock solid reliable and returns to zero, even after being removed and reinstalled many times. They are a little costly, at about twice the price of a dual dovetail Leupold system. The finished set up does look very good.

The problem, if there is a problem, is that the Warne system seems overly engineered. The rings utilize two different size Allen head screws, the bases uses conventional cross slot screws, and each ring has a free fitting locating pin. That’s seems like a lot to fall off during a hunting trip. In all fairness, I have a Warne Quick Release set up on a Model 7 and it is rock solid reliable and returns to zero, even after being removed and reinstalled many times. They are a little costly, at about twice the price of a dual dovetail Leupold system. The finished set up does look very good.

When got to bore sighting the scope, was reminded of an important benefit of Warne mount systems. Every time I’ve plopped a scope into a Warne set up, it never takes more than a click or two from adjustment center to line up on the horizontal and vertical plane. This is without the aid of shims or offset bushings or even playing around with placement and alignment of mechanical parts. This is important as it allows for a full range of optical adjustment in all directions. With the scope related tasks completed, the rifles at least were ready to go.

Odds and Ends

The Weatherby has a good deal of free bore, which I believe will handle any reasonable overall cartridge length. I wasn’t as sure of the Remington, and I wanted a chance to examine headspace control with the long slopping shoulders of the .25-06 case. I was able to locate an RCBS Precision case mic for the Remington cartridge, so I will be able to make sure I’m sizing brass to correct dimensions, and I can check to see what latitude I have in establishing overall cartridge length.

The Weatherby has a good deal of free bore, which I believe will handle any reasonable overall cartridge length. I wasn’t as sure of the Remington, and I wanted a chance to examine headspace control with the long slopping shoulders of the .25-06 case. I was able to locate an RCBS Precision case mic for the Remington cartridge, so I will be able to make sure I’m sizing brass to correct dimensions, and I can check to see what latitude I have in establishing overall cartridge length.

By the time I wrap up the next installment, I should have my handloading plans well defined, and have a list of all components that will be utilized.

More “Quarter Inch Solutions”

Quarter Inch Solutions Part I

Quarter Inch Solutions Part II

Quarter Inch Solution III – Handload Development

Handload Data 25-06 Remington

Handload Data 257 Weatherby Magnum

Thanks,

Joe

Email Notification