That’s my wife loading up a clip full of .17 HMR rounds. These days we always go to the range together, it makes for a nice day out with pleasant people. Specifically, the reason she is smiling is because she was shooting half inch groups all day with a Marlin .17 VS, while I was beating myself back and blue by shooting many rounds through the Winchester. I’m not sure why people go to the range alone and refrain from sharing something so enjoyable. We hauled our kids up when they were younger, and we have high hopes of having the same opportunity with the grandkids when they get just a bit older. Seems the best way to perpetuate shooting sports is to continue to get people participating.

That’s my wife loading up a clip full of .17 HMR rounds. These days we always go to the range together, it makes for a nice day out with pleasant people. Specifically, the reason she is smiling is because she was shooting half inch groups all day with a Marlin .17 VS, while I was beating myself back and blue by shooting many rounds through the Winchester. I’m not sure why people go to the range alone and refrain from sharing something so enjoyable. We hauled our kids up when they were younger, and we have high hopes of having the same opportunity with the grandkids when they get just a bit older. Seems the best way to perpetuate shooting sports is to continue to get people participating.

Before I get too bogged down in the details, I have to say I haven’t had as much fun at the range since the muzzle loader project, and that’s saying a lot. The Winchester Super Shadow provided terrific accuracy and consistency of shot placement. This .270 WSM / Shadow combination has to be one of the best values on the market today.

Before I get too bogged down in the details, I have to say I haven’t had as much fun at the range since the muzzle loader project, and that’s saying a lot. The Winchester Super Shadow provided terrific accuracy and consistency of shot placement. This .270 WSM / Shadow combination has to be one of the best values on the market today.

The rifle handled all bullet weights well, even point of impact of bullets ranging from 90 grain to 150 grain shifted only about 3/4″ of an inch. It didn’t even seem to matter which powder or powder charge was behind which bullet to get a less than 1 MOA group size. I can only repeat, this rifle is a bargain. I paid $449 for mine and I believe it will stand up under rough service and be a reliable hunting rifle. It’s the kind of gun you hose off when you’re done hunting, rather than looking for a flat iron to remove dents from a finely finished walnut stock.

Recoil was very light with 90 gain bullets, as would be expected. I put together some handloads at this bullet weight, but I honestly can’t see this application as being useful; too inefficient and I think smaller cartridges could do a much better job of rodent popping. 150 gain bullets in what is a 8.5 lb rifle when complete with sling and large heavy optics certainly held my attention; not excessive recoil, but perhaps 7mm Remington Magnum like. The 90 grain loads generate 16 ft/lbs of recoil, while the 150 grain loads approximately 23 ft/lbs. The gun comes straight back, very quickly, and with very little muzzle climb. This makes it quite easy to hold on target, and also a rifle that works best with a little bit of extra eye relief. The recoil pad is very resilient and the fiber filled stock seems to absorb a good deal of recoil energy. The amount of travel in the resilient recoil pad may be what’s driving the need for greater eye relief.

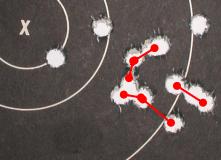

When I noted I was impressed by the gun’s performance, this is what I had in mind. These are three shots; two 150 grain Nosler Ballistic Tip bullets and one 150 grain Partition utilizing three types of powder with very close muzzle velocity. A 1/2″ group is better than most of my rifle can shoot with carefully selected and uniform components, and this is with a brand new barrel with no brake-in process.

The .270 WSM delivered nearly the same performance all day long and, within reason, seemed not sensitive at all to changes in components.

To the right is a 3/4″ group, this time all 150 grain Partitions, bullets that are at times difficult to work into an accurate combination. It is notable that the bullets are the same type and weight, but they were propelled with different types of IMR and RamShot powder.

The barrel heated up rather quickly. With an ambient temperature of 82°F the barrel just forward of the forearm climbed to 125°F after 6 shots, the breech end remained a warm 105°F and the muzzle temp wasn’t much higher than ambient. The barrel isn’t all that thin, in fact, it is the same as my old 7mm Mag Model 700 Remington BDL at .720″ midpoint on the barrel. The muzzle of the .270 WSM, however, is .050″ smaller at .610″.

130 grain bullets shot well. Hornady 130 grain bullets shot sub 1/2″ (Left-middle), Sierra 140 grain bullets sub 3/4″ (left – lower). I was able to get 5/8″ groups out of Barnes 130 grain XLC/XBT’s (Left – upper). Virtually everything for the day was under 1″ some not by much, others half that size. I had forgotten the rest, so I ended up shooting using sand bags as a rifle rest and I didn’t even have to hide my targets from view when returning to the firing line. A planned quick range outing, we ran ourselves out of both ammo and targets. The primary handload results looked something like this –

130 grain bullets shot well. Hornady 130 grain bullets shot sub 1/2″ (Left-middle), Sierra 140 grain bullets sub 3/4″ (left – lower). I was able to get 5/8″ groups out of Barnes 130 grain XLC/XBT’s (Left – upper). Virtually everything for the day was under 1″ some not by much, others half that size. I had forgotten the rest, so I ended up shooting using sand bags as a rifle rest and I didn’t even have to hide my targets from view when returning to the firing line. A planned quick range outing, we ran ourselves out of both ammo and targets. The primary handload results looked something like this –

| Bullet Wgt | Manufacturer | COL | Primer | Charge | Powder | Velocity FPS |

| 90 | Sierra HP | 2.655 | CCI 250 | 62.5 | Hodgdon Varget | 3652 |

| 90 | Sierra HP | 2.655 | CCI 250 | 69.0 | IMR 4350 | 3683 |

| 110 | Hornady | 2.735 | CCI 250 | 66.0 | IMR 4350 | 3440 |

| 110 | Hornady | 2.735 | CCI 250 | 58.5 | Hodgdon Varget | 3380 |

| 130 | Barnes XLC/BT | 2.797 | CCI 250 | 62.0 | IMR 4350 | 3141 |

| 130 | Barnes XLC/BT | 2.797 | CCI 250 | 68.5 | IMR 7828 | 3303 |

| 130 | Barnes XLC/BT | 2.797 | CCI 250 | 66.0 | Reloder 19 | 3351 |

| 130 | Barnes XLC/BT | 2.797 | CCI 250 | 68.0 | Reloder 22 | 3207 |

| 130 | Barnes XLC/BT | 2.797 | CCI 250 | 73.5 | RamShot Magnum | 3147 |

| 130 | Hornady SP Inter | 2.720 | CCI 250 | 63.5 | IMR 4350 | 3253 |

| 130 | Hornady SP Inter | 2.720 | CCI 250 | 66.0 | Reloder 19 | 3263 |

| 130 | Hornady SP Inter | 2.720 | CCI 250 | 75.0 | RamShot Magnum | 3234 |

| 130 | WSM Silver Tip | – | – | – | Factory Reference | 3275 |

| 140 | Sierra SPBT | 2.746 | CCI 250 | 66.0 | Reloder 22 | 3119 |

| 140 | Sierra SPBT | 2.746 | CCI 250 | 70.0 | Hodgdon 1000 | 3019 |

| 140 | Sierra SPBT | 2.746 | CCI 250 | 67.0 | IMR 7828 | 3198 |

| 140 | Sierra SPBT | 2.746 | CCI 250 | 72.5 | RamShot Magnum | 3138 |

| 140 | WSM Fail Safe | – | – | – | Factory Reference | 3125 |

| 150 | Nosler BalTip | 2.823 | CCI 250 | 65.5 | Reloder 22 | 3073 |

| 150 | Nosler BalTip | 2.823 | CCI 250 | 68.0 | Reloder 25 | 3023 |

| 150 | Nosler BalTip | 2.823 | CCI 250 | 65.5 | IMR 7828 | 3109 |

| 150 | Nosler BalTip | 2.823 | CCI 250 | 71.0 | RamShot Magnum | 3005 |

| 150 | WSM Silver Tip | – | – | – | Factory Reference | 3120 |

| 150 | Nosler Par | 2.773 | CCI 250 | 66.0 | Reloder 22 | 3129 |

| 150 | Nosler Par | 2.773 | CCI 250 | 68.0 | Reloder 25 | 3021 |

| 150 | Nosler Par | 2.773 | CCI 250 | 60.5 | IMR 4350 | 3071 |

| 150 | Nosler Par | 2.773 | CCI 250 | 66.5 | IMR 7828 | 3143 |

| 150 | Nosler Par | 2.773 | CCI 250 | 71.5 | RamShot Magnum | 3074 |

| 150 | WSM Power Point | – | – | – | Factory Reference | 3150 |

I couldn’t quite match all factory published velocity figures, however, handload results were at the top end of handloading manuals in performance. Without factory ammo on hand I had no real world point of comparison, and I’ve not seen anyone chronograph factory ammo within 100 fps of advertised velocity. I believe I stuffed as much powder in the cases as was safe and reliable. I didn’t have the best powder on hand for the light 90 and 110 grain bullets, so perhaps there is greater potential, although I don’t see the application as a much smaller cartridge would be more appropriate for rodent popping.

I couldn’t quite match all factory published velocity figures, however, handload results were at the top end of handloading manuals in performance. Without factory ammo on hand I had no real world point of comparison, and I’ve not seen anyone chronograph factory ammo within 100 fps of advertised velocity. I believe I stuffed as much powder in the cases as was safe and reliable. I didn’t have the best powder on hand for the light 90 and 110 grain bullets, so perhaps there is greater potential, although I don’t see the application as a much smaller cartridge would be more appropriate for rodent popping.

The standard Winchester 270 is an exceptional performer, I don’t believe there is 150 fps separating it from the 270 WSM in factory premium ammo. Lighter weight bullets, 130 grains and less, do seem to enjoy greater potential with the WSM, but I’m not sure these points of comparison are significant. I’m not replacing a 270 Winchester so the degree of gain doesn’t mean much, and I would purchase this rifle solely for its accuracy and consistency of shot placement.

Handloading the .270 WSM – Random Notes

When I am handloading a cartridge for the first time, I tend to over record information and steps in the process. Changes in minor dimensions can tell a lot about a cartridge, handload levels and the firearm they are passed through. The following table is just my routine bookkeeping with some before and after firing dimensional data for 50 of the handloads that were being closely monitored.

When I am handloading a cartridge for the first time, I tend to over record information and steps in the process. Changes in minor dimensions can tell a lot about a cartridge, handload levels and the firearm they are passed through. The following table is just my routine bookkeeping with some before and after firing dimensional data for 50 of the handloads that were being closely monitored.

For clarification – “CL” is case length and “Basic” is the datum line location on the cartridge case. There was nothing exceptional about the cases when loading, nor was there anything of particular interest after firing. I do believe the gun has a minimum size chamber and throat so there is not much growth after firing, and nothing approaches maximum length spec. No loads were compressed.

|

Case Length Spec 2.100″ – .020″ Case Basic Spec 1.730″ – .007″ |

|||||||||||||

| Case | Raw CL |

Sized CL |

Trim CL |

Trim Basic |

Fired CL |

Fired Basic |

Case | Raw CL |

Sized CL |

Trim CL |

Trim Basic |

Fired CL |

Fired Basic |

| 1 | 2.096 | 2.098 | 2.085 | 1.721 | 2.079 | 1.723 | 26 | 2.097 | 2.099 | 2.090 | 1.718 | 2.090 | 1.724 |

| 2 | 2.097 | 2.096 | 2.085 | 1.724 | 2.092 | 1.723 | 27 | 2.094 | 2.095 | 2.090 | 1.723 | 2.092 | 1.723 |

| 3 | 2.096 | 2.097 | 2.087 | 1.722 | 2.088 | 1.723 | 28 | 2.096 | 2.097 | 2.089 | 1.717 | 2.093 | 1.724 |

| 4 | 2.097 | 2.097 | 2.090 | 1.720 | 2.091 | 1.723 | 29 | 2.096 | 2.097 | 2.090 | 1.723 | 2.092 | 1.725 |

| 5 | 2.095 | 2.096 | 2.090 | 1.723 | 2.090 | 1.724 | 30 | 2.096 | 2.095 | 2.090 | 1.720 | 2.092 | 1.724 |

| 6 | 2.096 | 2.096 | 2.089 | 1.722 | 2.092 | 1.722 | 31 | 2.096 | 2.097 | 2.090 | 1.722 | 2.091 | 1.725 |

| 7 | 2.097 | 2.098 | 2.090 | 1.721 | 2.092 | 1.724 | 32 | 2.094 | 2.095 | 2.090 | 1.719 | 2.092 | 1.725 |

| 8 | 2.096 | 2.095 | 2.089 | 1.721 | 2.091 | 1.724 | 33 | 2.097 | 2.097 | 2.089 | 1.721 | 2.092 | 1.725 |

| 9 | 2.098 | 2.098 | 2.090 | 1.720 | 2.088 | 1.724 | 34 | 2.096 | 2.096 | 2.090 | 1.717 | 2.092 | 1.725 |

| 10 | 2.096 | 2.097 | 2.090 | 1.722 | 2.090 | 1.724 | 35 | 2.095 | 2.097 | 2.089 | 1.723 | 2.089 | 1.724 |

| 11 | 2.097 | 2.097 | 2.090 | 1.720 | 2.090 | 1.724 | 36 | 2.097 | 2.098 | 2.089 | 1.723 | 2.092 | 1.724 |

| 12 | 2.097 | 2.098 | 2.089 | 1.720 | 2.090 | 1.723 | 37 | 2.095 | 2.096 | 2.090 | 1.724 | 2.092 | 1.724 |

| 13 | 2.096 | 2.096 | 2.090 | 1.719 | 2.091 | 1.724 | 38 | 2.096 | 2.096 | 2.090 | 1.721 | 2.092 | 1.724 |

| 14 | 2.095 | 2.099 | 2.089 | 1.718 | 2.092 | 1.724 | 39 | 2.097 | 2.098 | 2.090 | 1.719 | 2.092 | 1.724 |

| 15 | 2.099 | 2.097 | 2.090 | 1.717 | 2.091 | 1.724 | 40 | 2.097 | 2.098 | 2.090 | 1.724 | 2.089 | 1.724 |

| 16 | 2.095 | 2.096 | 2.089 | 1.719 | 2.092 | 1.724 | 41 | 2.095 | 2.096 | 2.090 | 1.724 | 2.092 | 1.724 |

| 17 | 2.096 | 2.097 | 2.089 | 1.717 | 2.092 | 1.724 | 42 | 2.095 | 2.095 | 2.090 | 1.722 | 2.092 | 1.724 |

| 18 | 2.097 | 2.096 | 2.090 | 1.720 | 2.092 | 1.724 | 43 | 2.097 | 2.098 | 2.089 | 1.724 | 2.091 | 1.724 |

| 19 | 2.095 | 2.095 | 2.090 | 1.720 | 2.091 | 1.724 | 44 | 2.097 | 2.096 | 2.089 | 1.719 | 2.092 | 1.724 |

| 20 | 2.098 | 2.097 | 2.089 | 1.719 | 2.092 | 1.724 | 45 | 2.094 | 2.096 | 2.089 | 1.720 | 2.092 | 1.724 |

| 21 | 2.097 | 2.096 | 2.089 | 1.719 | 2.092 | 1.724 | 46 | 2.096 | 2.097 | 2.090 | 1.724 | 2.093 | 1.724 |

| 22 | 2.098 | 2.098 | 2.090 | 1.721 | 2.092 | 1.724 | 47 | 2.098 | 2.096 | 2.089 | 1.721 | 2.091 | 1.725 |

| 23 | 2.096 | 2.096 | 2.090 | 1.719 | 2.092 | 1.725 | 48 | 2.094 | 2.095 | 2.090 | 1.720 | 2.091 | 1.724 |

| 24 | 2.096 | 2.097 | 2.089 | 1.720 | 2.092 | 1.724 | 49 | 2.096 | 2.096 | 2.089 | 1.720 | 2.091 | 1.725 |

| 25 | 2.096 | 2.098 | 2.090 | 1.719 | 2.092 | 1.724 | 50 | 2.097 | 2.096 | 2.089 | 1.722 | 2.091 | 1.724 |

Hornady New Dimension Dies

I’m not one for trends and gimmicks, but I believe the Hornady seating die had a lot to do with the rifle’s accuracy. In most die sets the handloader must keep bullets aligned with finger tips, and guide the bullet and case neck into the open large diameter end of a seating die. The Hornady floating alignment sleeve component of their inline seating system, protrudes from the die, and captures the neck and bullet in near perfect alignment before the cartridge enters the die body.

Using a concentricity checking fixture and dial indicator, I had no cartridge with more than .0020″~.0025″ run out, which is exceptional for me. I generally just bend them straight when I close the bolt…no, not really, but cartridges rarely see this level of alignment. The standard New Dimension die sets also have a crimping ring integral to the die, so appropriate adjustment will crimp the cartridge case to the bullet cannelure without a separate process step or tool. The only problem I encountered is that the Hornady instructions described a different O ring set up for the bullet seating stem. Minor deal.

Mixed Equipment Shell Holder Selection

Handloading details make or break the effort in terms of performance and safety. One such detail was the choice and use of shell holders. I wanted to work with a set of Hornady New Dimension dies, so my first choice was to select a Hornady shell holder. Unfortunately, Hornady shell holders aren’t designed to be interchangeable with RCBS shell holders for use with an RCBS press, and I wasn’t prepared to purchase a Hornady press. Fortunately, while the press retaining portion of the shell holders are different, the distance between the surface supporting the cartridge case head, and the top surface of the shell holder that limits how far into the die the case can travel, are virtually the same. This allowed me to use my RCBS shell holder, and set up the Hornady dies following the Hornady instructions. RCBS dies are tightened against the shell holder until the press cams over on the contact, while the Hornady die is tightened only until light contact with the ram in the full up position.

Handloading details make or break the effort in terms of performance and safety. One such detail was the choice and use of shell holders. I wanted to work with a set of Hornady New Dimension dies, so my first choice was to select a Hornady shell holder. Unfortunately, Hornady shell holders aren’t designed to be interchangeable with RCBS shell holders for use with an RCBS press, and I wasn’t prepared to purchase a Hornady press. Fortunately, while the press retaining portion of the shell holders are different, the distance between the surface supporting the cartridge case head, and the top surface of the shell holder that limits how far into the die the case can travel, are virtually the same. This allowed me to use my RCBS shell holder, and set up the Hornady dies following the Hornady instructions. RCBS dies are tightened against the shell holder until the press cams over on the contact, while the Hornady die is tightened only until light contact with the ram in the full up position.

Control of Cartridge Basic or Headspace Dimension

Where the .270 WSM has a chamber headspace dimension, the corresponding point on the cartridge case drawing is the “B” or “Basic” dimension. The Basic dimension is the point of origin for all other derivative cartridge reference dimensions. The .270 WSM Basic dimension is the point on the cartridge where the shoulder diameter is .4450″, which should occur 1.730″ – .007″ from the flat of the case head. In order to develop mature handloads for this specific rifle I would have to know the actual chamber headspace dimension as interpreted from a fired case. In the absence of a fired case I could only assemble to insure cartridges were under the maximum Basic spec, which would insure the handloads would chamber, extract and eject even with a minimum sized chamber. After firing the cases would be fire formed to the gun’s actual chamber, then I would be able to adjust my sizer die to bump the shoulder back only .002″ more than the fire formed dimension. This would insure minimum headspace in this particular rifle with handloads.

I wanted a good case measurement before and after case firing. Stony Point product support suggested I use their D .400 bushing which isn’t even close to the headspace diameter for the .270 WSM. Since, no finished bushing from Stony Point was appropriate for the WSM series, I would have been stuck using the gauge for no more than measuring relative differences before and after firing, and I wanted to check the case in comparison to the Basic specification. I had some Stony Point bushing blanks, so I made a correct .4450″ diameter bushing.

I wanted a good case measurement before and after case firing. Stony Point product support suggested I use their D .400 bushing which isn’t even close to the headspace diameter for the .270 WSM. Since, no finished bushing from Stony Point was appropriate for the WSM series, I would have been stuck using the gauge for no more than measuring relative differences before and after firing, and I wanted to check the case in comparison to the Basic specification. I had some Stony Point bushing blanks, so I made a correct .4450″ diameter bushing.

I am not a good machinist, now there’s a news flash, but I was still able to make the correct bushing in about 20 minutes. I used a micro lathe to drill the hole to approximate size, although the same could have been done with a hand drill and the bushing clamped in a vice.

I am not a good machinist, now there’s a news flash, but I was still able to make the correct bushing in about 20 minutes. I used a micro lathe to drill the hole to approximate size, although the same could have been done with a hand drill and the bushing clamped in a vice.

The 7/16″ drill opened the pilot hole to .4375″. I stopped at a hole depth of .750″ so I wouldn’t break though the sides of small diameter end of the bushing. I made two other bushings for different applications; one using a boring head, the other with a mill. I believe the drill method gets the best results and is the least time consuming.

I used an adjustable reamer to get to the final inside diameter of .4450″. I ran the speed down on the lathe, mounted the reamer in the tailstock chuck and, with a little careful adjustment, the was able to get to the correct hole diameter.

I used an adjustable reamer to get to the final inside diameter of .4450″. I ran the speed down on the lathe, mounted the reamer in the tailstock chuck and, with a little careful adjustment, the was able to get to the correct hole diameter.

I pick up a lot of small tools from Enco. A set of three adjustable reamers 3/8-15/16″ ran $13.96, a good investment as they are frequently put to use when I am making small fixtures and gauges. I know there are a number of these types of supplier out there, but Enco’s customer service is excellent, and they ship same or next day when orders are placed.

This is the finished product for the WSM, and one for my .338-378 Weatherby. Because the shoulder angle is constant on the WSM series, this one bushing will cover everything in the WSM line up. The Weatherby has a double radius shoulder, so as bullet diameter changes, the shoulder basic dimension changes accordingly. Therefore, one gauge will not be useful across the range of .378 Weatherby based cartridges. Yes, I know the Weatherby case headspaces on the belt, but I never handload to headspace anything on the belt. I enjoy this part of handloading. Making parts and tools is very rewarding, and I can exercise a lot more individual control over the process. One day I’ll get better at the machinist end of things.

Trimming – Just a Little Off the Top

I sized 50 pieces of new Winchester .270 WSM brass, then used a Hornady trimmer to take them all down to “trim to” case length of 2.090″. While setting up and getting use to the new trimmer, I cut two cases shorter, but still well within the minimum case length spec of 2.080″. The best way to make sure the case mouth is square to the cutter, is to apply light pressure against the case with the cutter spindle while rocking the case head against the shell holder until square to the holder. Then the shell lock is rotated, clamping the case in place for cutting.

It took a bit to sort out length. I never use the index on my RCBS trimmer for more than a relative indicator of adjustment, but having no index at all makes setting up a little more time consuming. Once set however, cutting was fast and consistent with less than .001 separating one case length from another. I need to see if I can make it work with my RCBS trimmer power head for volume work.

After trimming, the cases were gone over with a deburring tool and processed in liquid cleaner to get rid of any residual lube or loose particles of brass. In addition to waiting 24 hours for washed brass to dry, I usually run a hair dryer over the brass for about 15 minutes before loading to make sure it is dry inside and out. Temp of the brass goes to about 130°F. On numerous occasions I have run tests for air drying of liquid cleaned cases and find 24 hours at 70°F~80°F and 60% humidity is a minimum dry time, so my SOP is 24 hours, 48 hours if I’m not rushed, and the hair dryer treatment.

Handloading Miscellaneous

No load was compressed. If the .270 WSM is shy on capacity, or giving up capacity to seat heavy bullets, the problem slipped by me. Every load, even the slowest powders, had room to spare. I guess there is just a big difference between theoretical capacity expressed in grains of water, and the actual density of smokeless powder.

No load was compressed. If the .270 WSM is shy on capacity, or giving up capacity to seat heavy bullets, the problem slipped by me. Every load, even the slowest powders, had room to spare. I guess there is just a big difference between theoretical capacity expressed in grains of water, and the actual density of smokeless powder.

It will be interesting to see how well brass holds up. There seemed to be a bit of case head stretching, particularly with the heavy bullet loads. I saw no signed of radial fractures or case head separation, but I was more concerned with work hardening of brass and possibly the need to anneal case shoulders and necks after reloading a couple of times. I’m sure time and more experience will shed some light in these areas.

All and all, the .270 WSM is an easy cartridge to reload. I’m going to expand my reloading selections with more Hornady rifle die sets, they seem to lead to improved quality and precision of assembly. I think I will also check out some other powder types. I can’t help but think there is a better powder choice out there still, and it would probably be worthwhile to connect the Winchester to the Oehler 43 to see what level of pressures the gun is generating at these current load levels. During range testing, none produced flattened primers, sticking cases or a bolt that was hard to open.

Summary

I like the rifle a lot. It has greater accuracy than my .25-06 and I like the bullet weight compared to the .257 Weatherby Magnum. Is it a practical choice? Depends. I don’t think it will do anything my 7mm Magnum can’t, and the 7mm has the option of 175 grain bullets. The .270 WSM might be a better bridge cartridge between the .243 Winchester guns and a .308″ cartridge than the .25-06 Remington because of the bullet weight spread. My rifle line up makes no sense anyway, so I am sure this won’t detract from my coverage.

| Overall Performance | ||||||||

| Cartridge | Bullet | Weight | Indices | Muzzle | Yards | |||

| 100 | 200 | 300 | 400 | |||||

| 270 WSM | Sierra HP | 90 | Velocity | 3683 | 3132 | 2651 | 2229 | 1874 |

| Energy | -2635 | 1961 | 1405 | 993 | 702 | |||

| Trajectory | — | +1.04 | 0 | -6.03 | -19.11 | |||

| 270 WSM | Hornady HP | 110 | Velocity | 3440 | 3143 | 2867 | 2606 | 2360 |

| Energy | 2840 | 2414 | 2007 | 1659 | 1360 | |||

| Trajectory | – | +1.01 | 0 | -5.25 | -15.64 | |||

| 270 WSM | Barnes XLC/BT | 130 | Velocity | 3351 | 3130 | 2920 | 2719 | 2527 |

| Energy | 3210 | 2828 | 2461 | 2134 | 1844 | |||

| Trajectory | – | +1.03 | 0 | -5.11 | -14.93 | |||

| 270 WSM | Hornady SP | 130 | Velocity | 3263 | 3044 | 2835 | 2636 | 2445 |

| Energy | 3040 | 2675 | 2320 | 2004 | 1725 | |||

| Trajectory | – | +1.13 | 0 | -5.46 | -15.93 | |||

| 270 WSM | Sierra BTSP | 140 | Velocity | 3198 | 2980 | 2773 | 2572 | 2380 |

| Energy | 3140 | 2762 | 2390 | 2056 | 1761 | |||

| Trajectory | – | +1.21 | 0 | -5.74 | -16.74 | |||

| 270 WSM | Nosler BalTip | 150 | Velocity | 3120 | 2923 | 2734 | 2553 | 2379 |

| Energy | 3210 | 2845 | 2489 | 2170 | 1884 | |||

| Trajectory | – | +1.29 | 0 | +5.94 | -17.23 | |||

| 270 WSM | Nosler Par | 150 | Velocity | 3143 | 2932 | 2730 | 2537 | 2352 |

| Energy | 3245 | 2863 | 2482 | 2145 | 1843 | |||

| Trajectory | – | +1.27 | 0 | +5.95 | -17.30 | |||

| 270 Winchester | Nosler Par | 150 | Velocity | 3000 | 2795 | 2600 | 2412 | 2233 |

| Energy | 2960 | 2602 | 2250 | 1938 | 1660 | |||

| Trajectory | – | +1.48 | 0 | -6.63 | -19.23 | |||

If someone owned an accurate .270 Winchester, would I suggest they replace it with a .270 WSM? Not at all, there just isn’t enough field difference in trajectory or energy and velocity to take on the overhead of a new cartridge, and a .270 Winchester is less expensive to feed and ammo is more readily available. There is also the factor of that very special look that comes at you from behind a rural general store counter when you ask for a box of .270 Nooneelseusesthese cartridges. If someone were getting ready for a deer, antelope or black bear hunt, and needed a good solid accurate utility firearm, the Super Shadow, specifically the .270 WSM, makes a lot of sense.

While I like the .270 WSM, based on the overall performance, I won’t be heading out to add another short magnum to my collection, particularly since the larger diameter bullets demonstrate disproportionately lower levels of performance. I use to wonder why the series wasn’t made .30-06 length, where an almost 25% increase in capacity surely would pick up performance over corresponding short magnums like the 7mm Remington Magnum, or .300 Winchester Magnum. Then there would have be no need for separate new long and short magnum introductions, the consolidation would bring about lower production cost and there would be real 100+ grain capacity performance to write about. The problem is, the capacity gain brings almost nothing in performance as a 24″ barrel is of inadequate length to burn the additional powder, and moving up to 26″ would only match existing ancient Weatherby cartridges. I think we’ve hit a wall for now.

Short magnums create enough stir to make sales, and 24″ barrels save money, and short actions save money, and there is really nowhere to go without a powder with burn characteristics more suitable for this generation of magnums or the next generation of overbore magnums.

More on the 270 WSM:

The .270 WSM – In pursuit of stubby cartridges

The .270 WSM – In pursuit of stubby cartridges Part 2

The .270 WSM – In pursuit of stubby cartridges – Part 3 – Conclusion

Handload Data – 270 WSM

Thanks

Joe

Email Notification