It was a little chilly at the range, and a little overcast and the 17-357 RG prototype was a little uncooperative, but all and all, the combination performed admirably. The combination was able to push a 20 grain bullet over 3,300 fps and a 25 grain bullet at slightly over 3,000 fps from a 10″ barrel, and at a relatively modest 43k~46k psi of chamber pressure. Load details have been posted.

The little cartridge produces 2,000~2,070 fps out of a 3.9″ barrel SIG P229 and 3,700~3,850 from 18″ and 20″ rifle barrels respectively. 10.5 grains of powder, no recoil and little more than a pop in rapport. That’s about half the powder utilized by a 17 Remington to produce similar performance from a longer barrel.

This wrap up specifically addresses the Thompson Center Contender prototype, as the others have unique minor mechanical problems to resolve and will be covered separately. The 17-357 RG proved to be a versatile little cartridge with a lot of potential and a 50% improvement over the 17 HMR. Parent brass is inexpensive and readily available, powder consumption is small and wear and tear on firearms is negligible. The rimless case head at 0.424″ is between a .223 Remington and .308 Winchester in diameter so lots of rifles can be chambered for the cartridge and overall length can run from 1.140″ for pistols to 1.300″ or so for heavy, long, 17 caliber bullets so case capacity can be preserved.

The load and chronograph performance data for the Contender are posted in the handload section on the home page. I have another data set for the short barrel SIG, as well as for a longer barrel rifle. I will try to put both data sets up in the handload section in the next few days, then follow up with detail firearm coverage. If you’d like to replicate this setup, I’d be glad to share any information I’ve accumulated regarding specs, tooling and firearm construction. It is an easy and inexpensive combination to put together and a pretty devastating cartridge for smaller varmints. The round absolutely explodes filled plastic gallon water jugs. We had the opportunity to take a few shots at the tin can range on our way out.

The load and chronograph performance data for the Contender are posted in the handload section on the home page. I have another data set for the short barrel SIG, as well as for a longer barrel rifle. I will try to put both data sets up in the handload section in the next few days, then follow up with detail firearm coverage. If you’d like to replicate this setup, I’d be glad to share any information I’ve accumulated regarding specs, tooling and firearm construction. It is an easy and inexpensive combination to put together and a pretty devastating cartridge for smaller varmints. The round absolutely explodes filled plastic gallon water jugs. We had the opportunity to take a few shots at the tin can range on our way out.

Creating the combination isn’t cost prohibitive for people who like wildcats. The barrel inserts, chamber cutting and extractor work were a little over $100 each including liners, but not barrels; I supplied Contender and SIG barrels. The full set of forming does and loading dies were approximately $225 and the dies are a one time buy. The reamer, also a one time buy, was $138. The 17 caliber does require all of the other overhead of handloading; funnels, cleaning rods, trimmer cutters and pilots, collect pullers, etc., but that cost would all be there for any new cartridge.

Accuracy and Consistency

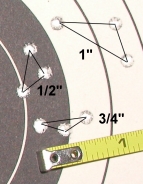

Accuracy and consistency potential, I believe, are on par with other 17’s; very good. – I was scopeless which, for me, means shooting by Braille. The Contender barrels have decent mechanical sights, so I stuffed the gun into a rest and sand bags until it was solid, and took my time at 50 yards. I would not project these out to 100 yards and double the size, I believe these groups indicate my limitations to hold on target from a rest and not the capability of the cartridge or gun. Other prototype combinations seem to indicate this is a sub 1/2 MOA cartridge and not fussy in terms of powder or bullet weight. the 17-357 also isn’t a scatter gun with bullet weight shifting point of impact. I didn’t notice any more than typical 17 caliber copper fouling, but in my experience 17 caliber guns need to be kept clean or performance falls off dramatically. Kept clean in my 17 HMR typically means a good scrubbing every 100 rounds. I’ll have a better idea after the 17-357 RG has seen more use.

Accuracy and consistency potential, I believe, are on par with other 17’s; very good. – I was scopeless which, for me, means shooting by Braille. The Contender barrels have decent mechanical sights, so I stuffed the gun into a rest and sand bags until it was solid, and took my time at 50 yards. I would not project these out to 100 yards and double the size, I believe these groups indicate my limitations to hold on target from a rest and not the capability of the cartridge or gun. Other prototype combinations seem to indicate this is a sub 1/2 MOA cartridge and not fussy in terms of powder or bullet weight. the 17-357 also isn’t a scatter gun with bullet weight shifting point of impact. I didn’t notice any more than typical 17 caliber copper fouling, but in my experience 17 caliber guns need to be kept clean or performance falls off dramatically. Kept clean in my 17 HMR typically means a good scrubbing every 100 rounds. I’ll have a better idea after the 17-357 RG has seen more use.

Cartridge and range notes, and some observations

A 17-357 RG case requires fire forming to bring out the negative surfaces of the shoulder that are created during die forming. This expands the case shoulder to conform with the chamber and sets the headspace contact surface. By design, the original 357 SIG shoulder is bumped back, extended and formed to a 40 degree angle when the 17-357 RG is formed to insure an adequate 0.200″ neck length. I picked up about half a grain of useful capacity after fire forming, but capacity has not been a limiting factor.

A couple of case necks split when fired, actually, 1%. The 17-357 RG is subjected to a number of cold forming steps and sees significant dimensional change, which results in work hardened brass. I came to the realization I would need to add annealing to the case forming process for increased case longevity. Since no cases were lost in forming, only firing, I thought I would save annealing for a step just before full length sizing, and let full length resizing prep the brass for bullet seating.

A couple of case necks split when fired, actually, 1%. The 17-357 RG is subjected to a number of cold forming steps and sees significant dimensional change, which results in work hardened brass. I came to the realization I would need to add annealing to the case forming process for increased case longevity. Since no cases were lost in forming, only firing, I thought I would save annealing for a step just before full length sizing, and let full length resizing prep the brass for bullet seating.

Relative headspace measurement was interesting, for those who find headspace measurement interesting. Fired cases were either 0.600″ on the nose, or 0.604″ on the nose. Neither are out of spec, but only the Blue Dot lighter loads resulted in the longer case. I thought this might be pressure rise time, or perhaps the powder performing differently in this cartridge configuration. I don’t know. There were no signs of excessive pressure, primers looked normal, other than mechanical problems, cases chambered and extracted normally.

Minor Bugs to Work Out

I encountered two problems with the prototype barrel. The first was an extractor that was too tall, and had sharp edges at the end of the radius that dug into the brass on extraction. There was no sample cartridge cases when the barrel was being fabricated, only a chamber reamer and headspace gauge, so this extraction problem wasn’t a surprise. The second problem, a rough chamber finish with lots of radial tool marks was disappointing. The surface was rough enough to emboss the finish on cases and cause them to stick at virtually any pressure level. Easy to correct, but this shouldn’t have happened.

I encountered two problems with the prototype barrel. The first was an extractor that was too tall, and had sharp edges at the end of the radius that dug into the brass on extraction. There was no sample cartridge cases when the barrel was being fabricated, only a chamber reamer and headspace gauge, so this extraction problem wasn’t a surprise. The second problem, a rough chamber finish with lots of radial tool marks was disappointing. The surface was rough enough to emboss the finish on cases and cause them to stick at virtually any pressure level. Easy to correct, but this shouldn’t have happened.

The SIG prototype fires and performs well as a single shot, but requires some time and energy to see if it will ever be able to cycle multiple rounds with such low bullet mass. The feed ramp and magazine need further work to feed smoothly and reliably. The 17 bullet is basically a needle point in the world of auto feed pistols. The ramp contour needed to be more shallow and stepped to pick up the case neck and lift the bullet tip and the magazine needed to be altered in timing to permit earlier forward release of the case.

The SIG prototype fires and performs well as a single shot, but requires some time and energy to see if it will ever be able to cycle multiple rounds with such low bullet mass. The feed ramp and magazine need further work to feed smoothly and reliably. The 17 bullet is basically a needle point in the world of auto feed pistols. The ramp contour needed to be more shallow and stepped to pick up the case neck and lift the bullet tip and the magazine needed to be altered in timing to permit earlier forward release of the case.

I hope this works out as the gun is a lot of fun to shoot and as a single shot provides pretty substantial ballistic performance. The short barrel does not do well with H 110, Power Pistol seems best, with Blue Dot a near second.

Shops & Services

I used three primary shops during this project. Despite my grumbling about minor issues, the result worked out OK. I have no arrangement with these shops, other than as a retail customer. If you are interested in pursuing a 17-357 RG or similar project, these folks can get you started.

Dennis Olson – Gunsmithing

P.O. Box 337

500 First Street

Plains, Montana 59859

406-826-3790

Dennis is a very talented guy and able to handle any fabrication project in wood or metal, or complete guns. The guy has a great work ethic, fair pricing and his stuff works. The insert barrels he put together are very accurate and I will go back to have a long gun put together. I may have driven him a little crazy.

CH4D

P.O. Box 889

711 N. Sandusky St.

Mt. Vernon, OH 43050

U.S.A

Phone: 1-740-397-7214

Fax: 1-740-397-6600

Other than minor problems with an expander, the dies set from CH4D worked as intended and did some relatively radical cold forming without losing brass. The prices are fair, there is a lot of experience in the shop, and they can make just about anything. Again, I have no relationship with these folks other than as a retail customer.

Pacific Tool and Gauge

PO BOX 2549 – 598 Ave C

White City, Oregon 97503

1-541-826-5808

FAX: 541-826-5304

Pacific Tool & Gauge did a nice job with a reamer and headspace gauge. First experience with them, but the price was reasonable, they delivered on time and the reamer and gauge were to spec.

QuickLoad RCBS.Load and the 17-357 RG

Normally, QuickLoad is consistent with range testing, but normally I am working with less than fly spec cartridges. midrange pistol powder like No. 7 worked out well and were within 1%-2% on velocity. Fast and slow powder were off a good deal on velocity, in some cases as much as 10%-15%, the least consistency came with H 110 and Power Pistol powder. H 110 calculated consistently lower than chronograph data and Power Pistol, with light bullets only, calculated high compared to chronograph data.

After entering very specific case dimension and material thickness information to create a 17-357 RG cartridge in QuickLoad, the case capacity was off significantly; calculated 14.3, actual 13.2, fire formed 13.7. Because the subject cartridge is small, the differences seem insignificant, but there is enough variation to account for the same charge resulting in 44,000 psi or 51,000 psi of chamber pressure, and that difference is not insignificant. RCBS.Load seems to be right on in volume calculation within its cartridge design module. Both programs remain inexpensive and invaluable modeling tools.

Conclusions

I believe the 17-357 RG will end up in a great little varmint rifle, perfect for small animals and target shooting where noise is an issue and distances are not too long; maybe a couple hundred yards maximum. I’m going to try one on a lightened Model 7 with an 18″ fluted barrel and see if I can’t come up with a 5 pound varmint rifle. In the mean time, I will fit a scope to the Contender and work some more on the SIG as I have time.

More “The 17-357 RG – Real Guns Project Cartridge”

The 17-357 RG – Real Guns Project Cartridge Part I

The 17-357 RG – Real Guns Project Cartridge Part II

The 17-357 RG – Real Guns Project Cartridge Part III

The 17-357 RG – Real Guns Project Cartridge Part IV

The 17-357 RG – Real Guns Project Cartridge Part V

The 17-357 RG – Real Guns Project Cartridge Part VI

The 17-357 RG – Real Guns Project Cartridge – Finished

Handload Data 17-357RG

Joe

Email Notification